Patents

Literature

69results about "Roller electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for welding and real time monitoring of seam welded parts

Owner:UNIV OF KENTUCKY RES FOUND

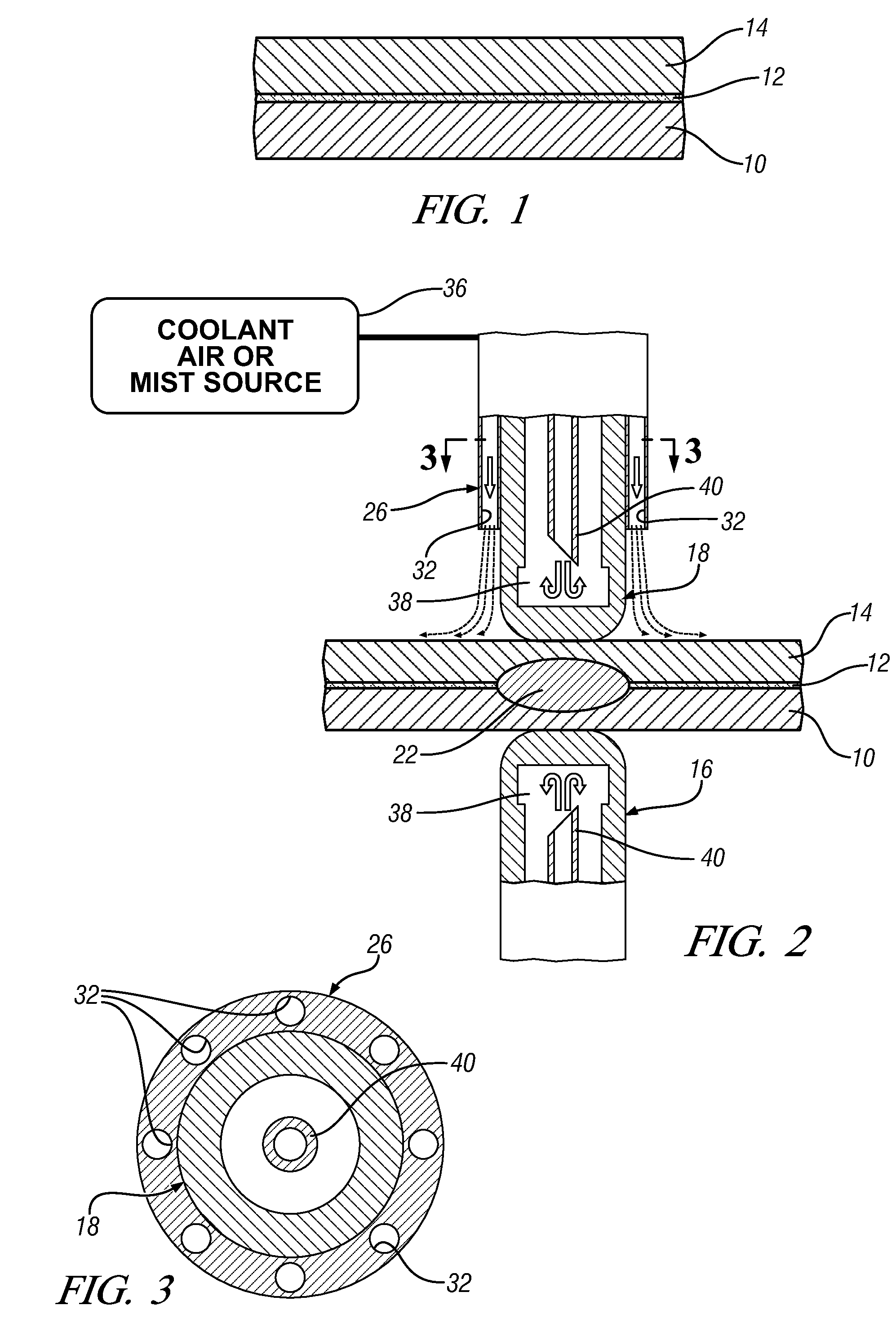

Method to reduce thermal degradation of adhesive in weldbonding

InactiveUS20110073572A1Adhesive quality of may deteriorateInhibit transferRectilinear seam weldingPressure electrodesAdhesiveEngineering

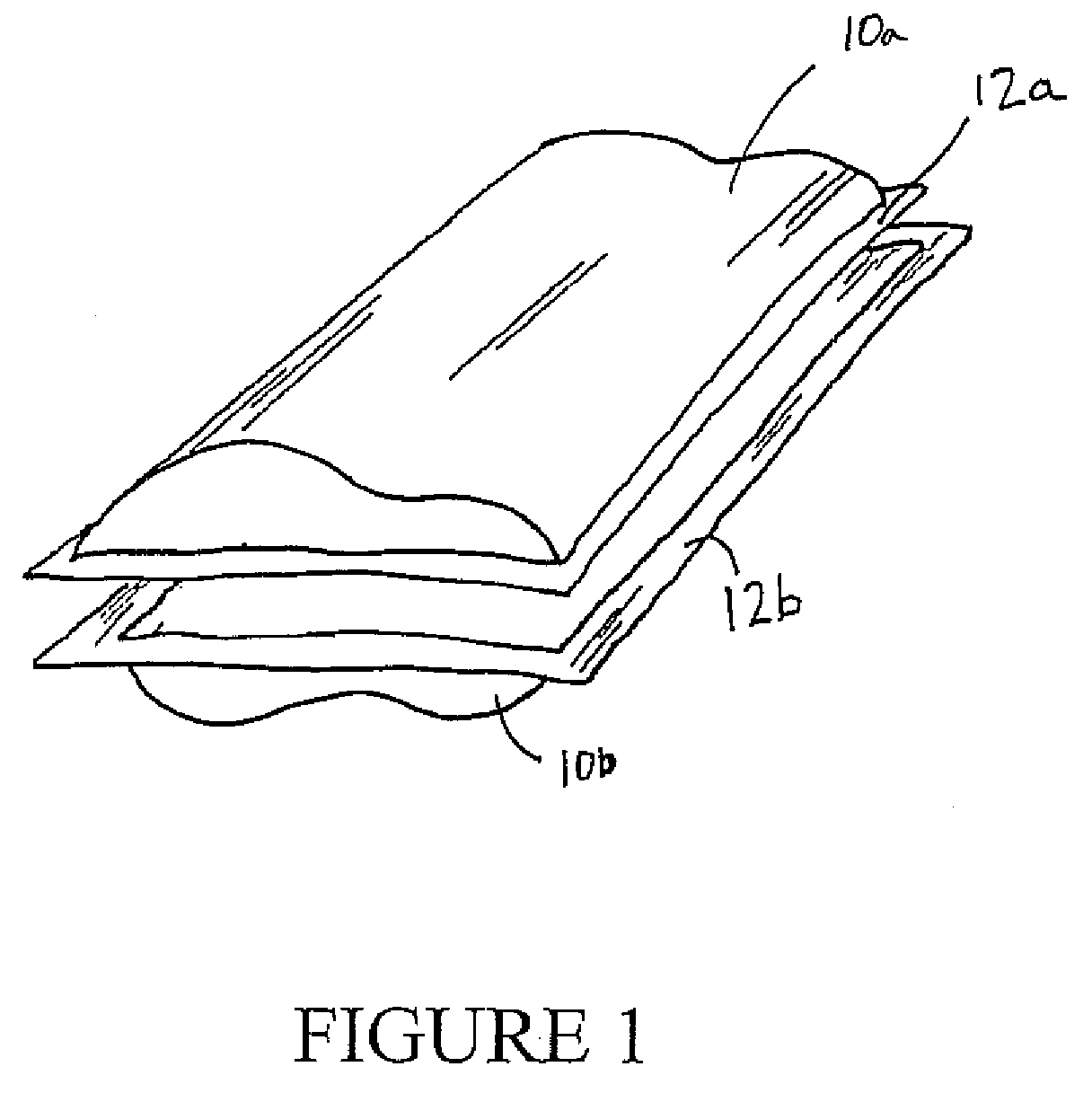

A method for weldbonding together metal sheets includes applying adhesive on the surface of a first sheet and placing a second sheet atop the first sheet. The sheets are heated at a selected location to a high temperature forming a metallic weld nugget between the first sheet and the second sheet. The adhesive may be a heat curable adhesive that is cured by the heat, or the adhesive may be heated at ambient temperatures. One or both of the sheets is then cooled in the area surrounding the selected location of heating so that the high temperature needed to created the metallic weld nugget is prevented from transferring so far beyond the selected location as to overheat the adhesive layer and thereby degrade the quality of the adhesive bond.

Owner:GM GLOBAL TECH OPERATIONS LLC

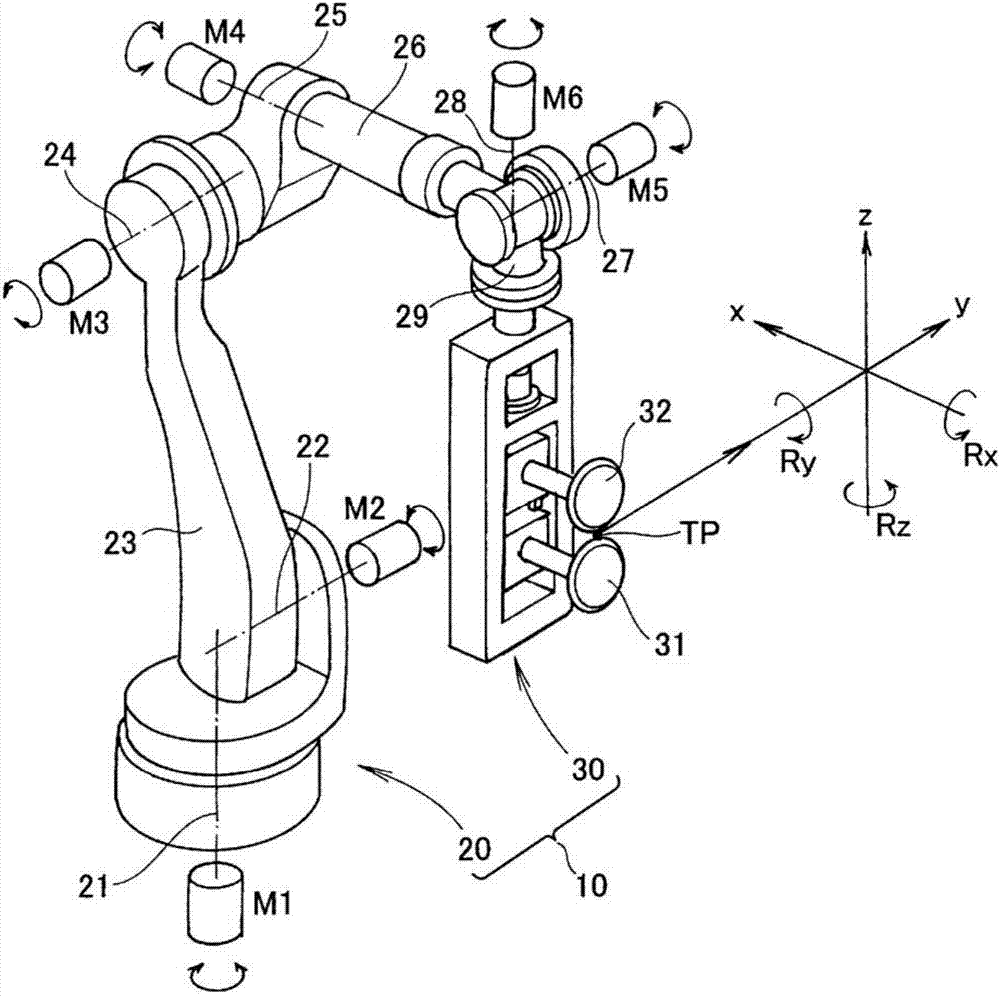

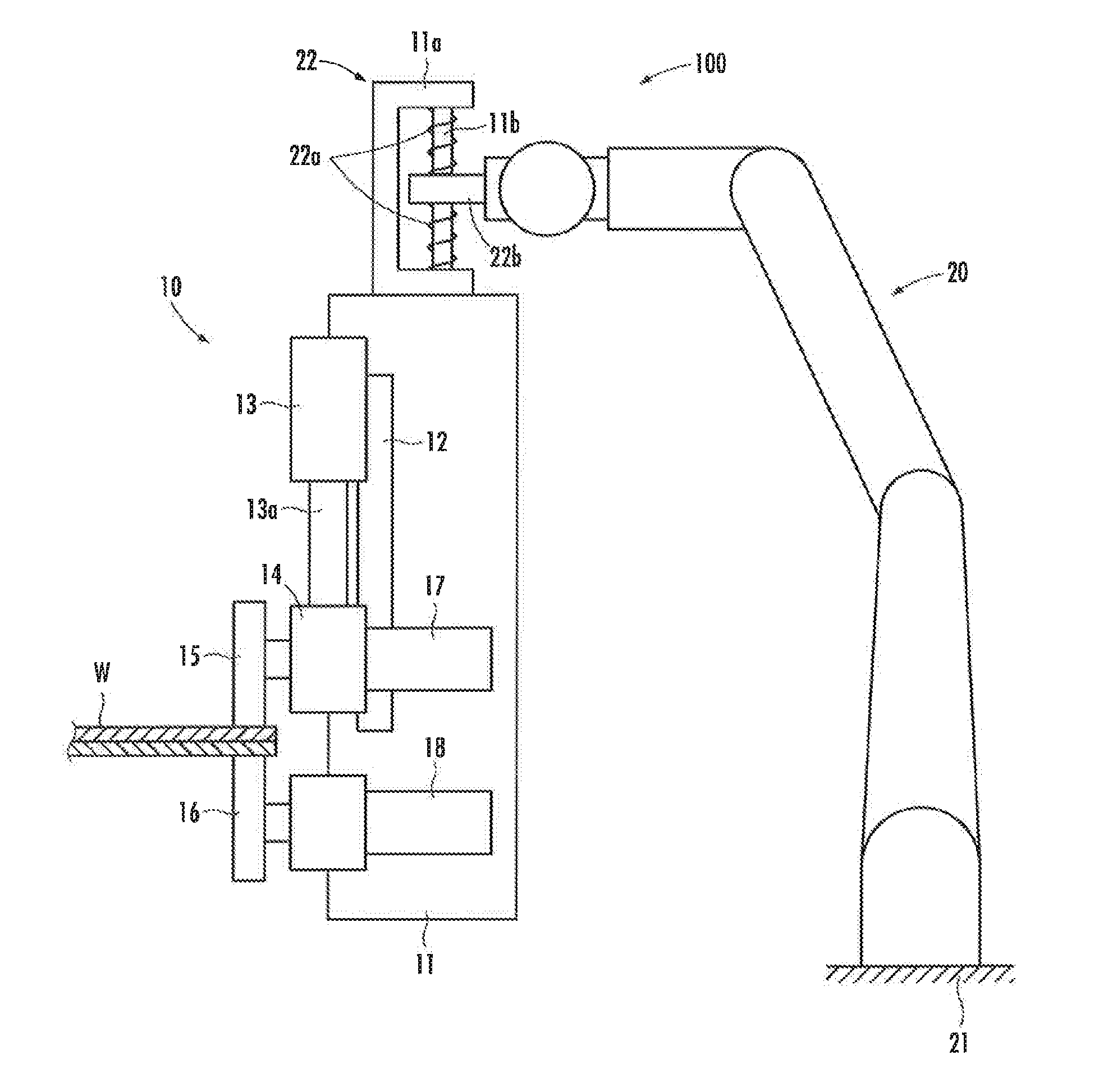

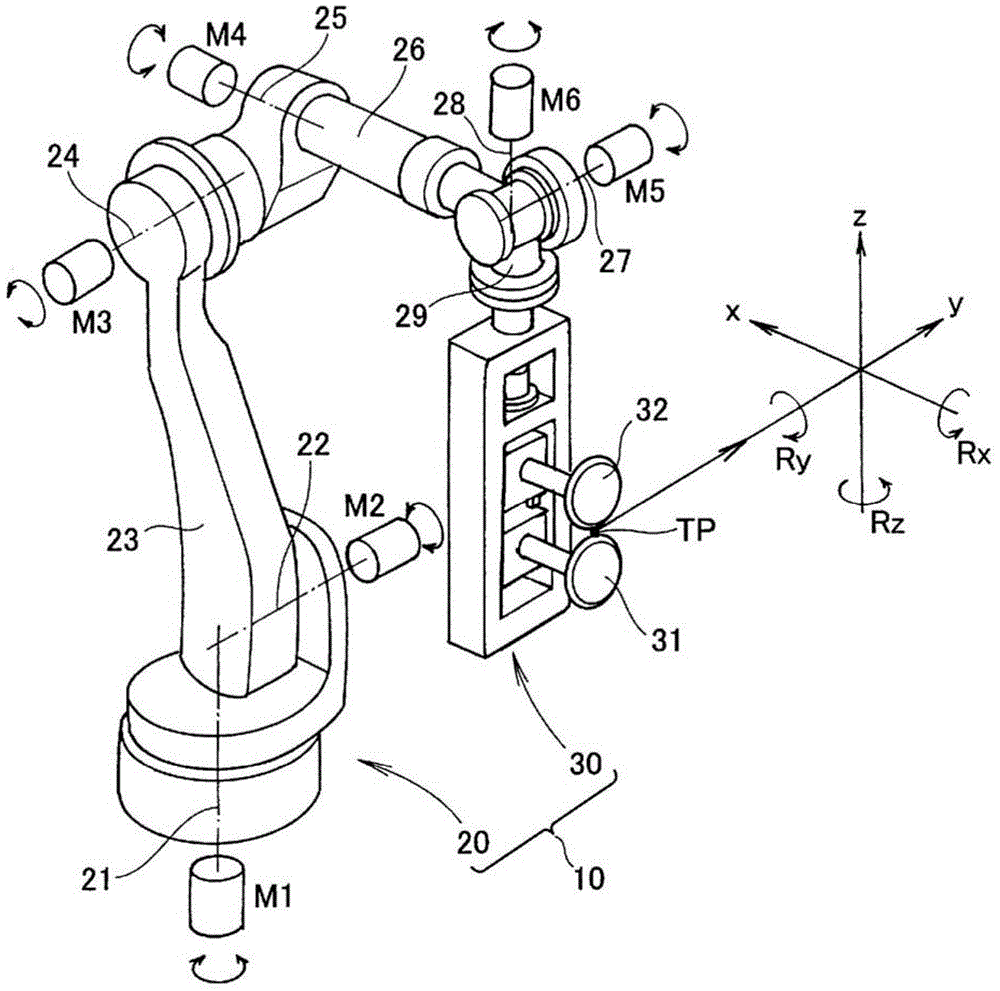

Robot control device and robot control method

ActiveCN106862741AMiniaturizationDistance measurements are not affectedProgramme controlResistance electrode holdersEngineeringRobot control

The invention aims to settle a technical problem of supplying a robot control device of a seam welding apparatus which is not affected by surface shape and integral shape of a workpiece, and a robot control method. For settling the technical problem, the robot control device includes an error acquiring unit, a convertor and a robot control unit. The error acquiring unit acquires error between a measured or estimated position of an end effector mounted on a robot including a plurality of drive sections and a target position of the end effector. The convertor converts the error to a correction angle for a predetermined revolving angle of the end effector. The robot control unit controls the robot so that the end effector revolves based on the correction angle.

