Special insulation barrier for drop-out fuse protector

A technology of drop-out fuses and insulating baffles, which is applied to switchgear, electrical components, etc., can solve problems such as affecting replacement operations, unstable insulation blanket shapes, and dangers, and achieve the effect of reducing labor intensity and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

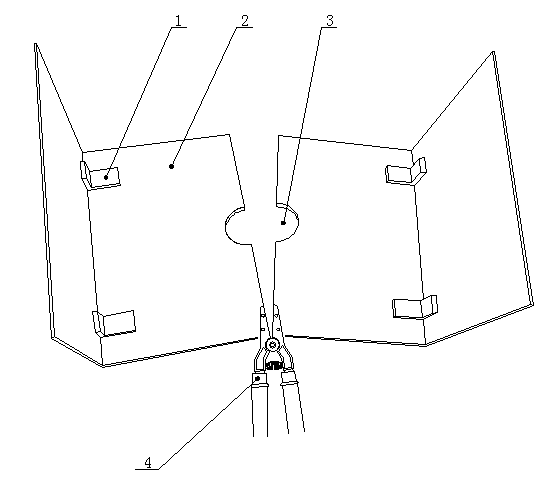

[0010] Example: such as figure 1 As shown, the special insulating baffle for drop-out fuses is composed of two butt-connected insulating plates 2, the insulating plates 2 are in the shape of angle iron, and a semicircular notch 3 is provided at its opposite end, and the two notches 3 are butted to form a closed round hole. One corner of the opposite ends of the two insulating plates 2 is fixedly connected with the two clamp heads of the elastic clamp 4 respectively, and an insulating sheath is set on the hand-held part of the elastic clamp 4. The insulating clamp 2 is a market purchase part, and its structure is the same as that of a common clamp. The two pliers bodies are flexibly connected in a cross shape, and a spring is arranged between the pliers bodies of the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com