Roll welding device for producing noble metal composite band

A welding device and composite belt technology, which is applied in the fields of roller electrode welding, welding equipment, metal processing equipment, etc., can solve the problems of inability to monitor the welding quality of the finished belt in real time, unable to detect the welding quality of the finished belt, and unable to find the finished belt in time. , to achieve the effect of improving welding quality, ensuring welding and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

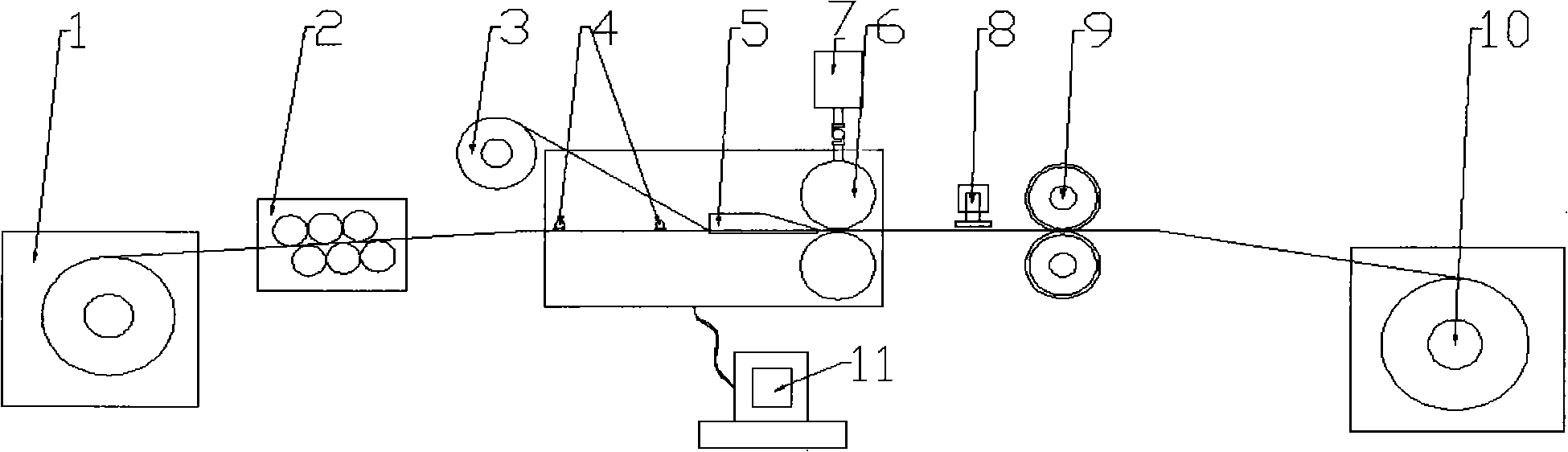

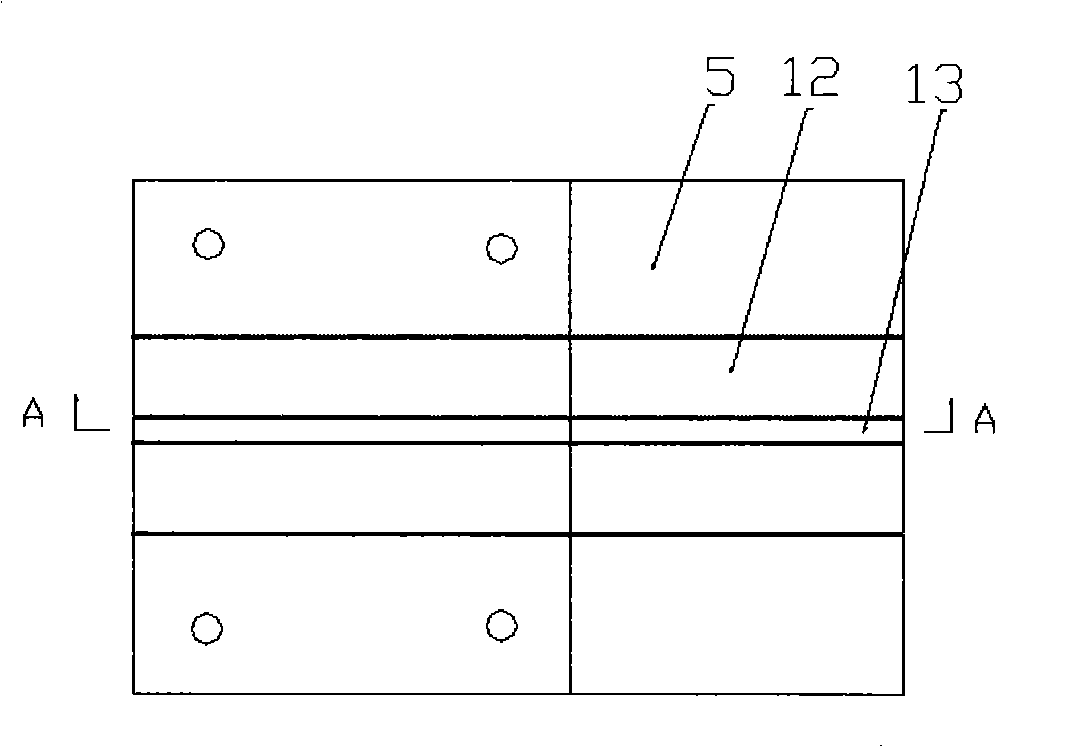

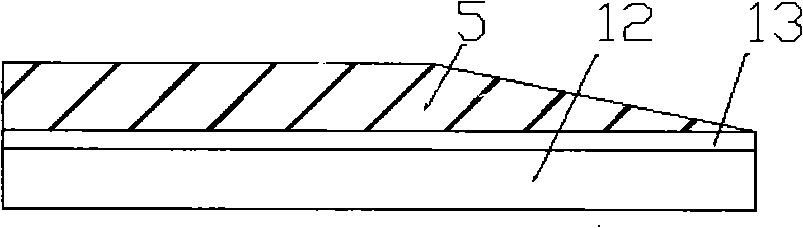

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an embodiment of a roll welding device for producing a precious metal composite strip is disclosed. Such as figure 1 As shown, the device of the present invention includes a coil material feeding mechanism 1, a leveling mechanism 2, a multiple belt feeding tray 3, a positioning mold 5, a rolling welding wheel 6, a welding cylinder 7, a traction mechanism 9, and a coil material unloading mechanism 10 , welding power supply and IPC controller 11, the coil material feeding mechanism 1, the leveling mechanism 2, the multiple belt feeding tray 3, the positioning mold 5, the rolling welding wheel 6, the traction mechanism 9, and the coil material unloading mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com