Owner:YASKAWA DENKI KK +1

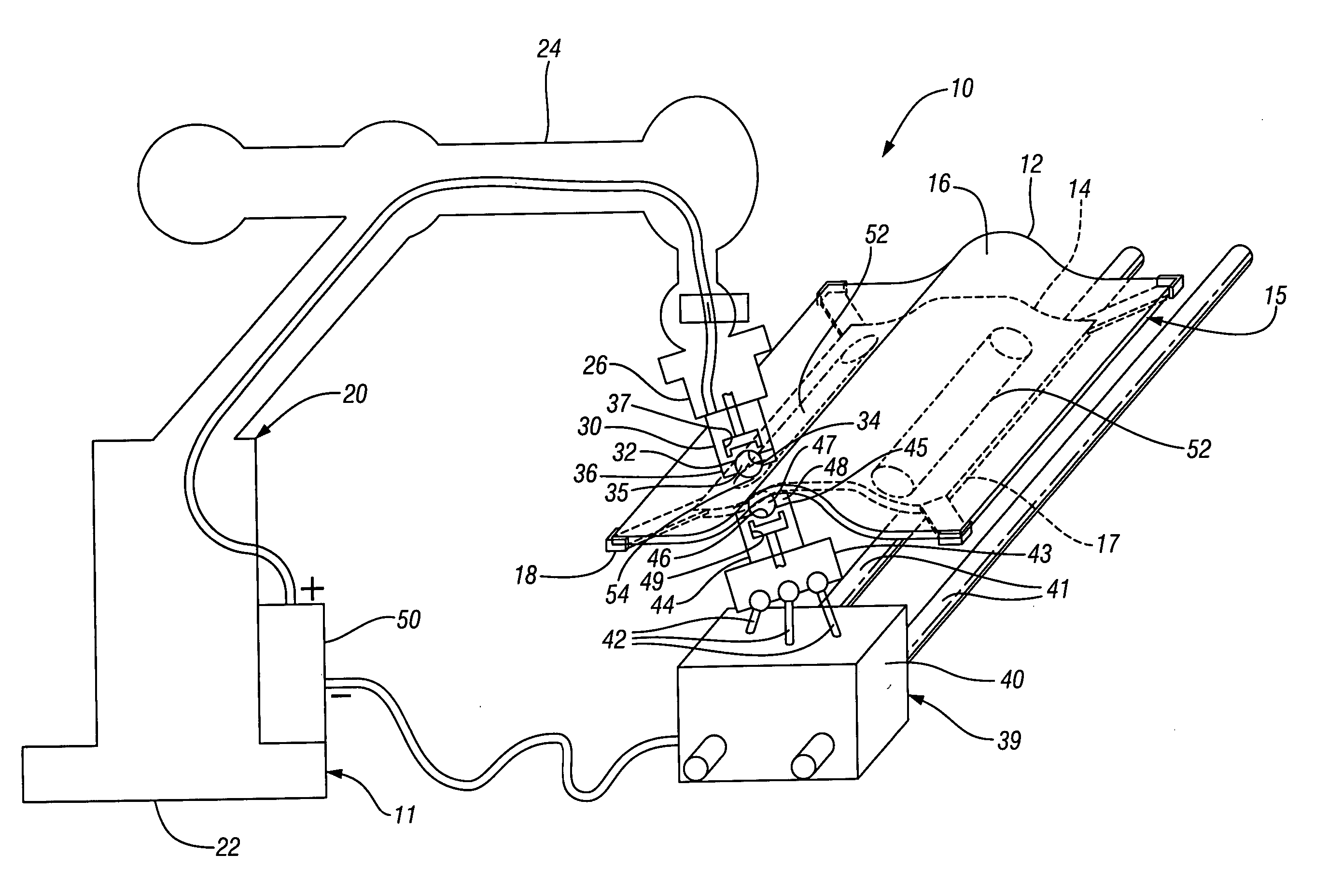

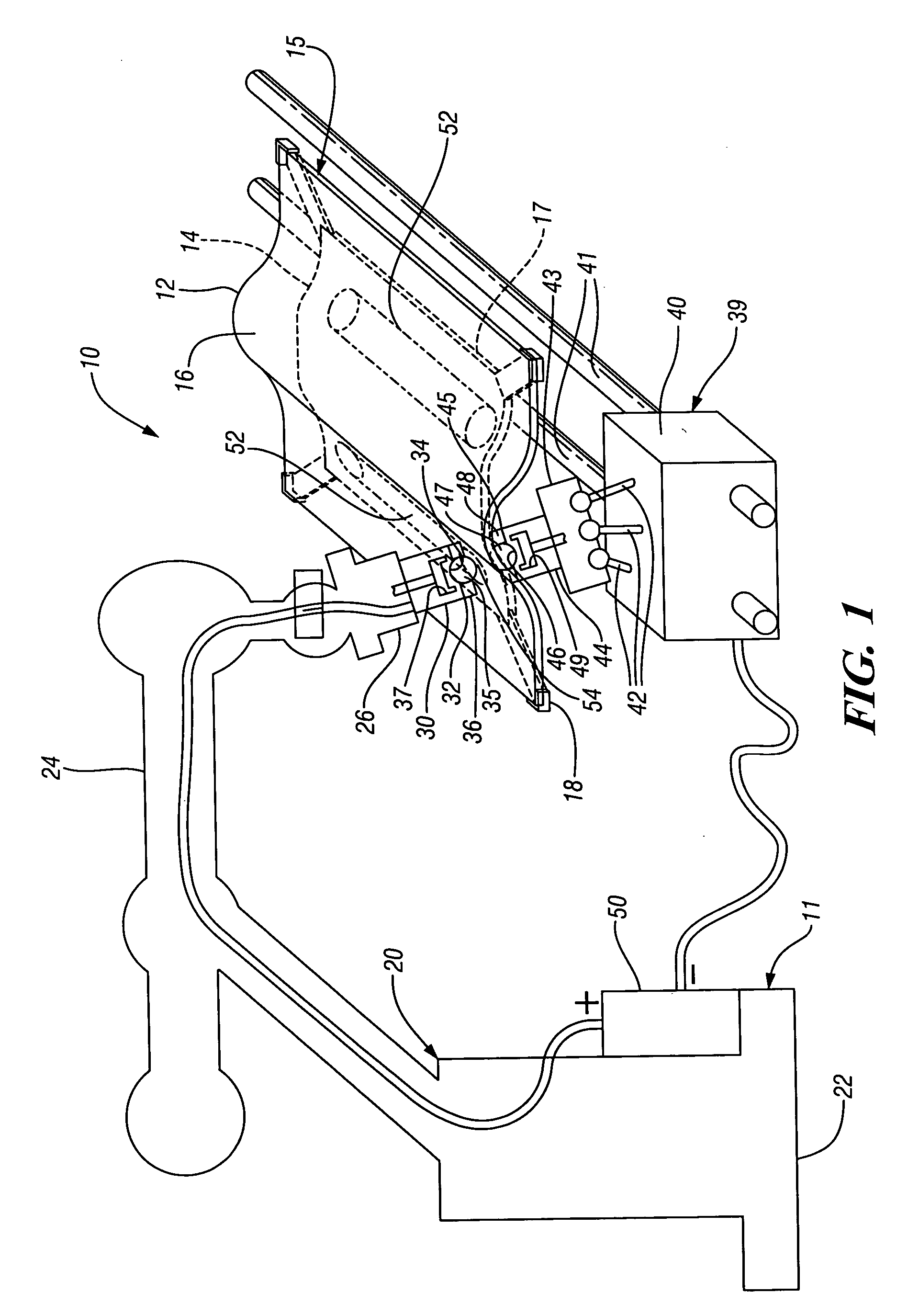

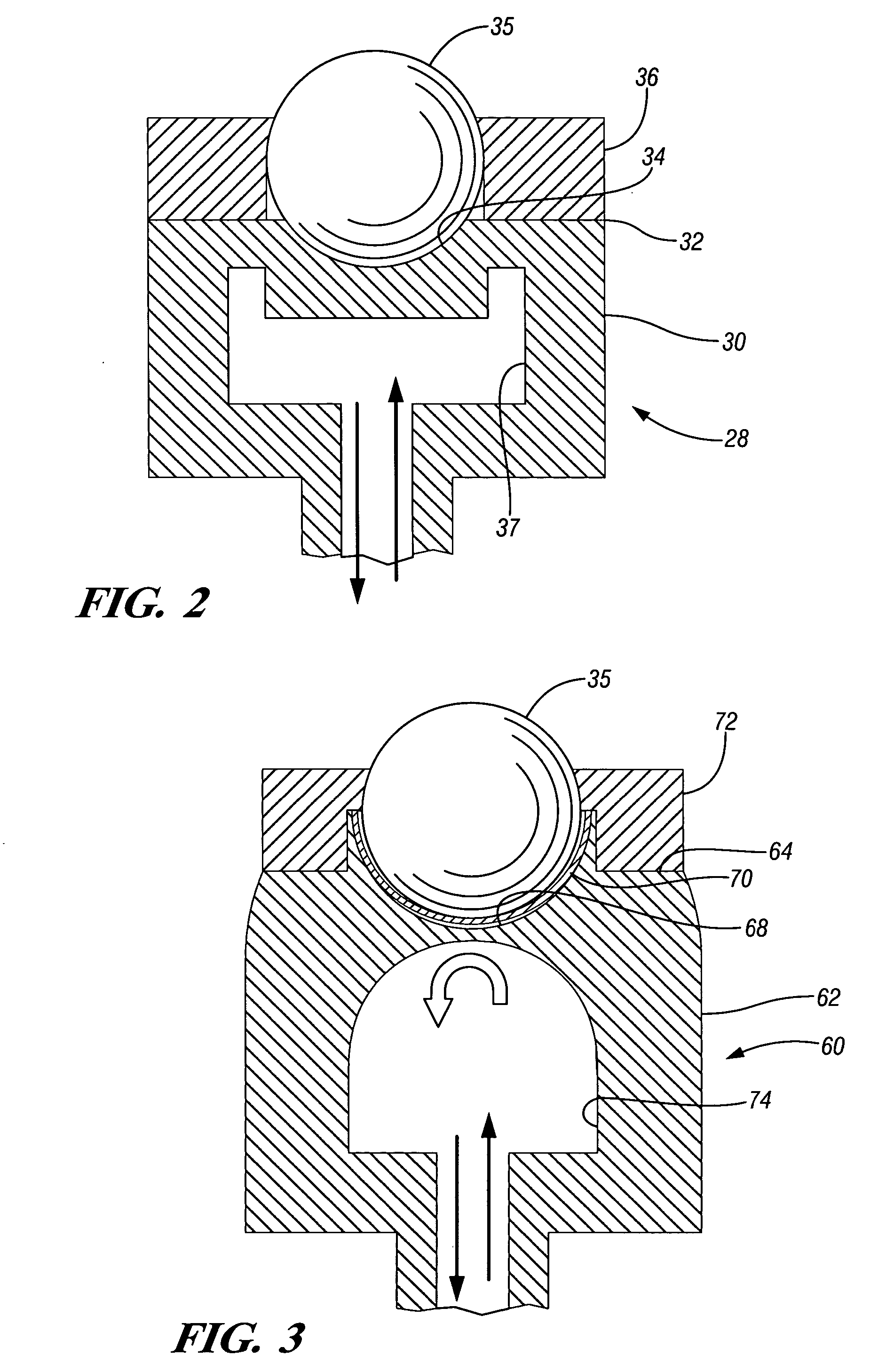

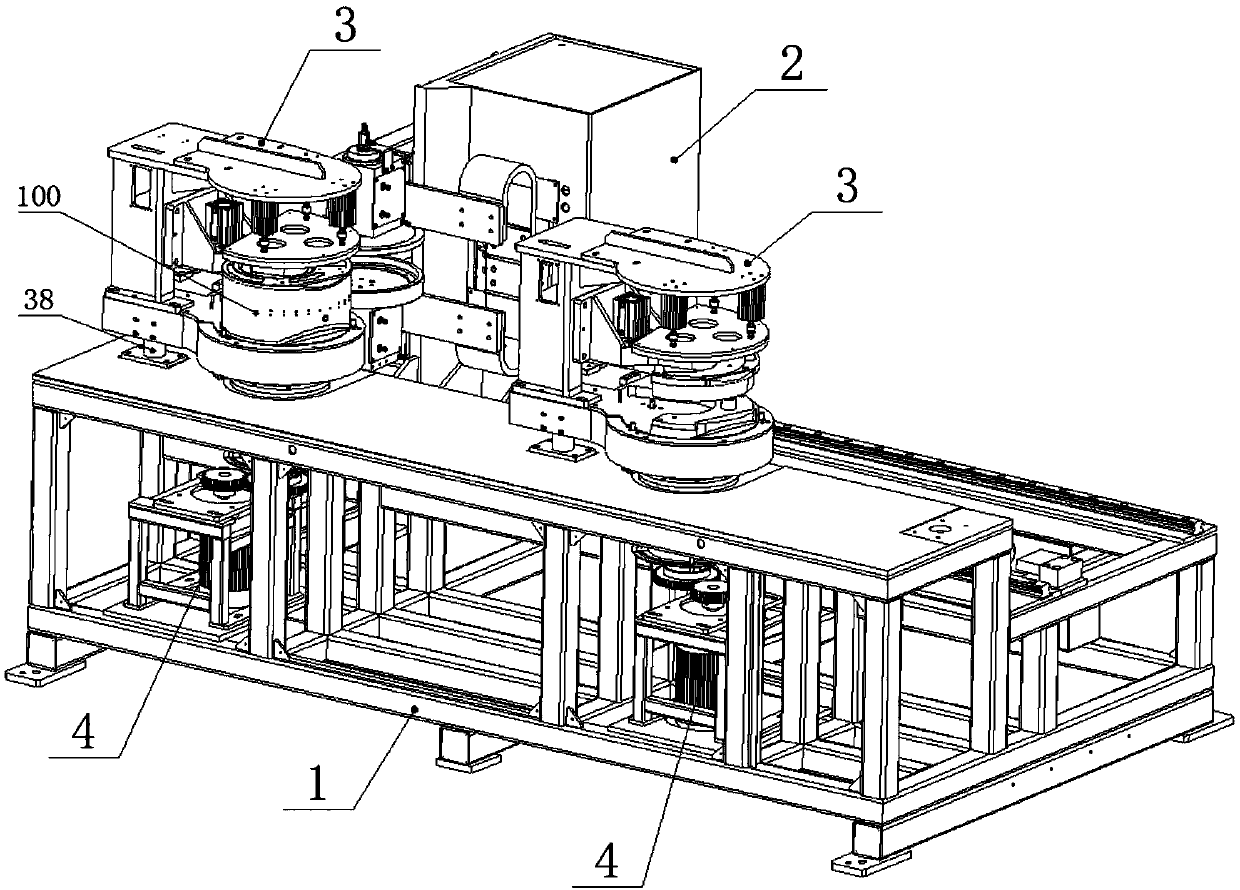

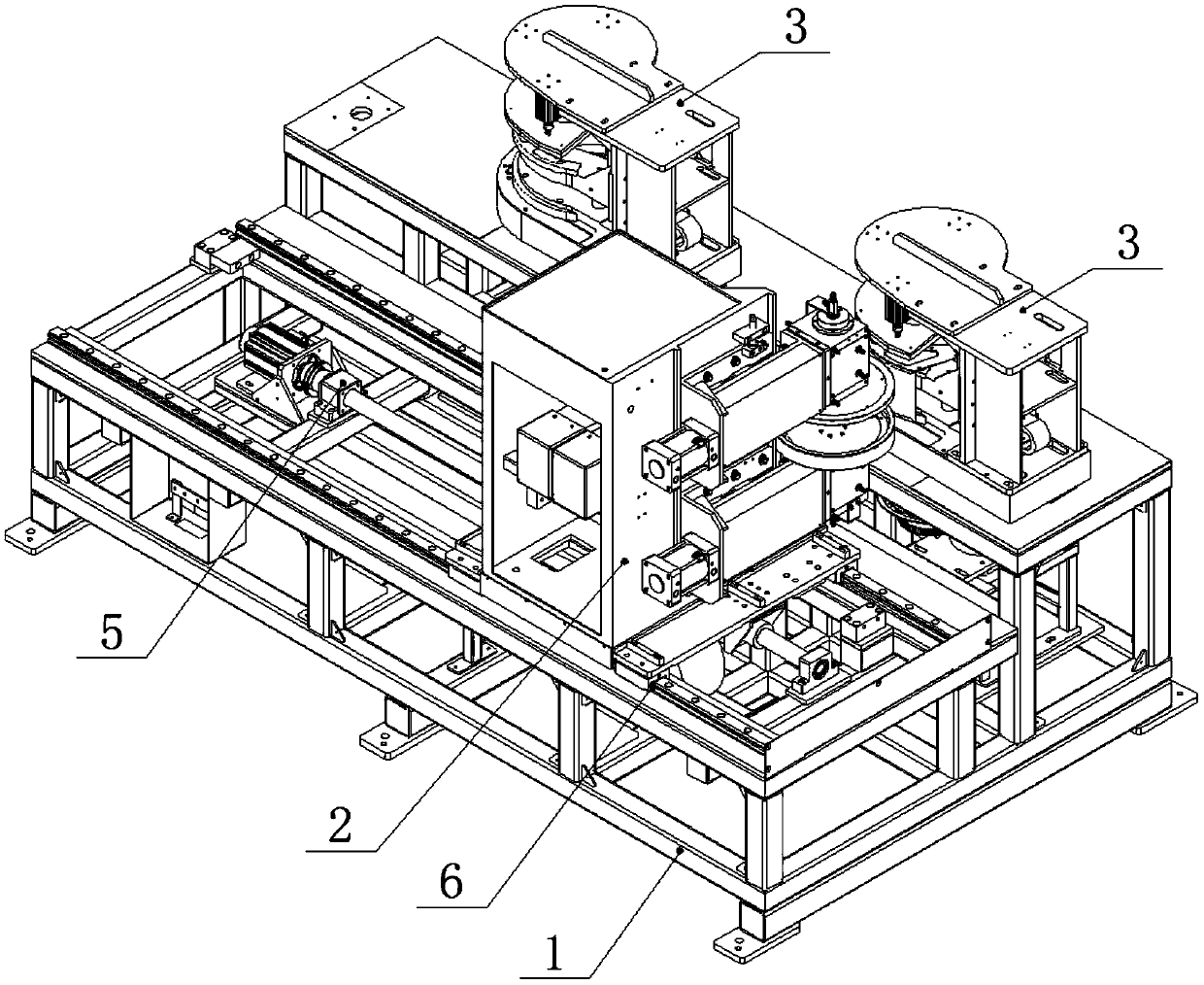

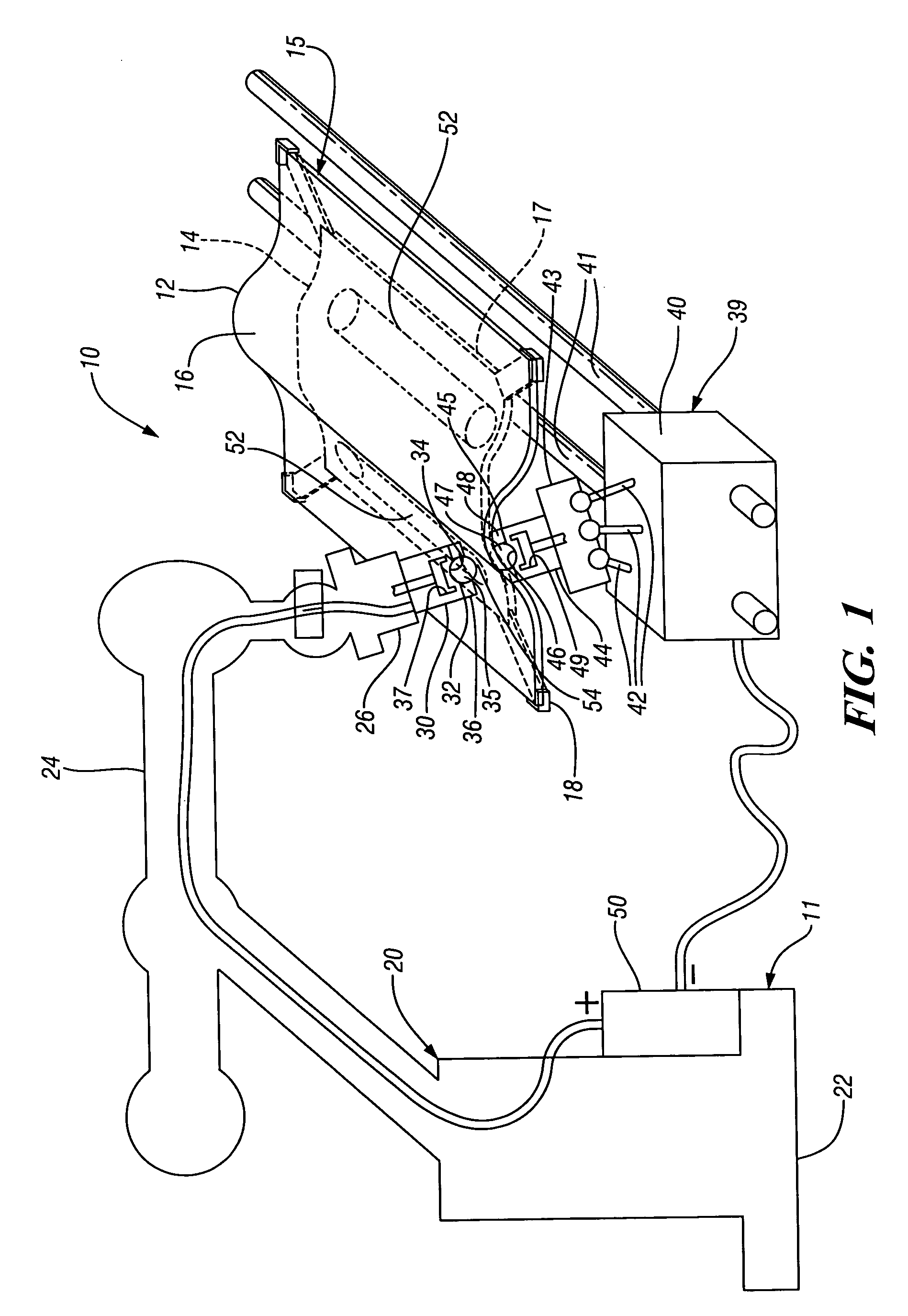

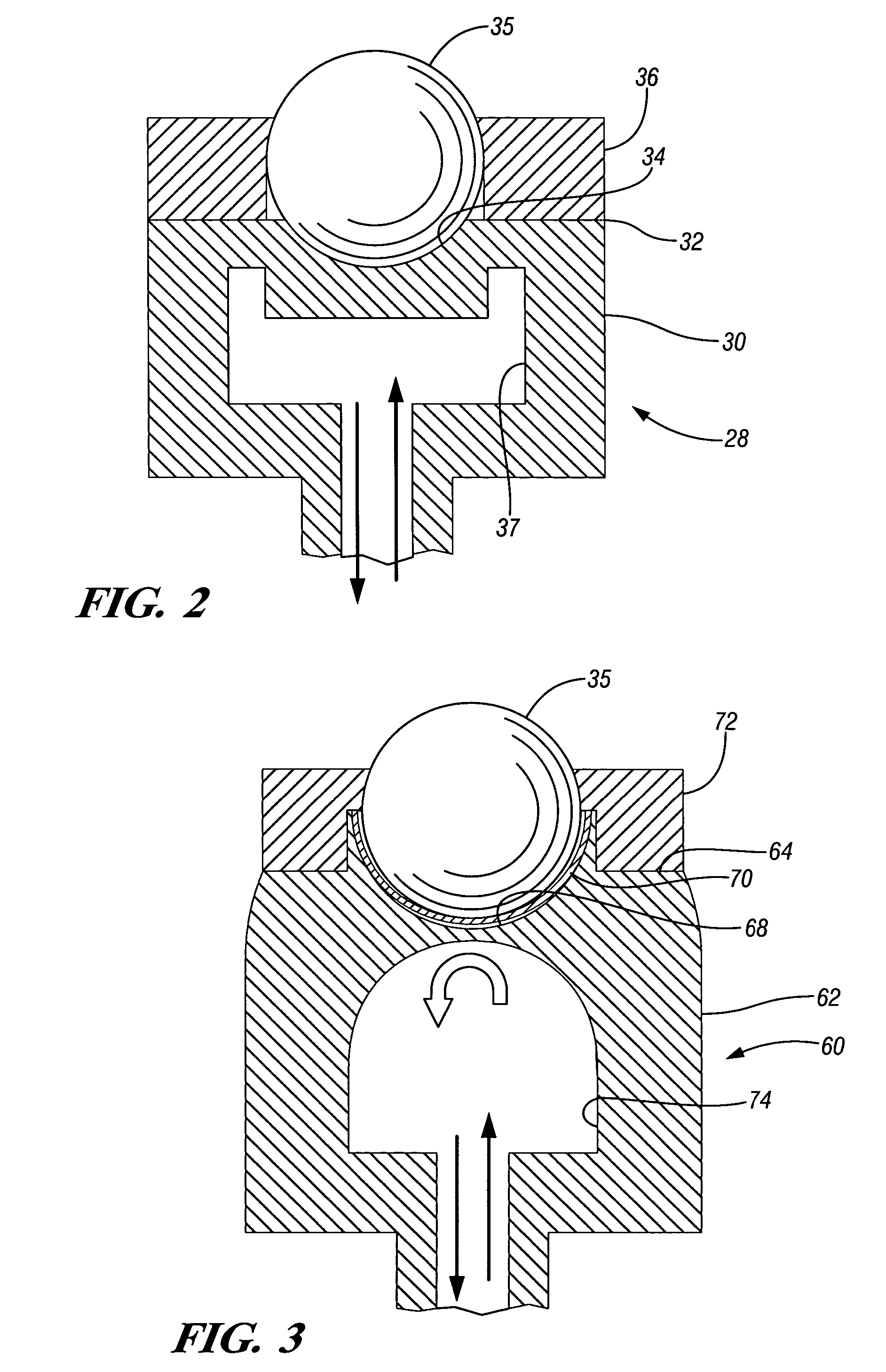

Programmable resistance seam welding apparatus and method

InactiveUS20060043074A1Small welding contact pointReduce amountOhmic-resistance electrodesWelding with roller electrodesElectrical resistance and conductanceEngineering

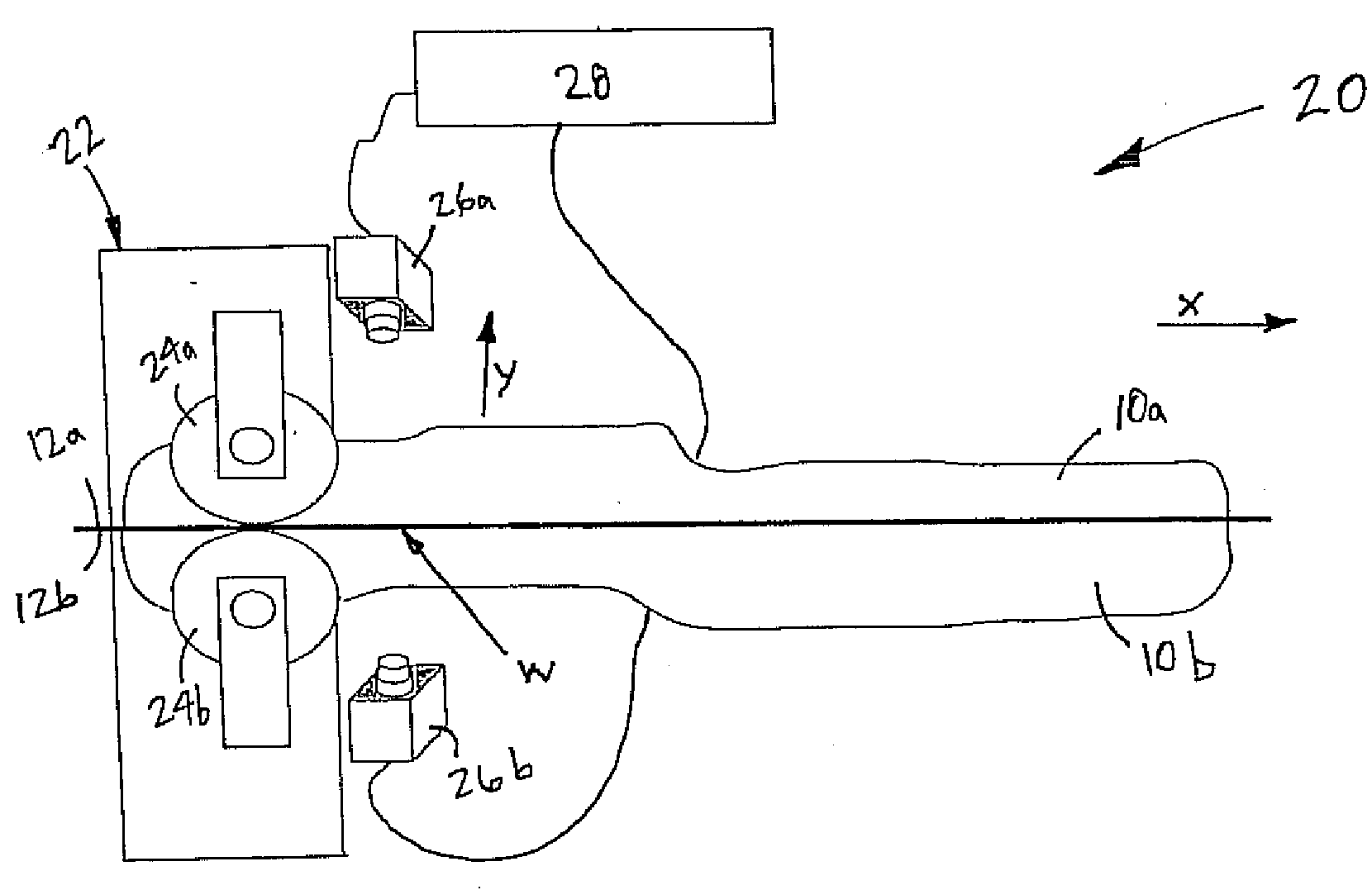

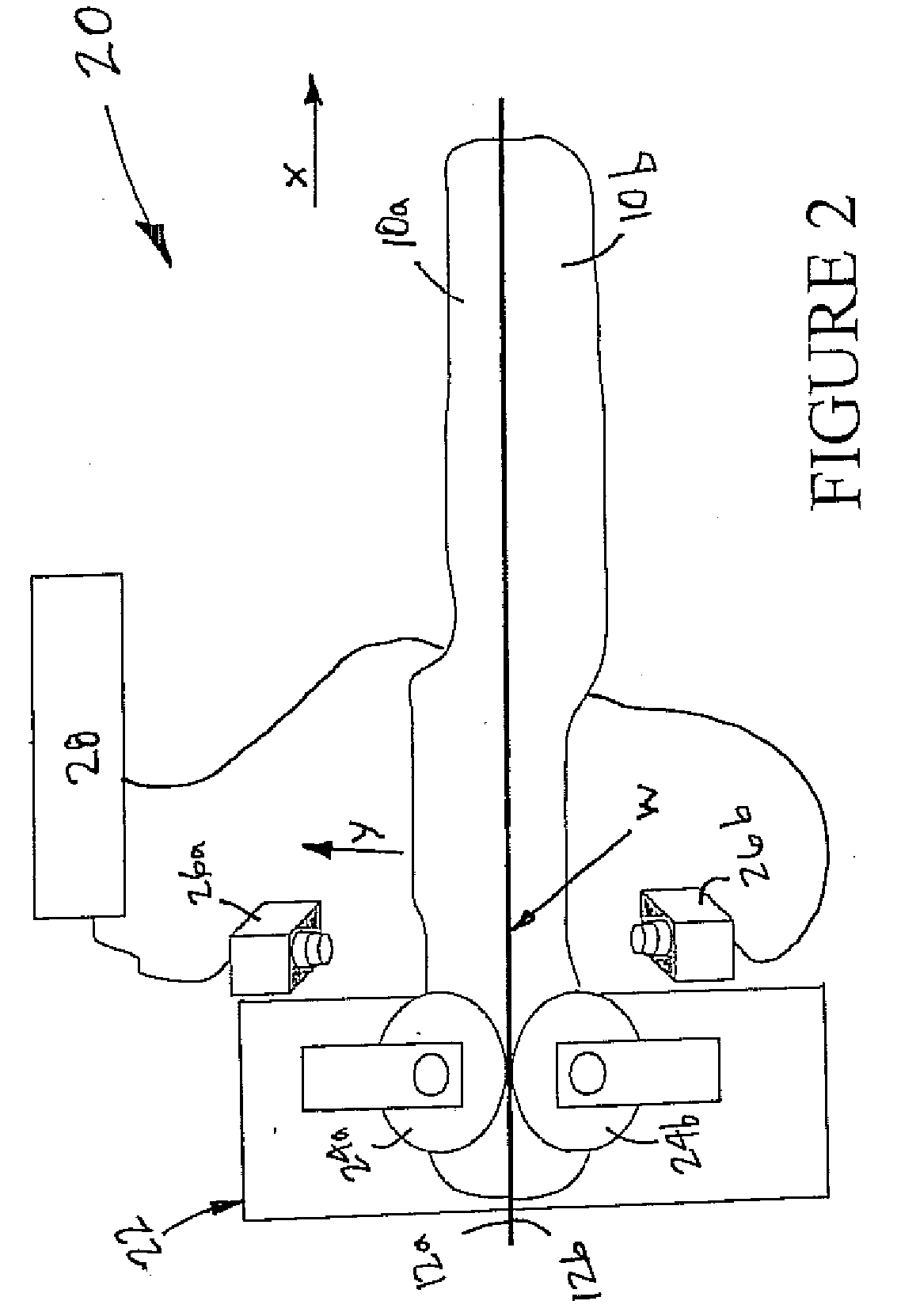

A resistance welding apparatus having a pair of programmable ball electrodes carried on universally movable positioners. The positioners are programmed to move the ball electrodes simultaneously along a seam line so that the ball electrodes clamp and support opposite sides of a pair of stacked workpieces and are electrically charged to form resistance seam welds along the seam lines to connect the workpieces.

Owner:GM GLOBAL TECH OPERATIONS LLC

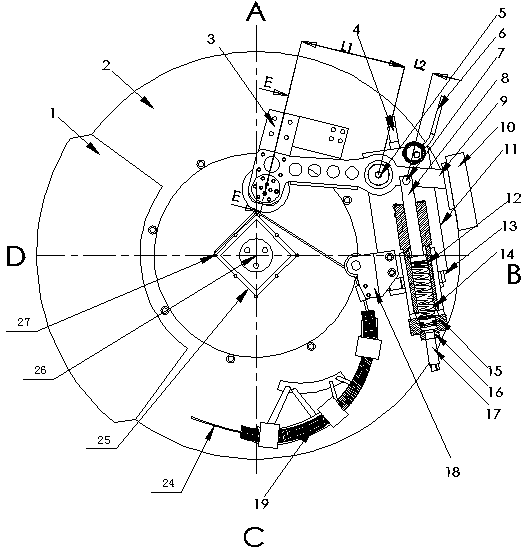

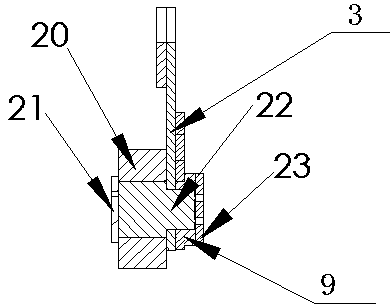

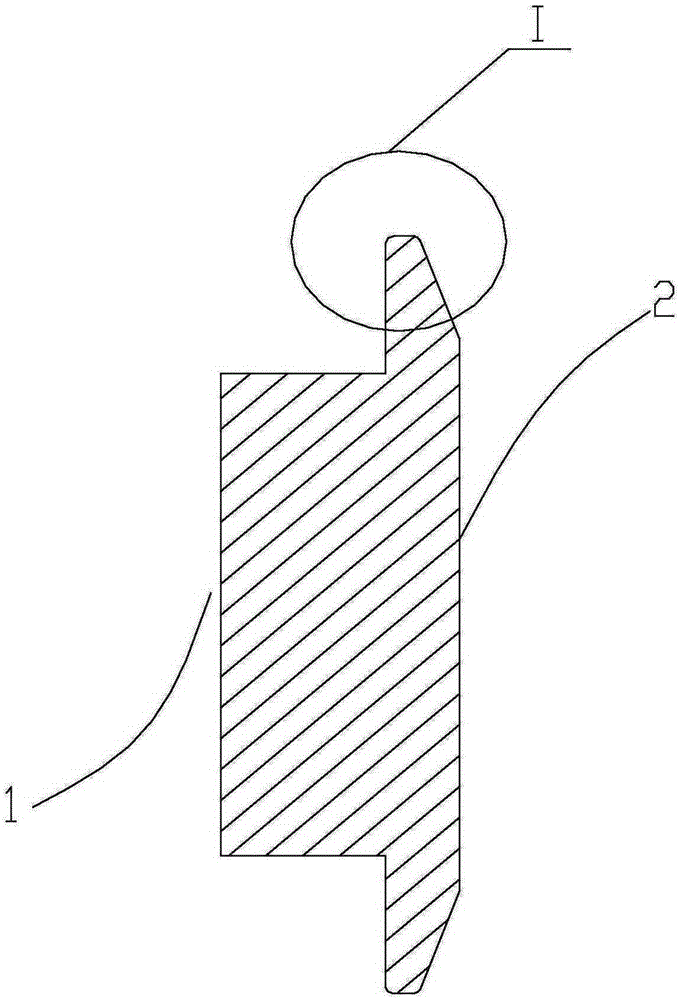

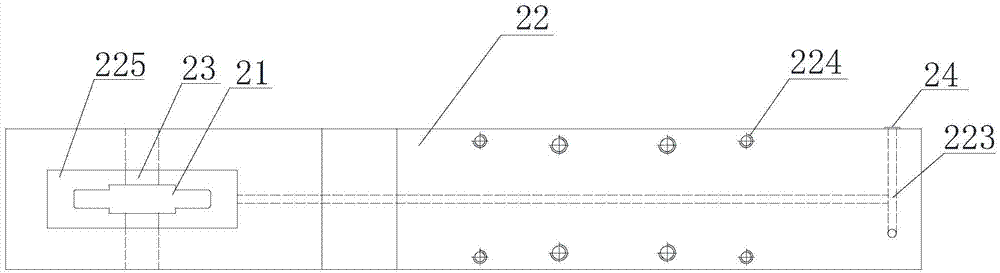

Rotating electrode of seam welder for welding concrete pile reinforcement cages with different cross sections

ActiveCN103624389AEasy to manufactureSimple structureResistance electrode holdersWelding with roller electrodesFailure rateEngineering

The invention relates to a rotating electrode of a seam welder for welding concrete pile reinforcement cages with different cross sections, which comprises a fixed electrode arranged on a conductive central shaft and a rotating disc arranged at the outer side of the fixed electrode, wherein the rotating disc is provided with an adjusting sliding seat; the adjusting sliding seat is provided with an adjusting sliding plate; the adjusting sliding seat is provided with an adjusting screw rod for adjusting the position of the sliding plate; the adjusting sliding plate is provided with a positioning shaft; a welding arm is connected with the adjusting sliding plate through the positioning shaft; the outer side of the welding arm is connected with a support bar through a positioning pin; and the end part of the outer side of the welding arm is provided with a balance. The rotating electrode of a seam welder for welding concrete pile reinforcement cages with different cross sections can be used for manufacturing reinforcement cages with various odd-shaped cross sections; in work, reinforcement cages with corresponding cross sections can be manufactured by simply replacing the fixed electrode with fixed electrodes with corresponding cross sections and replacing corresponding traction discs and reinforcement guide discs; and the structure has the advantages of simple structure, low failure rate, firm welding and high universality.

Owner:TANGSHAN TIANZE SPECIAL WELDING EQUIP

Metallurgy welding method of double-metal mechanical compound pipe ends

ActiveCN106825963AAvoid corrosionImprove bindingCurved planar seam weldingArc welding apparatusButt weldingEngineering

The invention discloses a metallurgy welding method of double-metal mechanical compound pipe ends. The method includes the steps of firstly, performing pipe end seam welding; secondly, performing edge preparation; thirdly performing pipeline butt welding. The metallurgy welding method has the advantages the metallurgy combining of the mechanical compound pipe ends by using the seam welding technology, and the welding difficulties of mechanical compound pipes are solved fundamentally; compared with a traditional soldering and sealing process, the metallurgy welding method can prevent weld toe cracks and is good in reliability and high in efficiency; compared with a novel pipe end build up welding process, the metallurgy welding method does not need a complex end processing process, does not consume a large amount of alloy welding materials, and is simple and convenient to operate and low in cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

