Cooling water circulation structure of seam welder

A technology of cooling water circulation and roll welding machine, which is applied in the direction of roller electrode welding, roller electrode, welding equipment, etc., can solve the problems of steel cage corrosion, affecting the quality of steel cage, affecting the working environment, etc., to improve the service life, Effects of saving costs and recycling water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

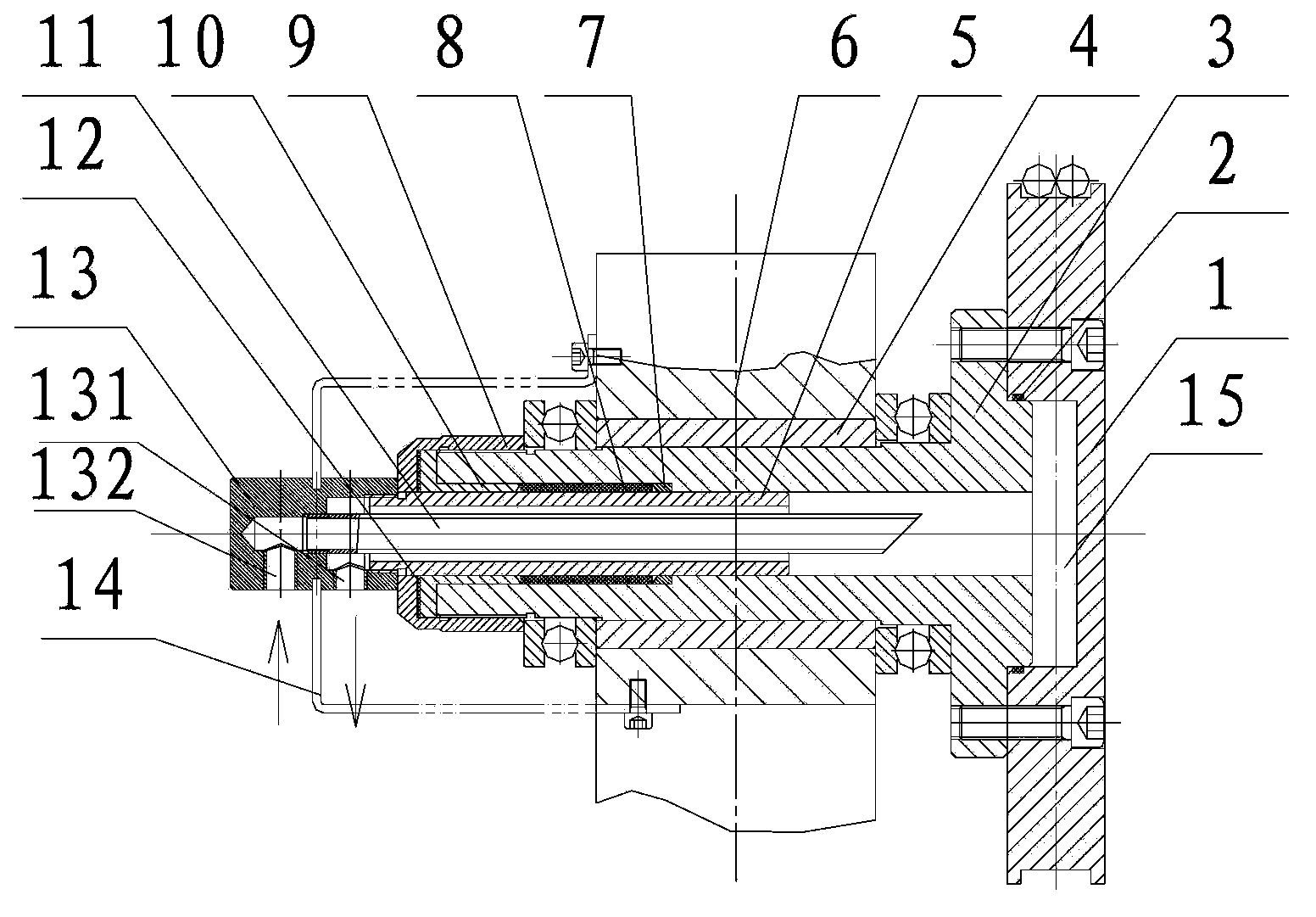

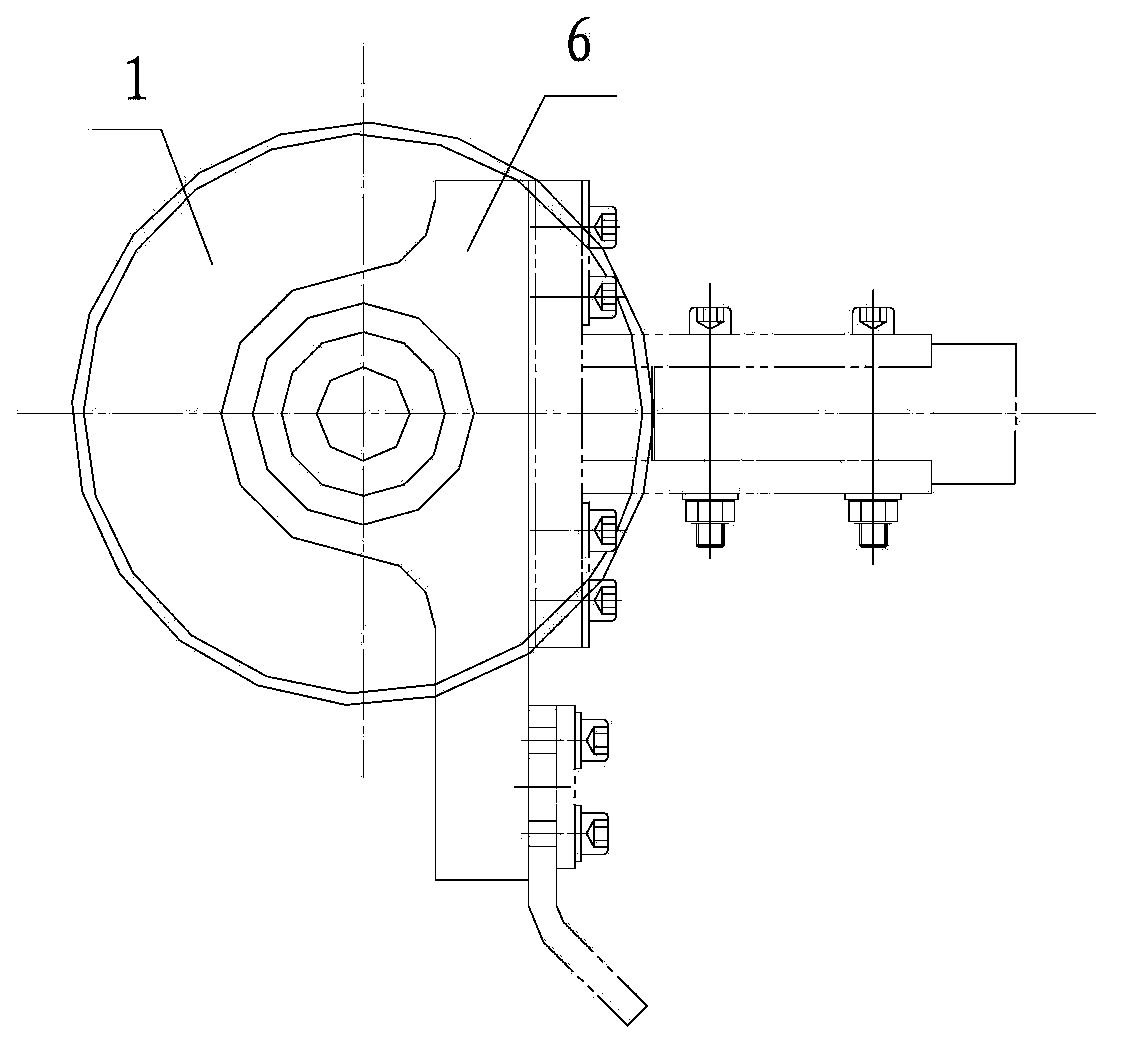

