Metal foil tube and method and apparatus for production thereof

a metal foil tube and tube body technology, applied in the direction of electrographic process, manufacturing tools, instruments, etc., can solve the problems of reducing strength, reducing hardness (hv) to about half, and roughness (rz) about 3 m, so as to achieve the effect of elongating the shape and surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

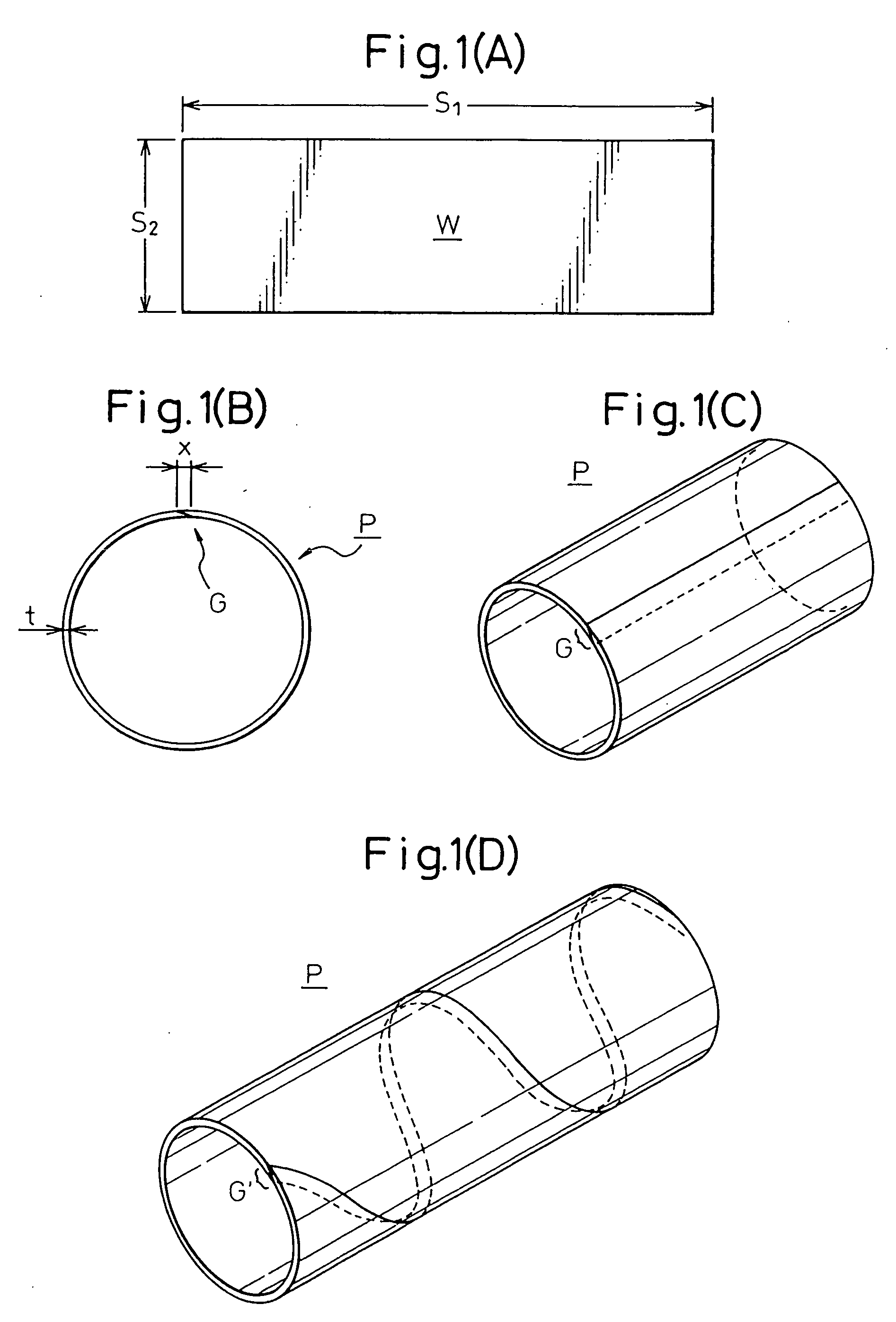

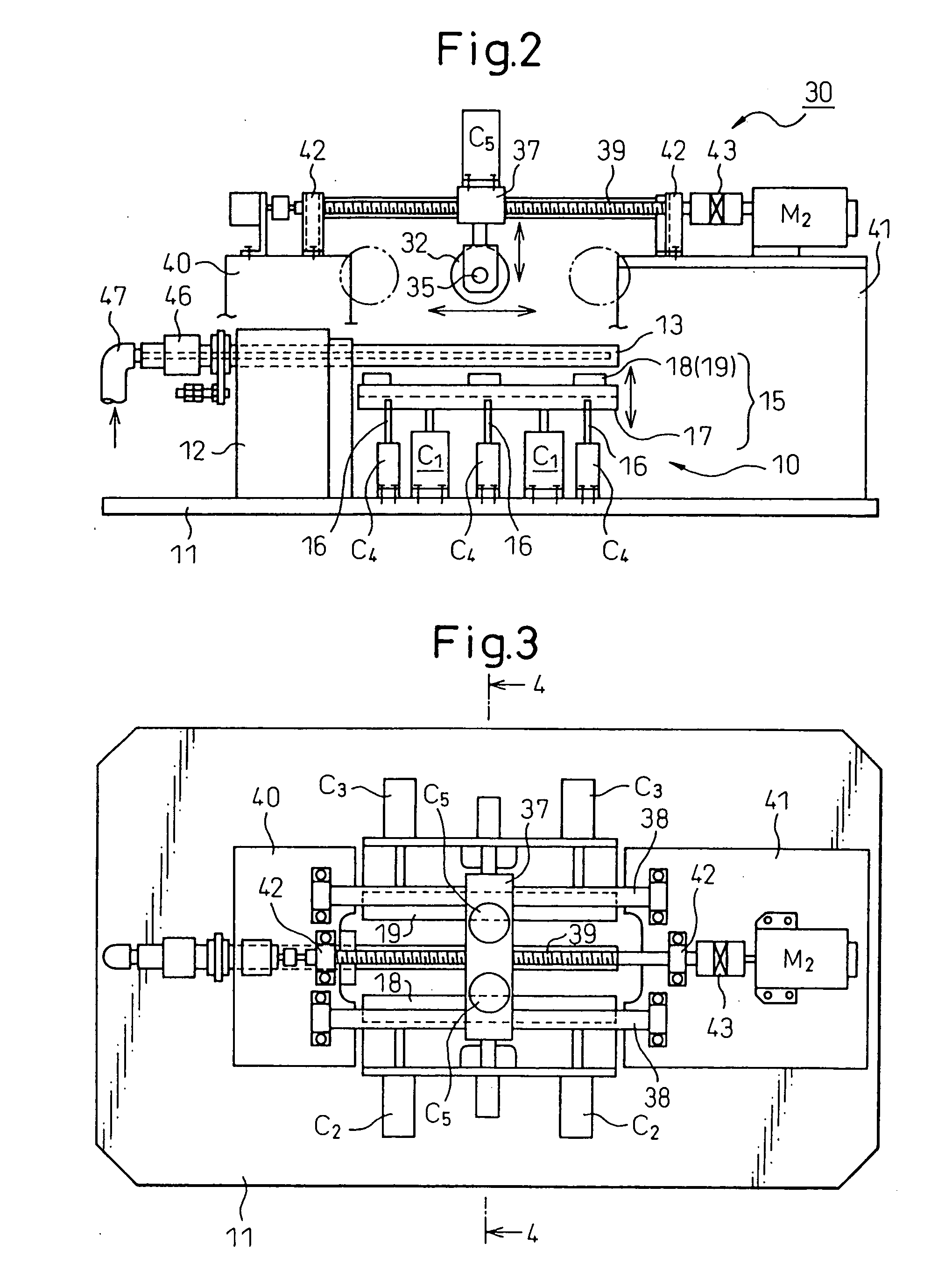

[0259] Stainless steel foils made of SUS410L (11% Cr-0.02% C) were rolled to thicknesses of 40 μm while suitably controlling the rolled surface roughnesses to give surface roughnesses Rz of 1.5 μm and 0.8 μm. The rolled materials were cut to 94.3 mmL×250 mmW. The foils having the two types of surface roughnesses were wrapped around 30 mmφ copper alloy tools and joined at the 100 μm overlap parts by mash seam welding. At this time, the vicinities of the joint zones of both tubes ((a) tube having a surface roughness Rz of 1.5 μm and (b) tube having a surface roughness Rz of 0.8 μm) were cut out, buried, and polished. In both cases, it was confirmed that the hardness of the matrix part was, in Hv, around 270, while the hardness of the joint zone was, in Hv, around 230. The two polishing samples were etched and examined for metal structure. As a result, in both cases, there was no melted and solidified phase at the joint zone, the joint surface was a solid phase in state, and a low carb...

