Carbon brush holder assembly for starter and assembling method thereof

A carbon brush holder and starter technology, used in electromechanical devices, electric components, casings/covers/supports, etc., can solve the problems of large current fluctuations, large carbon brushes and commutators, etc., to extend service life, improve Motor performance, easy assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

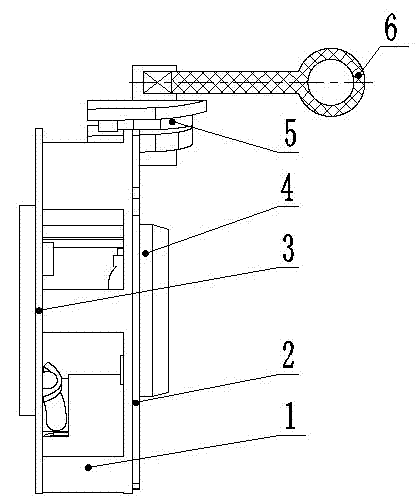

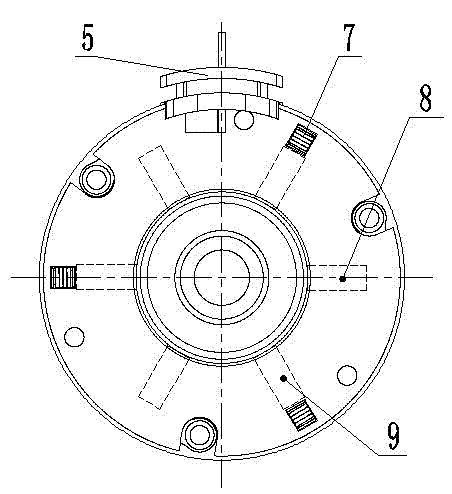

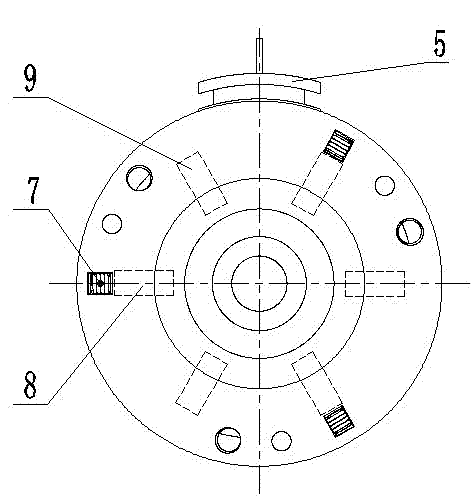

[0039] Such as Figure 1-Figure 3 As shown, the carbon brush holder assembly includes a brush holder box 1, a positive electrode base plate 2 and a negative electrode base plate 3, a positive electrode carbon brush 9 and a negative electrode carbon brush 8 and a spring 7 that drives them to move, an insulating sheath 5, a positive electrode connecting wire 6 and Carbon brush temporary fixing ring 4. The brush holder box 1, the positive base plate 2 and the negative base plate 3 are correspondingly provided with coaxial hollow holes for the starter shaft to pass through. Before assembly, the carbon brush temporary fixing ring 4 is installed in the coaxial hollow holes. There are three positive electrode carbon brushes 9 and three negative electrode carbon brushes 8 , which are respectively welded on the positive and negative electrode base plates 2 and 3 .

[0040] Such as Figure 4-Figure 6 As shown, the brush holder box 1 is one-time injection molding, and it is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com