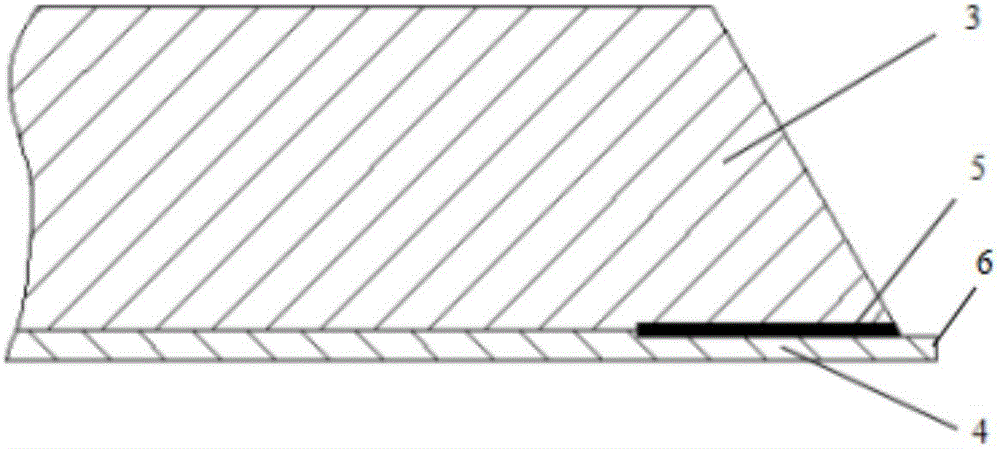

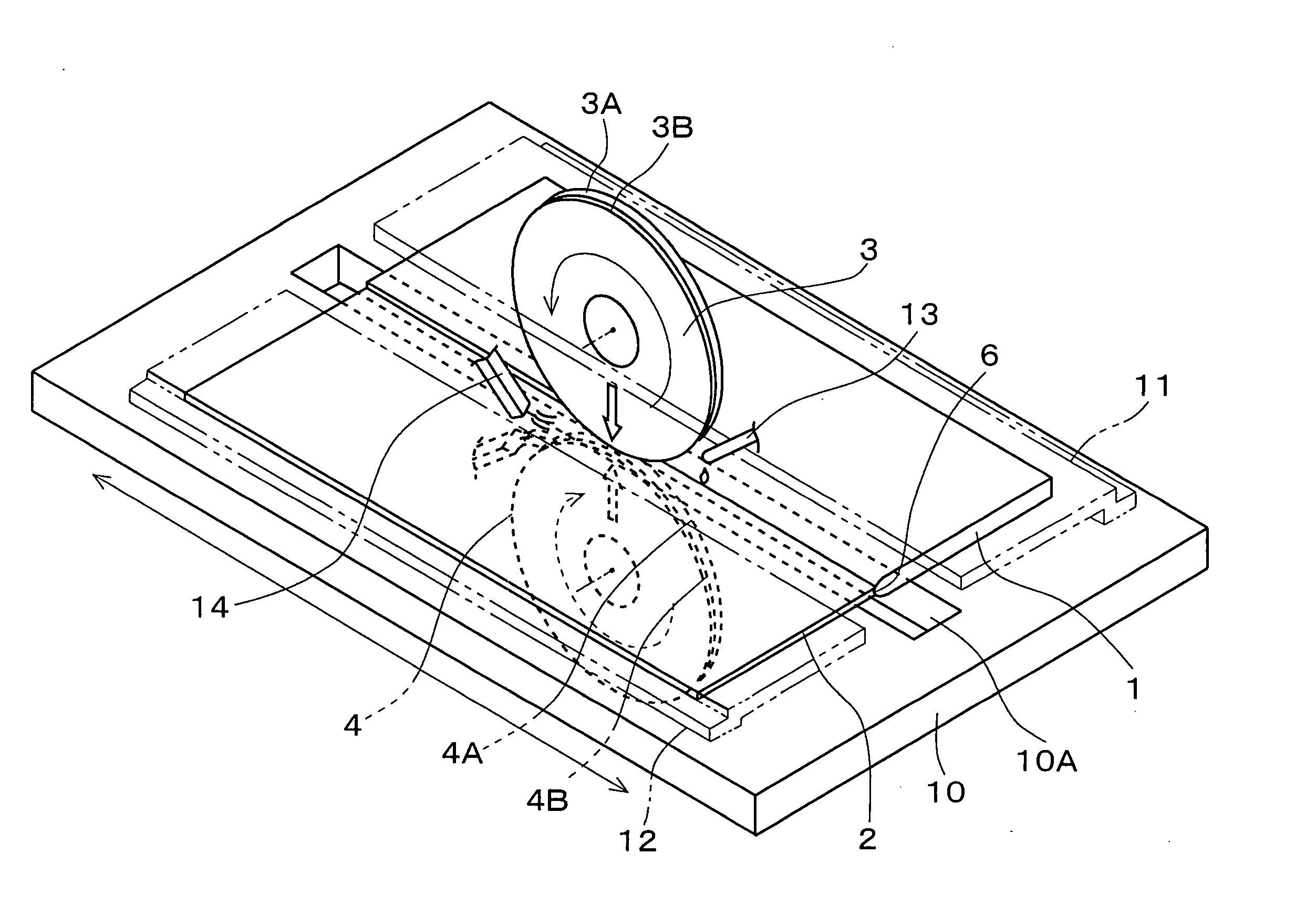

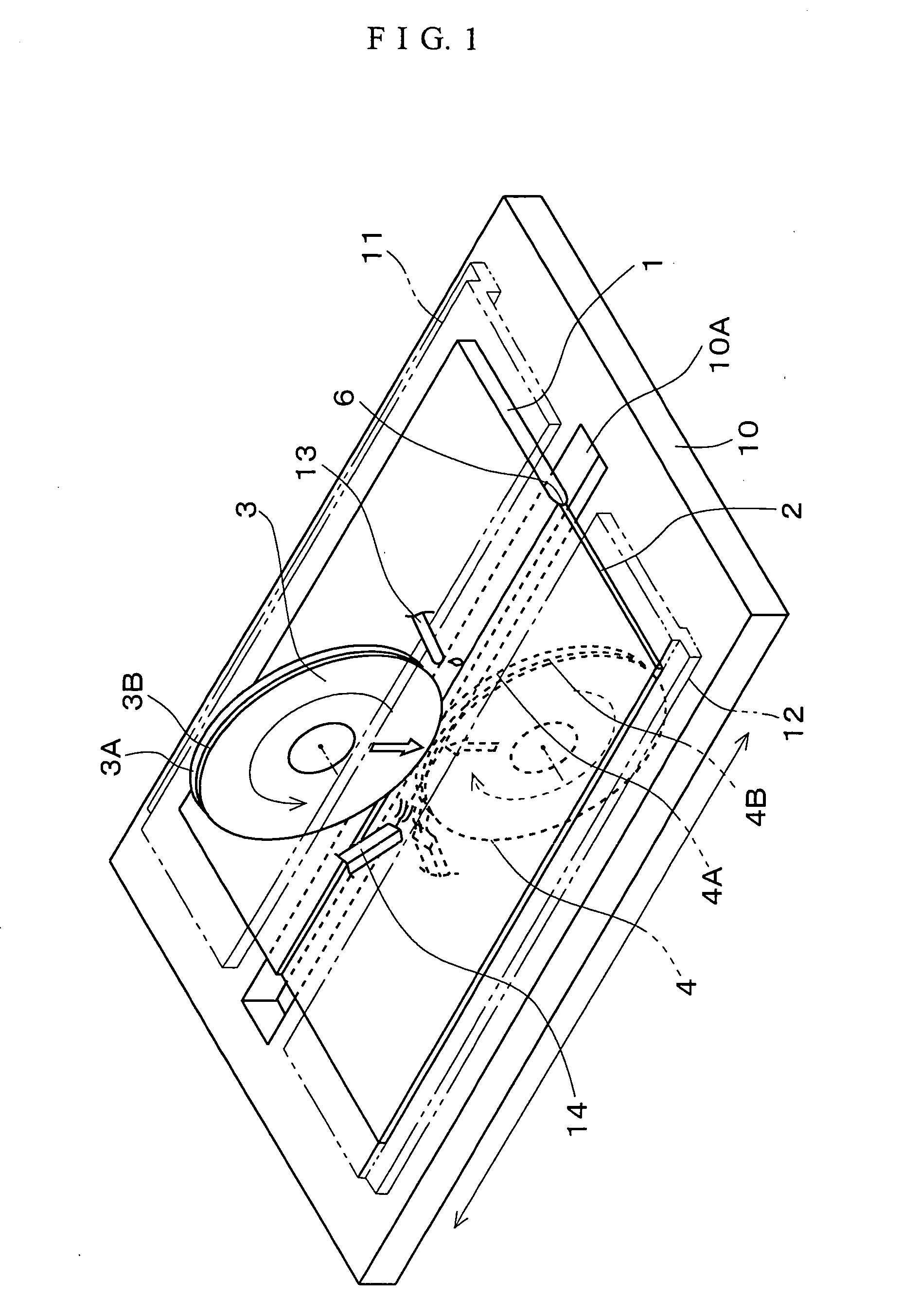

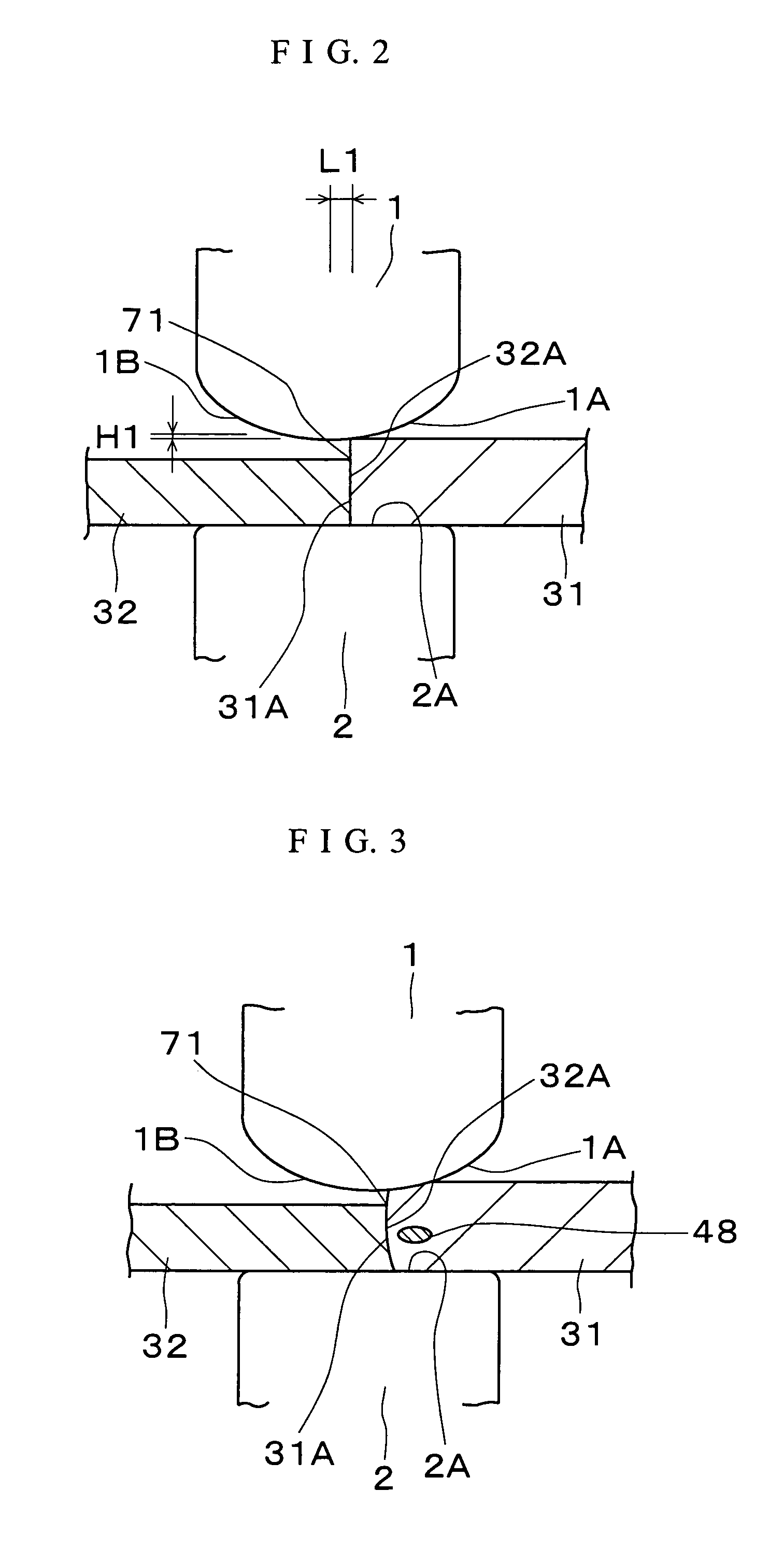

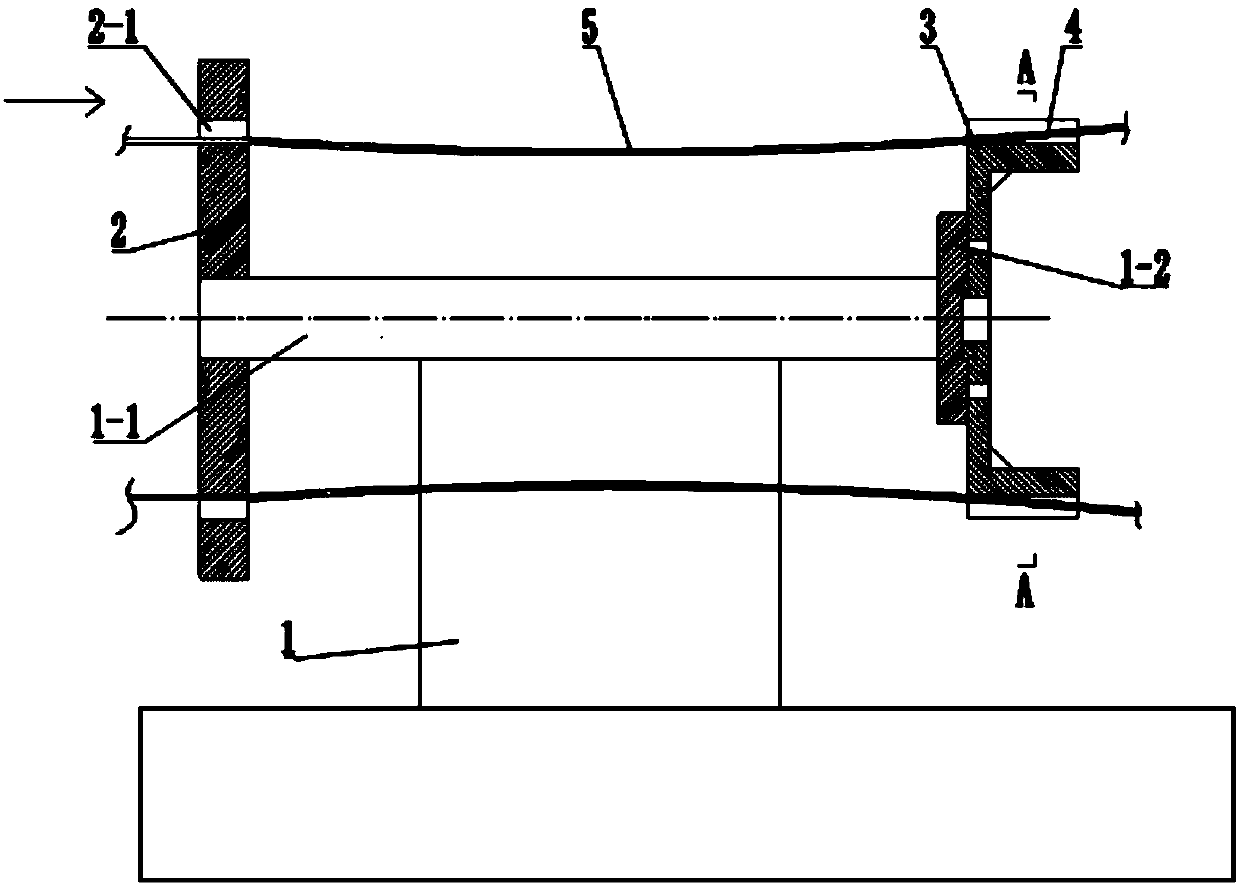

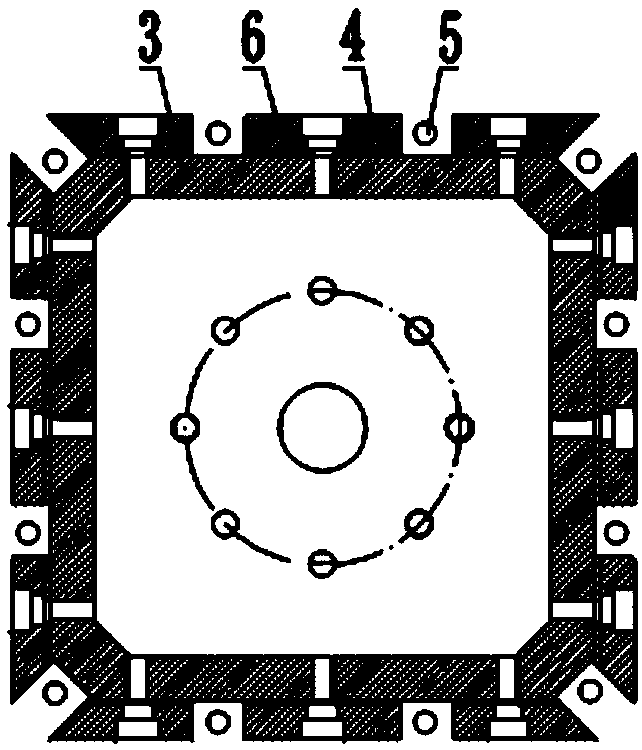

Butt welder and butt welding method and butt welded product

InactiveUS20050011864A1Reliably securedLow costRectilinear seam weldingArc welding apparatusButt weldingEngineering

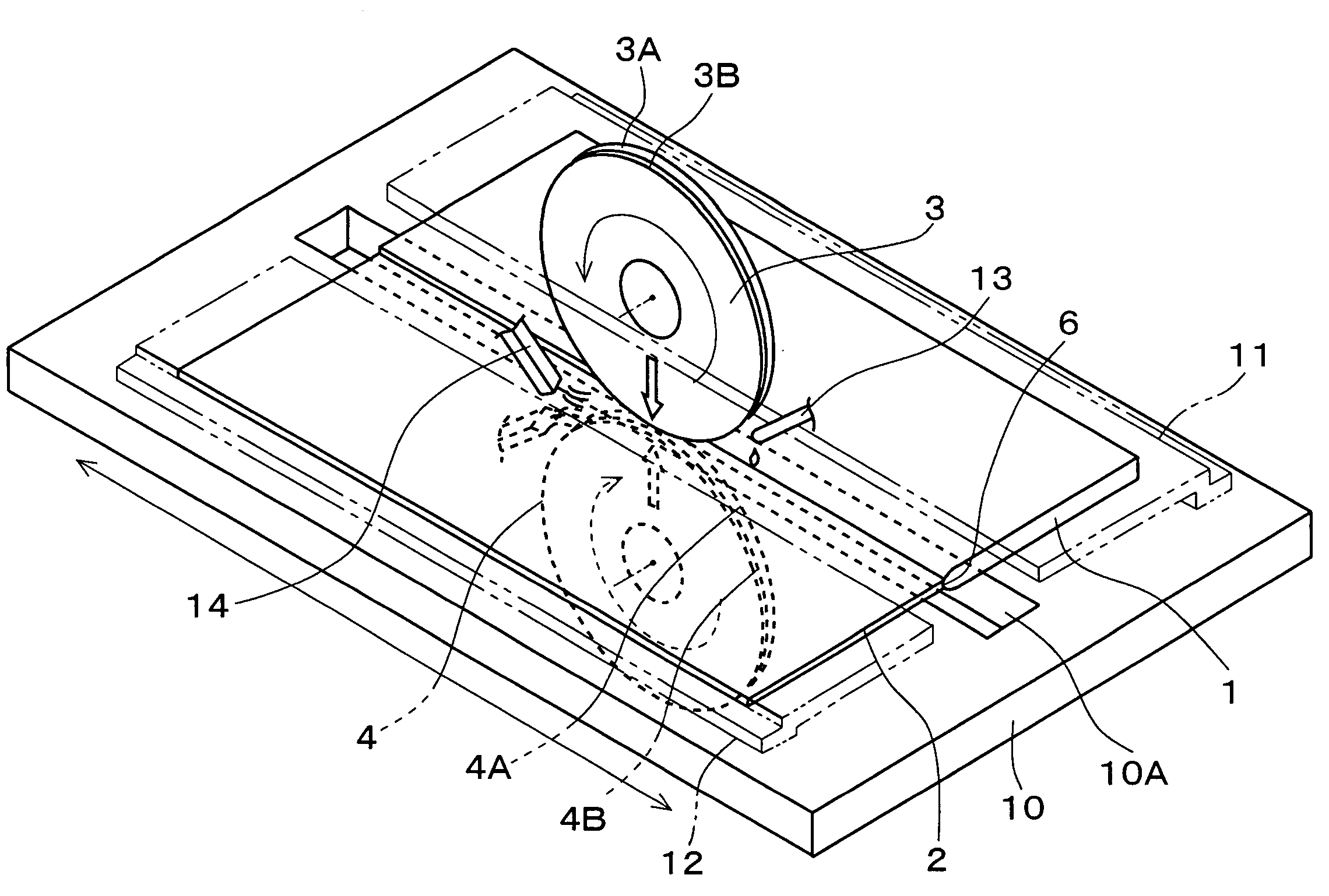

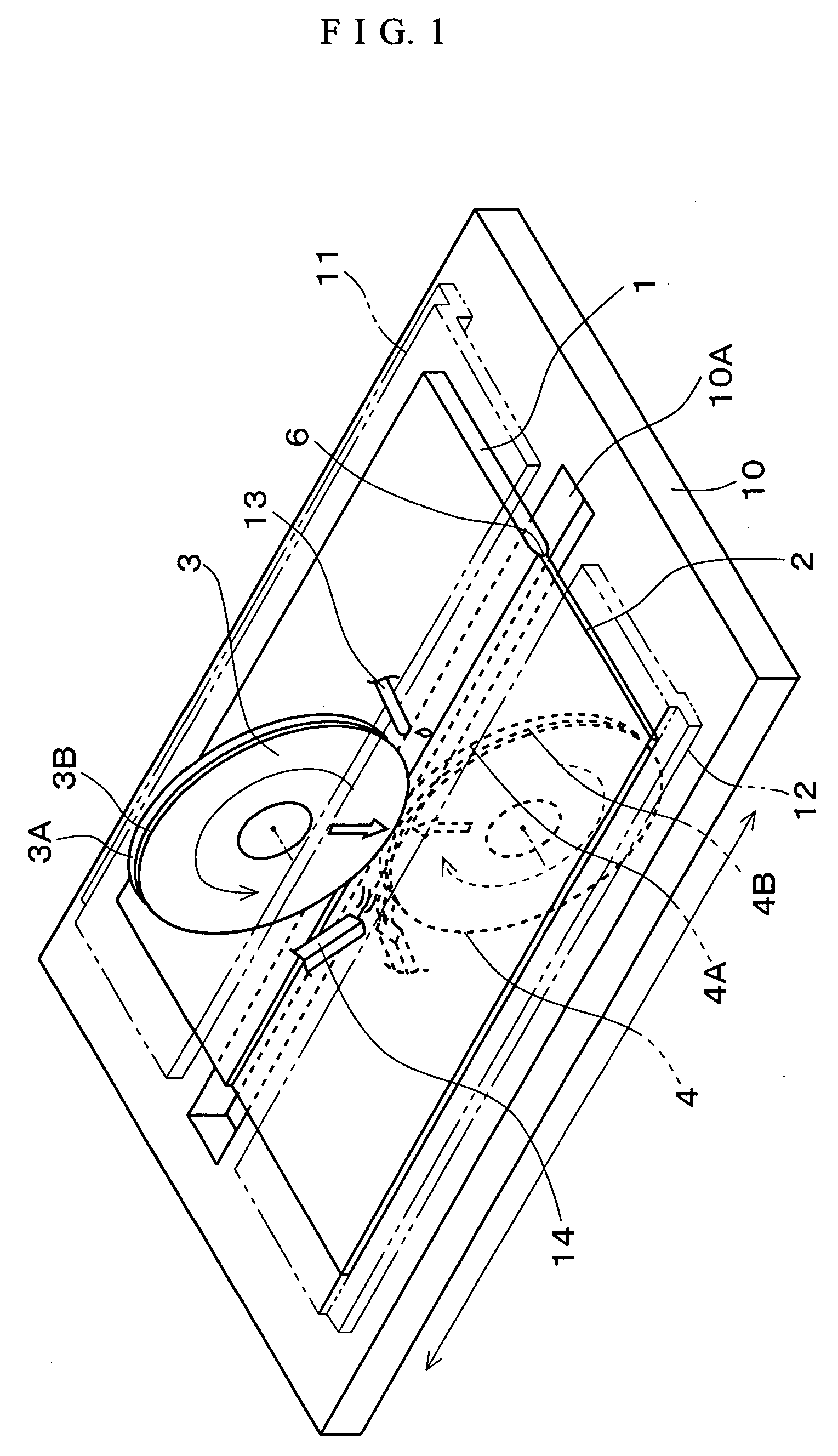

Disclosed are a butt welding apparatus, a butt welding method, and a product manufactured by the butt welding method. Two electrode rollers (3, 4) are disposed on both the front and back sides of a thick sheet member (1) and on both the front and back sides of a thin sheet member (2) whose end surfaces (1A, 2A) are butted. The electrode rollers (3, 4) are applied with power, melt the butt portion (6) of the sheet members (1, 2) with electric resistance heat, and joint the butt portion. Further, the electrode rollers (3, 4) have a length bridging across the sheet members (1, 2) and are composed of first portions (3A, 4A) arranged as small diameter portions on the side of the thick sheet member (1) and second portions (3B, 4B) arranged as large diameter portions on the side of the thin sheet member (2). The first portions (3A, 4A) come into contact with the thick sheet member (1) and presses it before the second portions (3B, 4B) come into contact with the thin sheet member (2). Thus, the end surface (1A) of the thick sheet member (1) swells and deforms toward the thin sheet member (2) and reliably comes into contact with the end surface (2A) of the thin sheet member (2). As a result, power is applied between the end surfaces (1A, 2A) even if the end surfaces (1A, 2A) are not finished by polishing and the like.

Owner:KIKUCHI KK (KIKUCHI CO LTD)

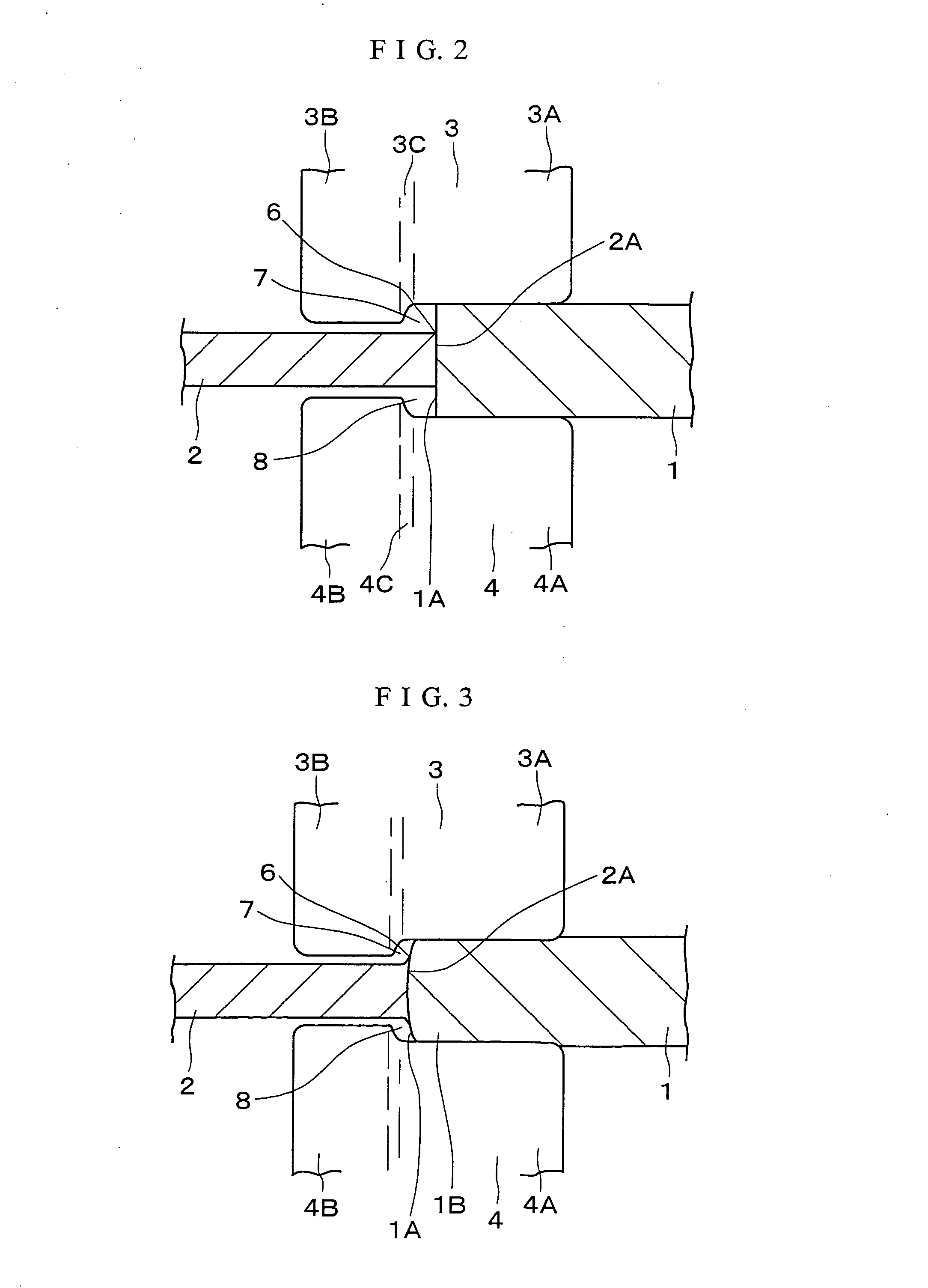

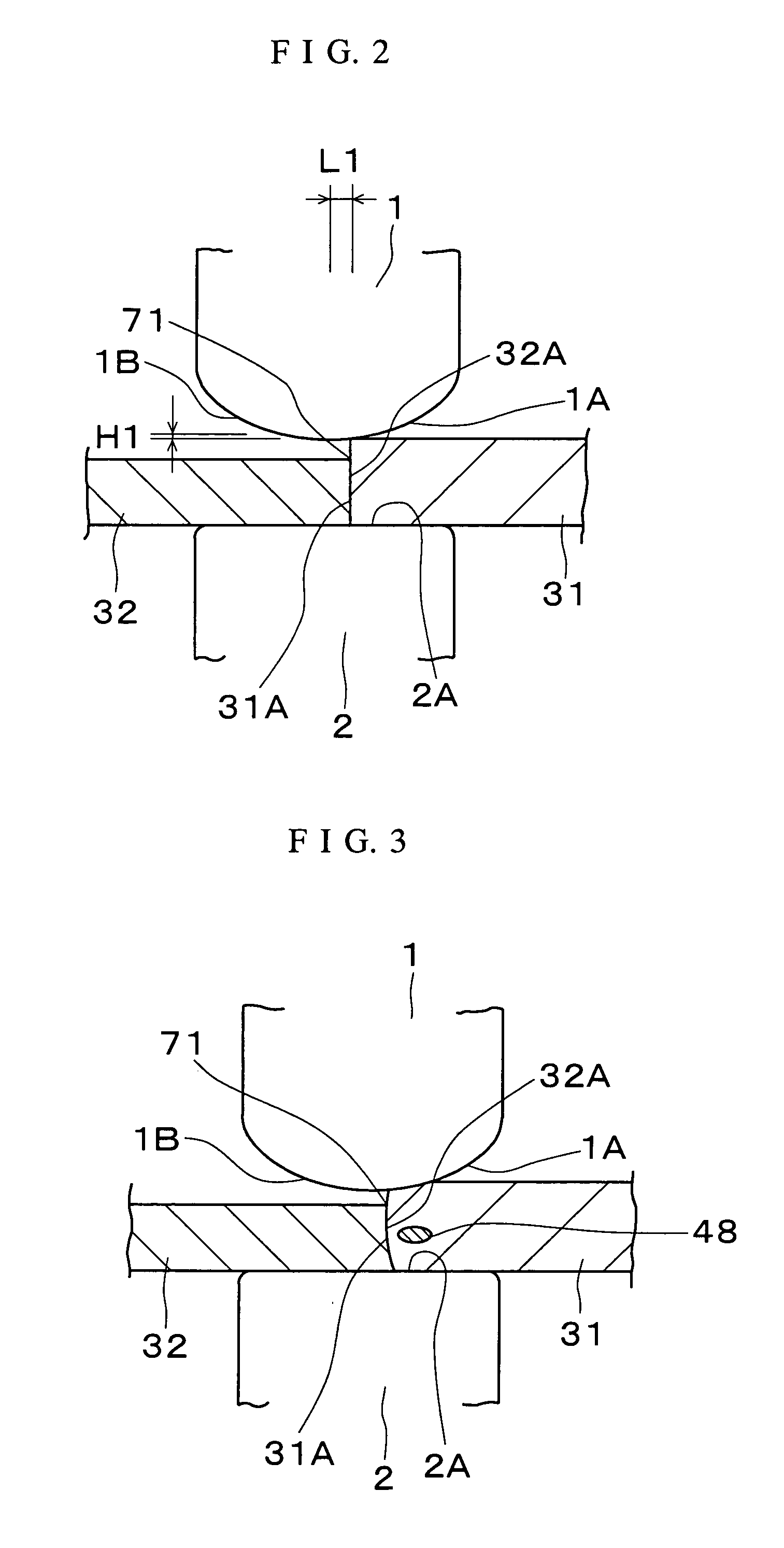

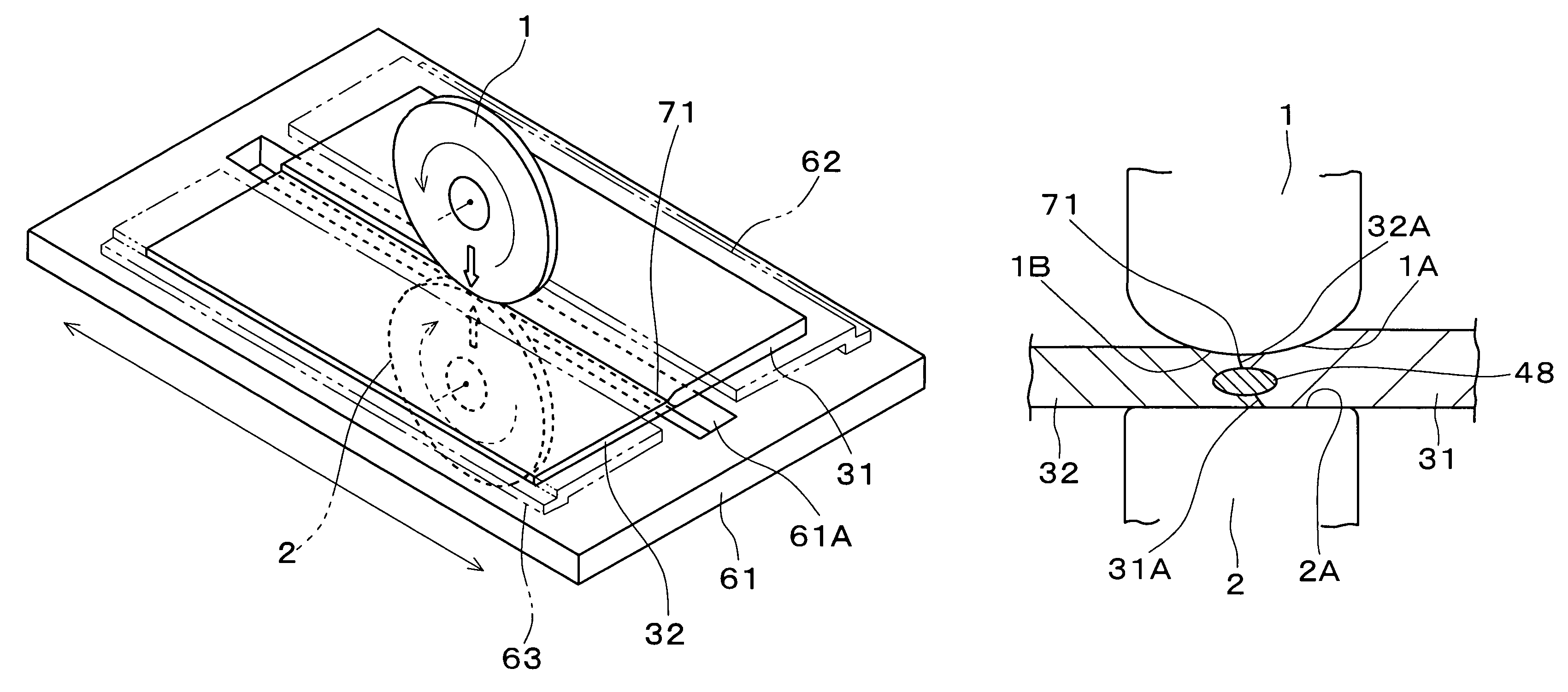

Butt welding device and butt welding method

InactiveUS20060151441A1Reduction in butt welding work timeImprove efficiencyRectilinear seam weldingArc welding apparatusButt weldingMechanical engineering

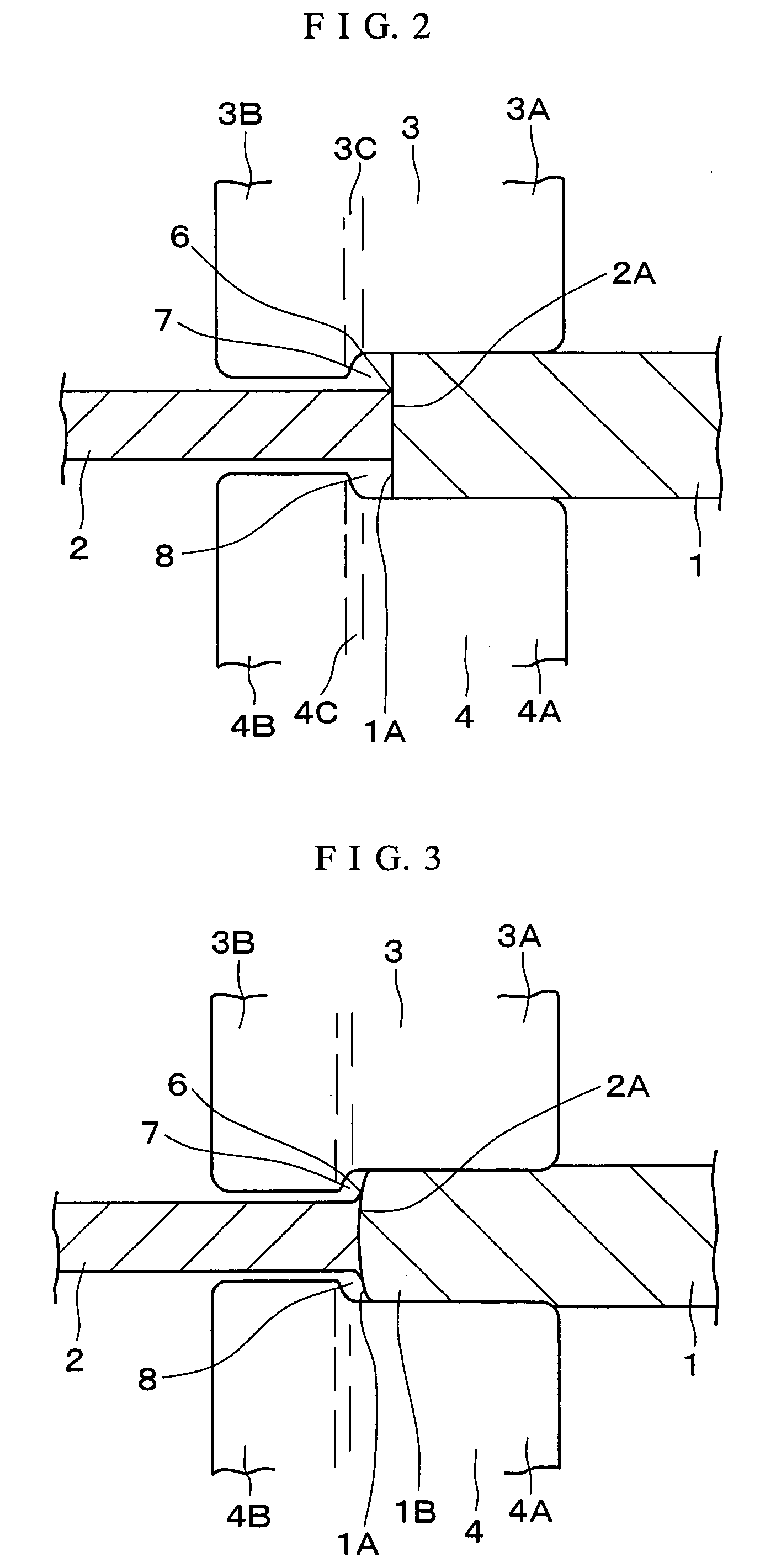

The present invention is a butt welding apparatus and a butt welding method where end faces of at least one plate member to be welded are butted to each other to form a butt portion, and butt welding can be performed on respective plate members to be welded which have various thickness sizes on both side portions of the butt portion with electric resistance heat by a pair of two electrode members which are made common to the respective plate members and are supplied with power. At least one electrode member (1) of a pair of electrode members (1, 2) for butt-welding two plate members (31, 32) is provided on an outer face thereof with a retreating-shaped portion (1A) which gradually retreats from one plate member (31) of the two plate members (31, 32) according to extension from an intermediate portion, in a thickness direction, of the one electrode member (1) along the one plate member (31). Butt welding of the two plate members (31, 32) is performed in a state that the position of the butting portion (71) of these plate members (31, 32) has been offset from intermediate portions, in thickness directions, of the electrode members (1, 2) to the retreating-shaped portion (1A) by an amount (L1) corresponding to a difference in thickness between the plate members (31, 32), and butt welding of two other plate members having different thickness sizes is performed with a changed offset amount.

