Shaping device and shaping method for roller electrode for seam welding

A roller electrode and shaping device technology, applied in the direction of roller electrode, electrode maintenance, electrode characteristics, etc., can solve the problems of manipulator 101 becoming heavier, manipulator purchase cost of manipulator, manipulator operation cost, etc., so as to reduce the burden and make the shaping device simple , The effect of equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

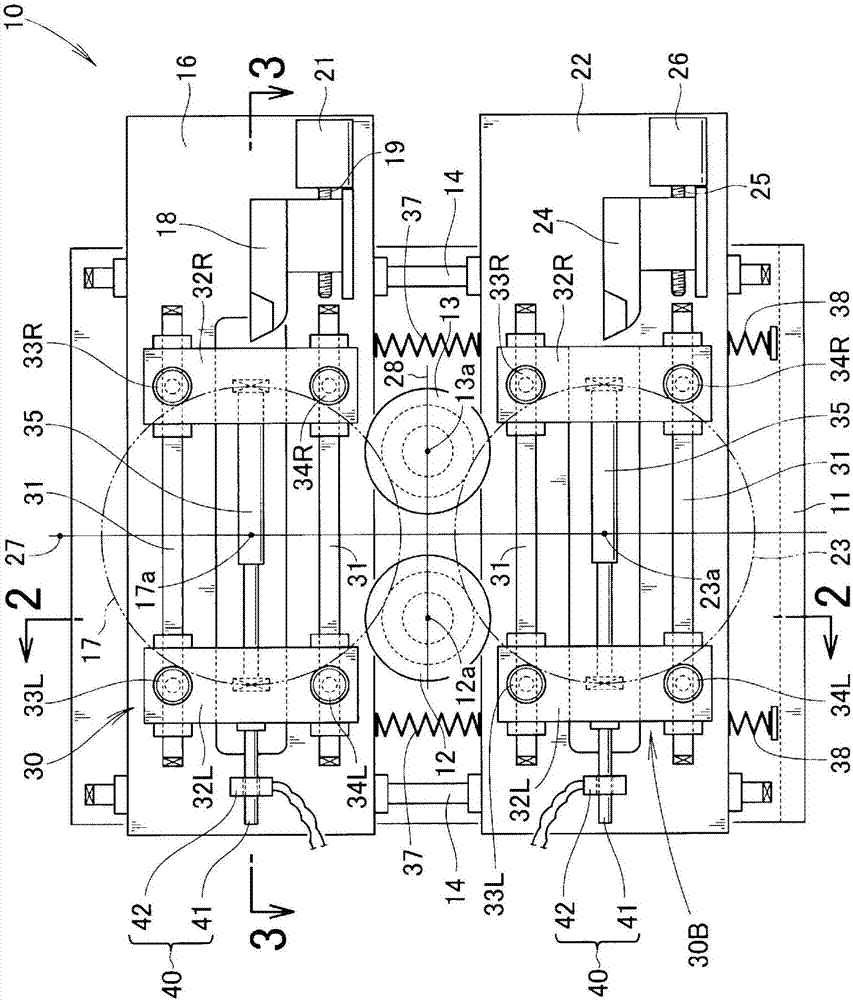

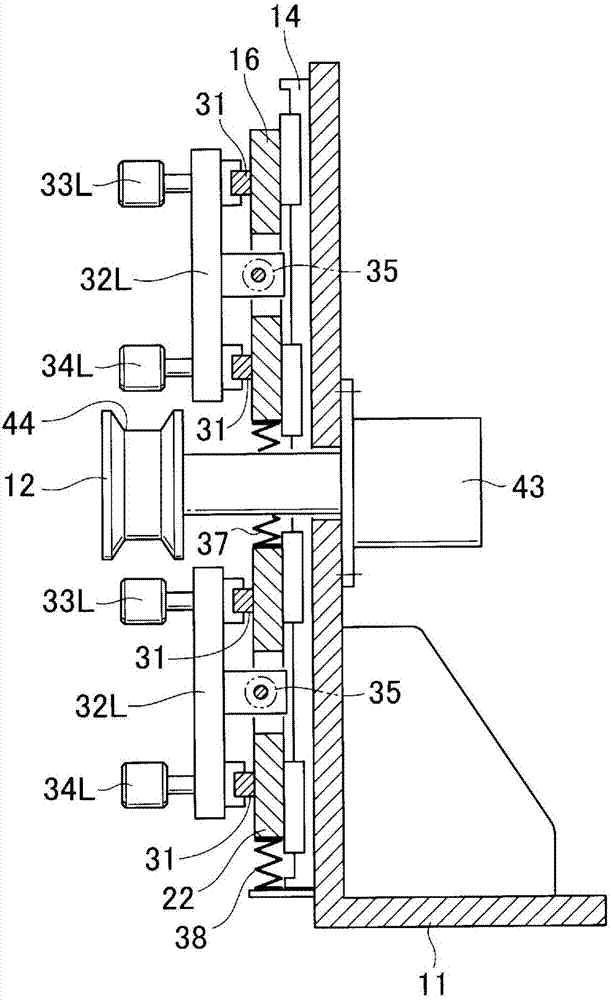

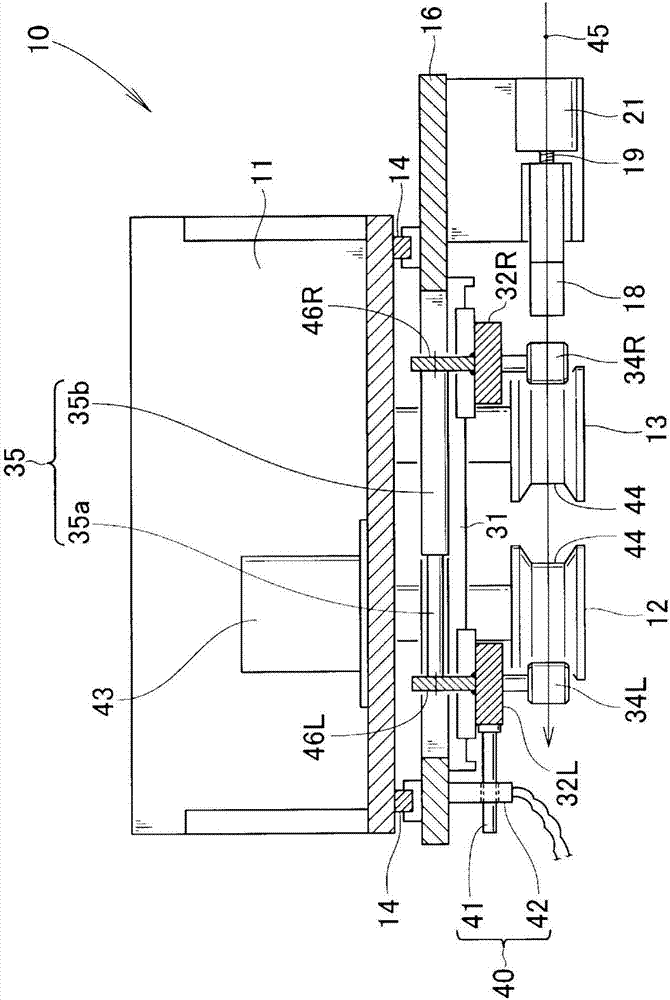

[0061] Such as figure 1 As shown, the shaping device 10 for seam welding roller electrodes includes: a machine platform 11 fixed on a base or a structure; a first roller 12 and a second roller 13 that are rotatably installed in the center of the machine platform 11; Two longitudinal rails 14,14 on the front of the machine table 11; one side (upper side in this example) of the first and second rollers 12,13 is supported on the longitudinal rails 14,14 in a freely movable manner up and down. The first slider 16 on the top; the first clamping mechanism 30 that is arranged on the front of the first slider 16 and clamps the outer periphery of the first roller electrode 17; is arranged on the first slider 16 and cuts the first Tool 18 sends the feed screw 19 sent to the first roller electrode 17 and the rotation mechanism 21 that makes this feed screw 19 rotate; side) the second slider 22 supported on the vertical rails 14 and 14 in a freely movable up and down manner; Mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com