Reinforcement cage welding tool and fixed electrode thereof

A fixed electrode and welding tooling technology, applied in the direction of electrode characteristics, roller electrodes, etc., can solve problems such as replacement and fixed electrode corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

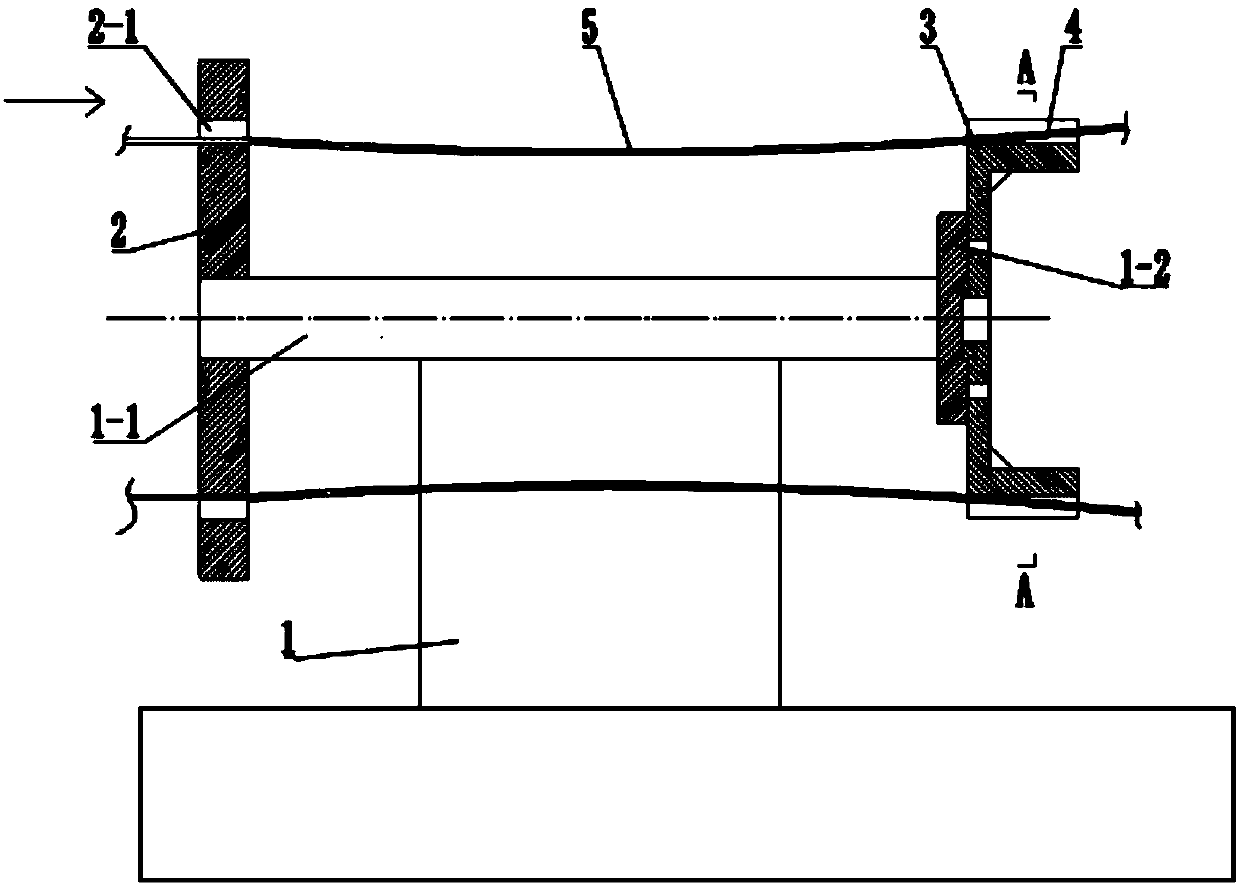

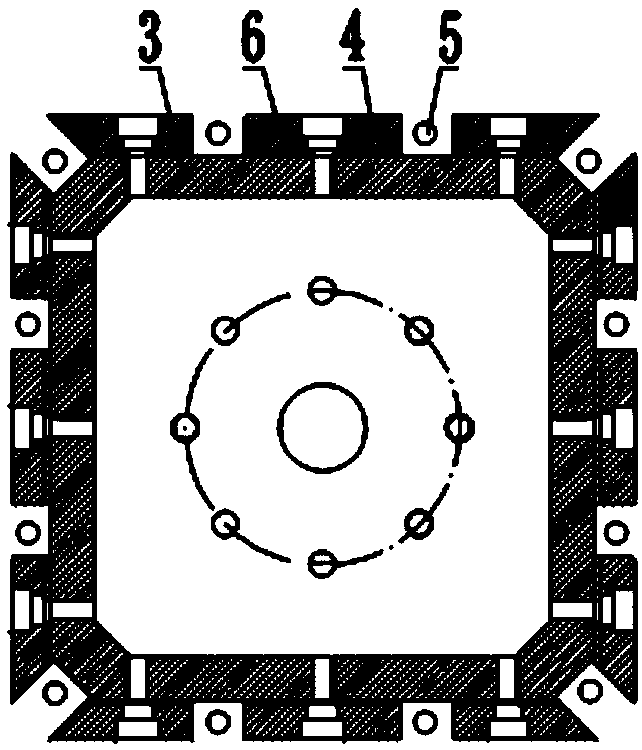

[0039] See attached Figure 1 to Figure 5 , which is the basic structure of the seam welding machine used for square reinforcement cages and circular reinforcement cages in the prior art, please refer to the background technology for details. The following describes the improved parts of the present invention emphatically.