Owner:SUMITOMO METAL IND LTD +1

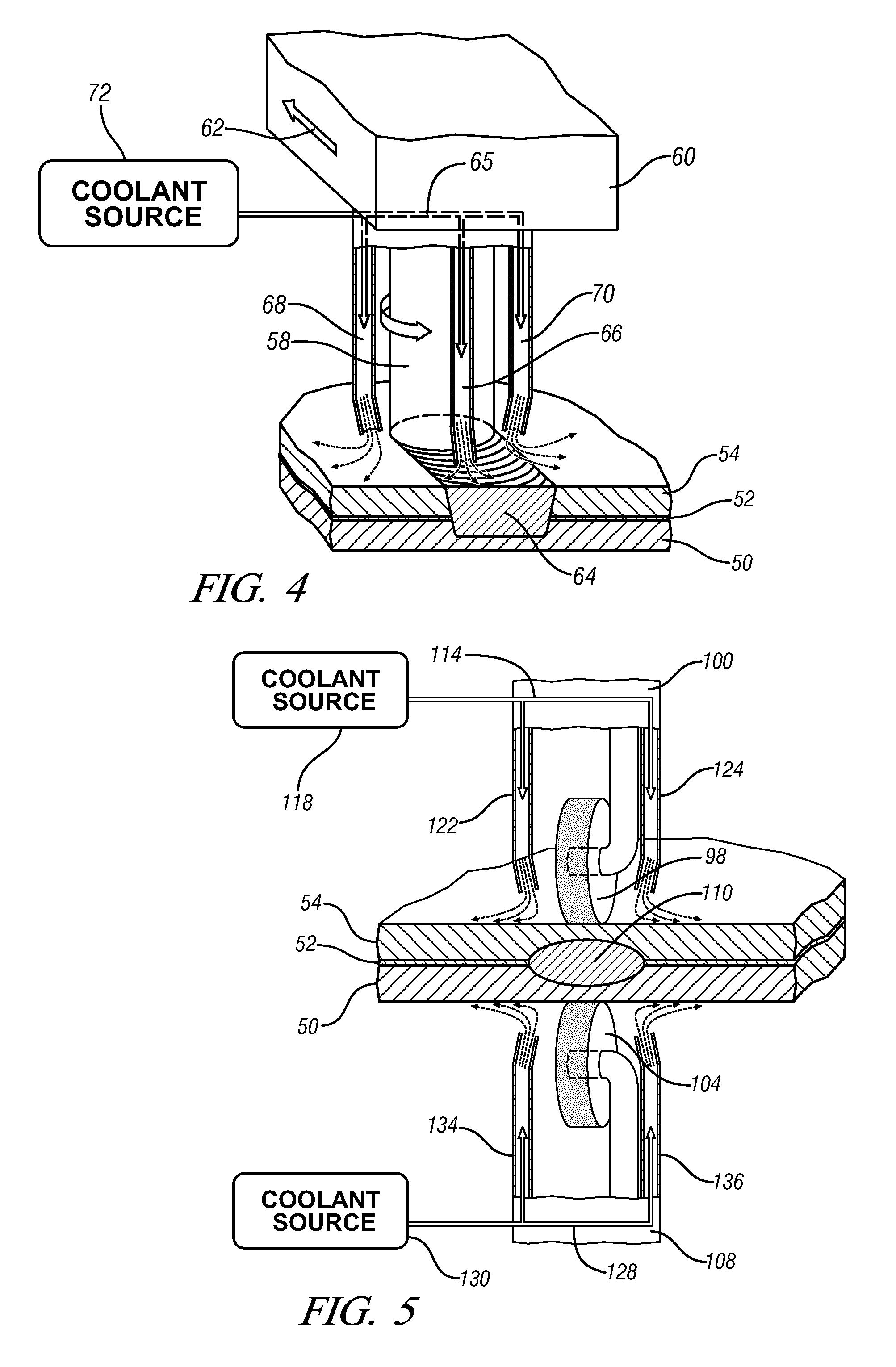

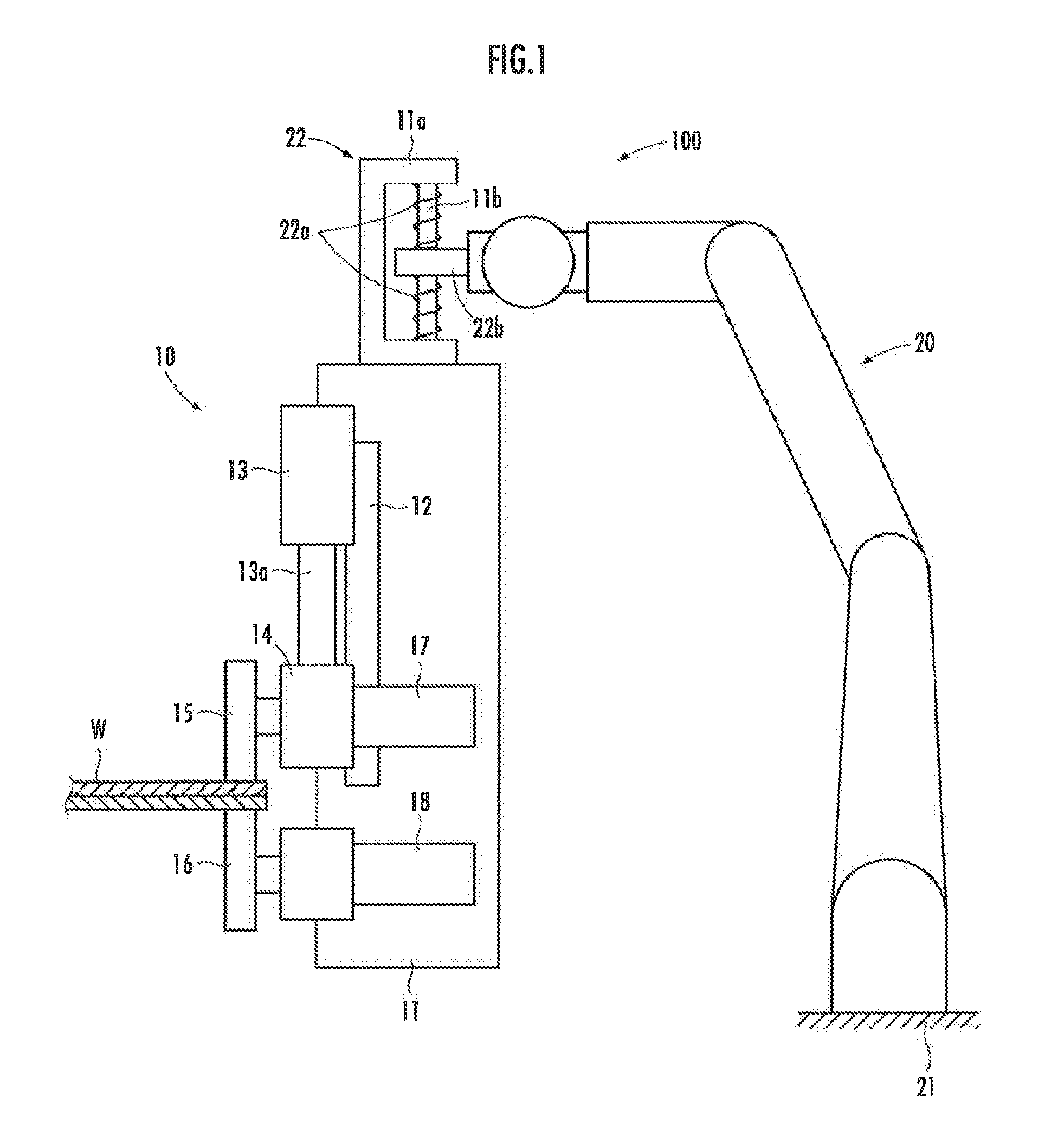

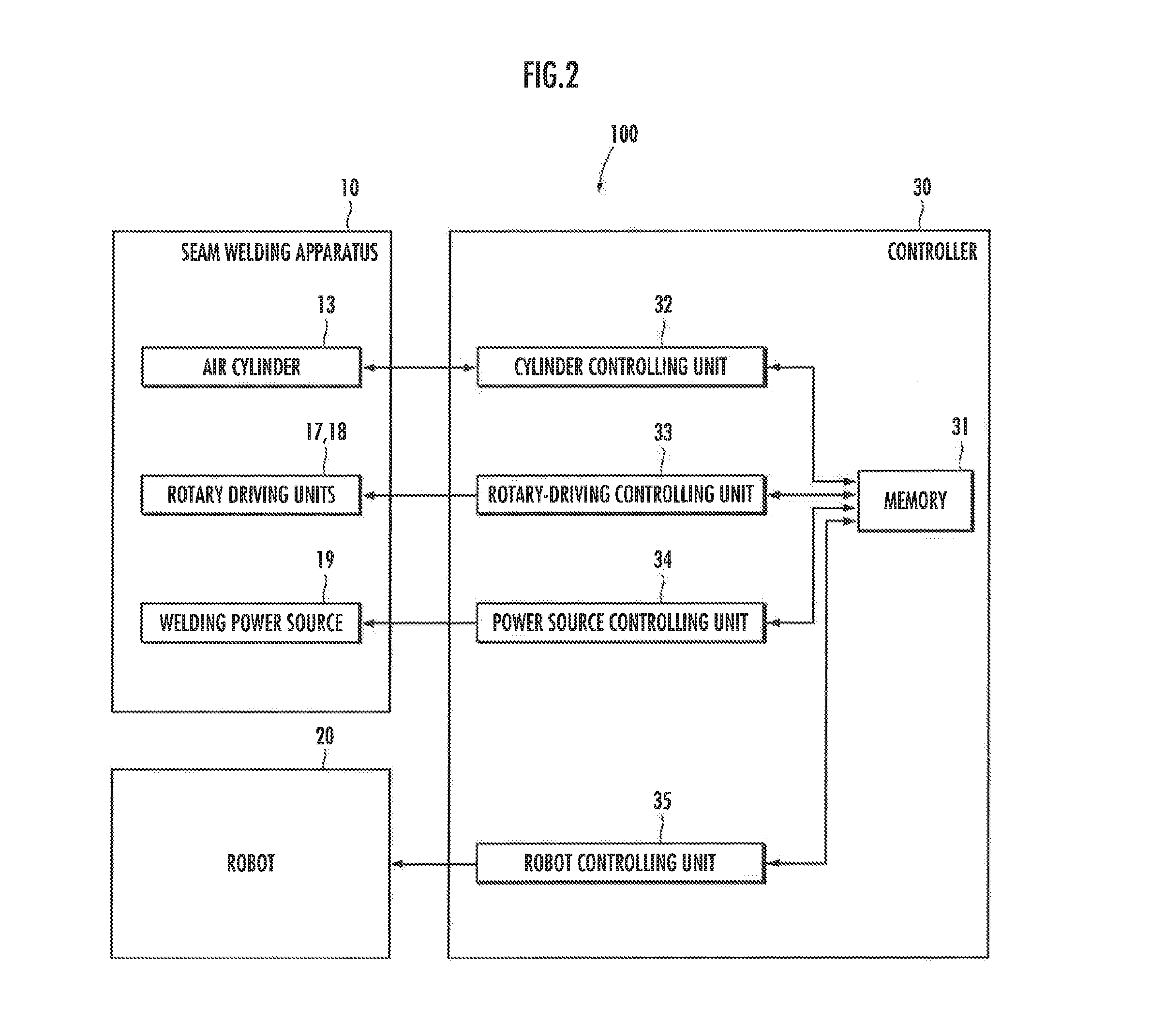

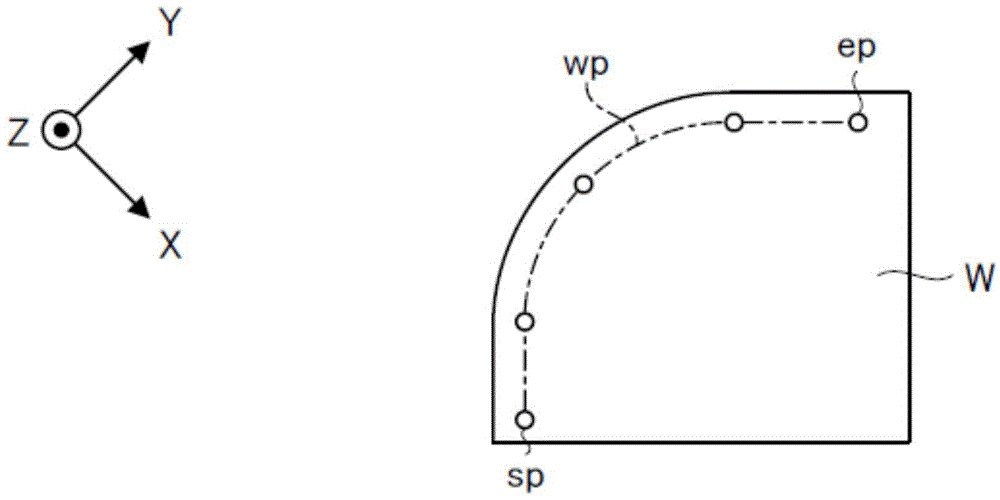

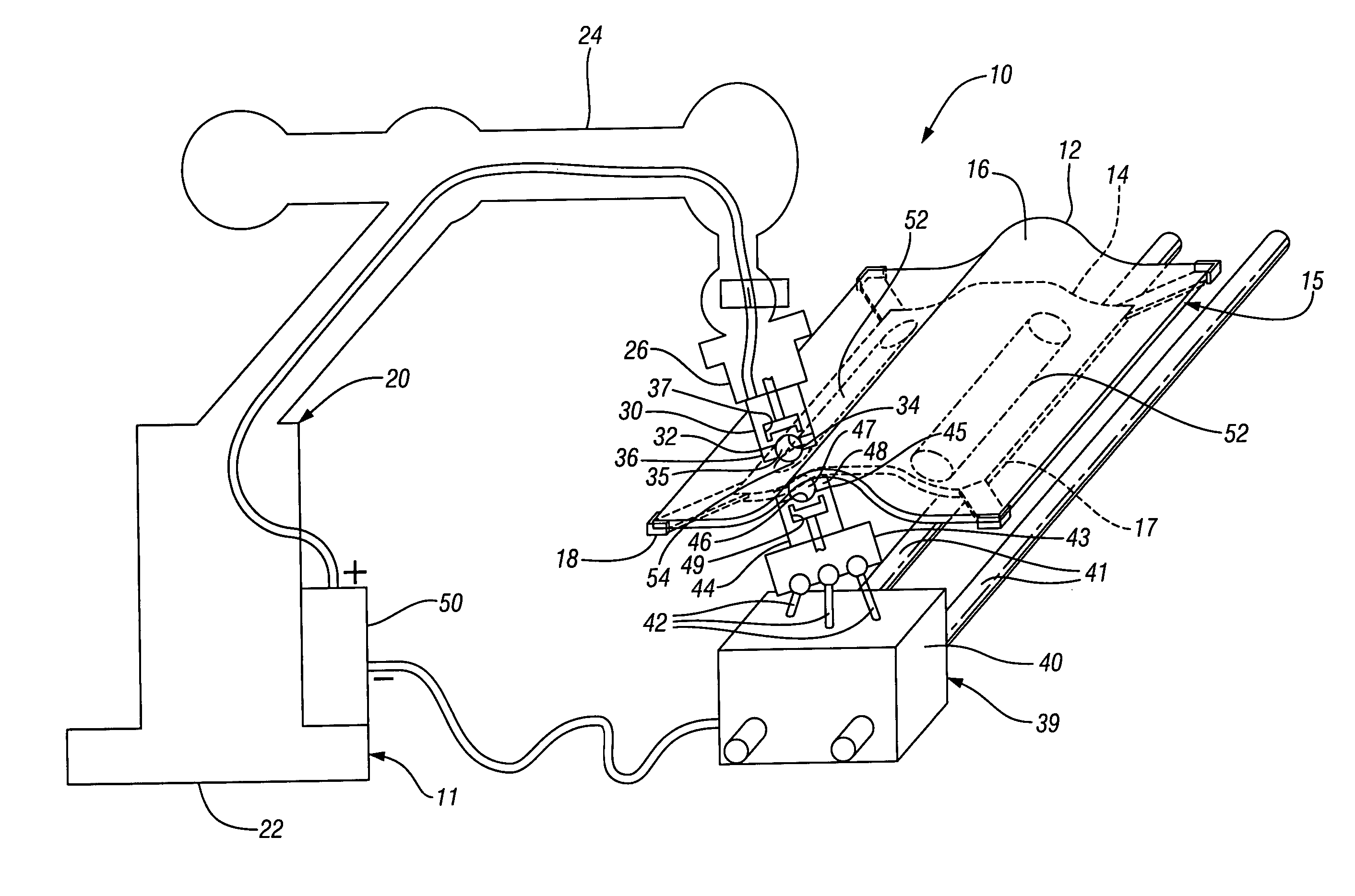

Seam welding method and system

ActiveUS20160045975A1Prevent discordanceNo improper weldingWelding with roller electrodesRoller electrodesEngineeringSeam welding

Shifts of a reference point C in a robot coordinate system among three postures of a seam welding apparatus 10 are found, and calibration data is obtained (STEP 1). Correction data is found from the calibration data based on deformation of elastic units 22a due to weight of the seam welding apparatus 10 in accordance with the posture of the seam welding apparatus 10 relative to a robot 20 (STEP 5). Teaching data is corrected based on the correction data (STEP 6).

Owner:HONDA MOTOR CO LTD

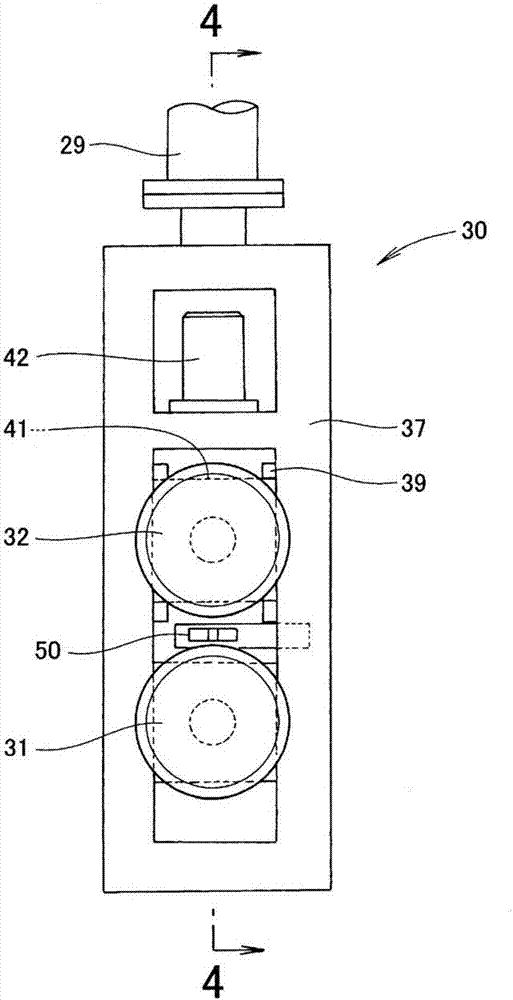

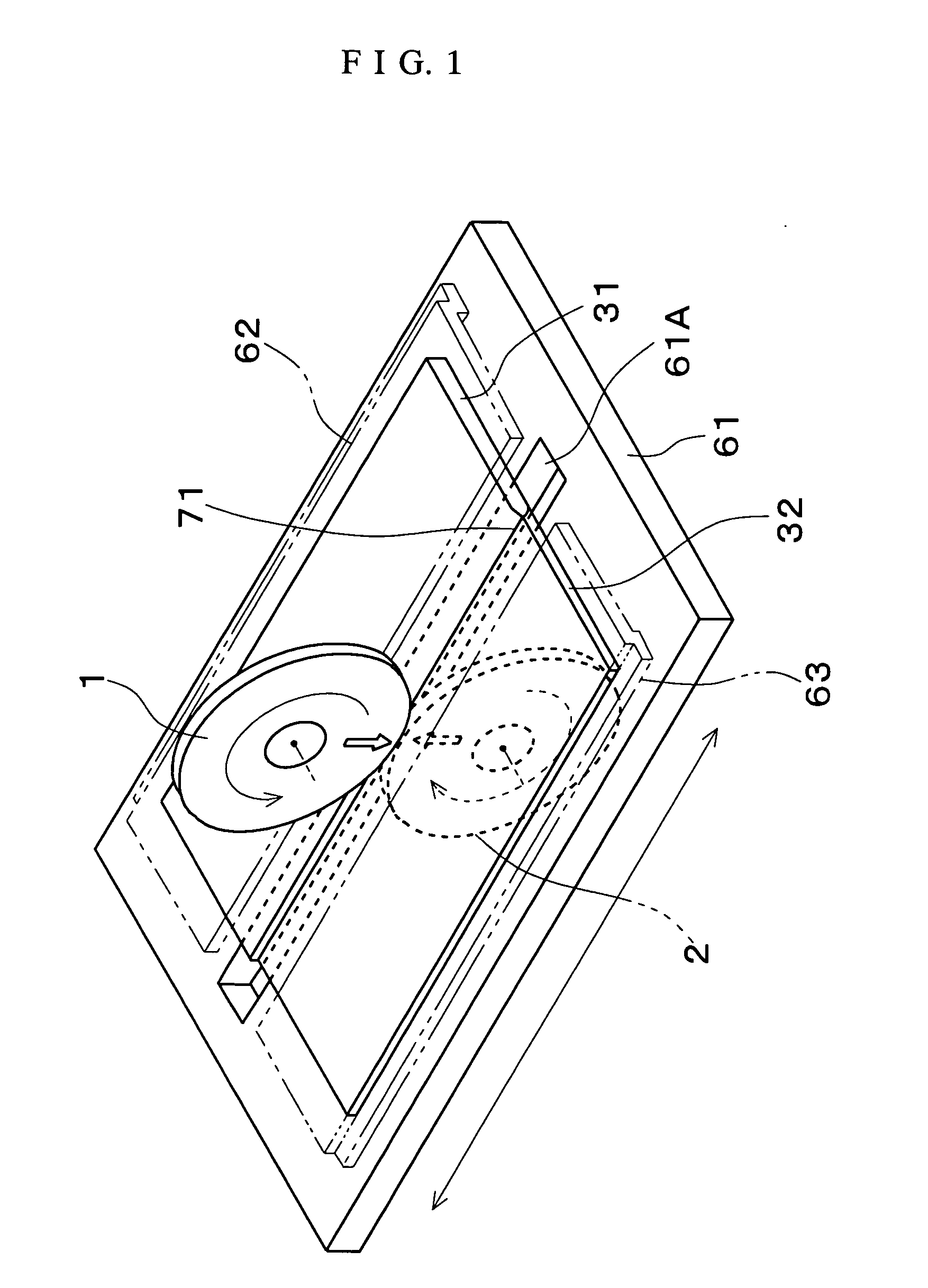

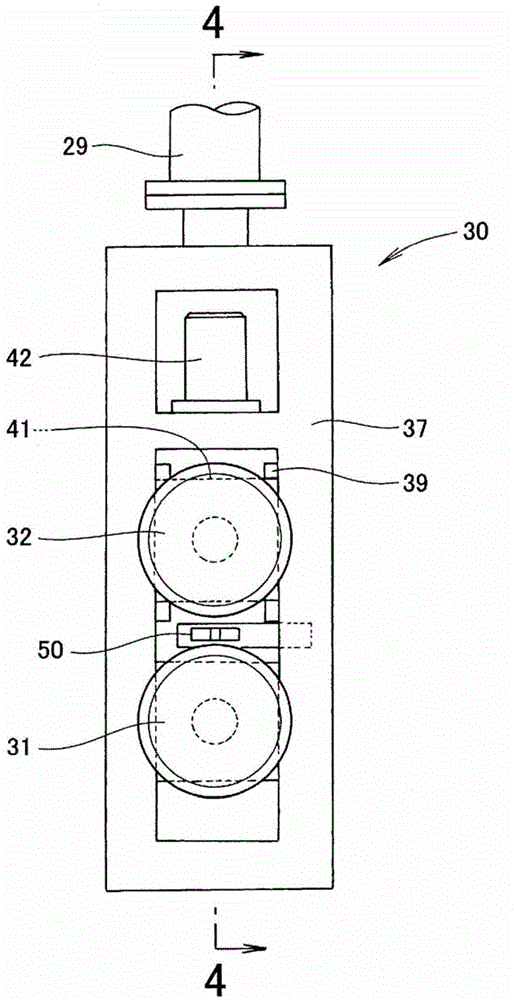

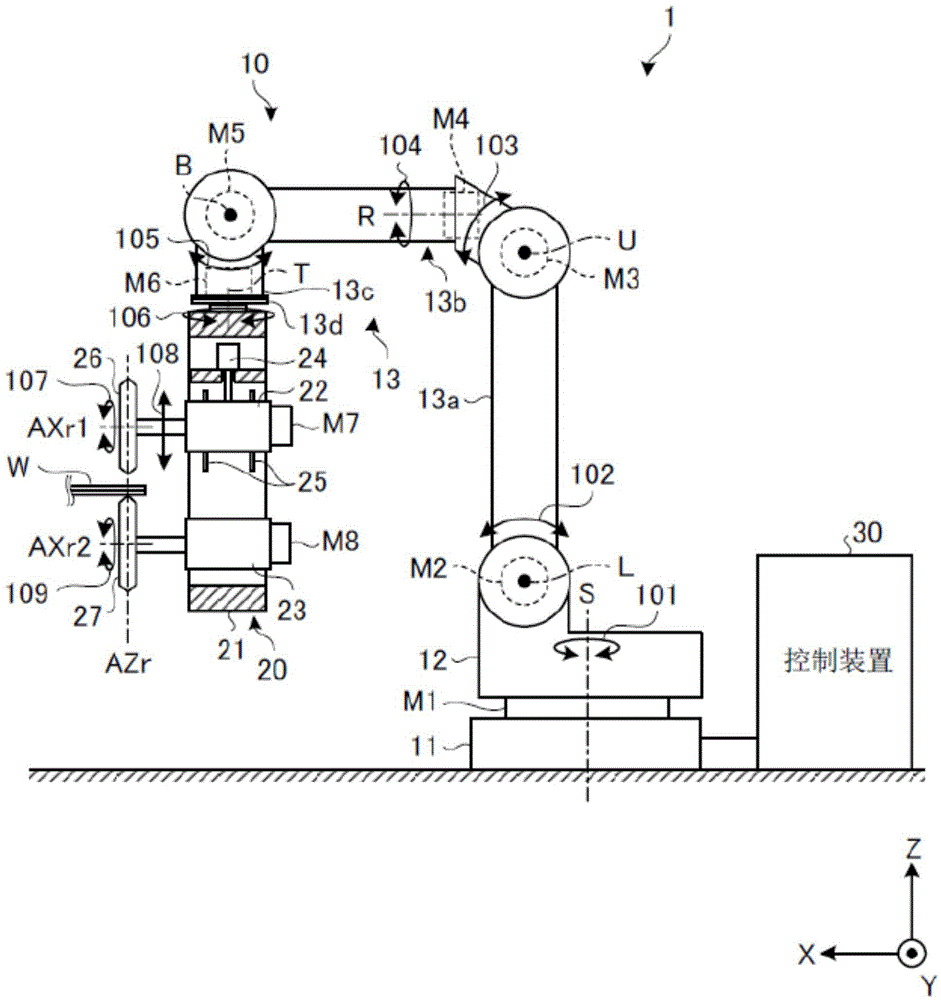

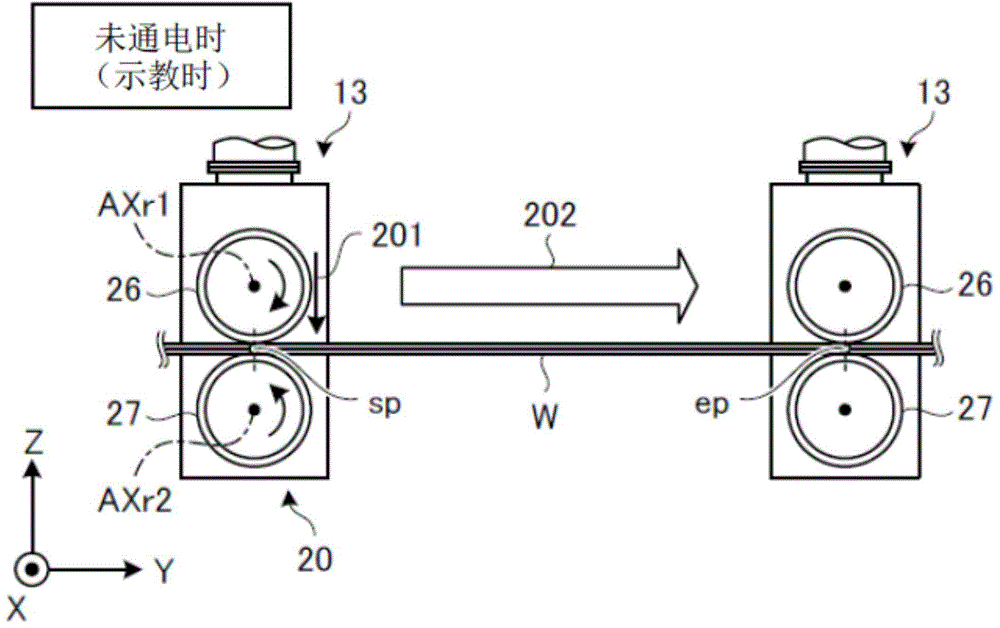

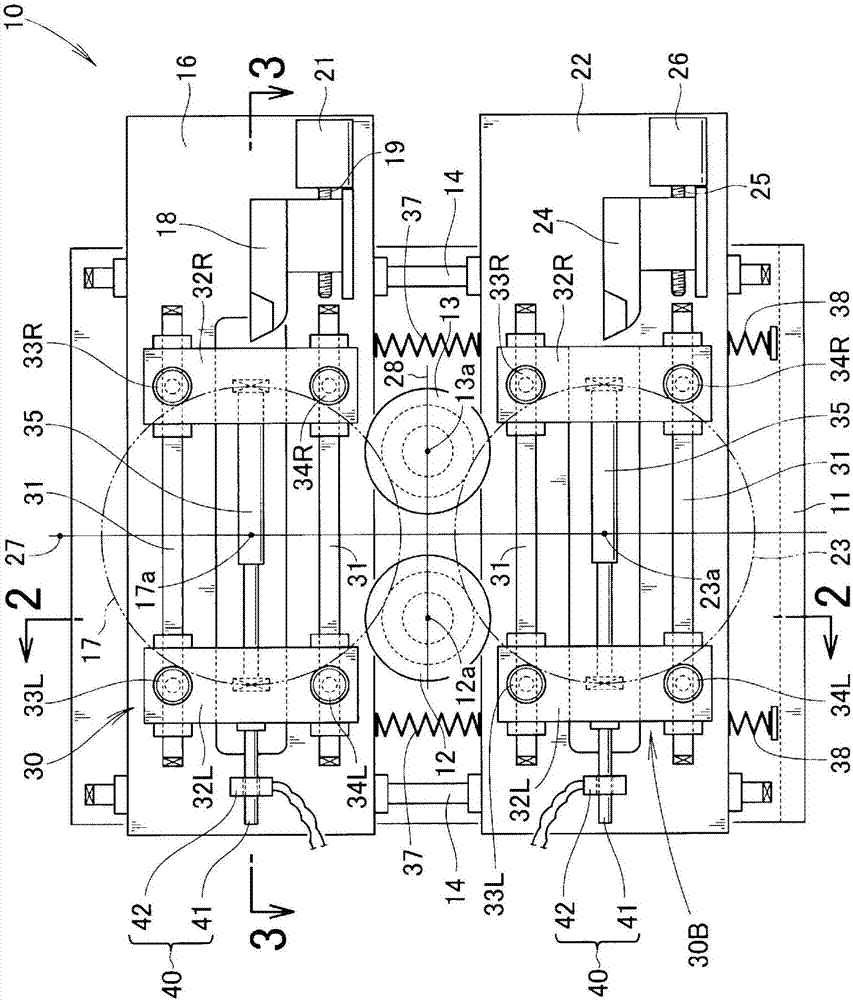

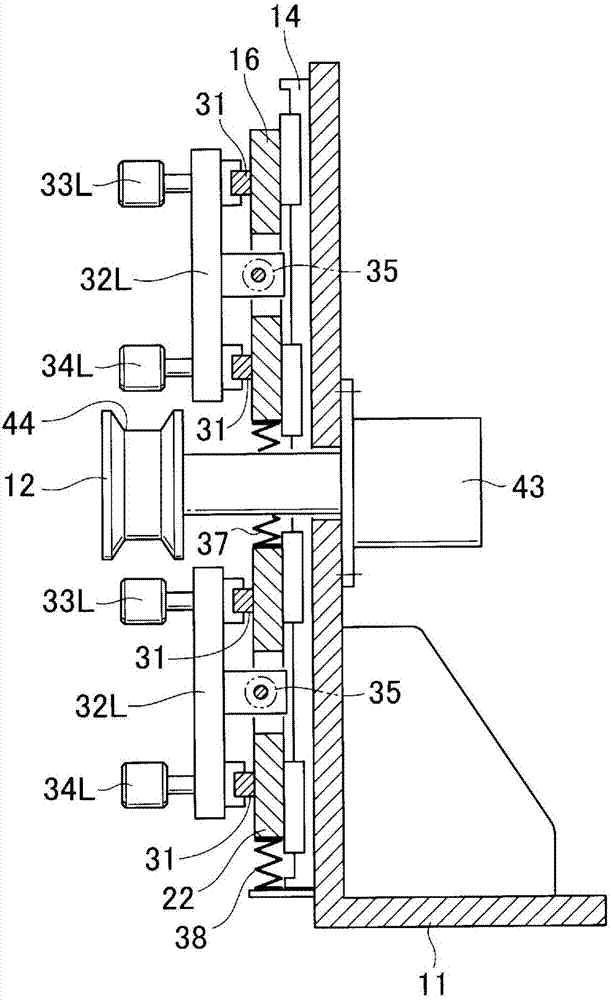

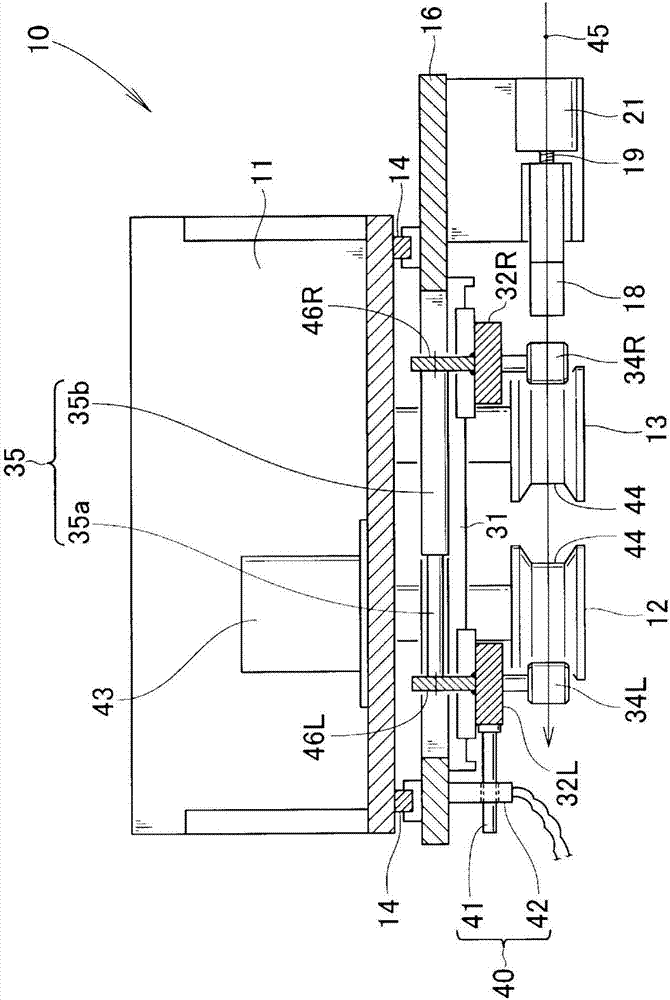

Seam welding apparatus, seam welding method, robot control device, and robot control method

ActiveCN104918741AMiniaturizationDistance measurements are not affectedProgramme controlProgramme-controlled manipulatorMiniaturizationReduced size

In order to solve the problem of providing a seam welding device that is not affected by the surface condition or the entire body shape of a piece of work, a seam welding apparatus (10) is provided with: a pair of rotary electrodes (31, 32), an electrode support frame (37), a distance measuring means (50), and a control unit (43). The electrode support frame (37) supports the pair of rotary electrodes (31, 32). The distance measuring means (50) is provided to the electrode support frame (37), and measures the distance to an edge (61a) of a steel plate (61). When a real distance measured by the distance measuring means (50) deviates from a prescribed distance, the control unit (43) controls a robot (20) to adjust the travelling direction of the rotary electrodes (31, 32) such that the deviation reaches zero. Thus, the provided seam welding apparatus (10) has a reduced size whilst not being affected by the surface condition or the shape of a piece of work (steel plate (61)).

