Fully-automatic narrow lap electric-resistance seam-welding machine for thin plates

A resistance seam welding, fully automatic technology, applied in the direction of resistance welding equipment, resistance electrode holder, welding/welding/cutting items, etc., can solve the problem of high cost of sliding conductive bearing, high cost of wheel welding machine head, and the use of copper materials Large volume and other problems, to achieve the effect of shortening the time of relative movement, improving shearing efficiency, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

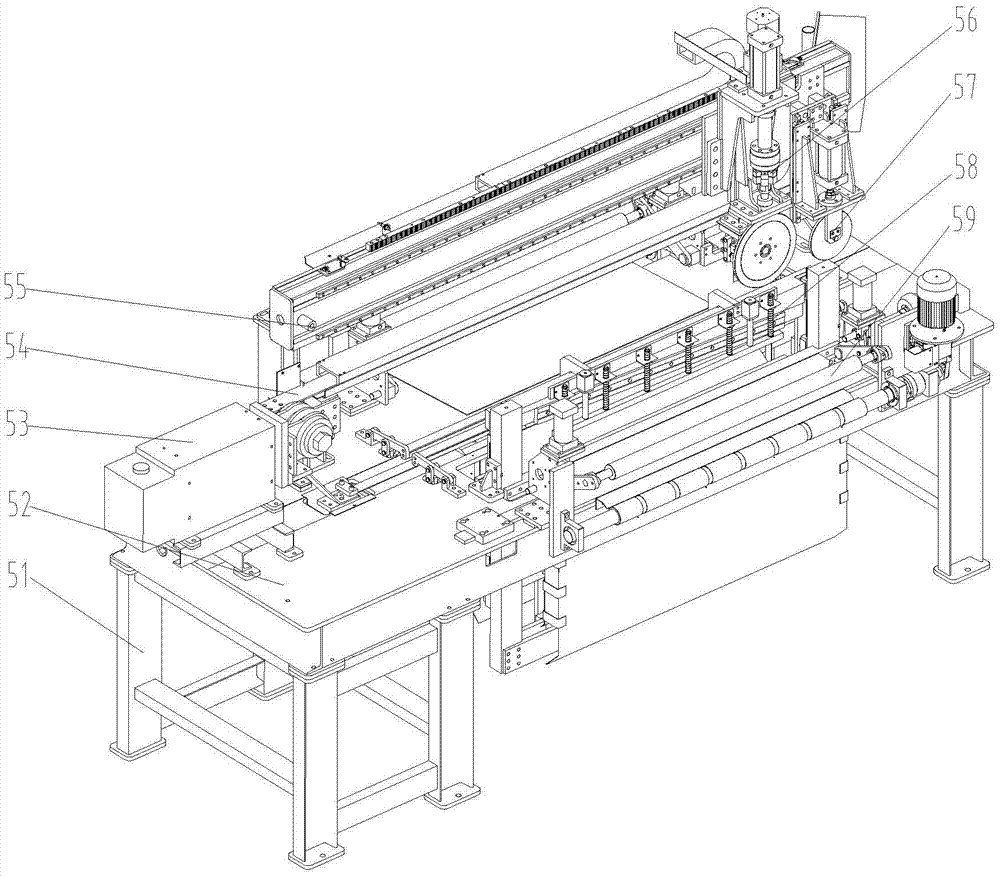

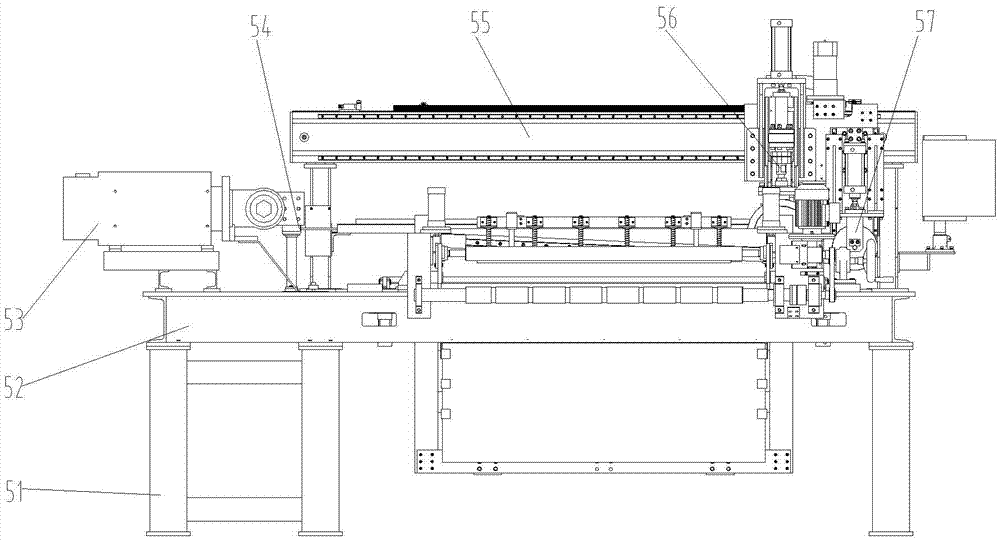

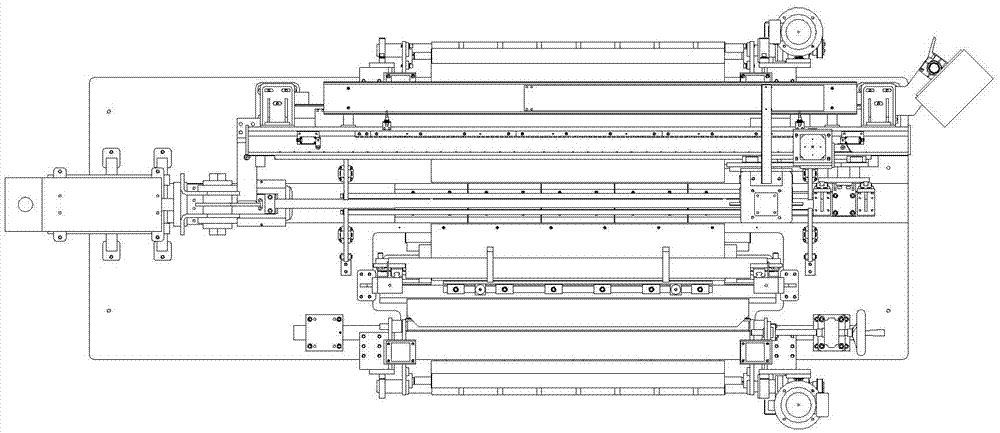

[0060]A fully automatic narrow lap resistance seam welding machine for thin plates, comprising a frame 51 and a workbench 52 located on the frame 51, the feed side of the frame 51 or the workbench 52 is sequentially provided with pinch feeding along the feed direction Device 59, single-edged scissors 58, described frame 51 is connected with beam assembly 55, and described beam assembly 55 is connected with resistance welding device 56 and rolling device 57 that can move along the length direction of beam assembly 55; The blade scissors 58 include a frame 35 installed on the workbench 52, between the left frame 351 of the frame 35 and the right frame 352 of the frame 35, an upper clip 36 and a lower clip 39 are arranged, wherein the upper clip 36 is fixedly connected 1. The lower cutting piece 39 is movably connected, and the lower cutting piece 39 is located between the upper cutting piece 36 and the bottom frame 353 of the frame 35, and the bottom frame 353 of the frame 35 is ...

Embodiment 2

