Rotating electrode of seam welder for welding concrete pile reinforcement cages with different cross sections

A technology of concrete piles and steel skeletons, applied in the direction of roller electrodes, electrode characteristics, welding equipment, etc., can solve the problems of restricting the development and application of special-shaped concrete piles, poor welding effect, low production efficiency, etc., and achieve simple structure and general use Strong, strong welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

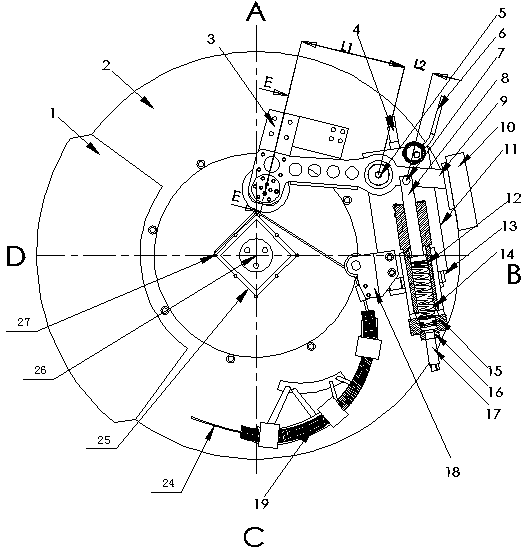

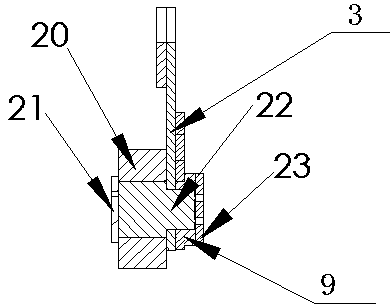

[0028] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0029] attached Figures 1 to 2 It can be seen that a rotary electrode of a seam welding machine for welding the steel skeleton of concrete piles with different cross-sections includes a fixed electrode 25 arranged on the conductive central axis 26 and a rotating disk 2 arranged outside the fixed electrode 25, and the rotating disk 2 is provided with Adjust the sliding seat 13, the adjusting sliding seat 13 is provided with the adjusting slide plate 11; the adjusting sliding seat 13 is provided with the adjusting lead screw 4 for adjusting the position of the sliding plate 11; It is connected with the adjustment slide plate 11; the outer side of the welding arm 9 is connected with the support rod 8 through the positioning pin 7; the support rod 8 is set in the spring guide sleeve 14, and the compression spring 12 is arranged in the spring guide sleeve 14; There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com