Owner:YASKAWA DENKI KK +1

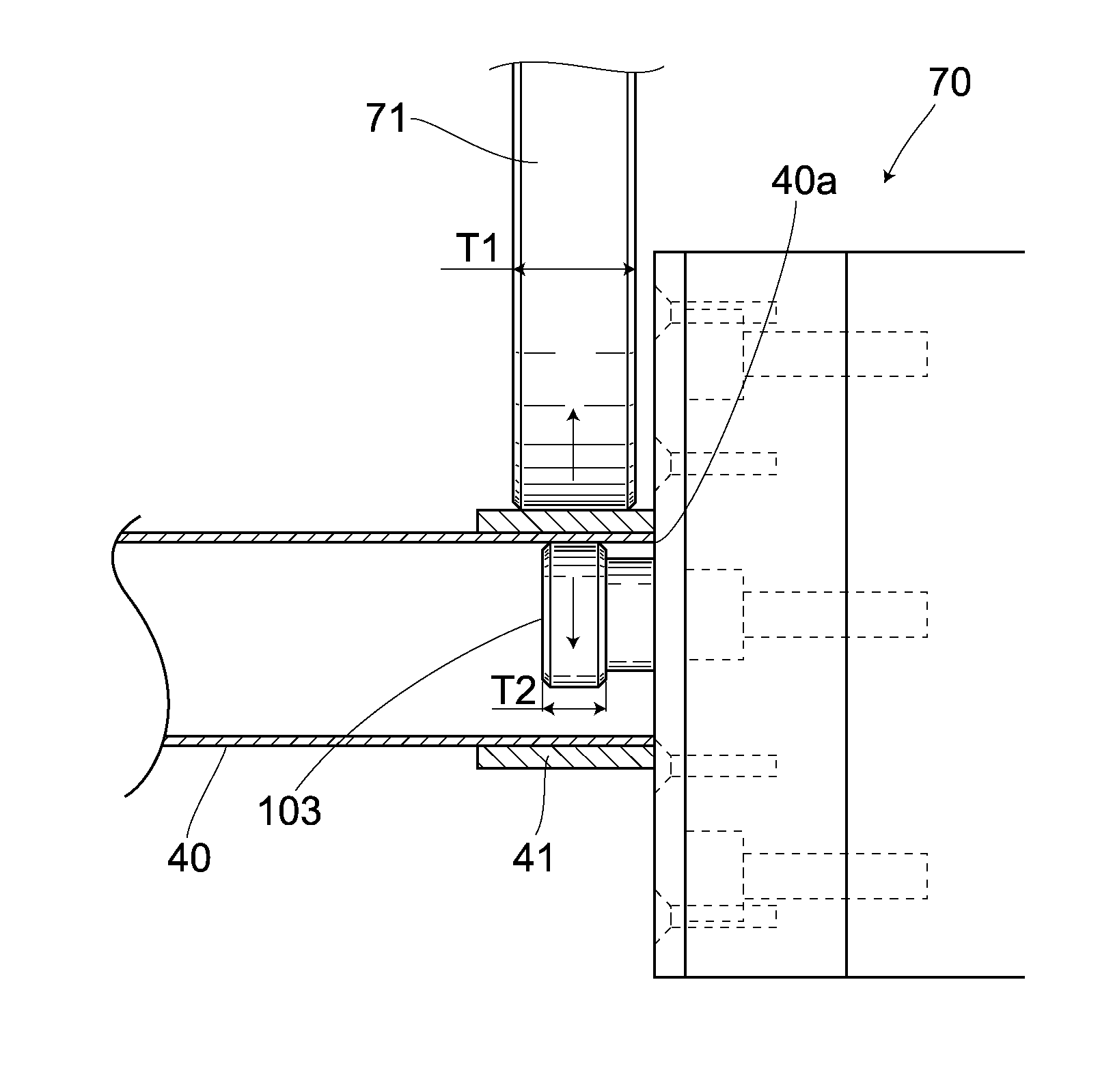

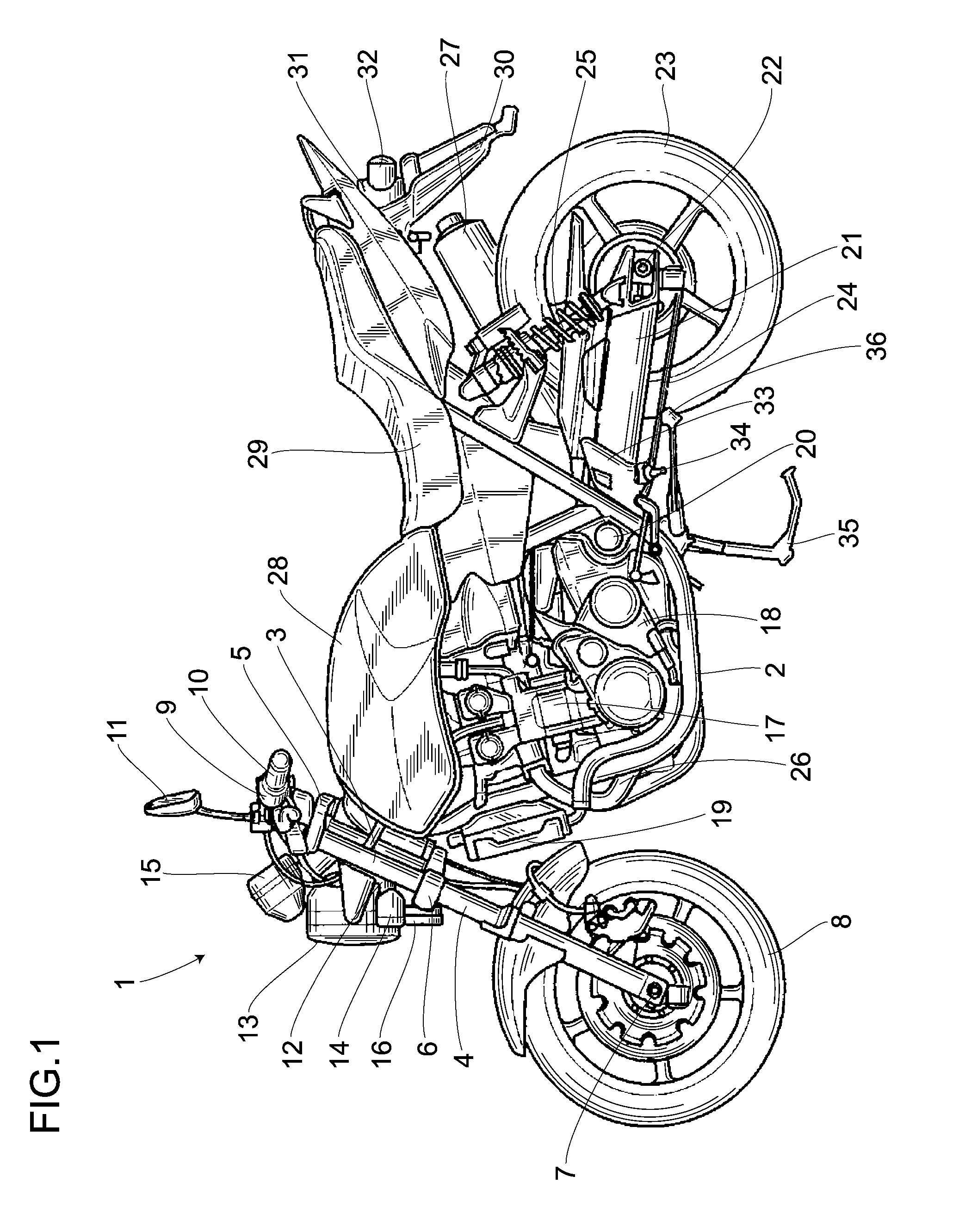

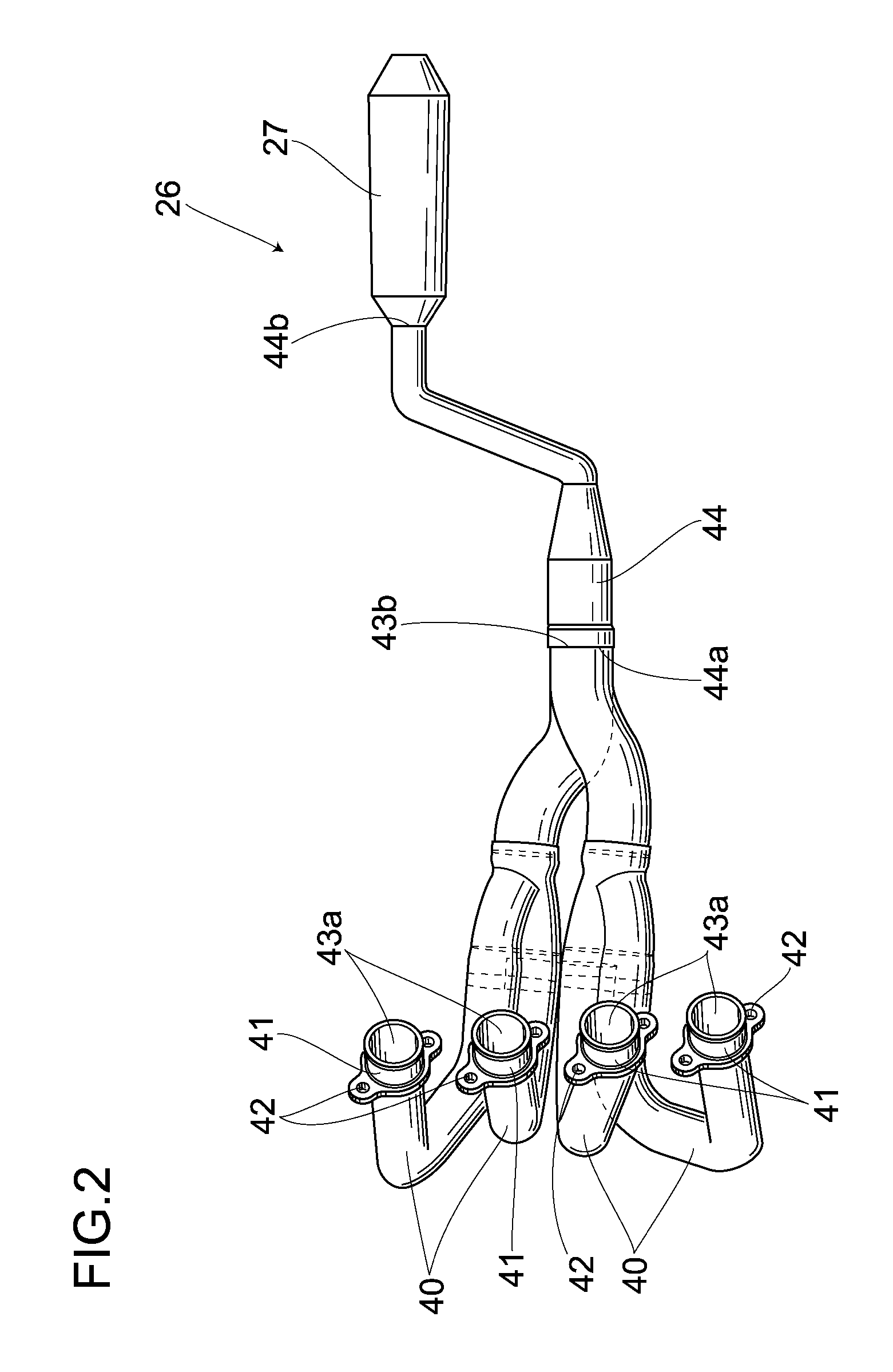

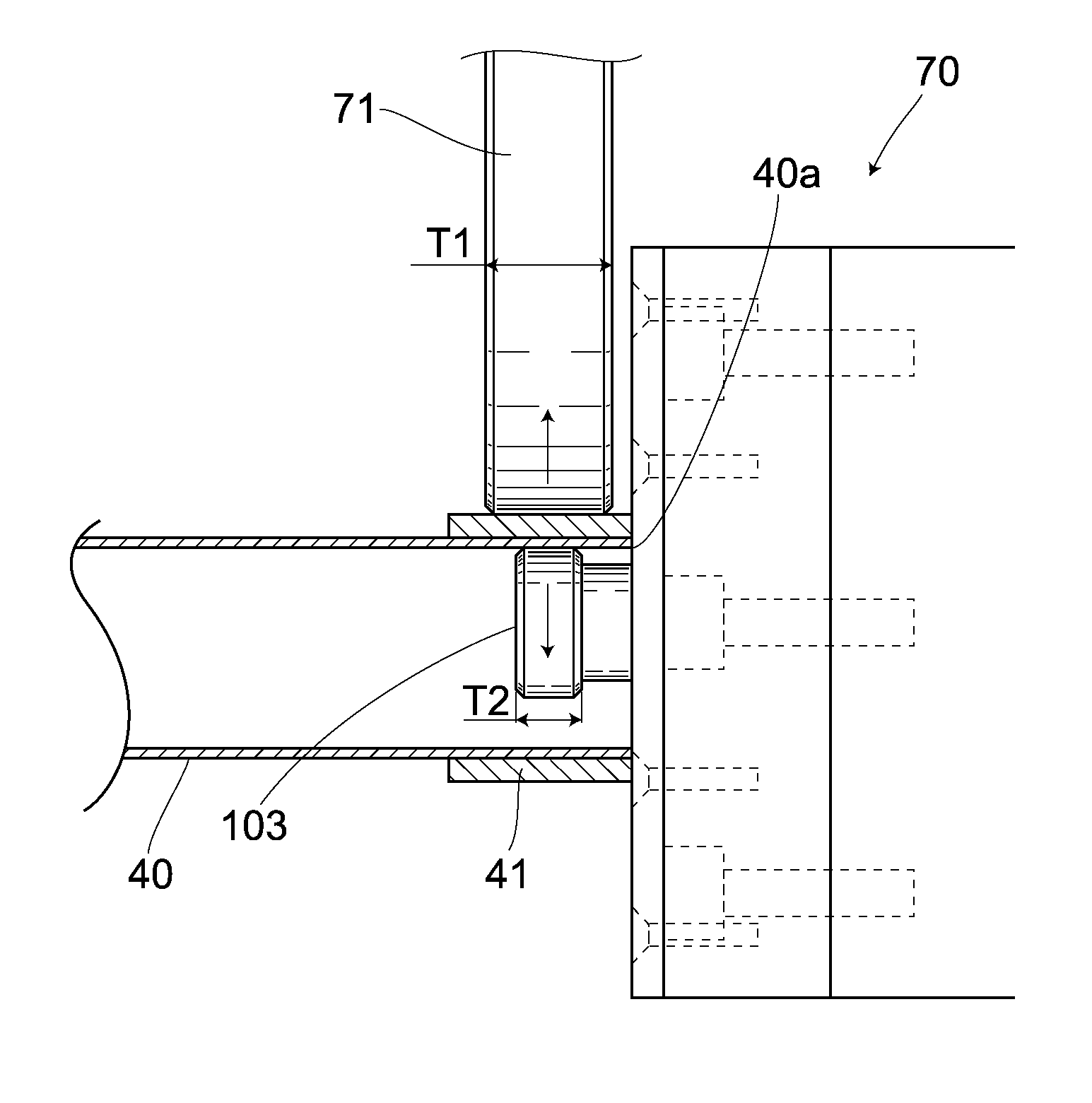

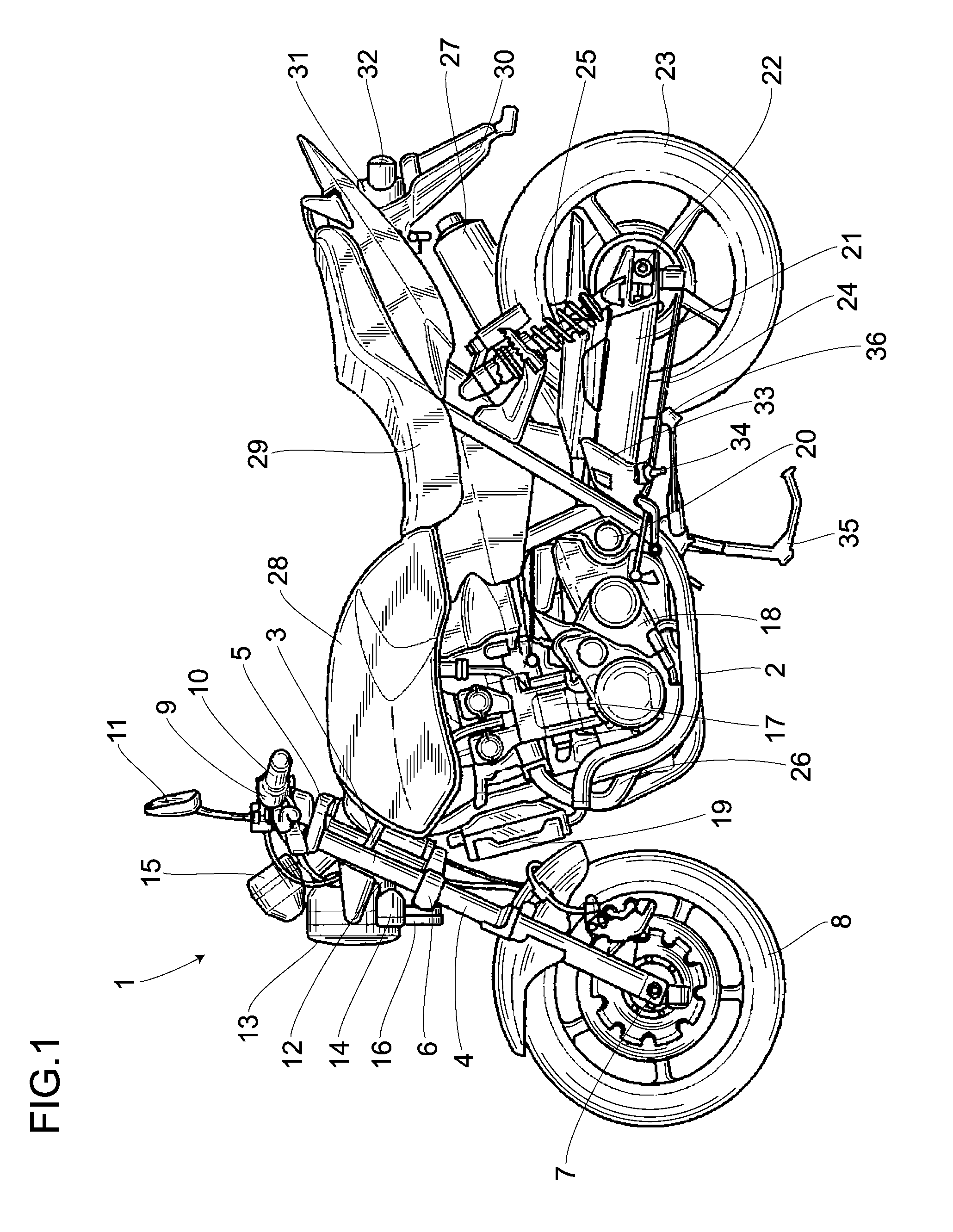

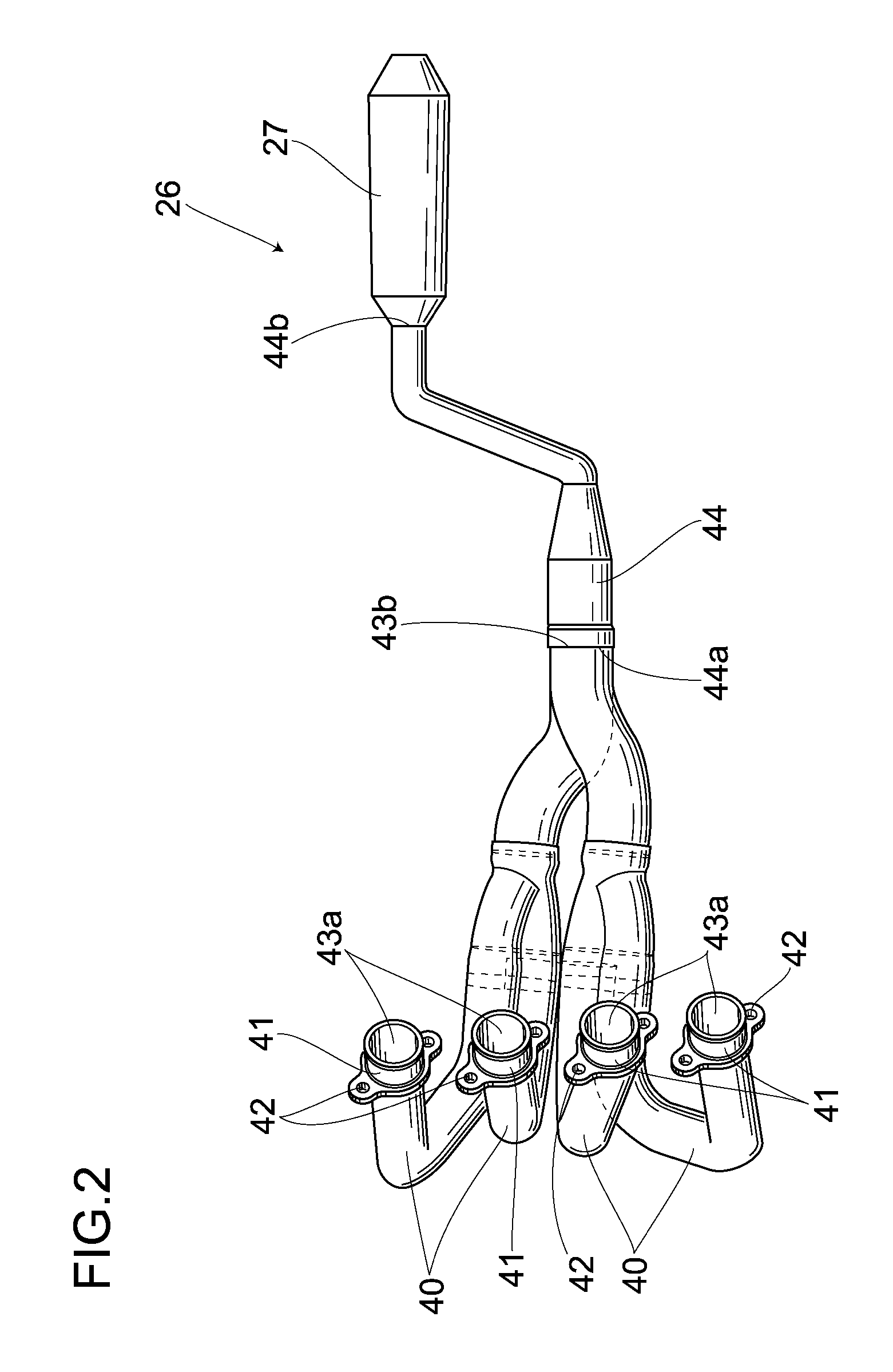

Method and apparatus for manufacturing an exhaust pipe assembly

ActiveUS20100326961A1Reduce temperature differenceReduce the temperatureCurved planar seam weldingSoldering apparatusTransformerTemperature difference

A method and apparatus for manufacturing an exhaust pipe assembly for an engine which are capable of decreasing a temperature difference between a seam-welded outer surface and a seam-welded inner surface at the time of seam welding. An exhaust pipe assembly manufacturing apparatus 70 comprises an outer circumferential electrode wheel 71 abutted on an outer circumference of a mounting ring 41, a pressing means 102 pressing the outer circumferential electrode wheel 71 to the mounting ring 41, an inner circumferential electrode wheel 103 abutted on an inner circumference of a pipe 40 making up an exhaust pipe assembly 26, a transformer 104 serving as a voltage supply means for supplying a predetermined voltage to the outer and inner circumferential electrode wheels 71 and 103, and a controller 105 for control of voltage of the transformer 104. Thickness T1 of the outer circumferential electrode wheel 71 is formed larger than thickness T2 of the inner circumferential electrode wheel 103.

Owner:HONDA MOTOR CO LTD

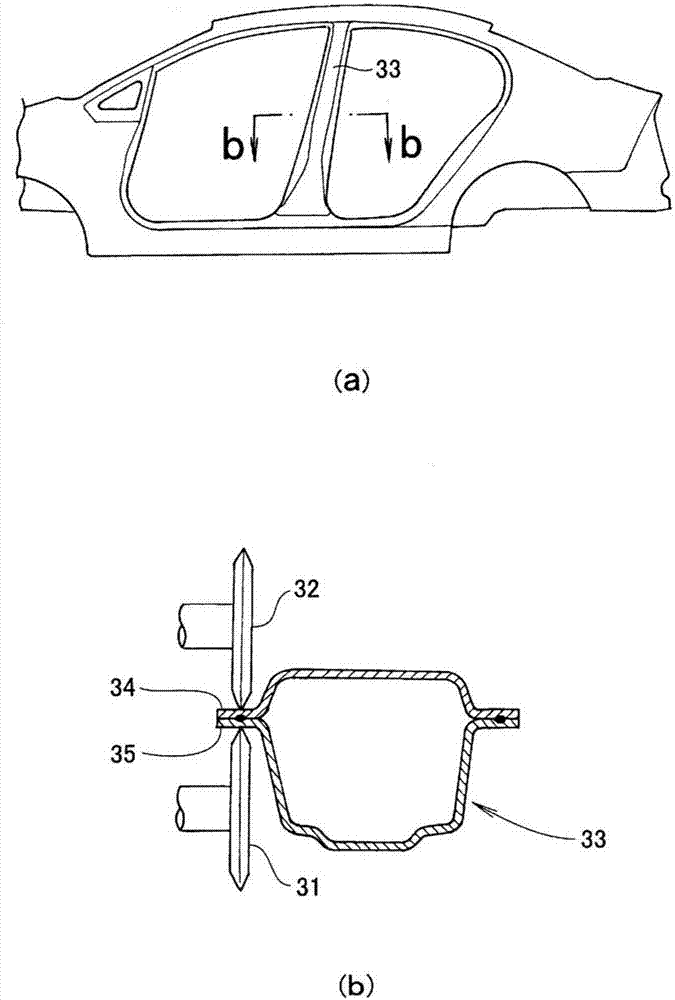

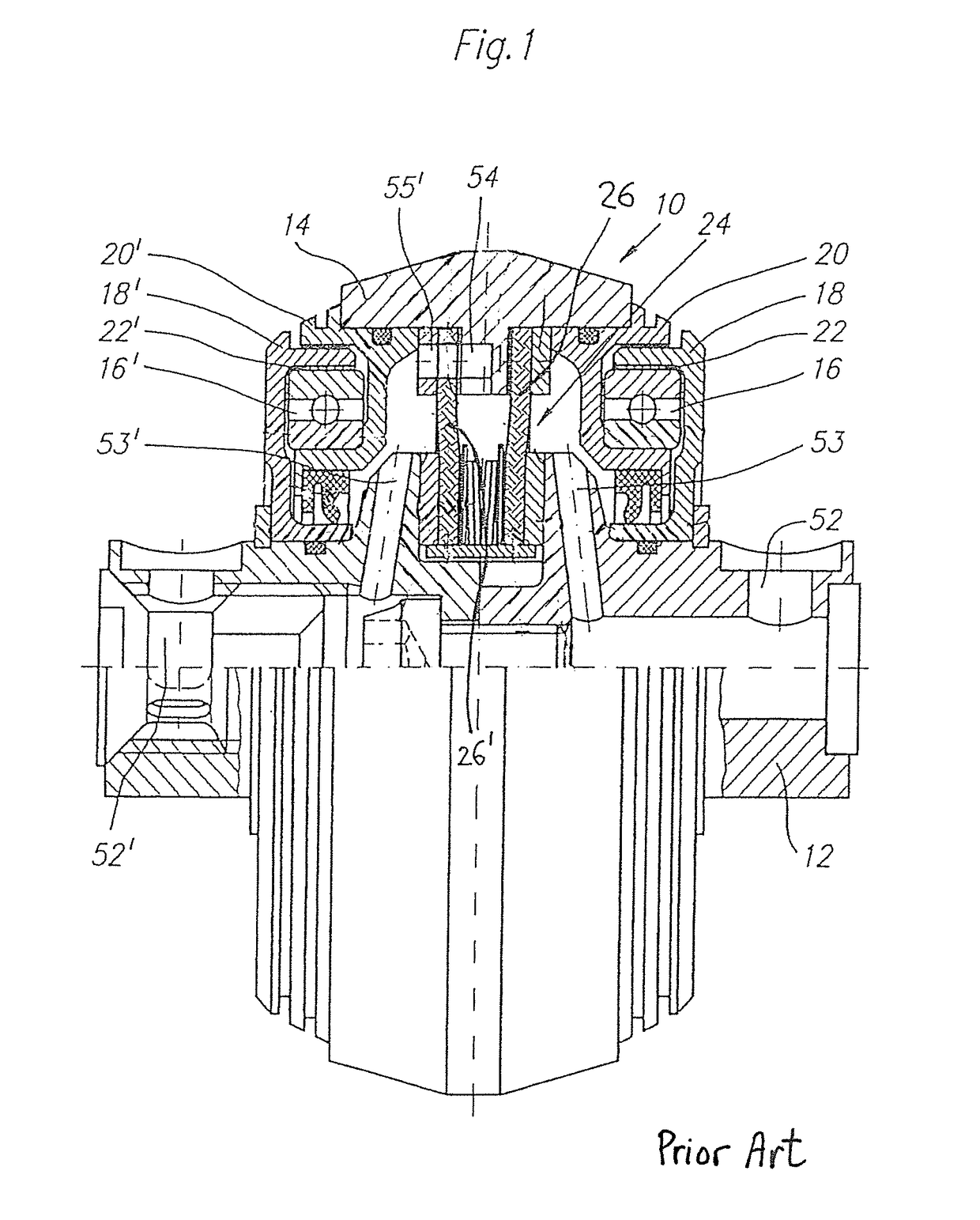

Butt welding apparatus, butt welding method, and butt welded product

InactiveUS20060124604A1Reliably securedReduce vehicle weightRectilinear seam weldingVehicle componentsButt weldingThin sheet

Disclosed are a butt welding apparatus, a butt welding method, and a product manufactured by the butt welding method. Two electrode rollers (3, 4) are disposed on both the front and back sides of a thick sheet member (1) and on both the front and back sides of a thin sheet member (2) whose end surfaces (1A, 2A) are butted. The electrode rollers (3, 4) are applied with power, melt the butt portion (6) of the sheet members (1, 2) with electric resistance heat, and joint the butt portion. Further, the electrode rollers (3, 4) have a length bridging across the sheet members (1, 2) and are composed of first portions (3A, 4A) arranged as small diameter portions on the side of the thick sheet member (1) and second portions (3B, 4B) arranged as large diameter portions on the side of the thin sheet member (2). The first portions (3A, 4A) come into contact with the thick sheet member (1) and presses it before the second portions (3B, 4B) come into contact with the thin sheet member (2). Thus, the end surface (1A) of the thick sheet member (1) swells and deforms toward the thin sheet member (2) and reliably comes into contact with the end surface (2A) of the thin sheet member (2). As a result, power is applied between the end surfaces (1A, 2A) even if the end surfaces (1A, 2A) are not finished by polishing and the like.

