Cold repair welding machine electrode tip

An electromechanical and cold compensation technology, applied in the direction of electrode features, roller electrodes, etc., can solve the problems of difficult to guarantee welding position, hot electrode hair, low welding efficiency, etc., to ensure the welding effect, large pressing force, and prevent burns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

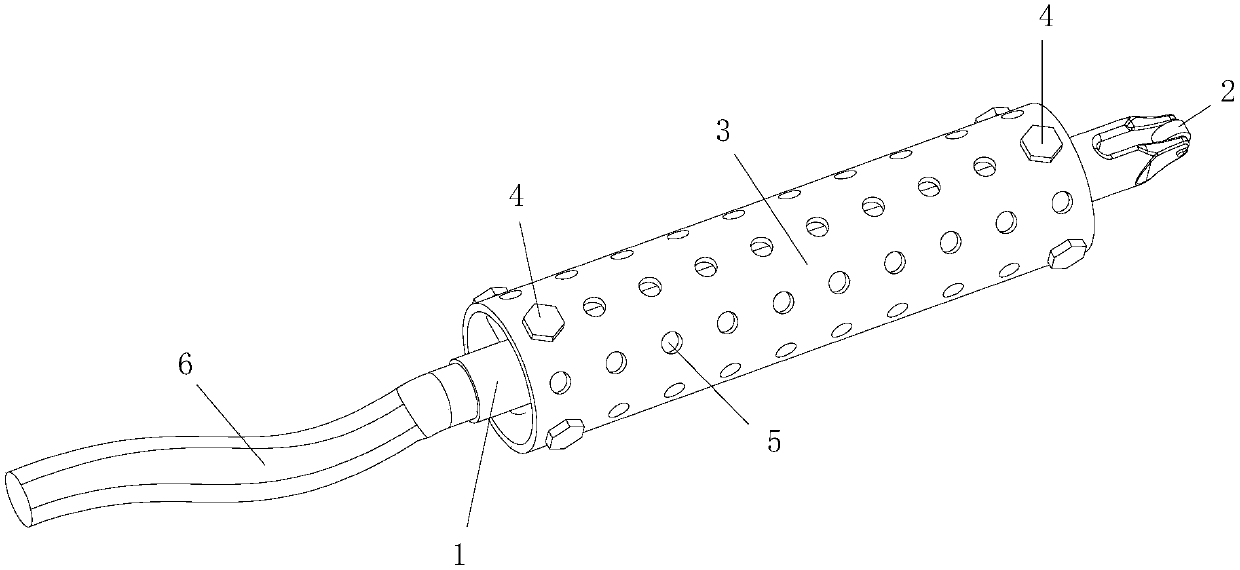

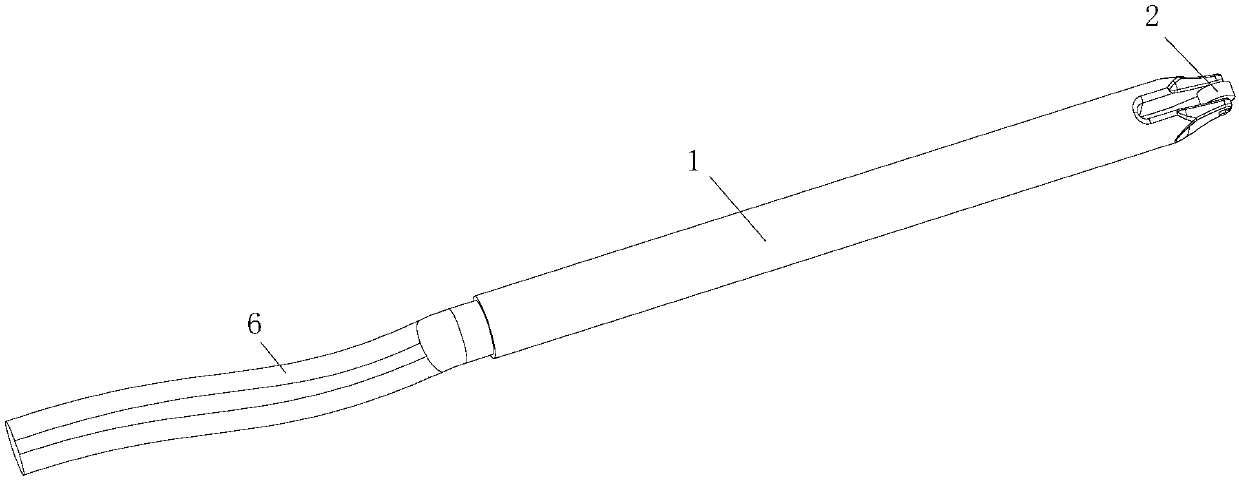

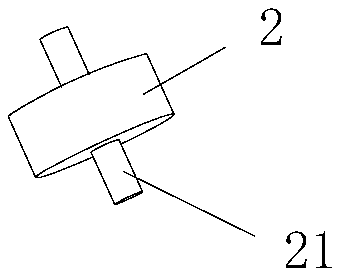

[0038] This embodiment relates to an electrode head of a cold repair welding machine, and its overall structure includes a plug and a hand-held part corresponding to the outer peripheral side of the plug, wherein one end of the plug is a cable connection end, relative to the cable connection end, The other end of the plug is provided with an electrode that can roll and press against the workpiece to be welded. The handle has an extension length along the axial direction of the plug, and the plug is fixed in the handle by a positioning component and is spaced from the handle. The end of the plug with the electrodes is also located outside the handle.

[0039] The electrode tip of the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com