Resistance welding electrode capable of conducting locating

A resistance welding and positioning technology, applied in resistance welding equipment, roller electrode welding, roller electrodes, etc., can solve the problems of affecting the sealing of the container, inaccurate marking, affecting the next capping process, etc. The effect of quality, clever idea, reduction of production cost and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

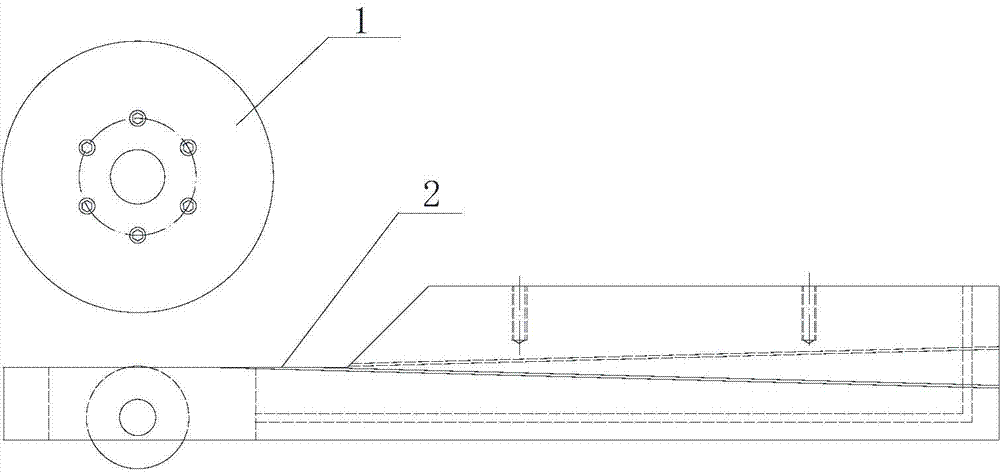

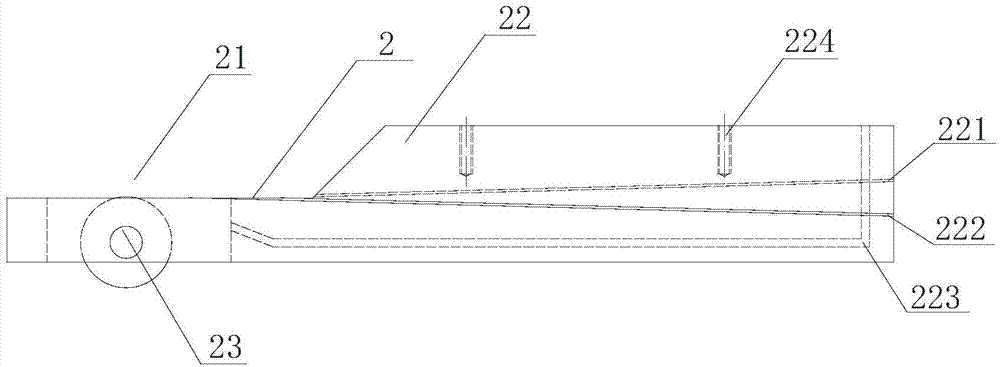

[0020] The present invention as Figure 1-4 As shown, it includes an upper electrode 1 and a lower electrode assembly 2 , the upper electrode 1 is arranged above the lower electrode assembly 2 and can move up and down relative to the lower electrode assembly 2 .

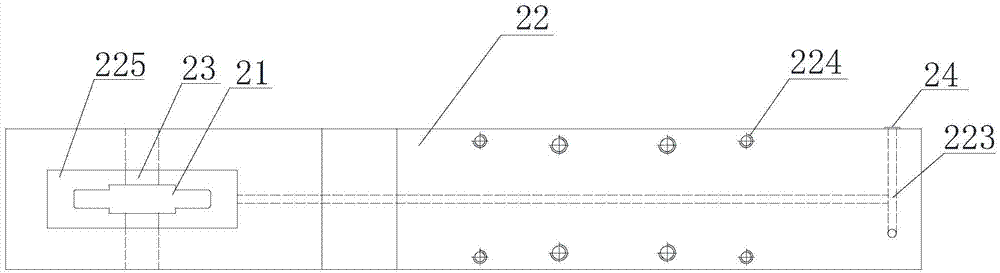

[0021] The lower electrode assembly 2 includes a lower electrode 21 , a positioning block 22 and a shaft pin 23 , and the lower electrode 21 is arranged on the positioning block 22 through the shaft pin 23 .

[0022] The positioning block 22 is provided with a positioning groove 1 221, a positioning groove 2 222, a flow channel 223, an electrode hole 225 and a plurality of fixing holes 224, and the positioning groove 1 221 and the positioning groove 2 222 are respectively located in the positioning The two sides of the block 22, the fixing hole 224 is located on the upper surface of the positioning block 22, for fixing the positioning block 22 on the welding equipment, and the electrode hole 225 is located at one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com