Owner:KIKUCHI KK (KIKUCHI CO LTD)

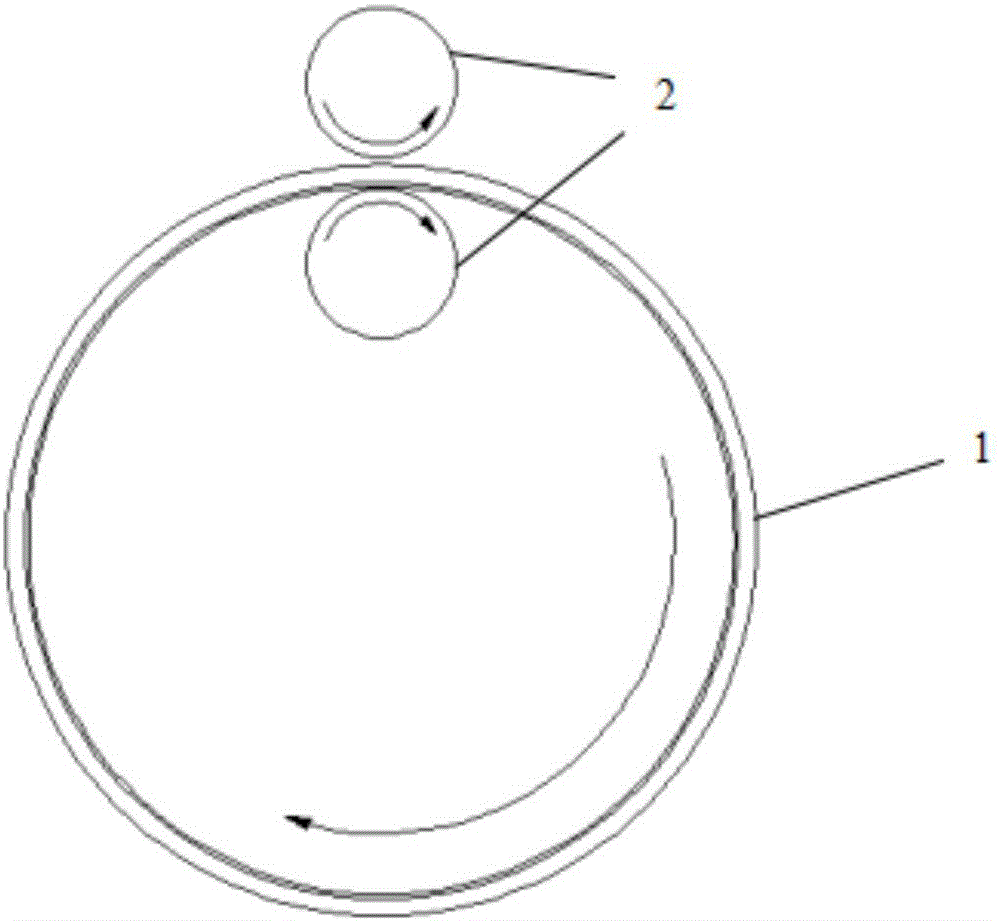

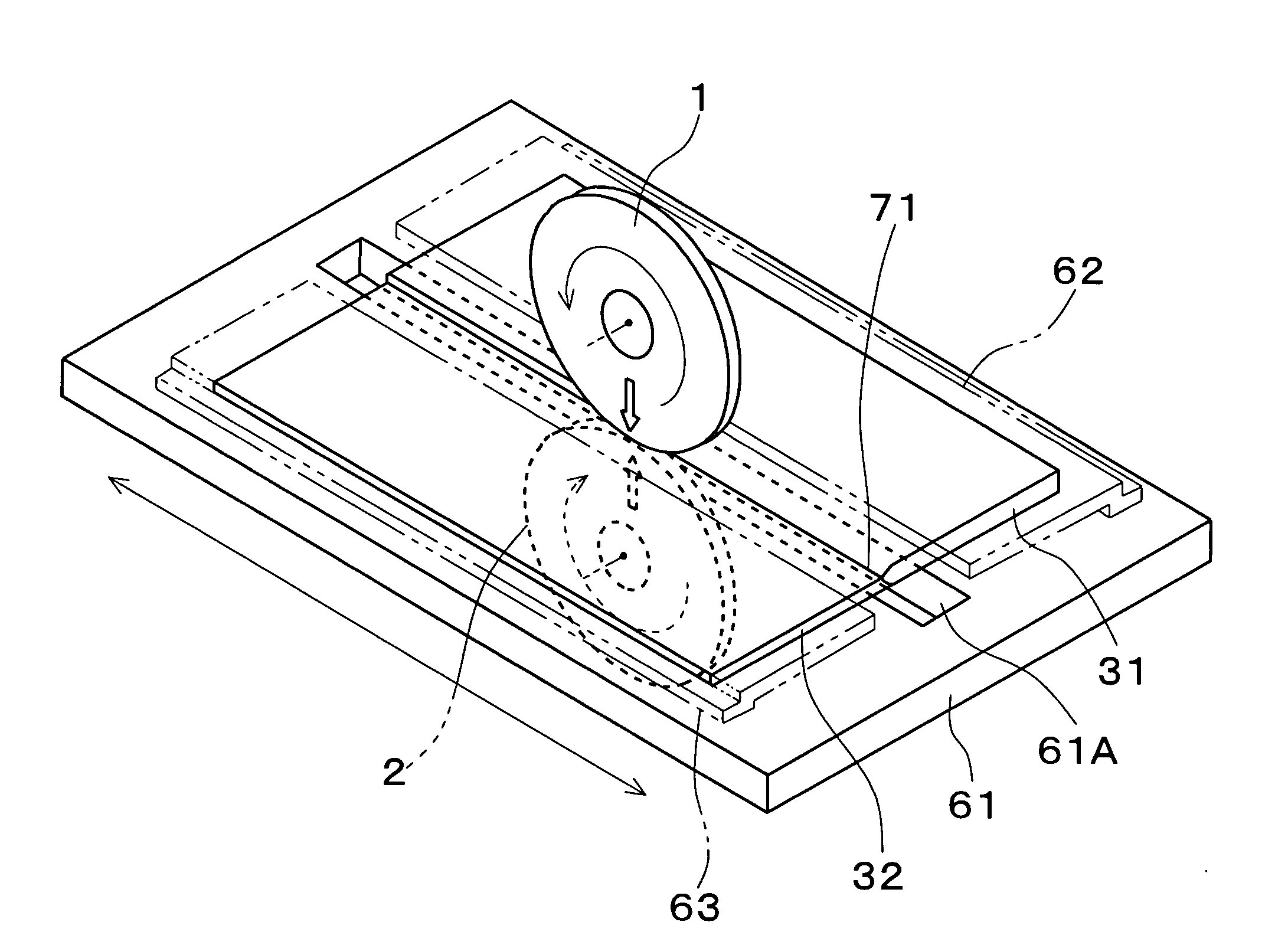

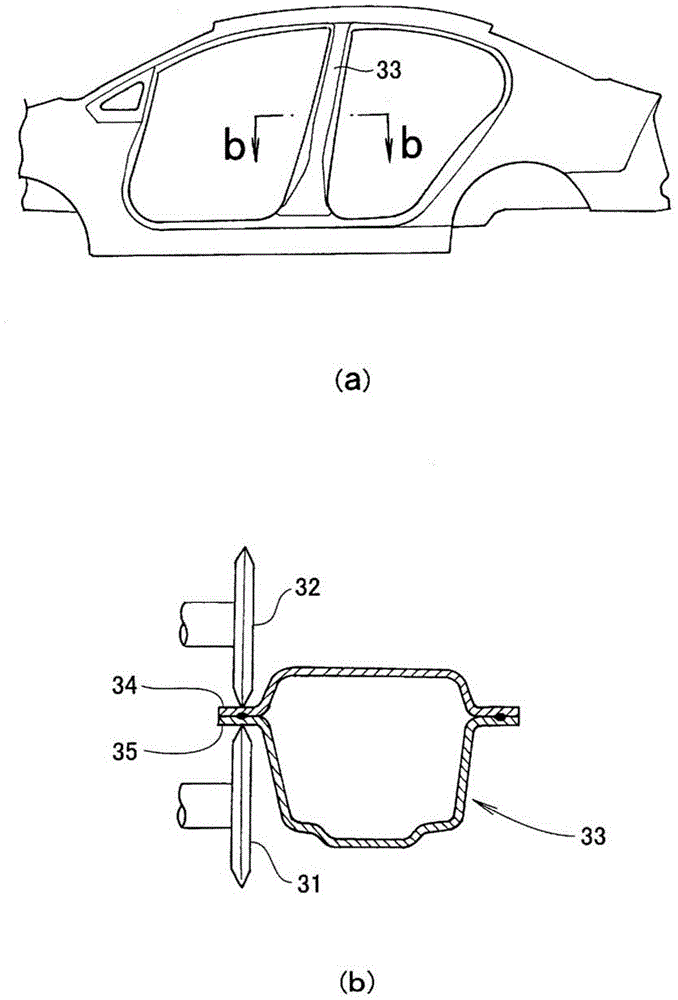

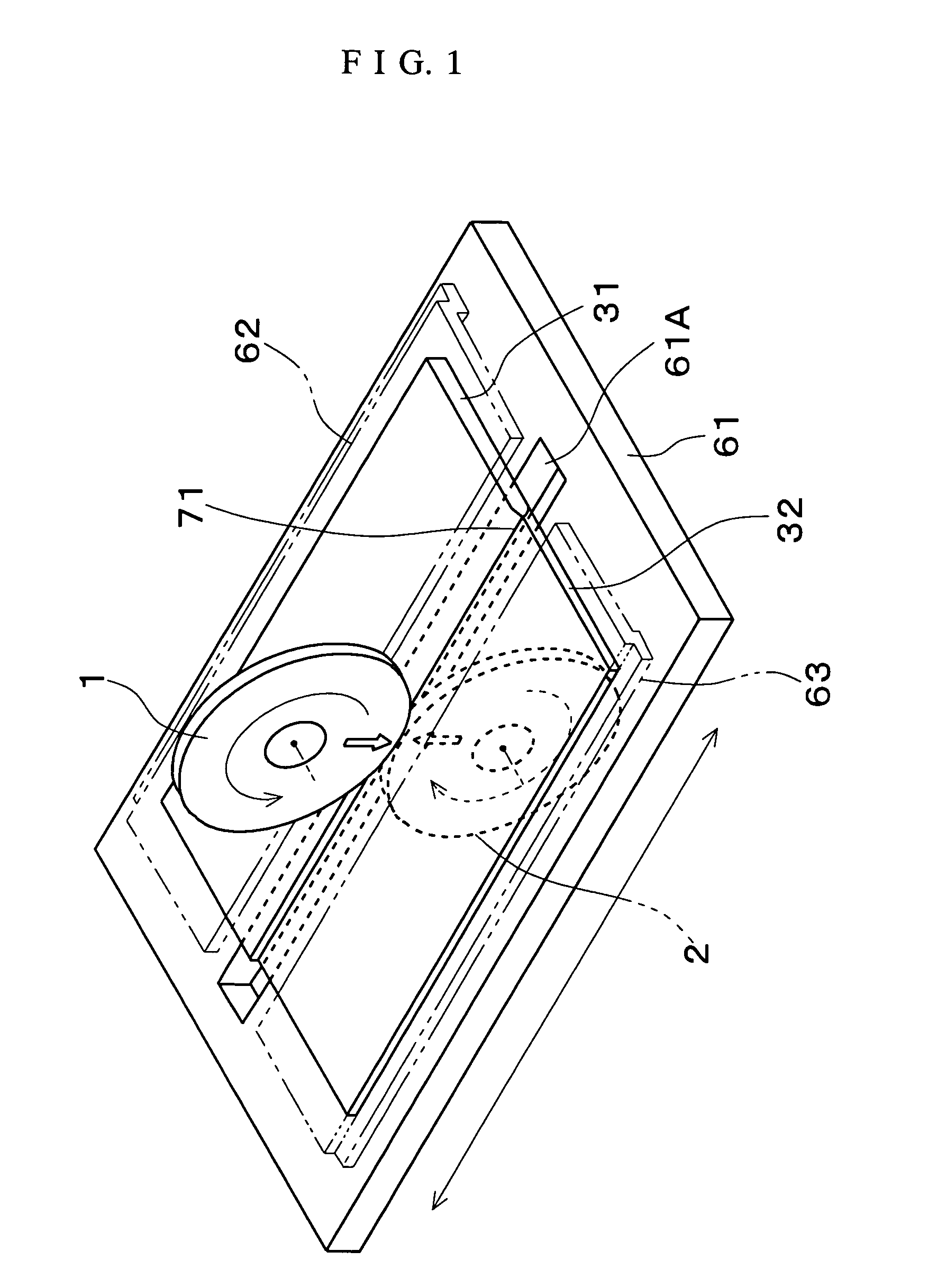

Seam welding system, seam welding method, and method for producing a to-be-welded object

ActiveCN105033431AImprove qualityEasy seam weldingResistance electrode holdersCurved planar seam weldingEngineeringSeam welding

A seam welding system includes a pair of roller electrodes. The pair of roller electrodes hold a to-be-welded object between circumferential surfaces of the roller electrodes, rotate while holding the to-be-welded object between the circumferential surfaces, and perform seam welding on the to-be-welded object when a current flows between the roller electrodes while rotating and holding the to-be-welded object between the circumferential surfaces. To an electrode movement mechanism, the roller electrodes are mounted. The electrode movement mechanism moves the roller electrodes along a welding line of the to-be-welded object. Drive sources respectively rotate the roller electrodes and a joint of the electrode movement mechanism. A controller controls an amount by which the roller electrodes rotate based on a torque change in the drive sources so as to keep torques respectively acting on the roller electrodes within a predetermined range.

Owner:YASKAWA DENKI KK +1

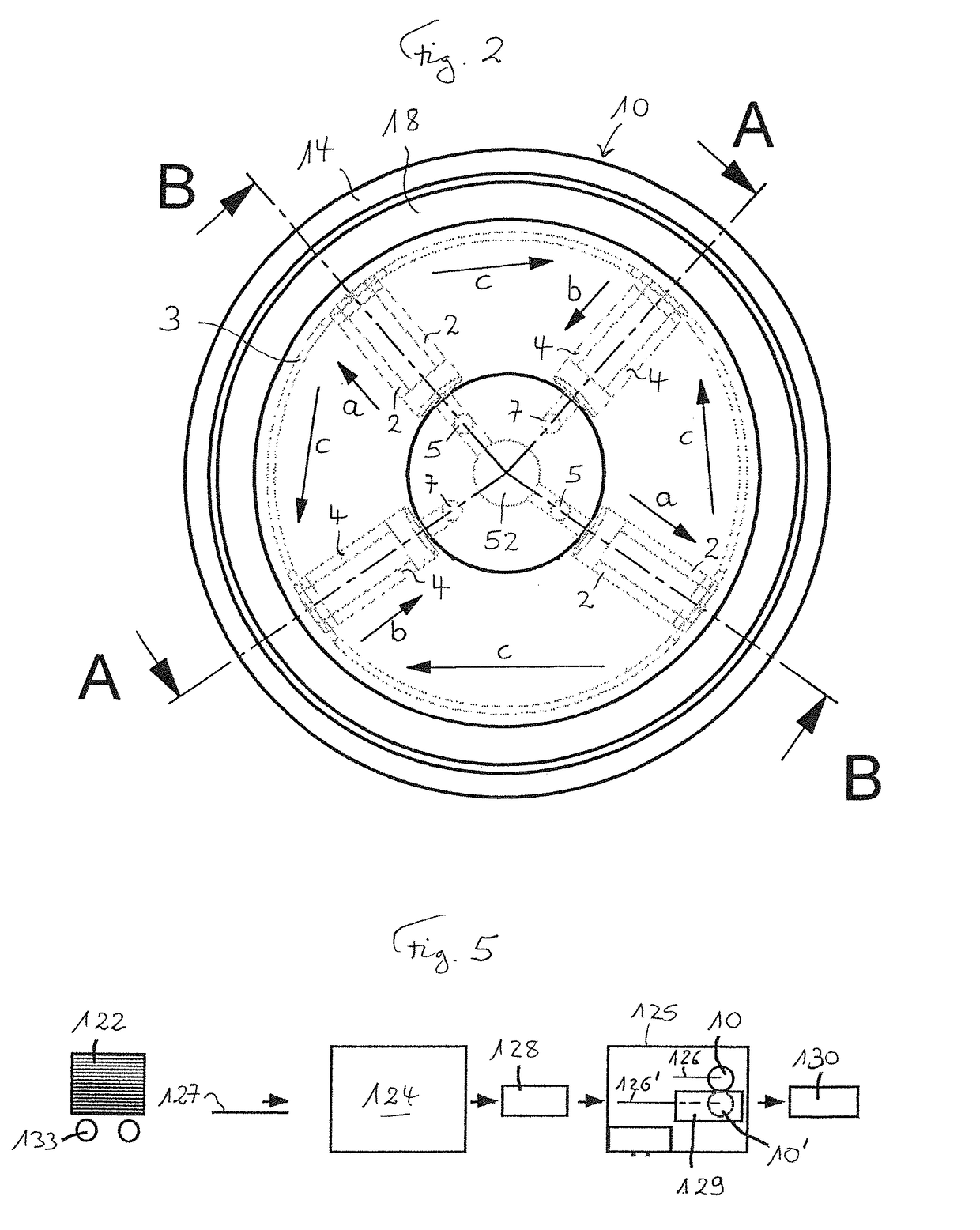

Apparatus for Welding Continuous Strips Wound on a Support Ring

Apparatus for welding continuous strips wound on a support ring is disclosed, comprising at least means for feeding the strips to be wound on the support ring, an assembly for winding said strips, an assembly for applying radial pressure onto the strips, comprising a first circular jaw and a second circular jaw, which are arranged opposite each other and spaced in the longitudinal direction by an amount corresponding to the width of the finished seal, and an assembly for welding one of said strips, said pressing assembly and said welding assembly being coaxial, wherein said welding assembly comprises a first electrode and a second electrode which are arranged inside the jaws of the pressing assembly so as to face each other and have a diameter smaller than that of the said jaws, each electrode being insulated both from the other electrode and from the jaws by means of rings made of insulating material, and wherein the electrodes act simultaneously with pressure in the radial direction on the strips.

Owner:GSKET

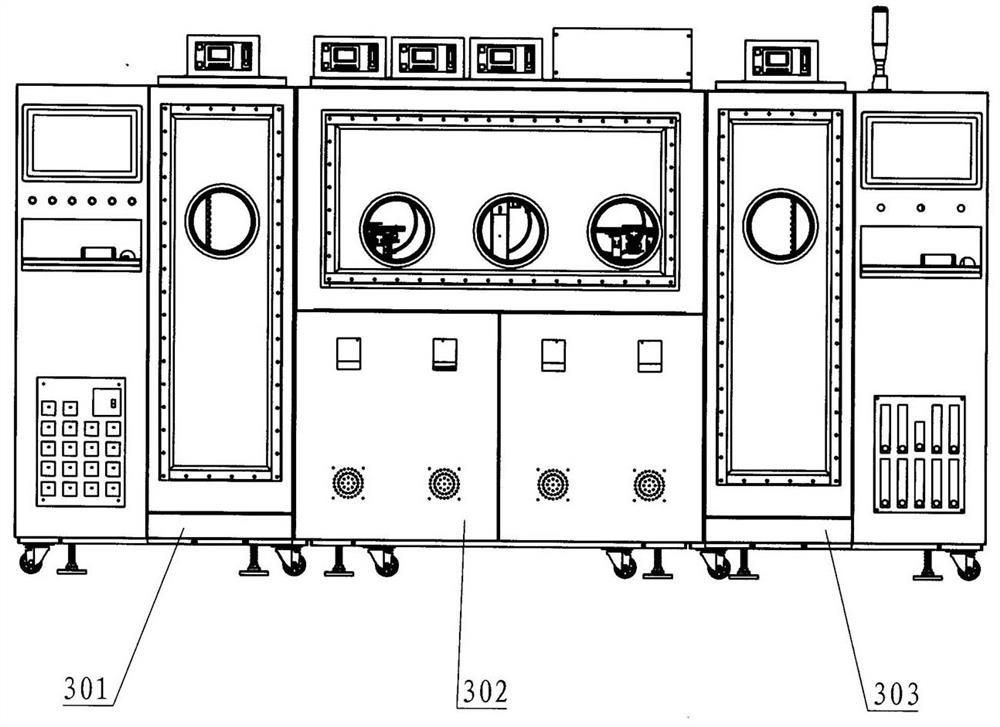

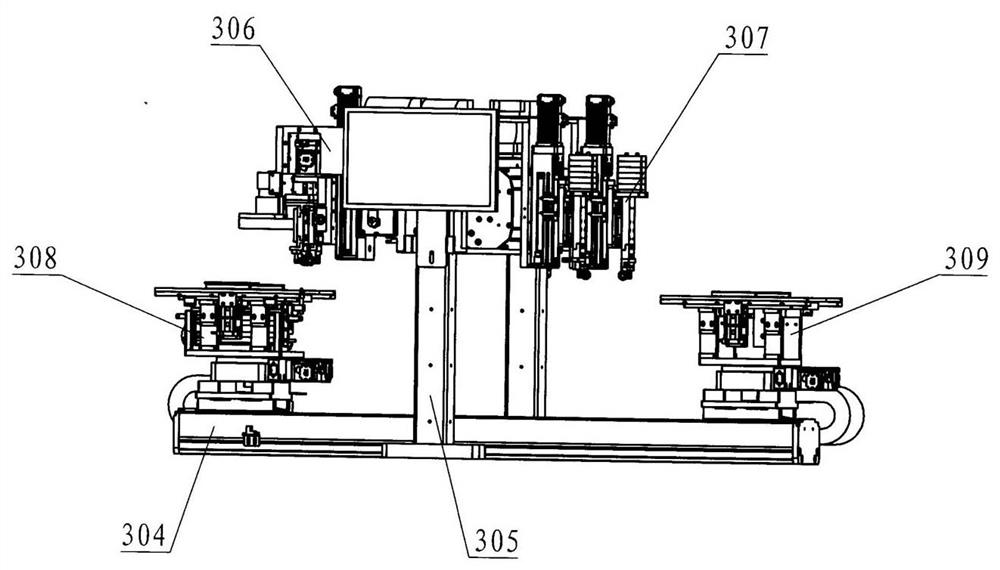

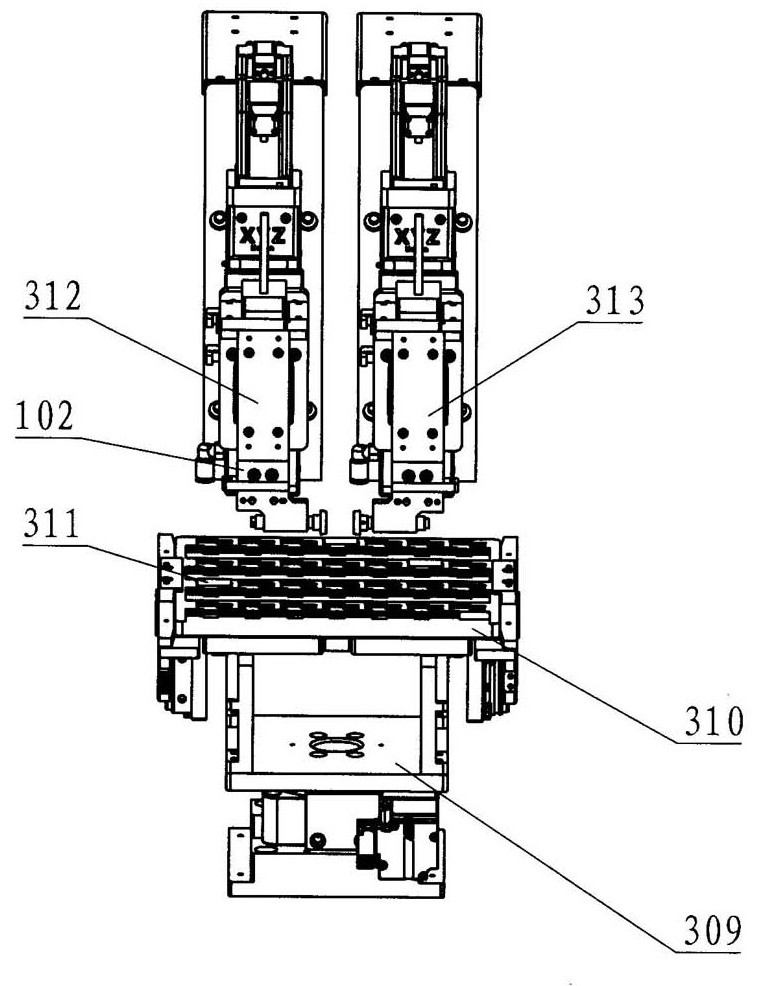

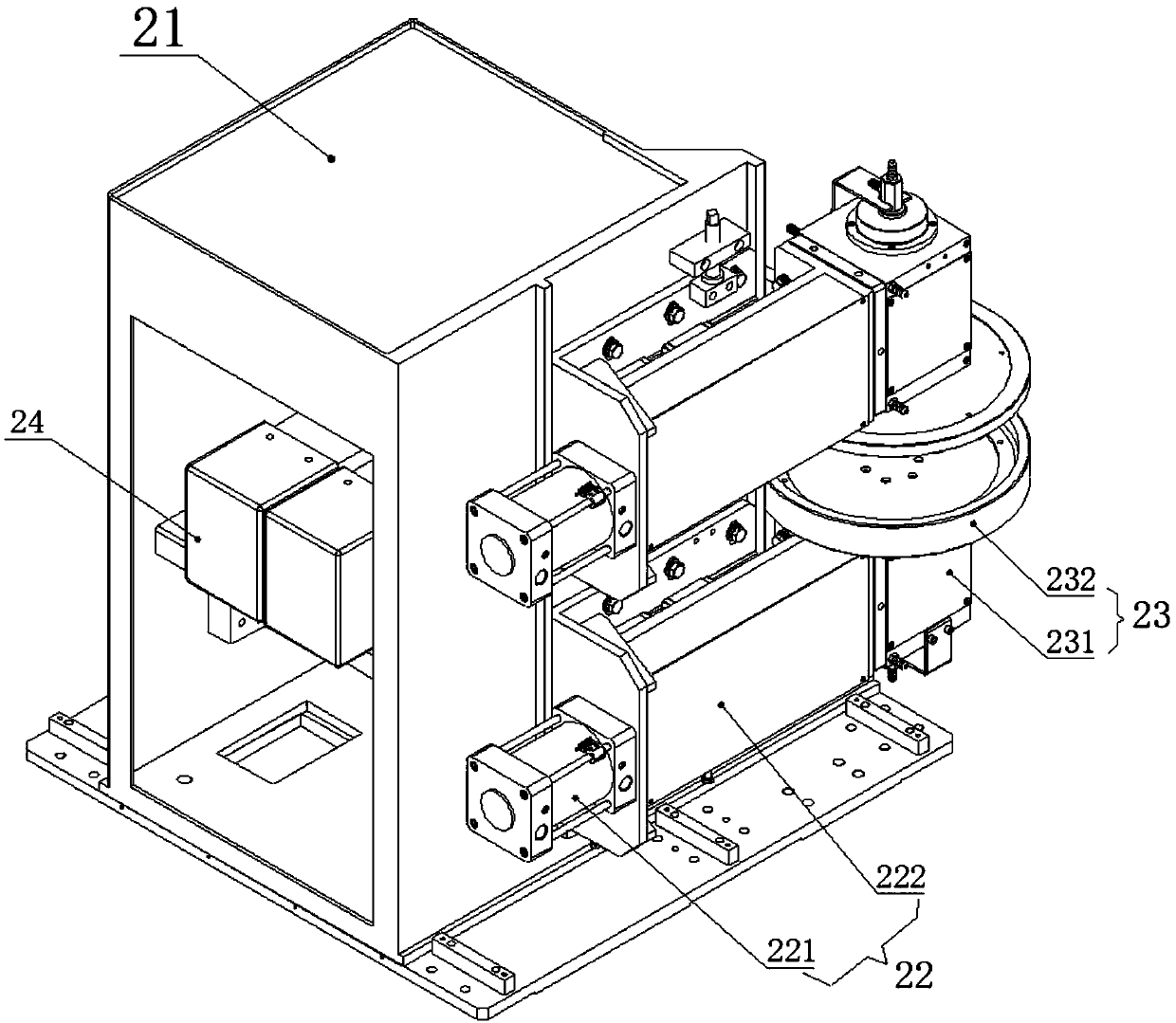

Split type full-automatic parallel sealing welding machine

ActiveCN114850640AEffective protectionImprove sealing and welding qualityFinal product manufactureWelding with roller electrodesEngineeringSpot welding

The invention discloses a split type full-automatic parallel seal welding machine which solves the technical problems of how to integrally improve the quality of the environment atmosphere of a parallel welding cavity and how to reduce the occurrence probability of sparking in seal welding. An X-direction welding material tray conveying module (304) and a welding mechanism installation portal frame (305) are arranged in the welding chamber (302), the X-direction welding material tray conveying module penetrates through the welding mechanism installation portal frame, a spot welding mechanism (306) and a seal welding mechanism (307) are arranged on a cross beam of the welding mechanism installation portal frame, a spot welding platform (308) is arranged under the spot welding mechanism, and the seal welding mechanism (307) is arranged under the spot welding platform (308). A seal welding platform (309) is arranged under the seal welding mechanism. A left sealing welding head mechanism (312) and a right sealing welding head mechanism (313) are arranged on the sealing welding mechanism, a material disc is arranged on a sealing welding platform (309) under the left sealing welding head mechanism and the right sealing welding head mechanism, and the sealing welding quality of elements is improved.