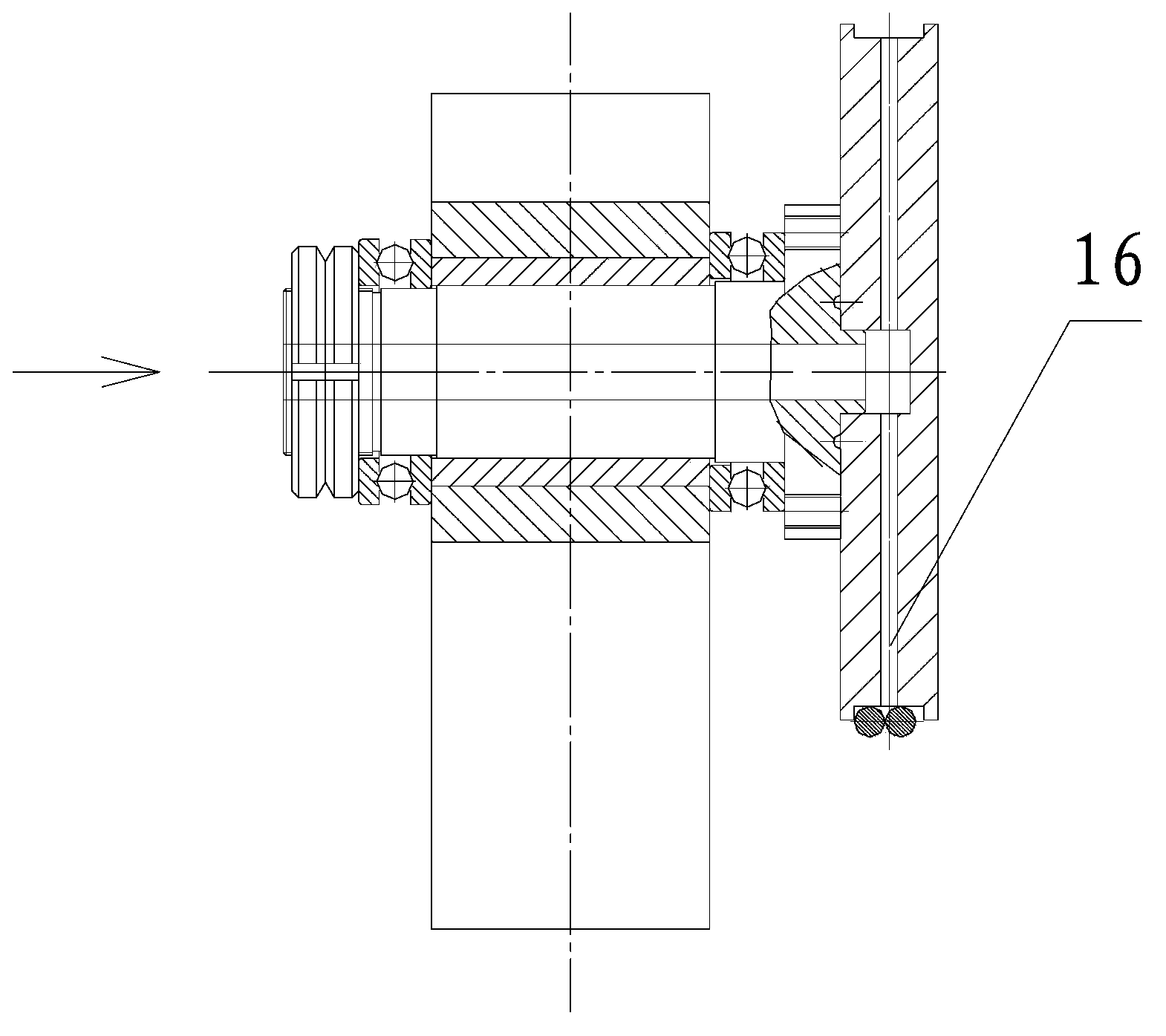

[0019] The invention as Figure 1-2 As shown, the seam welding machine includes a welding wheel 1, an inner cooling head shaft 3 and a welding wheel seat 6 with an axle sleeve 4, the welding wheel 1 and the inner cooling head shaft 3 are coaxial, and the welding wheel 1. Fixedly connect the internal cooling head shaft 3, and the internal cooling head shaft 3 is fixed in the bushing 4 of the welding wheel base 6;

[0020] The inner cooling head shaft 3 is provided with a middle hole, and the end surface of the welding wheel 1 facing the inner cooling head shaft 3 is provided with a cooling hole 15, and the middle hole communicates with the cooling hole 15;

[0021] It also includes a water circulation structure, the water circulation structure is arranged in the middle hole of the internal cooling head shaft 3;

[0022] The water circulation structure includes an outer pipe 5 of the water connection joint and an inner pipe 11 of the water connection joint, and the outer pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com