Method of producing tiny special-shaped composite connection point strip

A manufacturing method and technology of contact strips, which are applied in the directions of contacts, roller electrode welding, electrical components, etc., can solve problems such as poor spot welding performance, and achieve the advantages of reducing processing procedures, high composite bonding strength between layers, and reducing processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

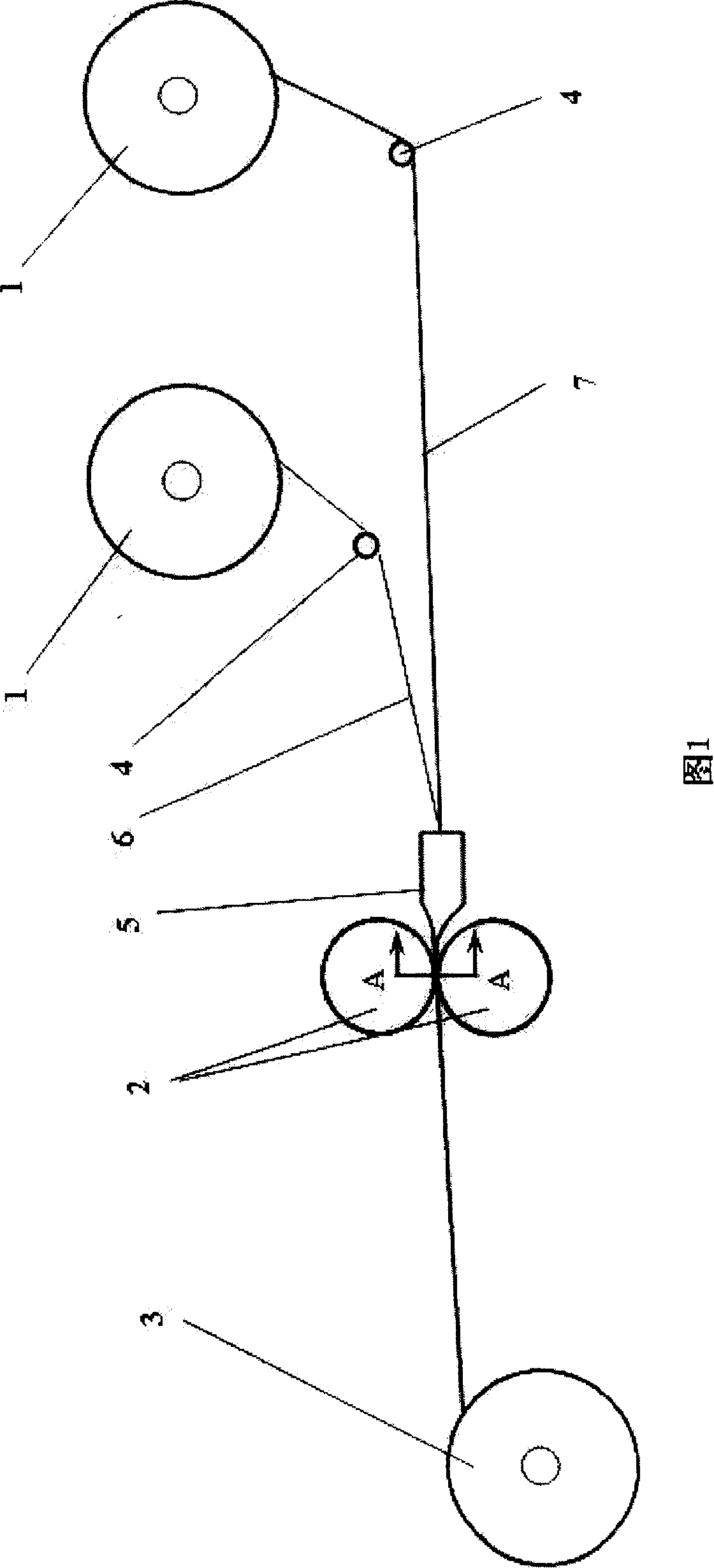

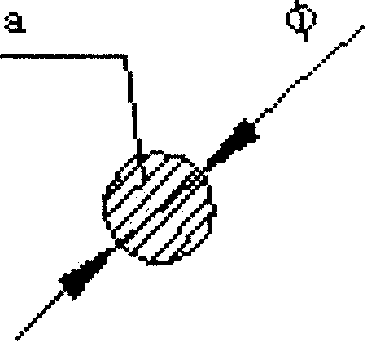

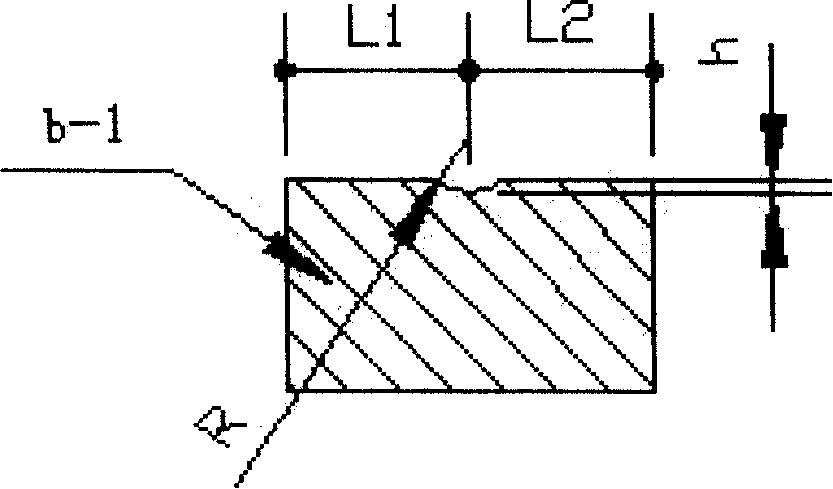

[0038] Figure 4 The width is 1.0mm, the thickness is 0.42 through multi-mode drawing, and after heat treatment, the preparation The AuAgPt25-6 alloy was prepared by drawing, rolling and heat treatment, and the Ni matrix strip with a size of 0.80×0.4mm was prepared. Combined by seam welding, making it a cross-section such as image 3 The long composite strip shown, and the composite composite strip is evenly wound on the bobbin. Adjust the mechanical performance parameters through heat treatment to ensure the final performance of the product. The prepared strips are precision-molded, and the cross-section of the obtained special-shaped composite strips is as follows: Figure 4 shown. This example is especially useful when there is a large difference in the width of the two layers of composite material in the product.

example 2

[0040] After multi-mode drawing and heat treatment, the preparation AgPd50 alloy wire; CuNi20 alloy matrix strip with a size of 0.85×0.45mm was prepared by drawing, rolling and heat treatment. Composite by seam welding, making it as Figure 5 The ribbon composite shown. The composite strip is orthoped, heat treated, and precision formed into a Figure 6 product shown. This example is especially suitable for the case where the ratio of the electrical contact layer to the base layer is greater than 1:3 and the width of the two layers is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com