Owner:西北电子装备技术研究所

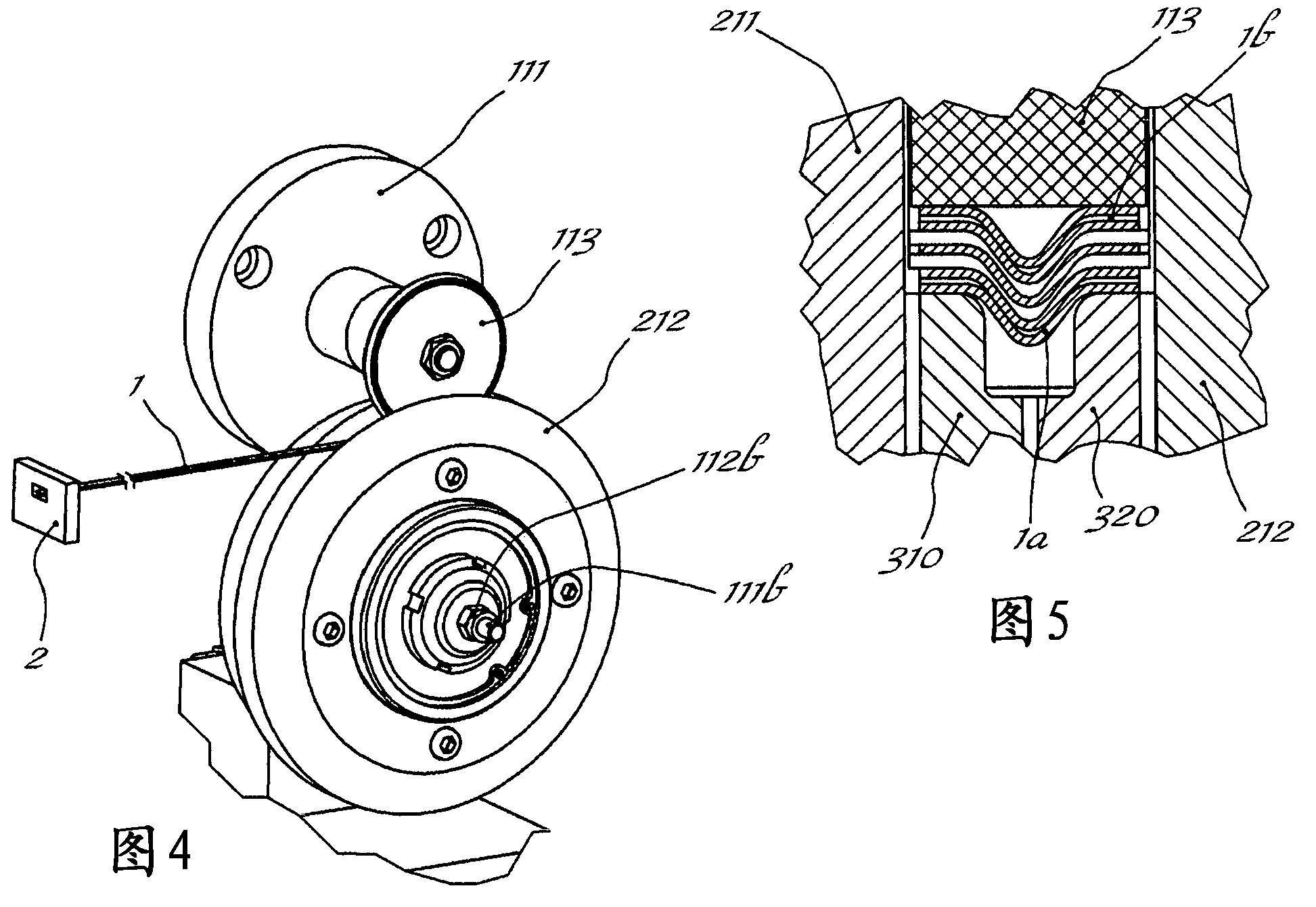

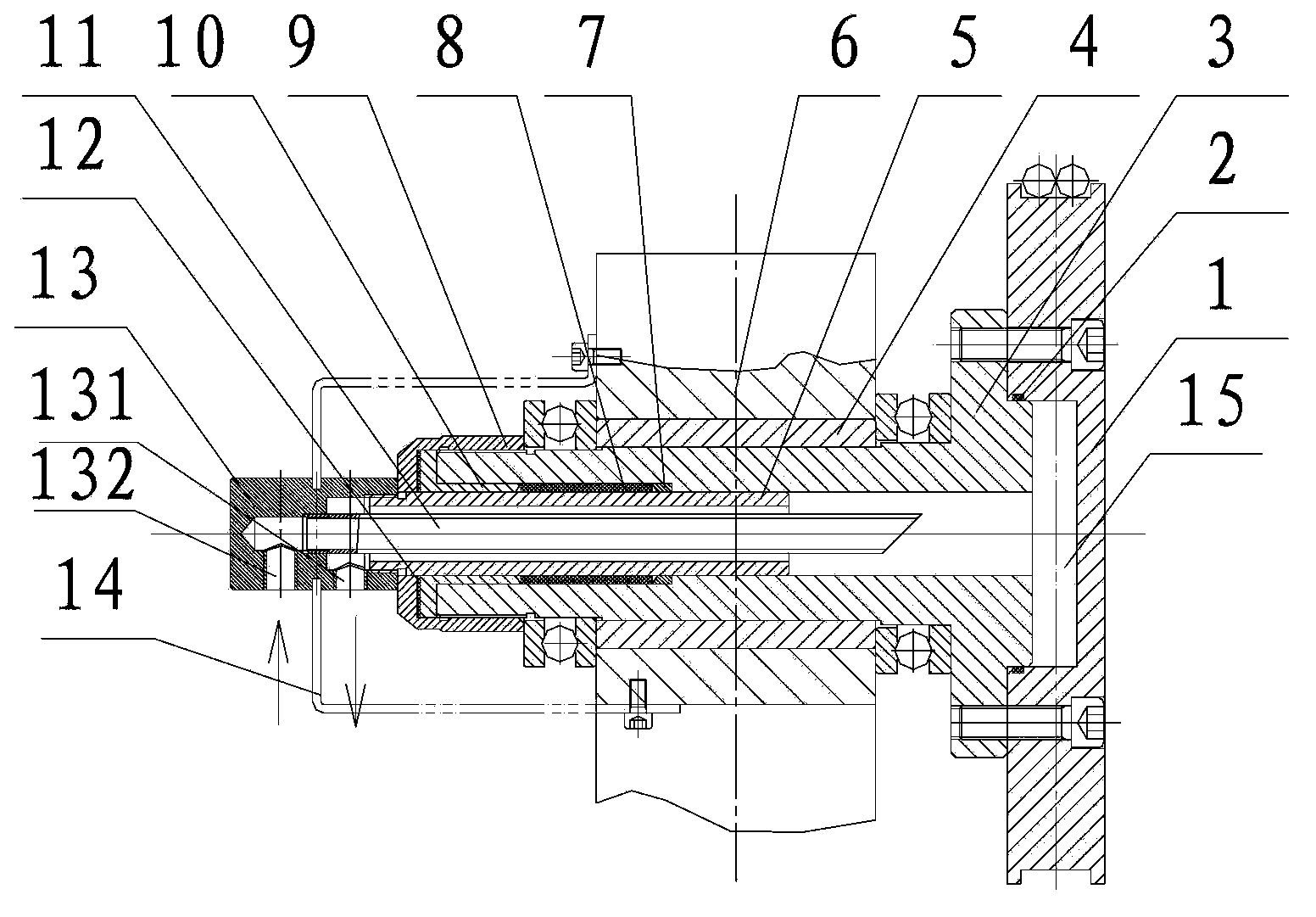

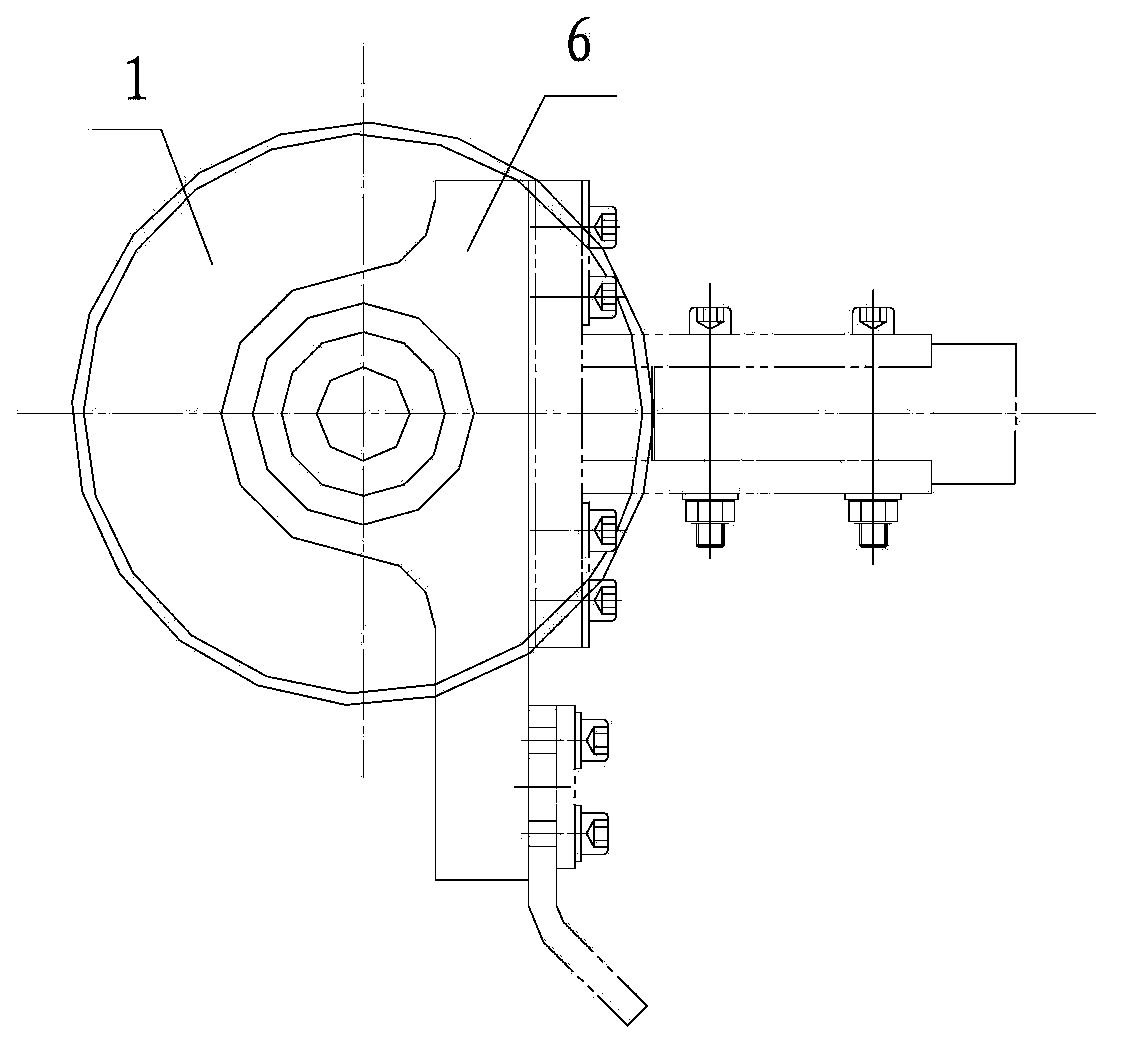

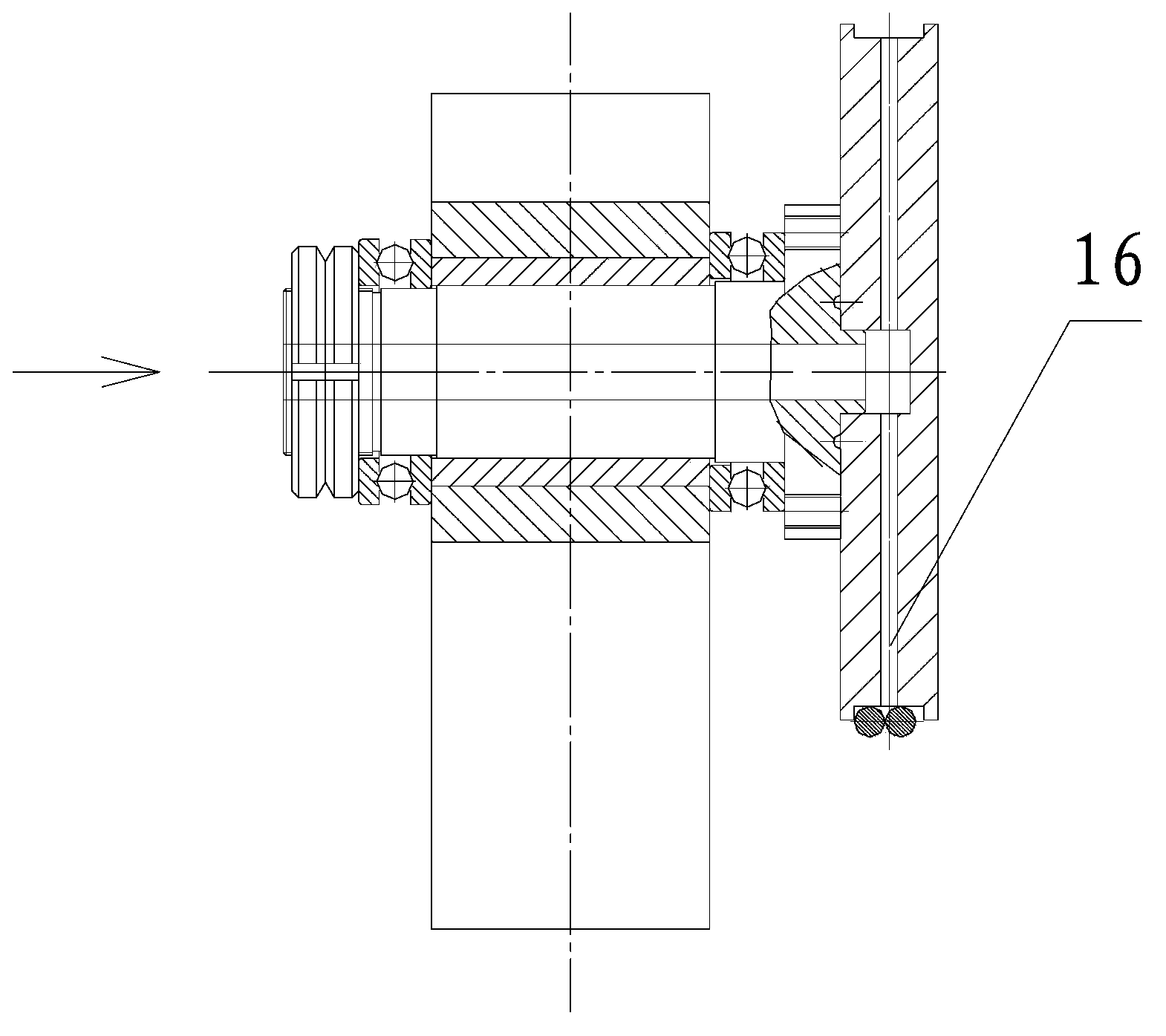

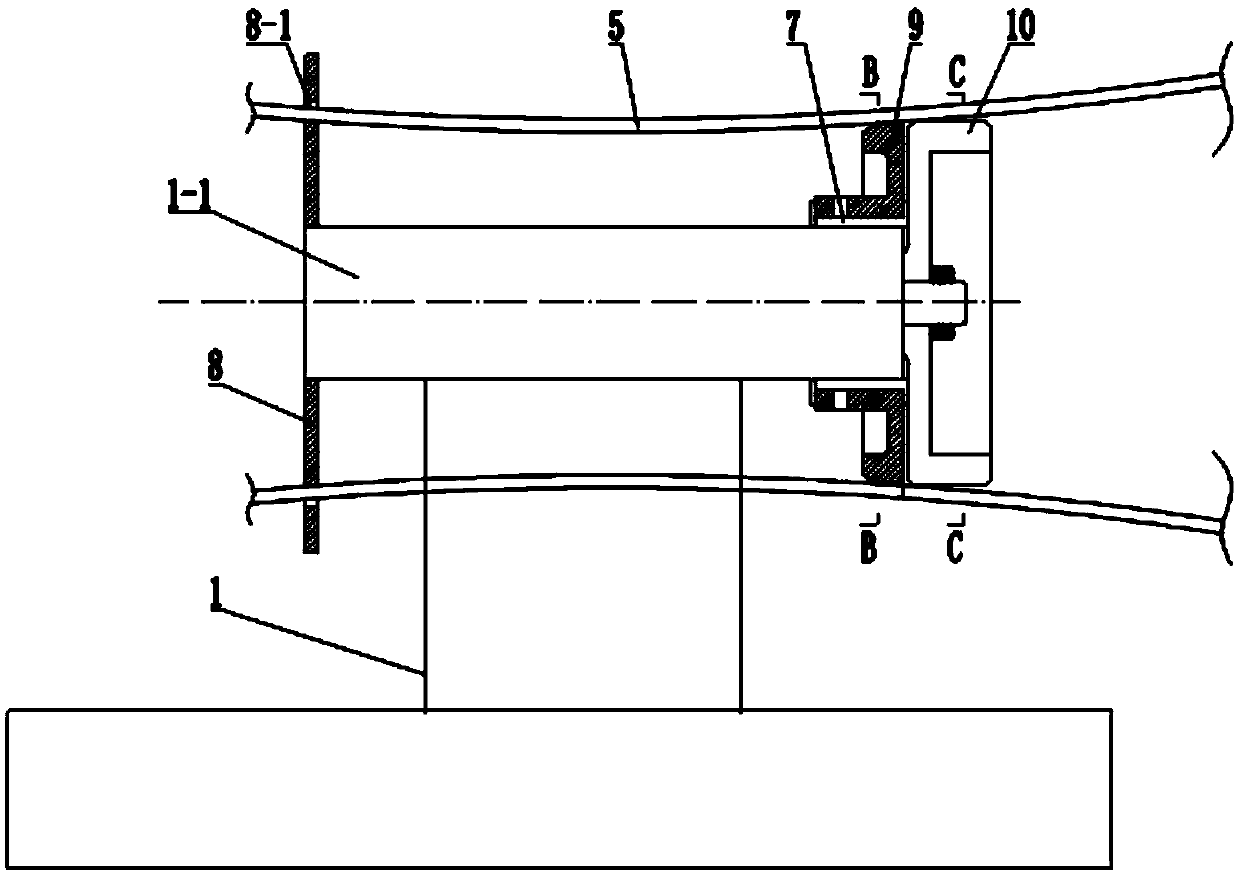

Cooling water circulation structure of seam welder

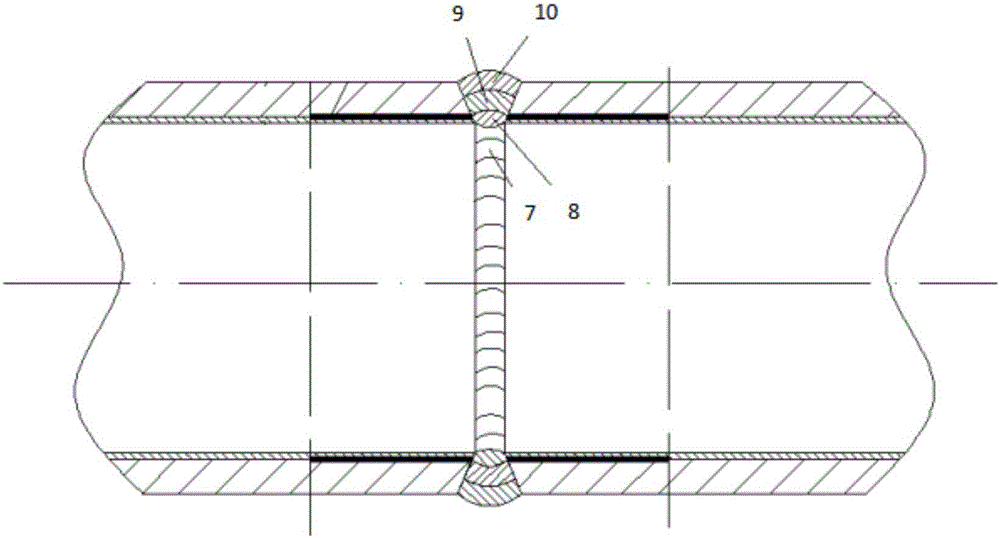

InactiveCN103909337AEfficient exchangeExtended service lifeWelding with roller electrodesRoller electrodesWater resourcesWater circulation

The invention discloses a cooling water circulation structure of a seam welder, which is simple in structure, is capable of effectively improving the service life of the welding wheel and the use ratio of cooling water, and relates to the improvement of a welding wheel cooling structure of the seam welded. The seam welder comprises a welding wheel, an internal cooling handpiece shaft and a welding wheel seat provided with a shaft sleeve, further comprises a cooling water circulation structure which is arranged in the central hole of the internal cooling handpiece shaft; the cooling water circulation structure comprises a flushing connector outer pipe and a flushing connector inner pipe, and the flushing connector outer pipe is fixedly arranged in the central hole of the internal cooling handpiece shaft; the inner diameter of the flushing connector outer pipe is greater than the outer diameter of the flushing connector inner pipe, and the flushing connector inner pipe is arranged in the flushing connector outer pipe. The cooling water circulation structure is arranged in the central hole of the internal cooling handpiece shaft, and water is fed in the flushing connector inner pipe and drained by the flushing connector outer pipe, so that the heat quantity of the welding wheel can be effectively changed, the water resources can be recycled simultaneously, and the cost can be saved.

Owner:江苏中意建材机械有限公司

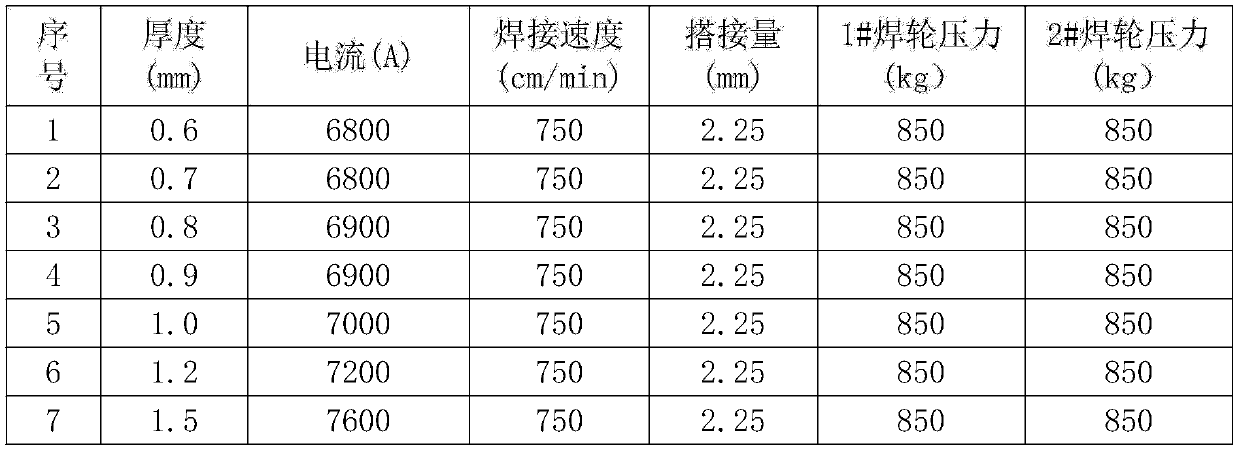

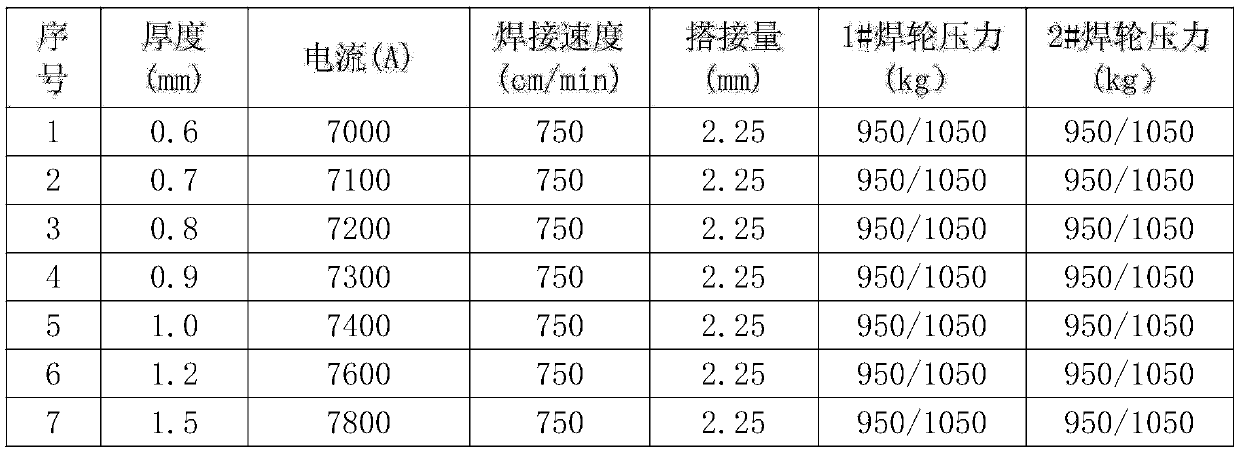

300-series stainless steel Tyler double-welding-wheel resistance seam welding process

InactiveCN110666320AControl cooling rateIdeal metallurgical structureWelding with roller electrodesRoller electrodesProduction lineWeld seam

The invention discloses a 300-series stainless steel Tyler double-welding-wheel resistance seam welding process which is characterized by adopting welding process parameters controlled during Tyler double-welding-wheel resistance seam welding comprising welding current, welding speed, overlap amount, No.1 welding wheel pressure, and No.2 welding wheel pressure, wherein the welding speed is 750cm / min, the overlap amount is 2mm, the No.1 welding wheel pressure is 950kg, the No.2 welding wheel pressure is 950kg, and a value of the welding current is adjusted according to the thickness of 300 stainless steel strip steel. The 300-series stainless steel Tyler double-welding-wheel resistance seam welding process provided by the invention has the beneficial effects that the 300-series stainless steel Tyler double-welding-wheel resistance seam welding process parameters with the thickness being smaller than or equal to 1.5mm are provided, and the welding current and the welding seam overlap amount are set according to the strip steel thickness, so that the welding seam fusion performance is improved, the welding seam strength and toughness can be optimized, a welding seam is flat and smooth, the occurrence of the phenomena such as cracking, incomplete fusion, lack of penetration and weld penetration is avoided, the production processing demand of an annealing-pickling production line ismet, the product quality is ensured, and the yield is improved.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

Method for producing connecting ends on metal tubes and tube piece comprising such connecting ends

InactiveUS20050056685A1Fast solderingLarge widthCurved planar seam weldingFlexible pipesWeld seamEngineering

Connecting ends on a tube piece comprising several metal layers, in particular a wound metal tube piece, are produced by fixing the overlapping metal layers of a tube of larger length or of an endless tube in the region of the point of separation through welding and subsequently cutting off the tube piece from the longer tube or the endless tube. For simple and inexpensive fixing of the metal layers in the region of the point of separation, the invention proposes effecting a welding seam which extends through at least part of the periphery of the tube or about its entire periphery, using seam welding. The tube piece can subsequently be separated along the welding seam obtained in this manner, e.g. along its central line, thereby ensuring permanent and reliable fixing of the metal layers in the region of the connecting end. The invention also concerns a tube piece having a connecting end produced in this manner.

Owner:BOA BALG UND KOMPENSATOREN TECH

Butt welding device and butt welding method

InactiveUS7423233B2Improve workabilityWork lessRectilinear seam weldingArc welding apparatusButt weldingMechanical engineering

A butt welding apparatus and a butt welding method where end faces of at least one plate member to be welded are butted to each other to form a butt portion, and butt welding can be performed on respective plate members which have various thickness sizes on both side portions of the butt portion with electric resistance heat by a pair of electrode members which are common to the respective plate members. At least one electrode member (1) is provided on an outer face thereof with a convex portion (1A) which gradually retreats from one plate member (31) of two plate members (31, 32) as it extends from an intermediate portion, in a thickness direction, of the one electrode member (1) along the one plate member (31). Butt welding of the two plate members (31, 32) is performed by the position of the butting portion (71) of these plate members (31, 32) being offset from the intermediate portions, in the thickness directions, of the electrode members (1, 2) to the convex portion (1A) by an amount (L1) corresponding to a difference in thickness between the plate members (31, 32).

Owner:SUMITOMO METAL IND LTD +1

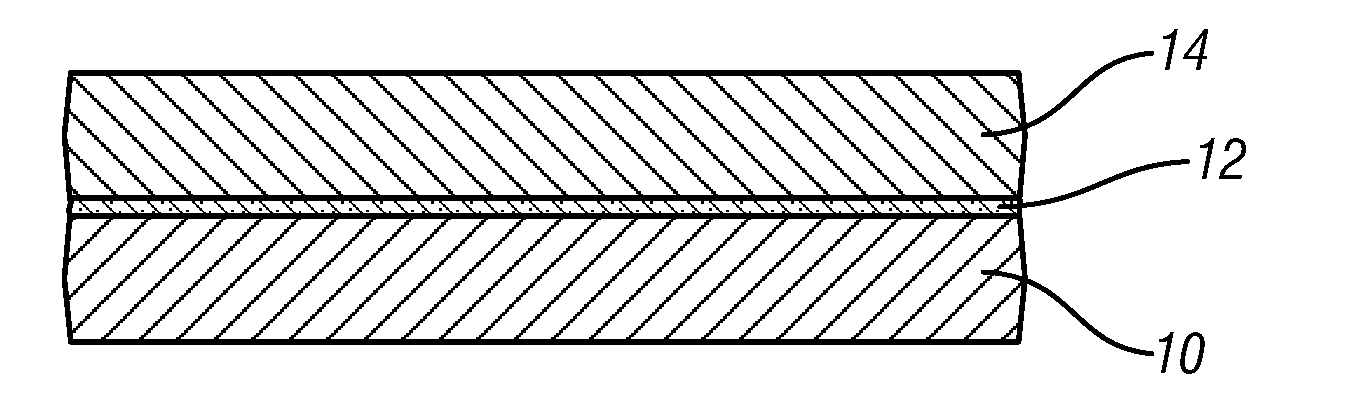

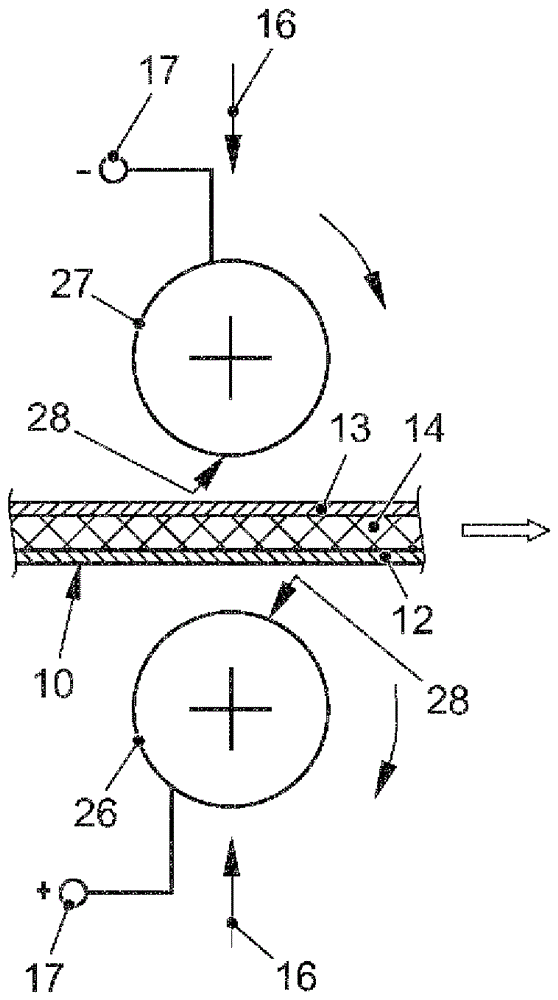

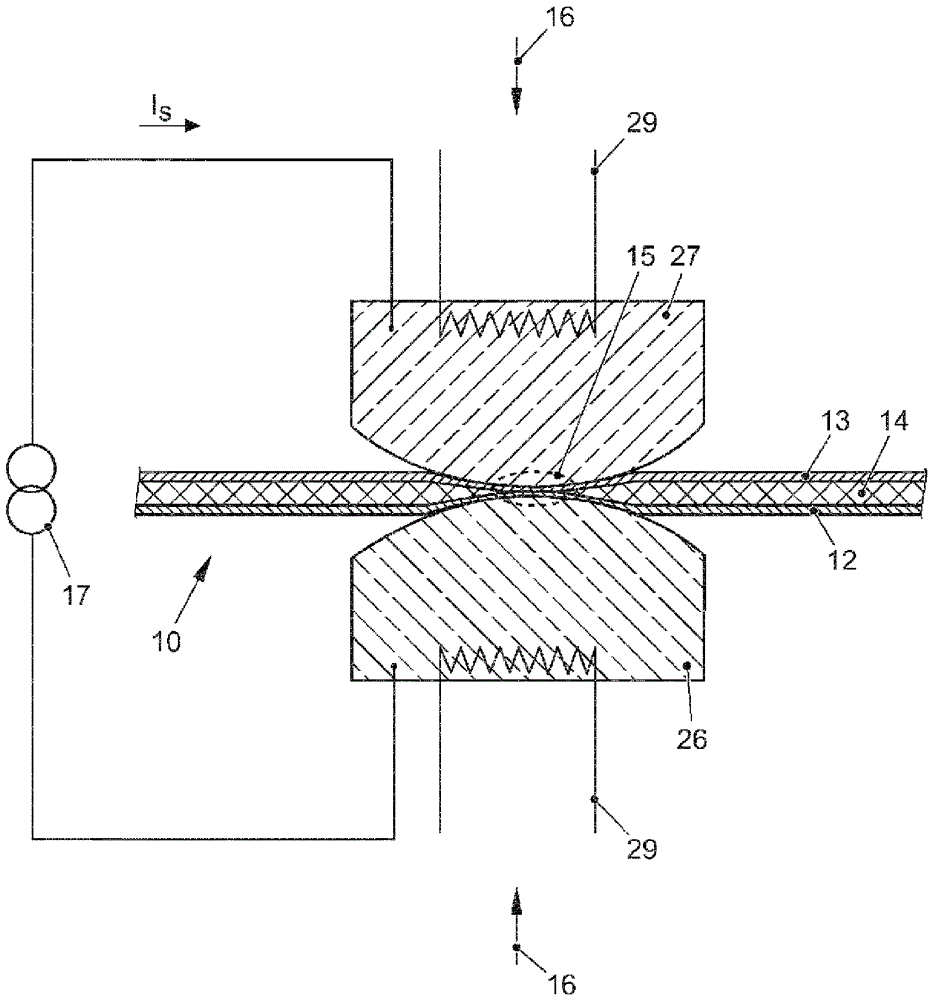

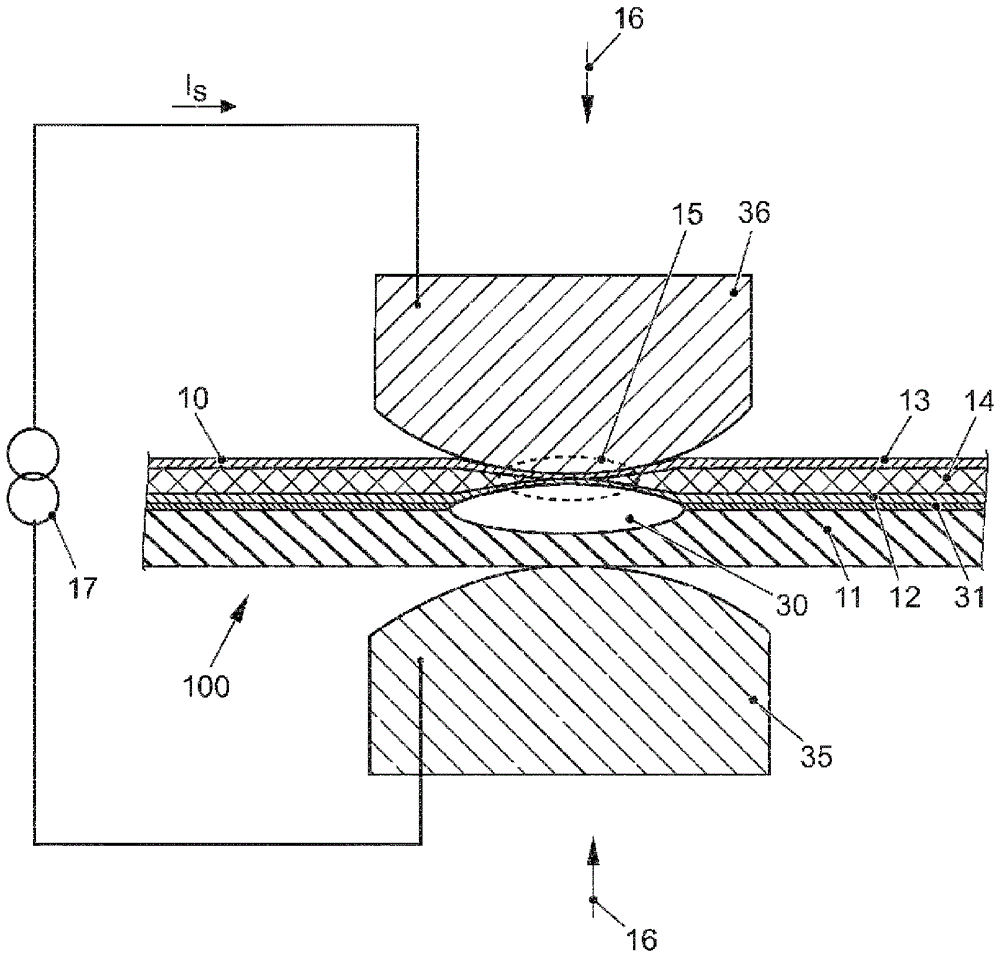

Method and device for joining a composite sheet metal component to another component

The aim of the invention is to improve a method for joining a multilayer component to another component such that the joining method and the preparation of the joint locations can be carried out as quickly as possible and inexpensively using an automatic method. This is achieved in that an intermediate layer (14) of the multilayer component is displaced in the region of the joint location (15) by means of a heating process and by exerting a compressive force (16), and the two outer components (10, 11) of the multilayer component are adhered together by applying an electric voltage (17).

Owner:VOLKSWAGEN AG

Volute welding device

ActiveCN109604793AReduce labor intensityIncrease productivityWelding with roller electrodesRoller electrodesEngineeringSeam welding

The invention discloses a volute welding device. The volute welding device comprises a frame body, a seam welding device, a positioning clamping device and a first driving device used for driving thepositioning clamping device to rotate; the positioning clamping device comprises a positioning clamping support seat, an inner supporting mechanism and an outer pressing mechanism used for pressing the outer wall of the welded volute, and an electrode matched with the shape of the inner wall of the welded volute is arranged on the inner supporting mechanism; the seam welding device comprises a welding machine and two seam welding mechanisms which are connected with the wiring end of the welding machine and are used for welding the welded volute, the two seam welding mechanisms rotate along with the rotation of the welded volute. During use, the welded volute is fixed in a spot welding mode, then the welded volute is fixed on the volute welding device, and can be welded and rotated to be matched with the work of a weld joint mechanism, so that automatic machining is realized, the labor intensity of workers is reduced, the production efficiency is improved, the weld joint is attractive and uniform, the weld joint strength is large, the connection is stable, the weld joint sealing performance is good, the leakage is avoided, the subsequent sealing treatment does not need to be subjected, and the volute welding device can be widely applied to the welding of volute.