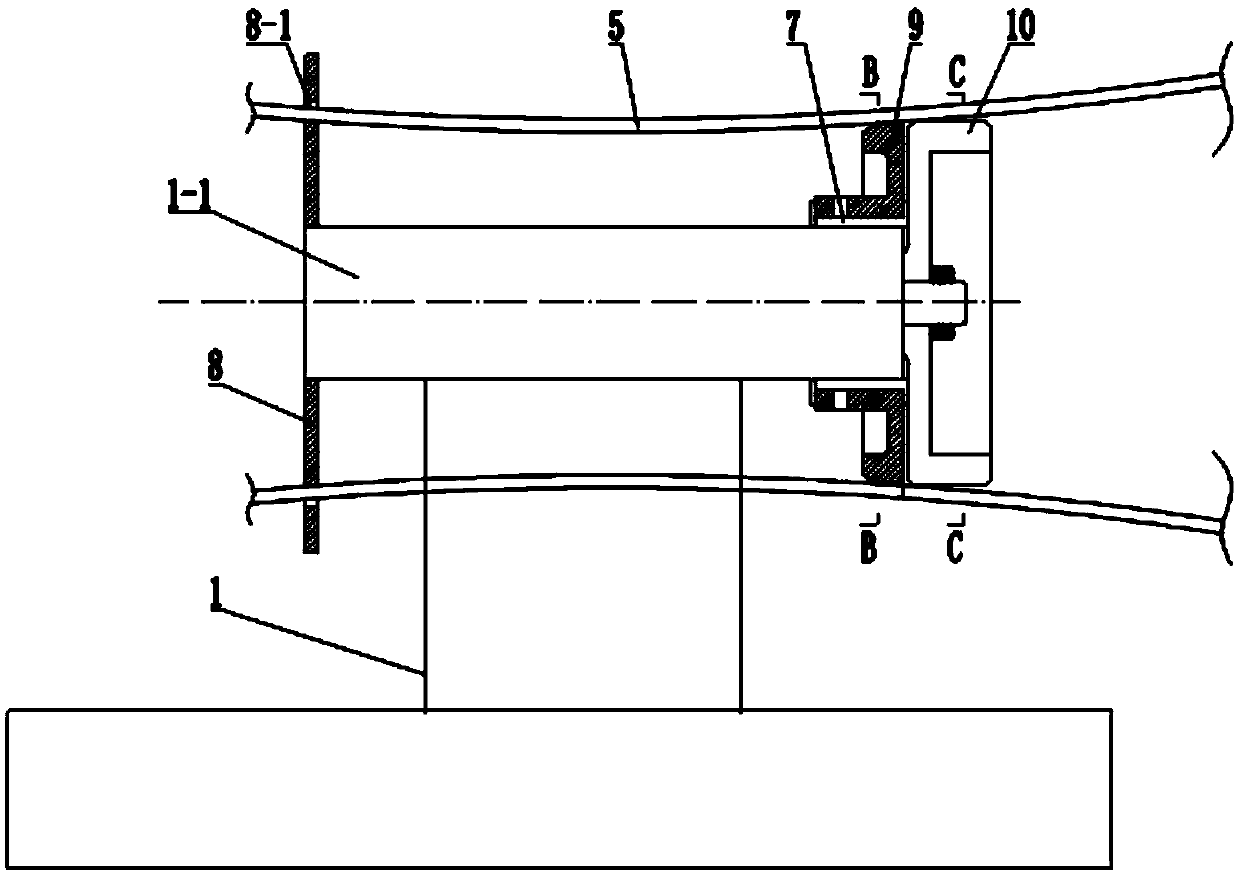

[0040] see Image 6 , Figure 7 , in order to solve the problems existing in the prior art, the present invention provides a steel cage welding tool and its fixed electrode, the fixed electrode is installed on the liner 1-2 at one end of the main shaft 1-1 of the seam welding machine 1, the welding process In the process, the fixed electrode is connected to a power output terminal of the welding machine. After the welding machine is energized, a closed circuit is formed between the fixed electrode, the moving electrode and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com