Apparatus for Welding Continuous Strips Wound on a Support Ring

A technology for supporting rings and strips, applied in the field of strip devices, can solve problems such as poor welding, loss of compactness of seals, and increase in size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

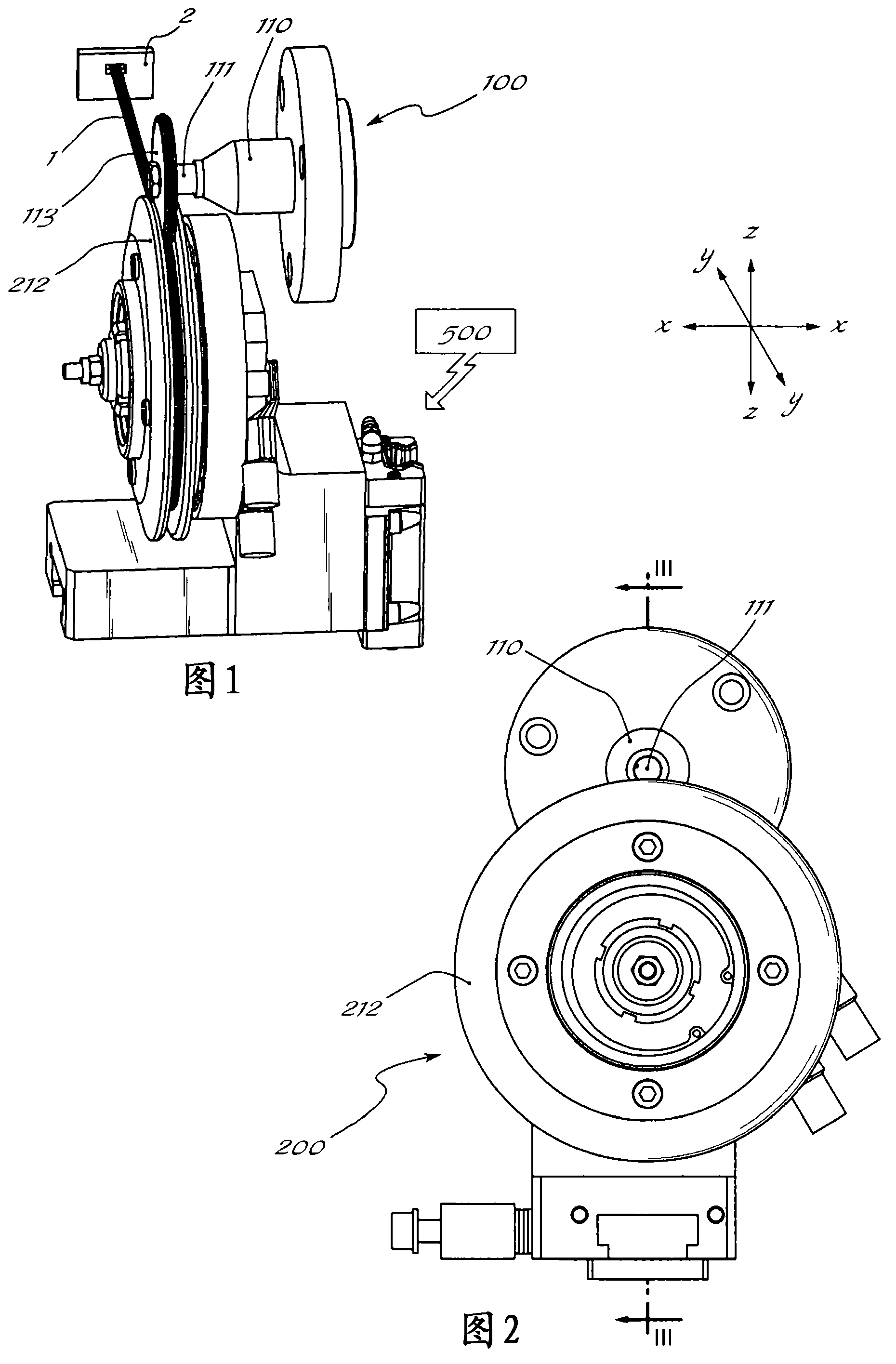

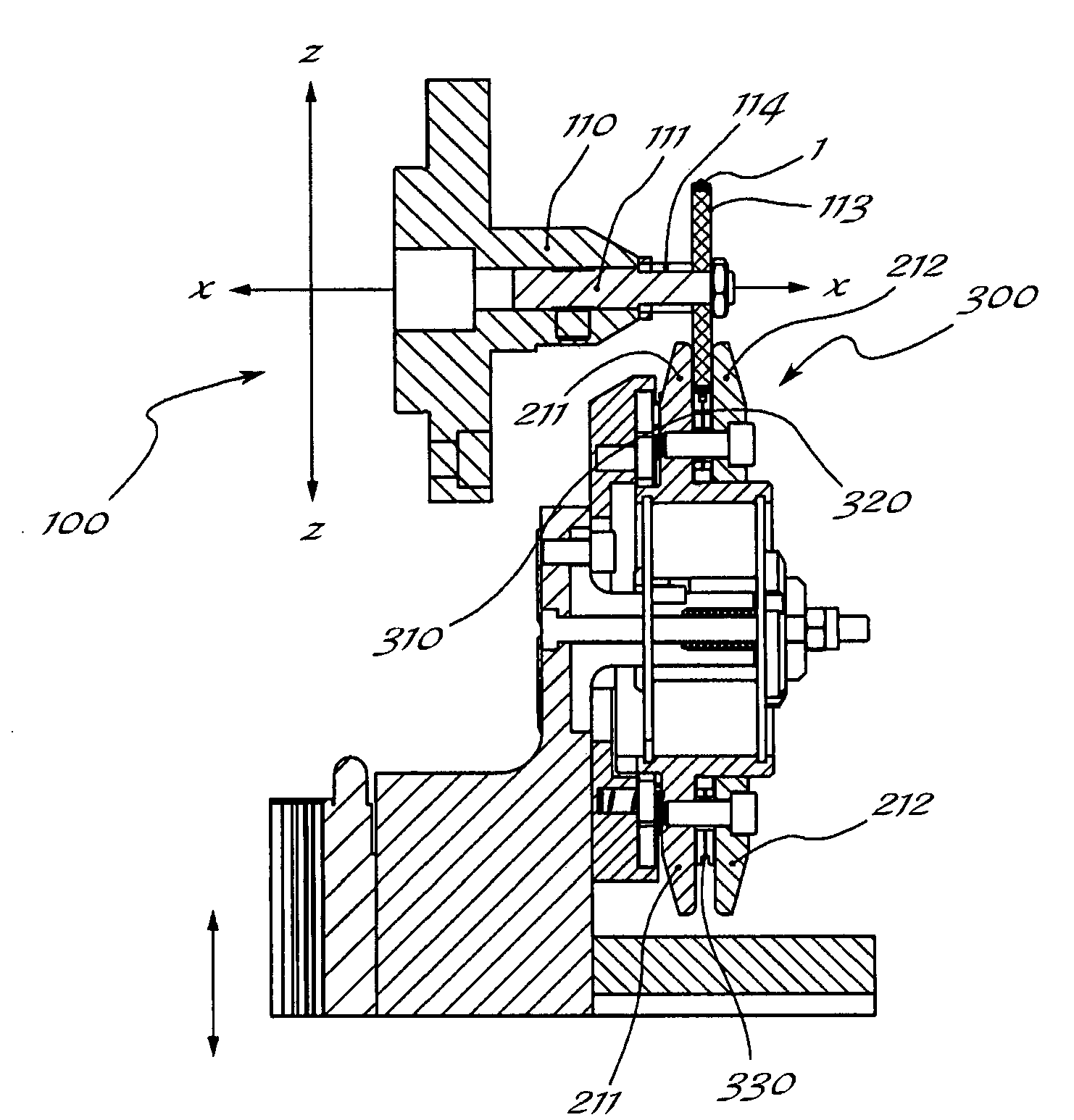

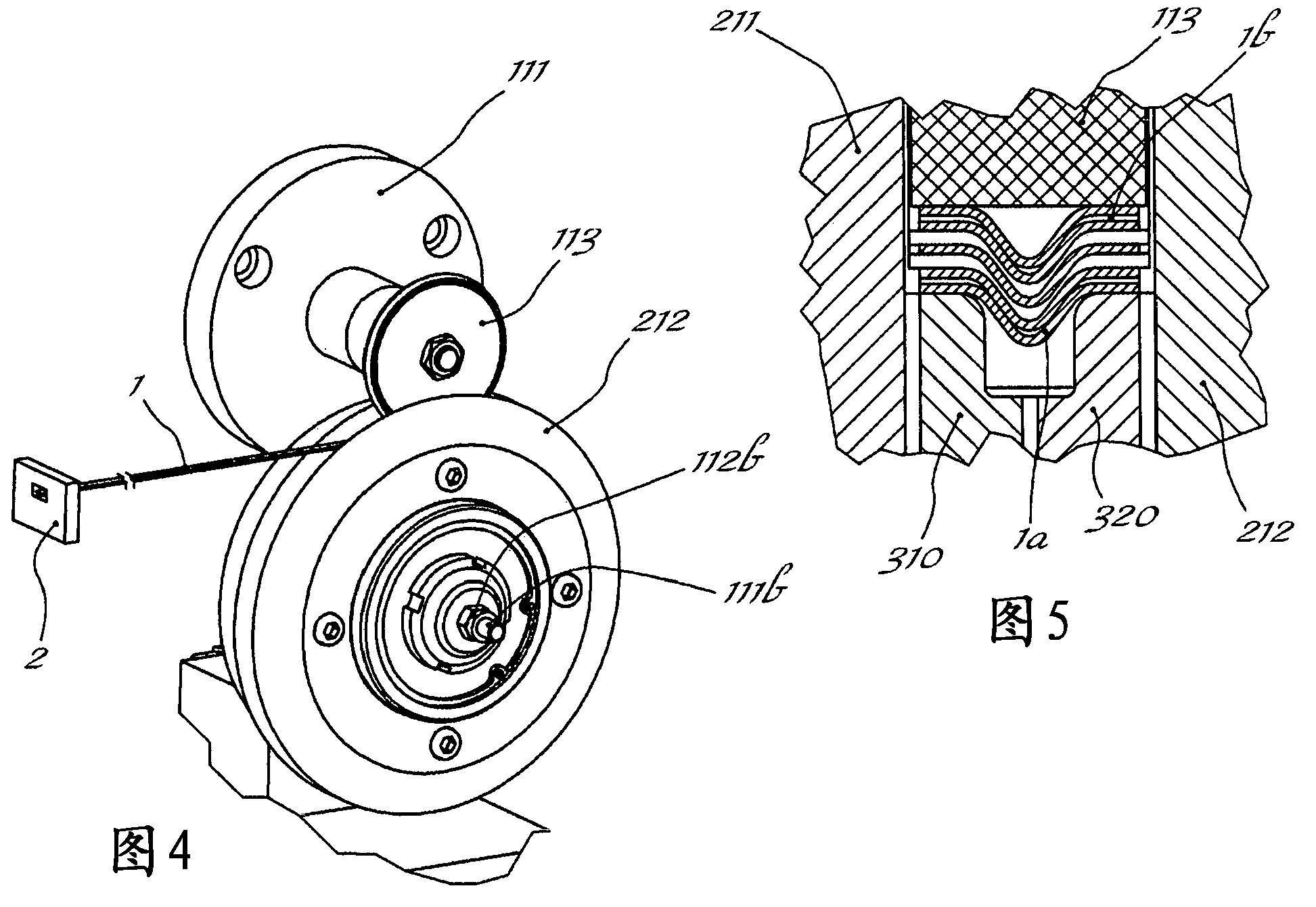

[0020] As shown, for illustrative purposes only and without any limiting meaning, a set of three reference axes are: the longitudinal direction X-X, which corresponds to the axis of rotation of the seal; the vertical direction Z-Z, which is perpendicular to the longitudinal direction and corresponds to the compression and the direction of movement of the welding assembly towards / from the seal; and the radial direction Y-Y, which is perpendicular to the other two directions; the device according to the invention basically comprises:

[0021] Assembly 100 for winding a strip 1, in particular a strip 1a made of a material with optimal mechanical properties, such as steel, and a strip 1b with optimal sealing properties, supplied by feeder 2, which itself is of the usual type and not shown and described in detail, the assembly comprises a mandrel 110 which rotates about a longitudinal axis X-X and which has a A pin 111 for supporting a ring 113 of suitable inner and outer diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com