Robot control device and robot control method

A control device and robot technology, applied in the fields of seam welding seam welding equipment, robot control, and robot control device, can solve the problems such as the separation of the rotating electrode, and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

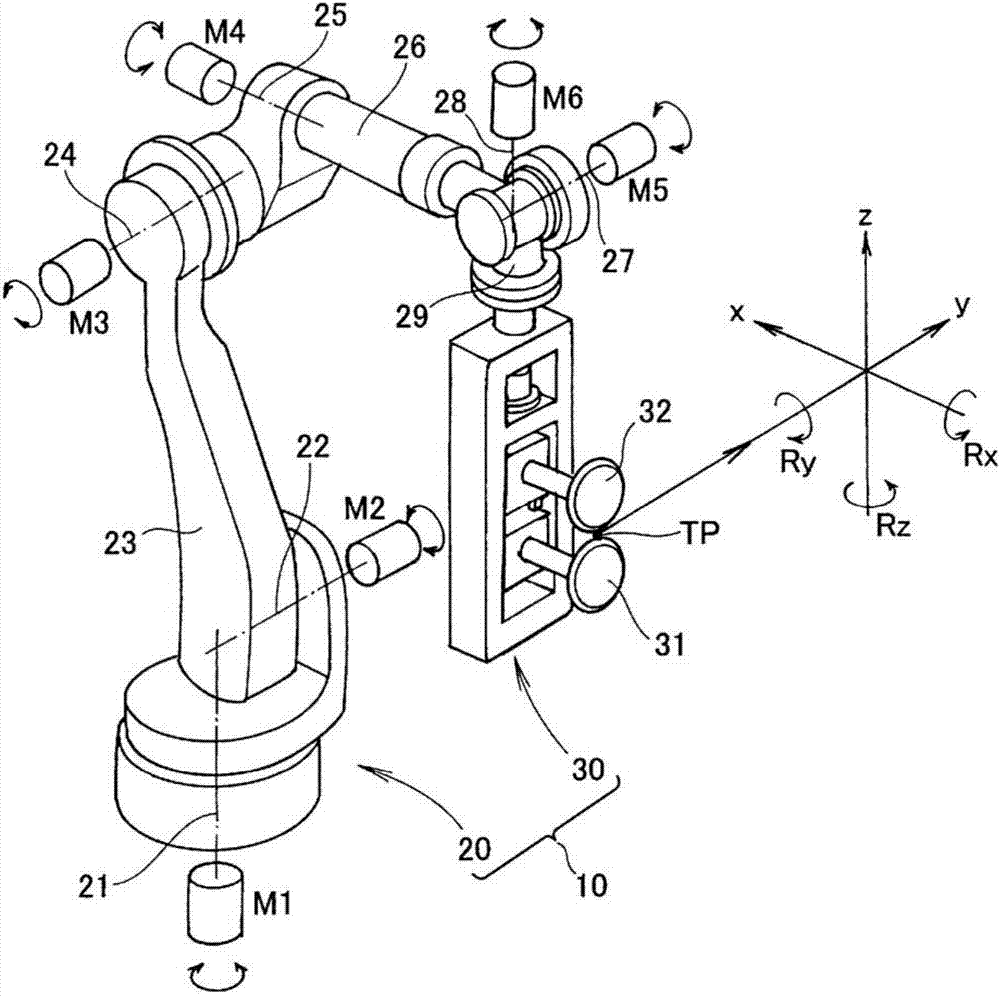

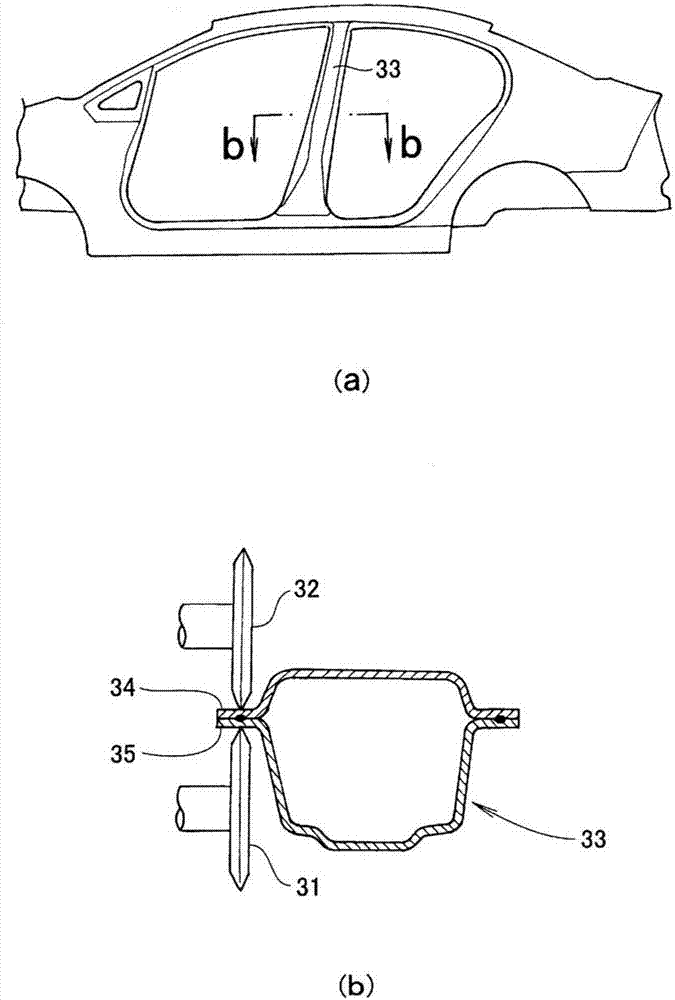

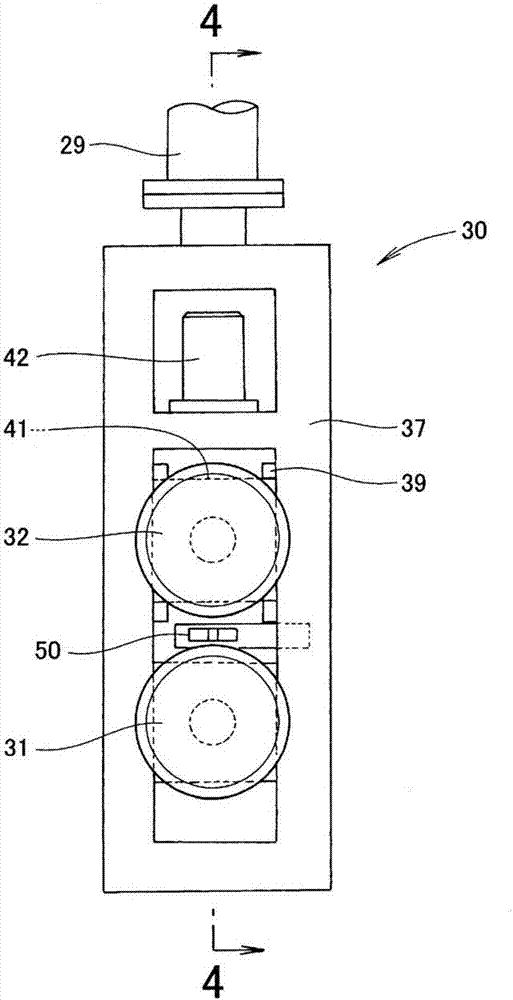

[0040] Such as figure 1 As shown, the seam welding facility 10 is composed of an articulated robot 20 and a welding device 30 attached to the robot 20 .

[0041] The articulated robot 20 is, for example, a six-axis robot composed of a lower arm 23, an upper arm 26, and a wrist 29, wherein the lower arm 23 utilizes a first motor M1 (although the motor is built-in, but for convenience of description , the motor is shown outside. Other motors are also the same.) Rotate around the first axis 21 corresponding to the axis perpendicular to the ground, and swing around the second axis 22 corresponding to the horizontal axis by the second motor M2, so The upper arm part 26 is connected to the front end of the lower arm part 23 via the third shaft 24 and swings around the third shaft 24 by the third motor M3, and swings around the fourth shaft orthogonal to the third s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com