Owner:湖南创研智能装备有限公司

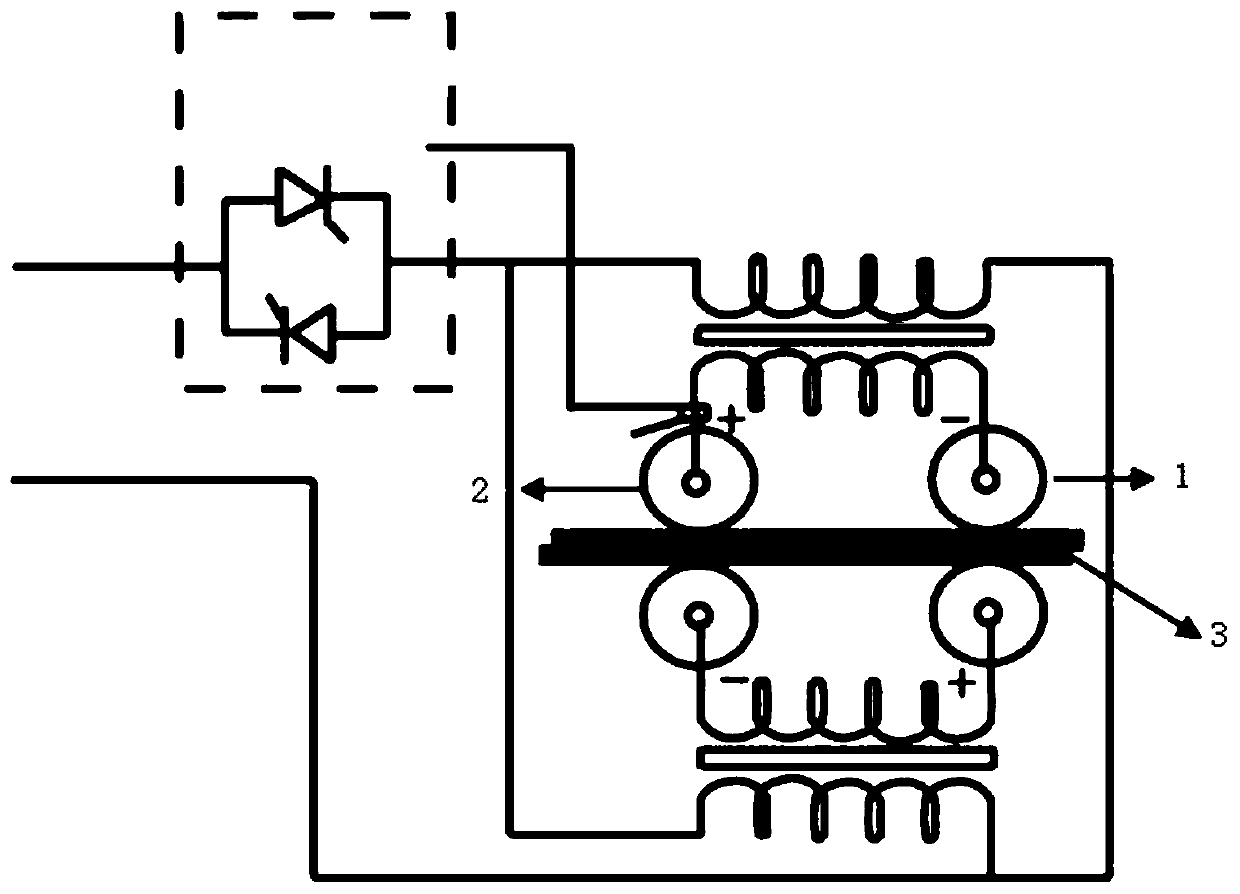

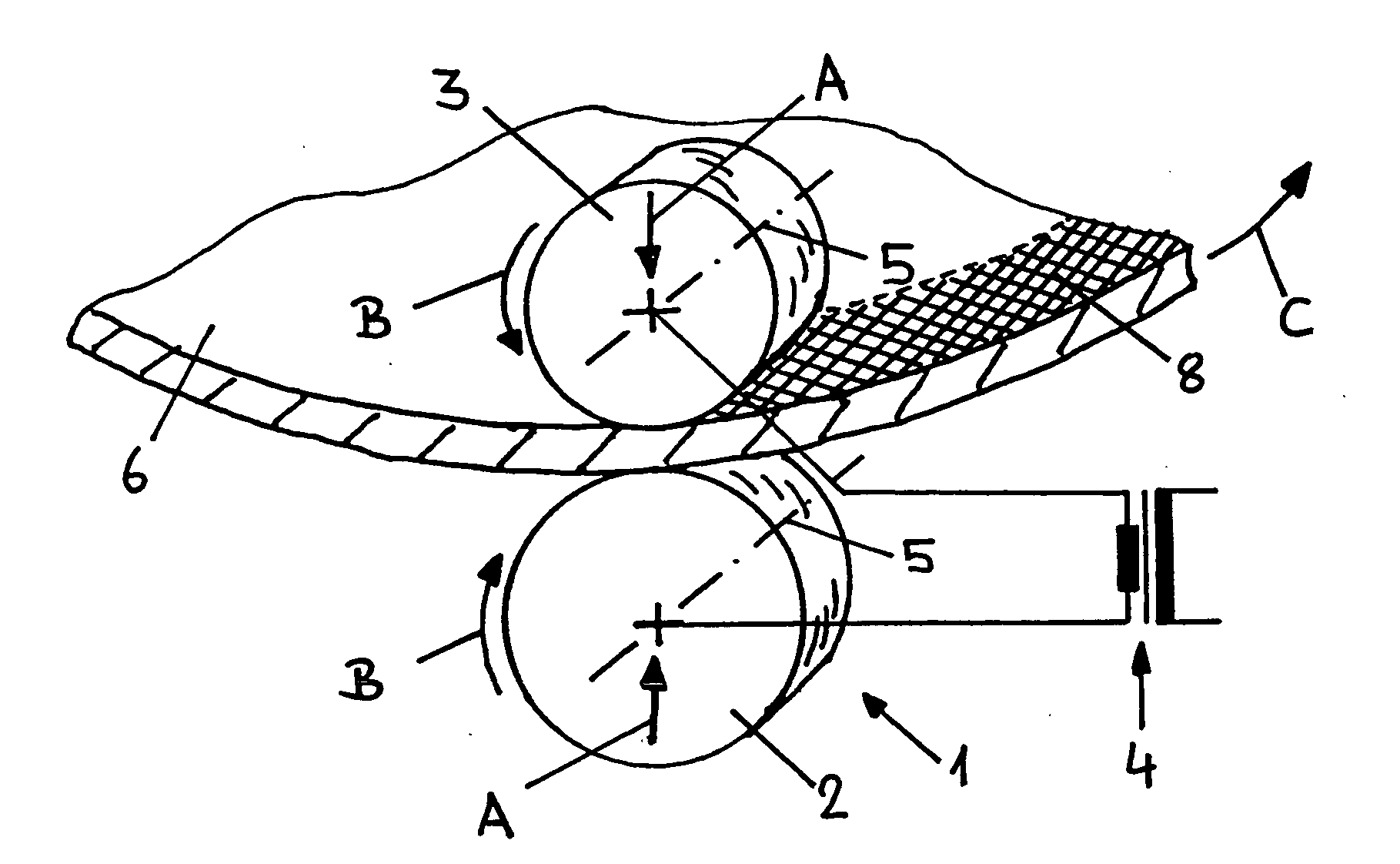

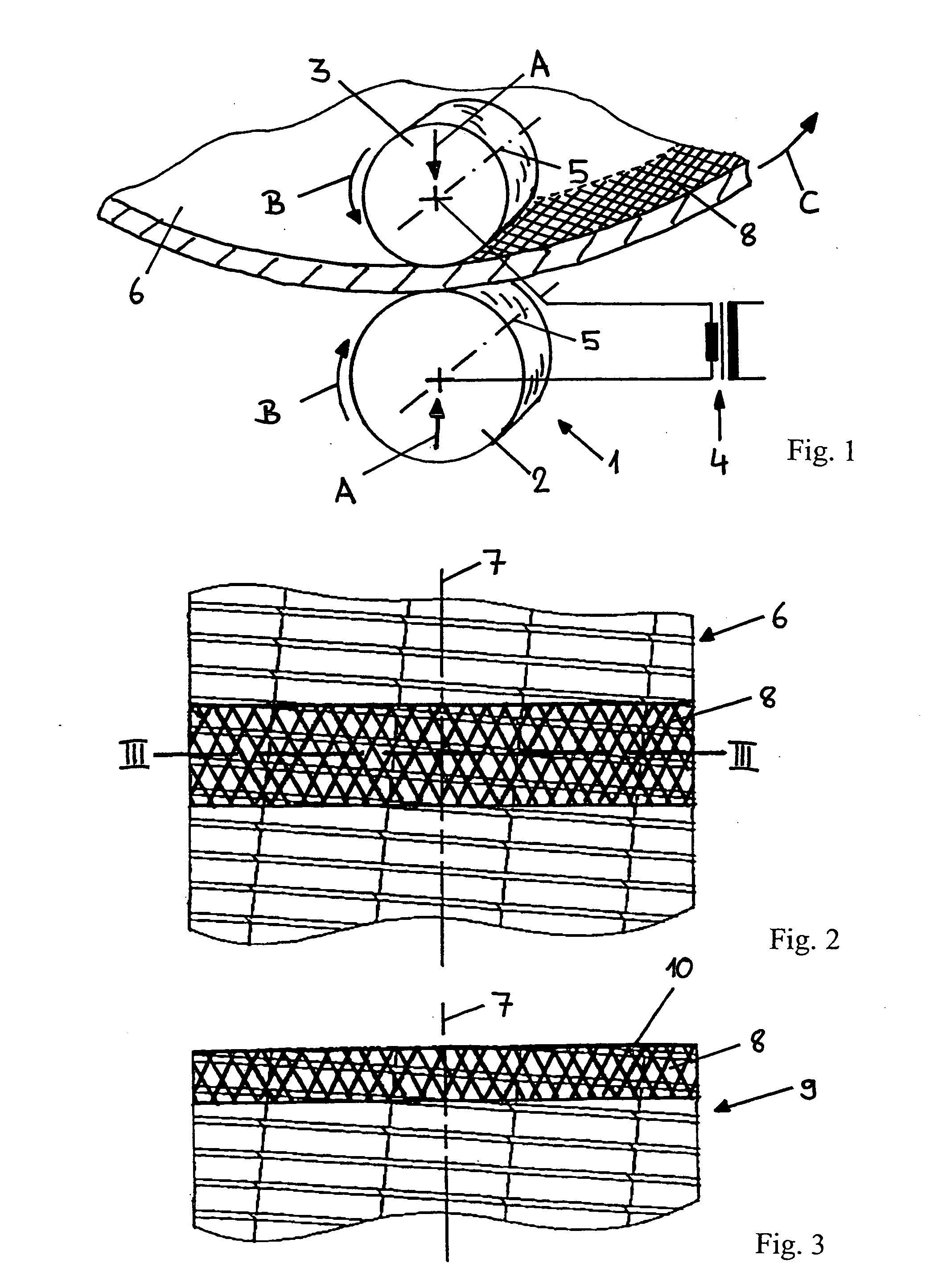

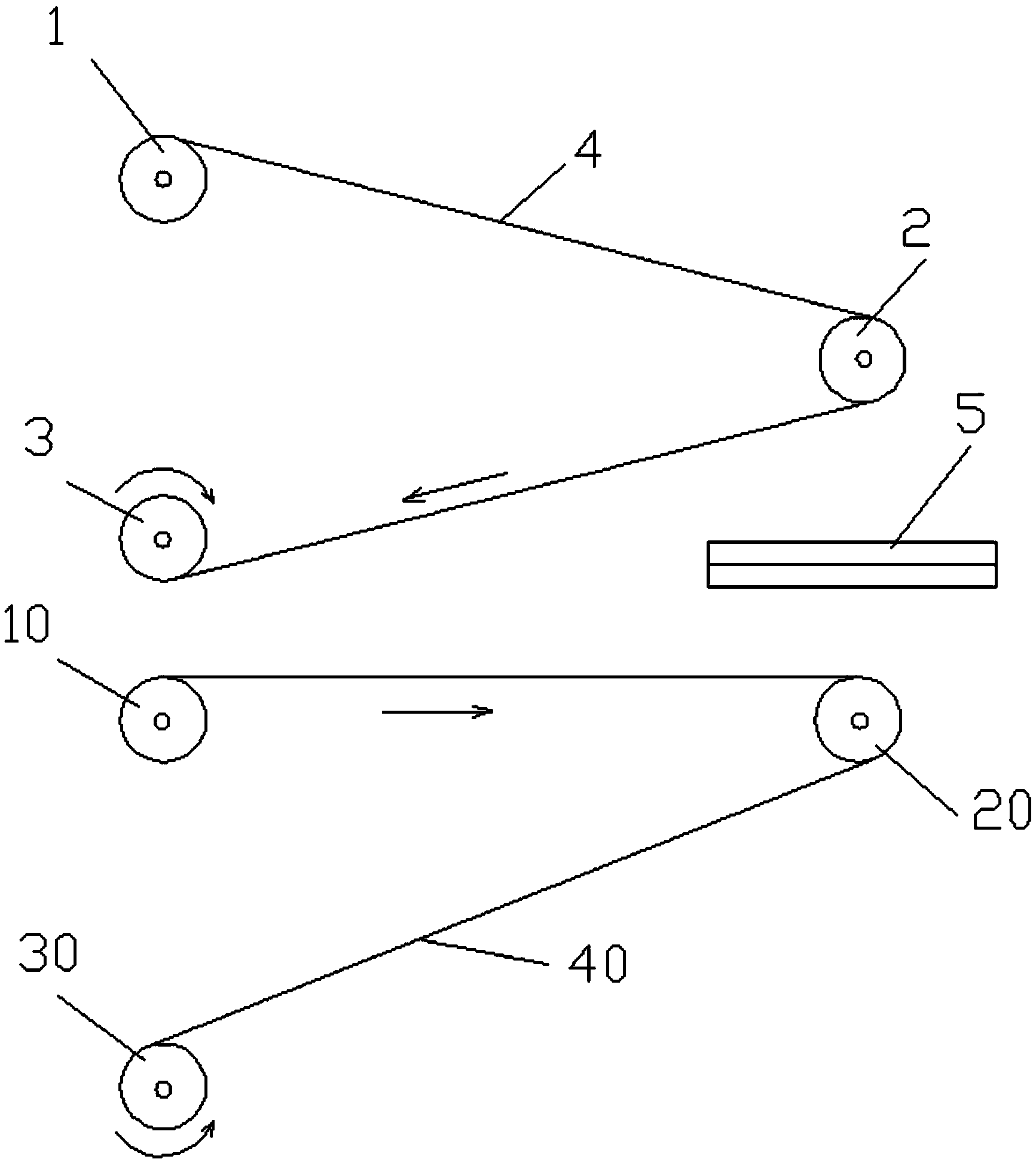

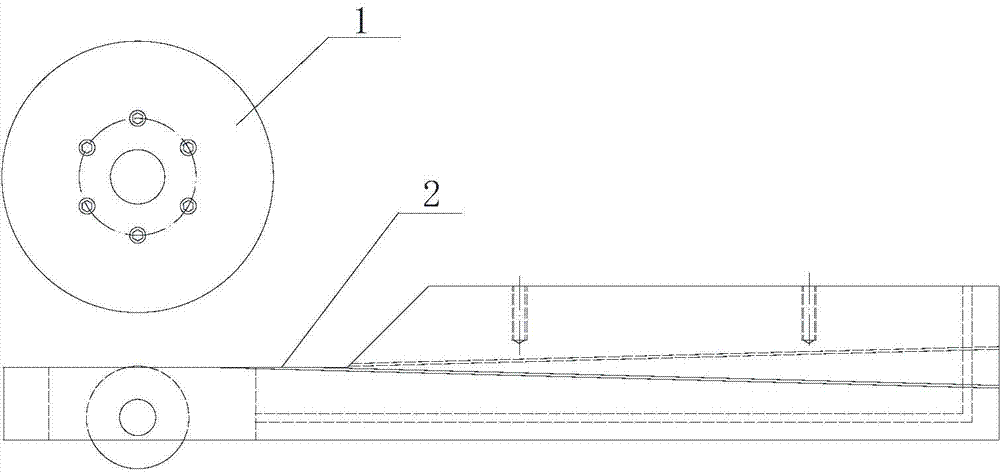

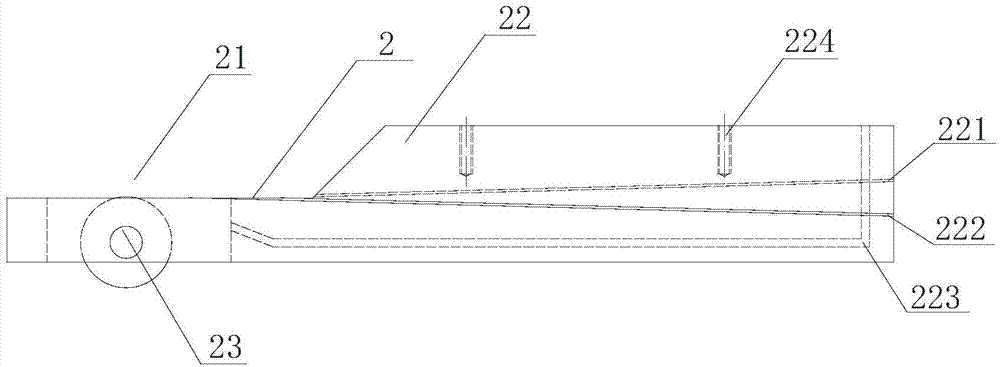

Novel resistance seam welding process and device for galvanized sheet fuel tanks

InactiveCN103480958AWill not destroy rust resistanceOmit the step of zinc brushing treatmentRectilinear seam weldingMetal working apparatusElectrical resistance and conductancePower flow

A novel resistance seam welding process for galvanized sheet fuel tanks is characterized by including the steps of allowing an anode copper wire roller (1) to convey an anode copper wire (4) to an anode conducting welding roller (2), and allowing the anode conducting welding roller (2) to transfer current of a transformer as welding current to firmly weld two galvanized sheets (5) through the anode copper wire (4). A novel resistance seam welding device is characterized by comprising the anode copper wire roller (1), the anode conducting welding roller (2), an anode power tension roller (3), the anode copper wire (4), a cathode copper wire roller (10), a cathode conducting welding roller (20), a cathode power tension roller (30) and a cathode copper wire (40). The novel resistance seam welding process has the advantages that no manually removing the galvanized layer at the welded part by a grinding machine or welding the seam by a seam welding machine is needed; the step of zincing the seam is omitted; accordingly, processing steps are decreased greatly, manpower sources are saved, and rust resistance of the galvanized sheets are kept intact.

Owner:江苏海德节能科技有限公司

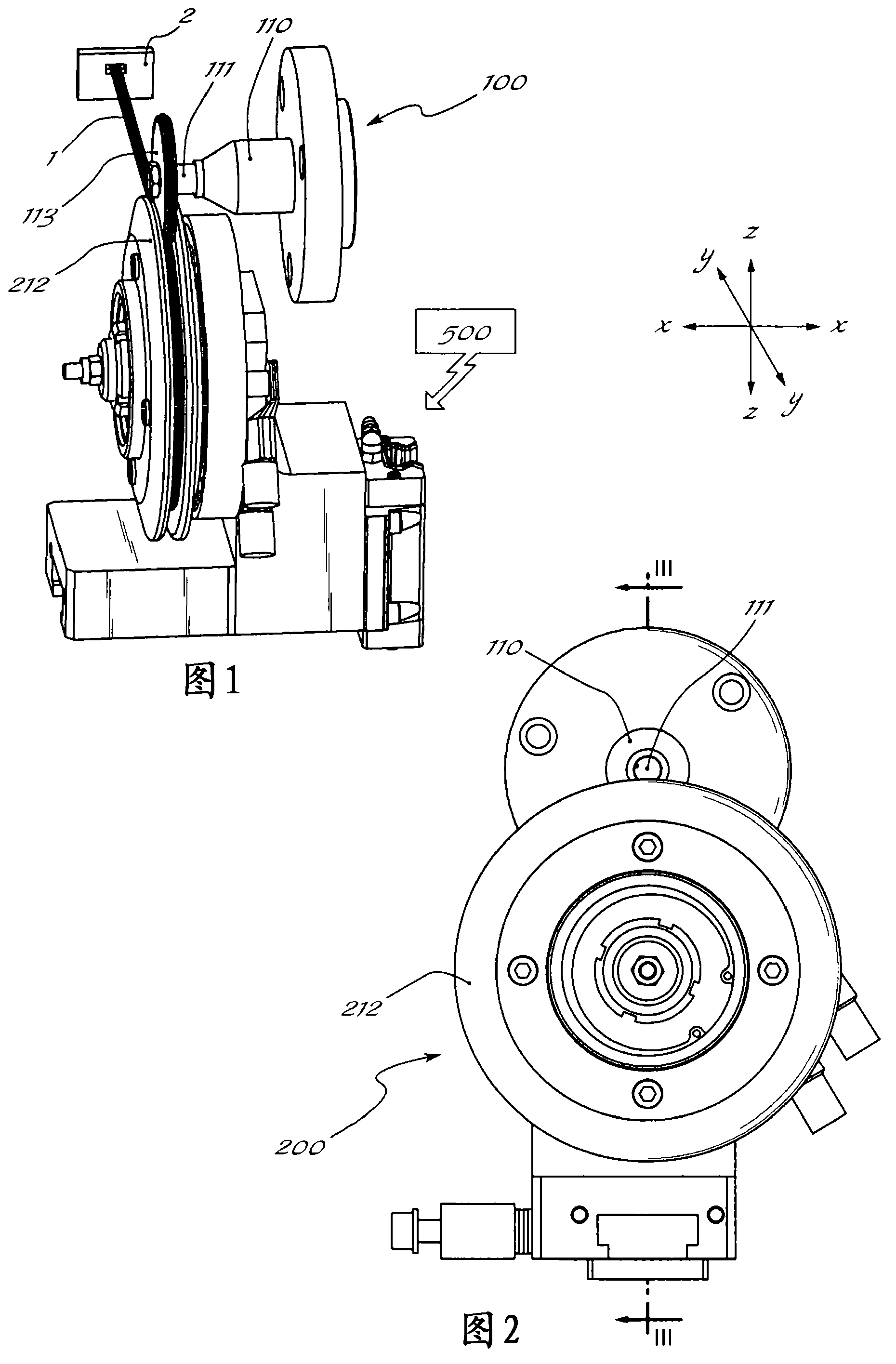

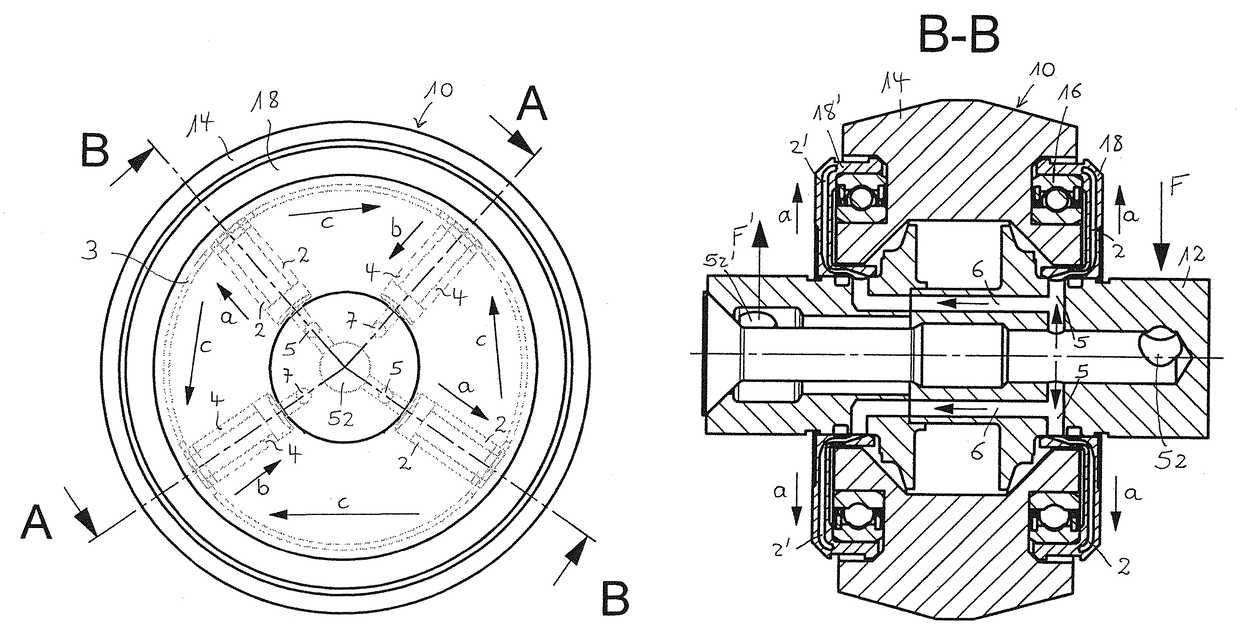

Roller head for a resistance welding machine

ActiveUS9969027B2Extended service lifeEasy to manufactureDomestic vesselsMetal working apparatusEngineeringSeam welding

Owner:SOUDRONIC

Method and apparatus for manufacturing for fixing a mounting ring to an exhaust pipe assembly

ActiveUS8610023B2Reduce the temperatureCurved planar seam weldingSoldering apparatusTransformerTemperature difference

A method and apparatus for manufacturing an exhaust pipe assembly which are capable of decreasing a temperature difference between a seam-welded outer and inner surface at the time of seam welding. The apparatus comprises an outer circumferential electrode wheel abutted on an outer circumference of a mounting ring, a pressing means pressing the outer circumferential electrode wheel to the mounting ring, an inner circumferential electrode wheel abutted on an inner circumference of a pipe making up an exhaust pipe assembly, a transformer serving as a voltage supply means for supplying a predetermined voltage to the outer and inner circumferential electrode wheels and, and a controller for controlling voltage of the transformer. Thickness T1 of the outer circumferential electrode wheel is larger than thickness T2 of the inner circumferential electrode wheel.

Owner:HONDA MOTOR CO LTD

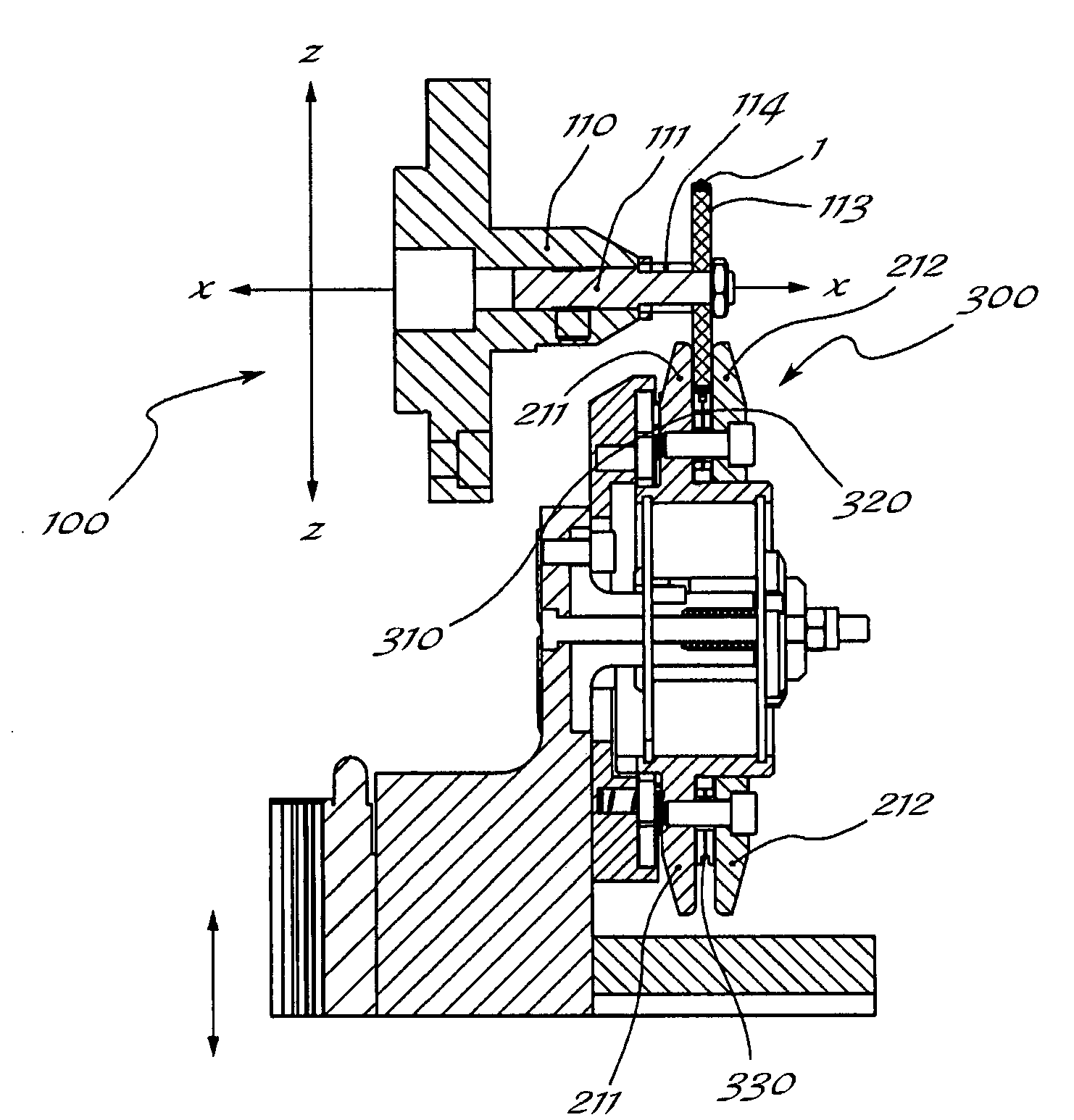

Shaping device and shaping method for roller electrode for seam welding

ActiveCN107000110AReduce the burden onExcellent machinabilityRoller electrodesMetal rolling arrangementsCentre of rotationEngineering

Owner:HONDA MOTOR CO LTD

Programmable resistance seam welding apparatus and method

InactiveUS7112757B2Small welding contact pointReduce amountOhmic-resistance electrodesWelding with roller electrodesElectrical resistance and conductanceEngineering

A resistance welding apparatus having a pair of programmable ball electrodes carried on universally movable positioners. The positioners are programmed to move the ball electrodes simultaneously along a seam line so that the ball electrodes clamp and support opposite sides of a pair of stacked workpieces and are electrically charged to form resistance seam welds along the seam lines to connect the workpieces.

Owner:GM GLOBAL TECH OPERATIONS LLC

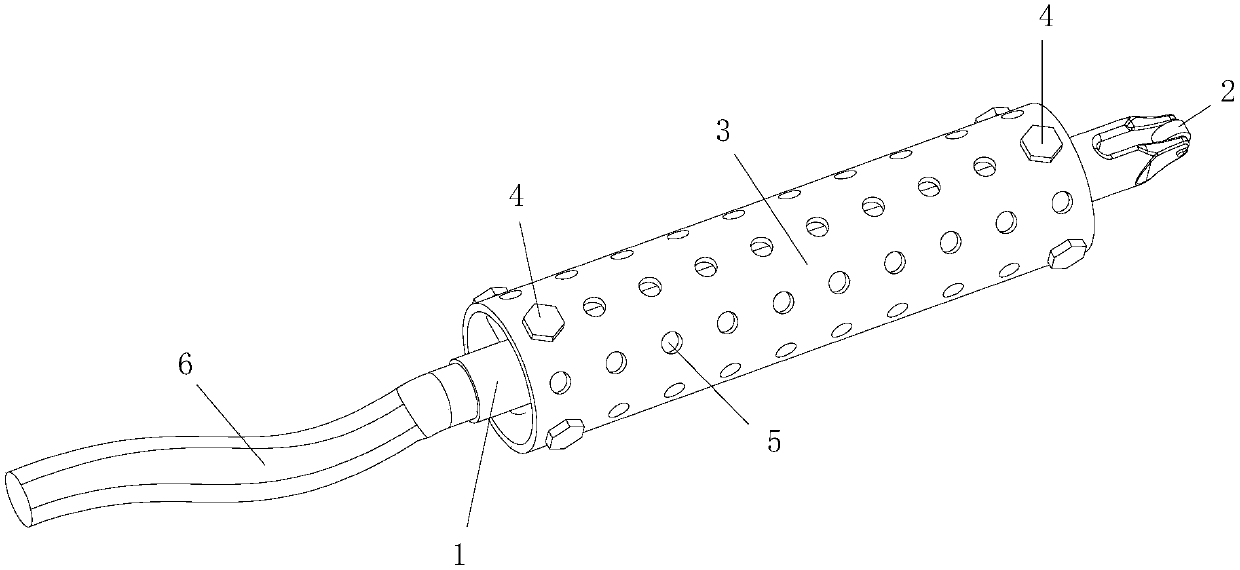

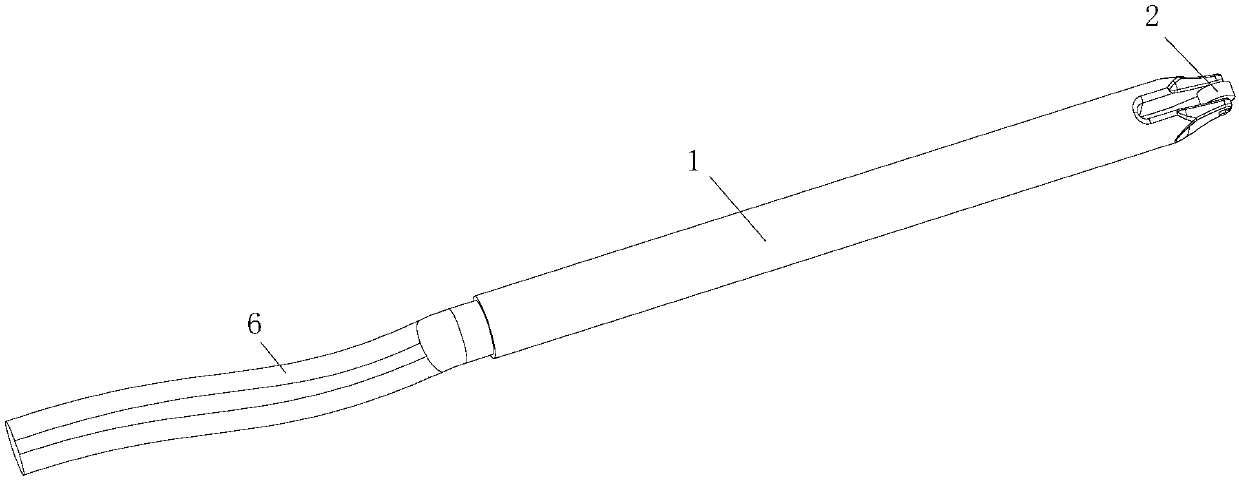

Reinforcement cage welding tool and fixed electrode thereof

InactiveCN111375877AImprove installation accuracyReduce manufacturing costRoller electrodesRebarMechanical engineering

The invention discloses a reinforcement cage welding tool and a fixed electrode thereof. The fixed electrode of the reinforcement cage welding tool comprises an electrode base body and a conductive part. The electrode base body is mounted at one end of a seam welder spindle. The conductive part is detachably and fixedly mounted on the electrode base body. A peripheral contour base line of the conductive part is matched with a peripheral contour base line of a reinforcement cage workpiece to be welded. The conductive part is provided with locating structures for reinforcement cage workpiece main reinforcement steel bars and can be electrically connected to one power output end of the welding tool through the electrode base body or a conductive mechanism arranged on the electrode base body.Through the reinforcement cage welding tool and the fixed electrode thereof, the problem that a fixed electrode is corroded in the manufacturing process of a reinforcement cage and needs to be integrally replaced is solved, and the purpose of reducing the production cost is achieved.

Owner:周兆弟

Cold repair welding machine electrode tip

The invention provides a cold repair welding machine electrode tip. The cold repair welding machine electrode tip comprises a plug and a handheld part; one end of the plug is a cable connecting end, opposite to the cable connecting end, the other end of the plug is provided with an electrode which is capable of rolling against a to-be-welded workpiece; and the handheld part is arranged corresponding to the outer peripheral side of the plug and has an extending length along the axial direction of the plug, the plug is fixed in the handheld part through a positioning assembly and is spaced apartfrom the handheld part, and one end, with the electrode, of the plug is located outside the handheld part. The cold repair welding machine electrode tip can overcome defects existing in an existing cold repair welding machine electrode tip, so that the electrode tip with a good use effect can be provided.

Owner:GREAT WALL MOTOR CO LTD

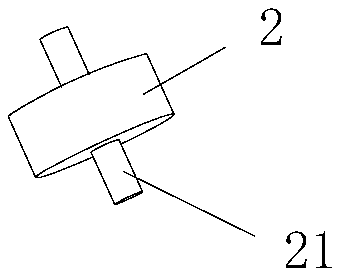

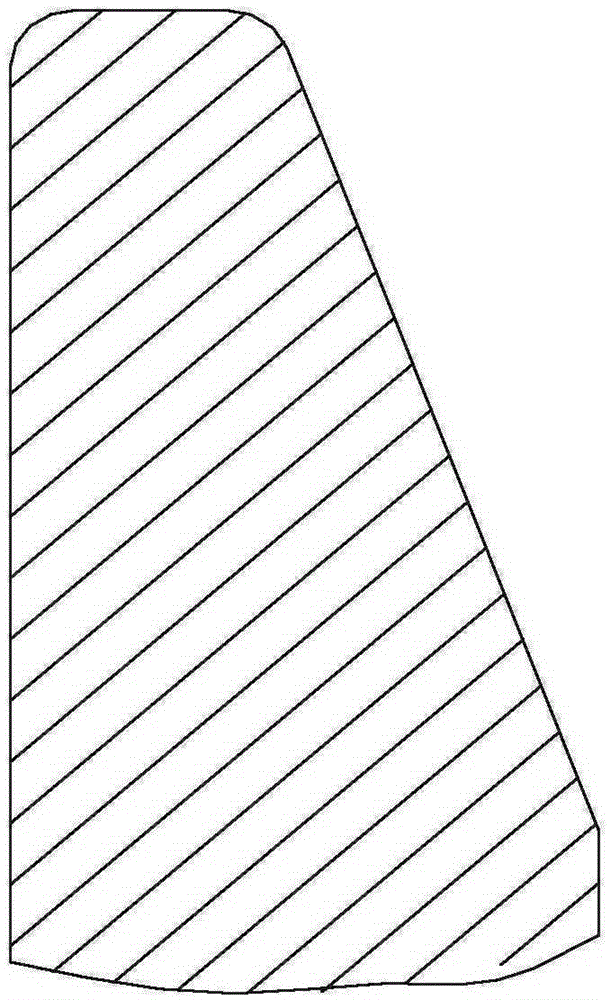

Electrode for roll welding between titanium alloy plate and stainless steel mesh

InactiveCN105364286AReduce the probability of wire breakageImprove pass rateWelding with roller electrodesRoller electrodesTitanium alloyWelding process

The invention provides an electrode for roll welding between a titanium alloy plate and a stainless steel mesh. The electrode comprises a first disc body and a second disc body, wherein the first disc body and the second disc body are integrally molded; and the diameter of the second disc body is larger than the diameter of the first disc body, the two sides of the bottom of the second disc body are inclination faces, and two corners at the edge of the end of the second disc body are profile bevels. By means of the manufactured electrode, the probability of wire breakage of the mesh in the roll welding process can be effectively decreased, and the percent of pass of products is improved.

Owner:SHANGHAI INST OF SPACE PROPULSION

Resistance welding electrode capable of conducting locating

ActiveCN103934563AIngenious ideaQuality improvementRectilinear seam weldingMetal working apparatusBiochemical engineeringUltimate tensile strength

The invention provides a resistance welding electrode capable of conducting locating. The resistance welding electrode capable of conducting locating is suitable for sheet metal, the lap joint sizes are identical, the number of the production steps can be reduced, and labor intensity can be relieved. The resistance welding electrode capable of conducting locating comprises an upper electrode body and a lower electrode body assembly. The upper electrode body is located above the lower electrode body assembly and can move vertically relative to the lower electrode body assembly. The lower electrode body assembly comprises a lower electrode body, a locating block and a shaft pin, the lower electrode body is arranged on the locating block through the shaft pin, the locating block is provided with a first locating groove, a second locating groove, a flow channel, an electrode hole and a plurality of fixing holes, the first locating groove and the second locating groove are located in the two side surfaces of the locating block, the fixing holes are formed in the upper surface of the locating block, the electrode hole is formed in one end of the locating block, the flow channel is located in the locating block, the first locating groove inclines downwards, and the second locating groove inclines upwards. By the adoption of the resistance welding electrode capable of conducting locating, the product quality is improved, the production cost and the labor intensity are lowered, and production efficiency is improved.

Owner:JIANGSU ELECTRIC POWER COMPANY YANGZHOU POWER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com