example 2

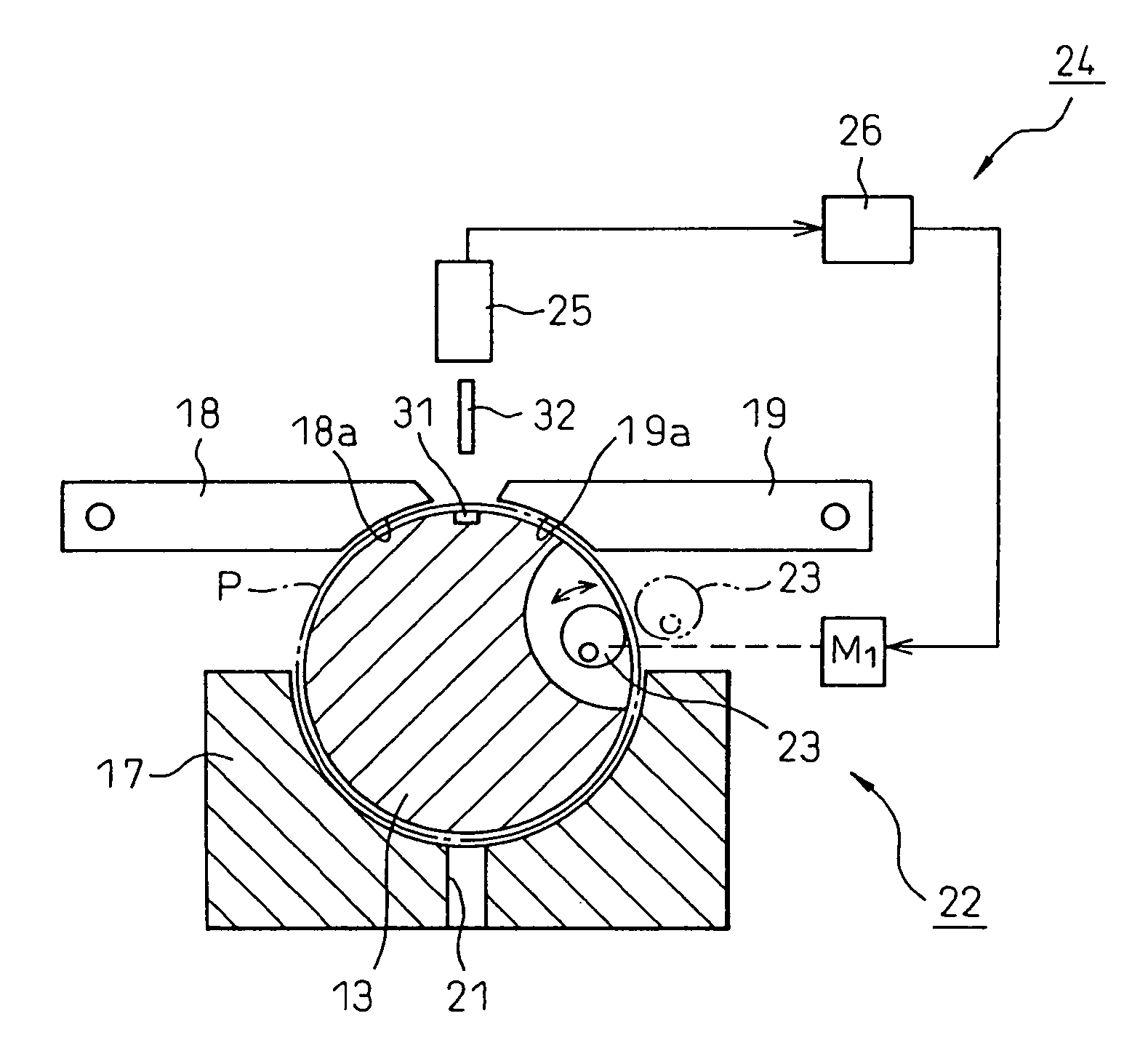

[0260] Annealed foils having surface roughnesses Rz of 1.0 μm and 0.5 μm, made of SUS316L (16% Cr-12% Ni-2% Mo), and having thicknesses of 30 μm were slit to 60 mm widths. These were wrapped in spirals around the above 30 mmφ copper alloy electrode rods. At this time as well, the foil with the surface roughness Rz of 1.0 μm and the foil with the surface roughness Rz of 0.5 μm were adjusted so that the overlap between sections of the foil became 100 μm. Further, it is possible to rotate the electrode rod and make it slide to the left and right and to roll over the overlap part by another copper alloy or other rolling electrode roller and pass current with the electrode rod for mash seam welding. The same procedure was followed as in Example 1 to investigate the hardnesses of the vicinities of the joint zones of the two tubes ((c) tube having a surface roughness Rz of 1.0 μm and (d) tube having a surface roughness Rz of 0.5 μm). As a result, in both tubes, the matrix part had a hardne...

example 3

[0262] Completely annealed foils having surface roughnesses Rz of 0.3 μm and 0.8 μm, made of SUS304 (18% Cr-8% Ni), and having thicknesses of 50 μm were used by the same method as in Example 1 to prepare two types of foil tubes. Note that the stainless steel foils were annealed in an Ar—H2 atmosphere. The nitrogen concentrations of the surfaces were 1.2%. In both cases ((e) tube having surface roughness Rz of 0.3 μm and (f) tube having surface roughness Rz of 0.8 μm), the joint zones had thicknesses of 75 μm. The inside and outside surfaces were polished to 60 μm. In this case, with both tubes, the hardness of the matrix part was about, in terms of Hv, 178, while that of the joint zone was, in Hv, around 220. The same procedure was followed as in Example 1 for a fatigue test. The result was that both tubes (e) and (f) withstood the fatigue test for 1 million cycles or more.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com