[0062] A fully automatic narrow lap resistance seam welding machine for thin plates, comprising a frame 51 and a workbench 52 located on the frame 51, the feed side of the frame 51 or the workbench 52 is sequentially provided with pinch feeding along the feed direction Device 59, single-edged scissors 58, described frame 51 is connected with beam assembly 55, and described beam assembly 55 is connected with resistance welding device 56 and rolling device 57 that can move along the length direction of beam assembly 55; The blade scissors 58 include a frame 35 installed on the workbench 52, between the left frame 351 of the frame 35 and the right frame 352 of the frame 35, an upper clip 36 and a lower clip 39 are arranged, wherein the upper clip 36 is flexibly connected , the lower cutting piece 39 is fixedly connected, and the lower cutting piece 39 is located between the upper cutting piece 36 and the bottom frame 353 of the frame 35, and the bottom frame 353 of the frame 35 is...

Embodiment 3

[0064] A fully automatic narrow lap resistance seam welding machine for thin plates, comprising a frame 51 and a workbench 52 located on the frame 51, the feed side of the frame 51 or the workbench 52 is sequentially provided with pinch feeding along the feed direction Device 59, single-edged scissors 58, described frame 51 is connected with beam assembly 55, and described beam assembly 55 is connected with resistance welding device 56 and rolling device 57 that can move along the length direction of beam assembly 55; The blade scissors 58 include the frame 35 installed on the workbench 52, between the left frame 351 of the frame 35 and the right frame 352 of the frame 35, an upper cutting sheet 36 and a lower cutting sheet 39 are arranged, and the lower cutting sheet 39 is located at Between the upper cutting piece 36 and the bottom frame 353 of the frame 35, the bottom frame 353 of the frame 35 is connected with a shear cylinder 37, and the end of the output shaft of the shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com