Method and device for joining a composite sheet metal component to another component

A technology of components and composites, applied in welding monitoring devices, welding equipment, welding power supplies, etc., to achieve the effects of reducing wear, fast cost, and improving takt time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

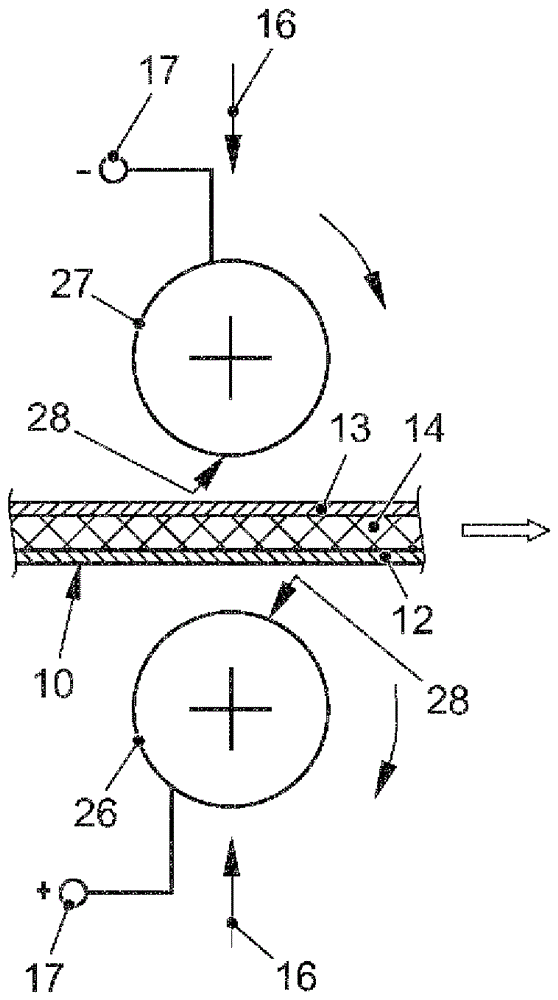

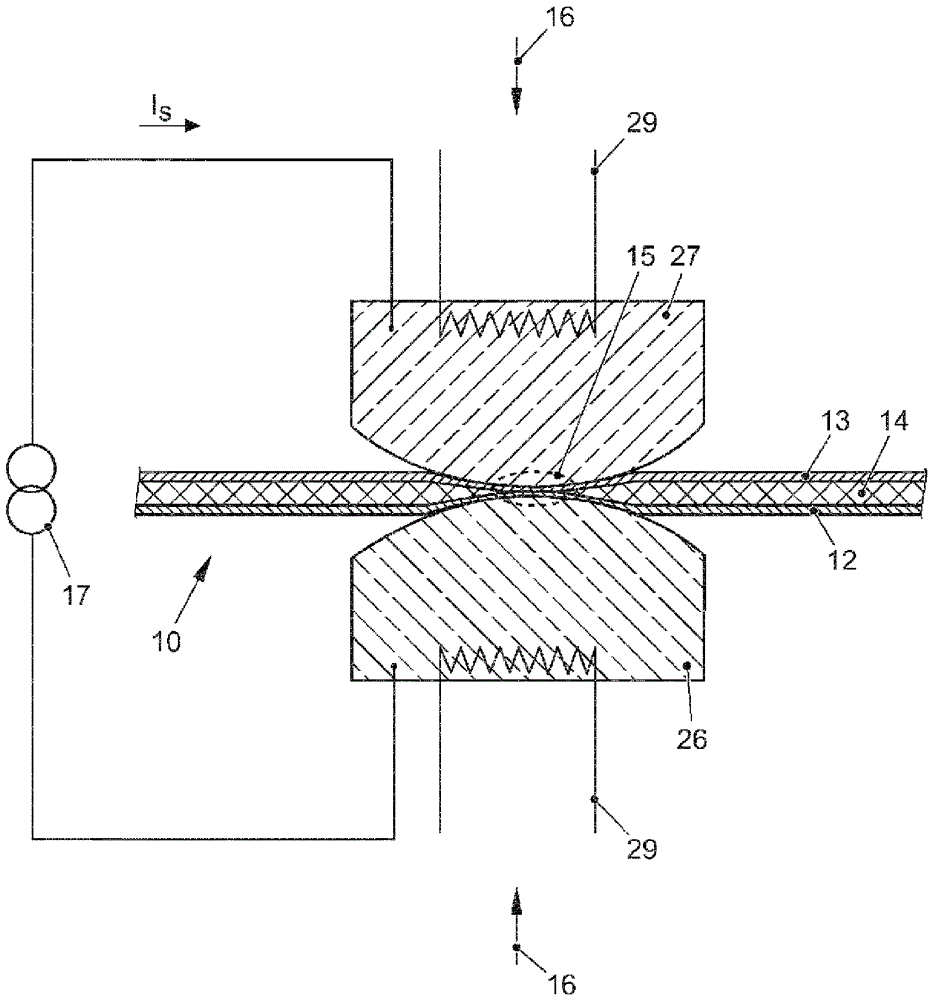

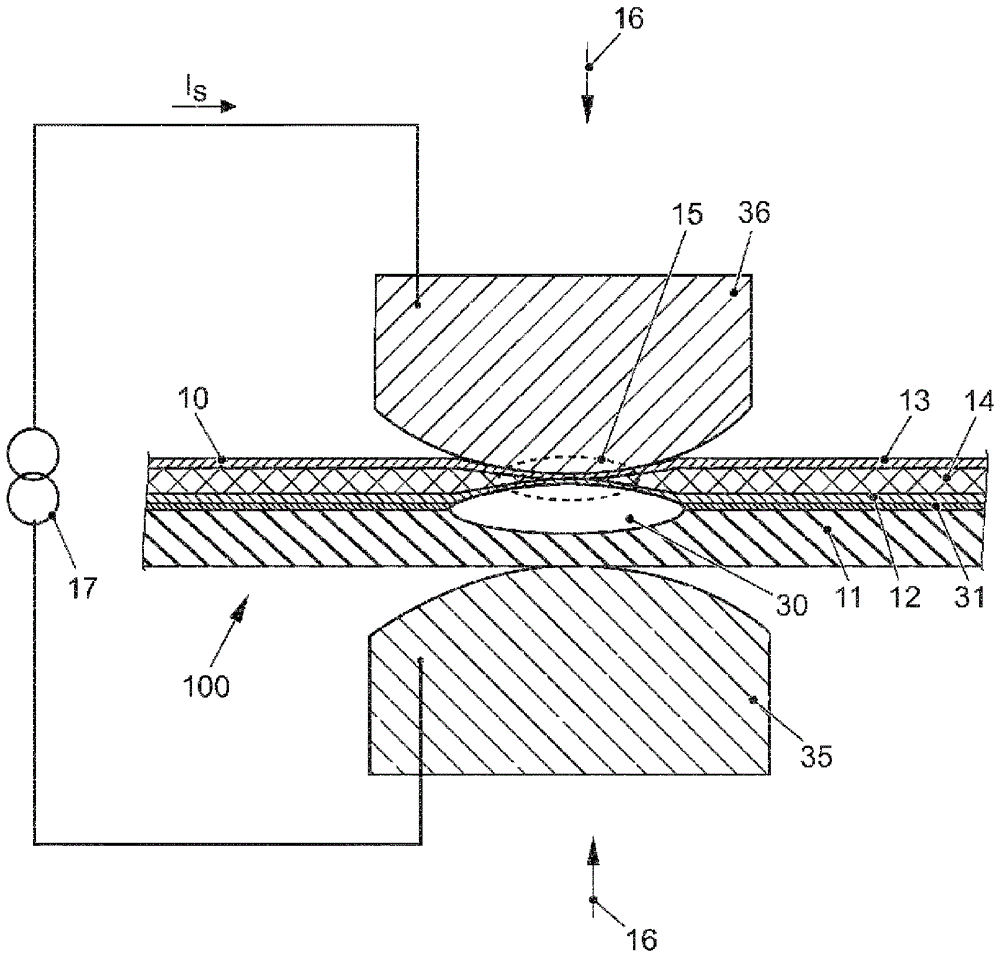

[0053] Figure 1a Method steps a) to c) for preparing the joining point 15 on the first component 10 are shown. The first component 10 is multi-layered and has two plate-like structural elements 12 , 13 and an intermediate layer 14 arranged between the two structural elements 12 , 13 . The intermediate layer is designed as a layer with plastic. In order to connect the first member 10 and the second member 11 (in Figure 1a not shown in ), the joining method must be arranged such that the joining site 15 is prepared before the first member 10 and the second member 11 are connected. It is important here that the intermediate layer 14 is pressed in the region of the joining point 15 so that a contact is produced in this region between the two structural elements 12 , 13 .

[0054] The pressing means 26 , 27 for applying pressure in step b) can be, for example, electrode caps of a welding device. Furthermore, different tools can be used for the individual method steps a) to c). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com