Plasma display panel with simultaneous address drive operation and sustain drive operation

A plasma and driving operation technology, applied in static indicators, components of color TVs, components of TV systems, etc., can solve the problem of increased noise signal radiation, complicated and expensive installation, and failure of increased circuit control, etc. problem, to achieve the effect of reducing current fluctuation and increasing driving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0067] Fig. 5 is a diagram for explaining the basic principle of the present invention. In FIG. 5, for convenience of explanation, 10 display lines L1 to L10 are provided, and one frame is composed of 10 sub-frames. This configuration is not a limiting example, and the present invention is equally applicable to configurations with other numbers of display lines and other numbers of subframes.

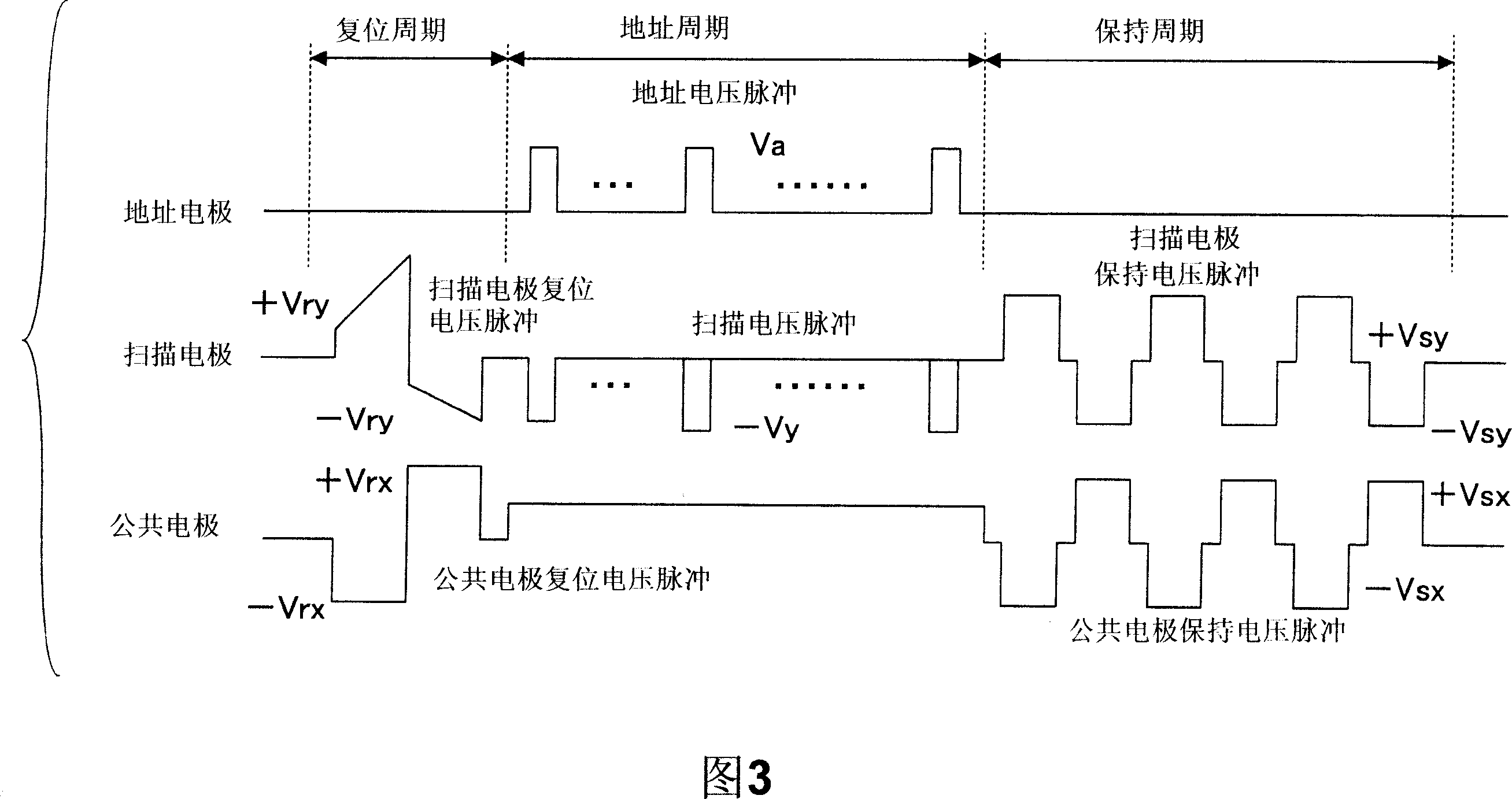

[0068] As shown in FIG. 5, one frame of 16.667 ms is divided equally to provide subframes SF1 to SF10 of equal length (1.667 ms). Each sub-frame is composed of three types of driving operations, namely, a reset driving operation, a scan driving operation (address driving operation), and a sustain driving operation.

[0069] The driving operation starts from the first sub-frame SF1. At the beginning of this subframe, a reset driving operation is performed for all display lines, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com