High-power DC voltage converter

A boost converter and power electronics technology, which is applied in the direction of high-efficiency power electronic conversion, DC power input conversion to DC power output, output power conversion device, etc., can solve relatively expensive problems and achieve the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

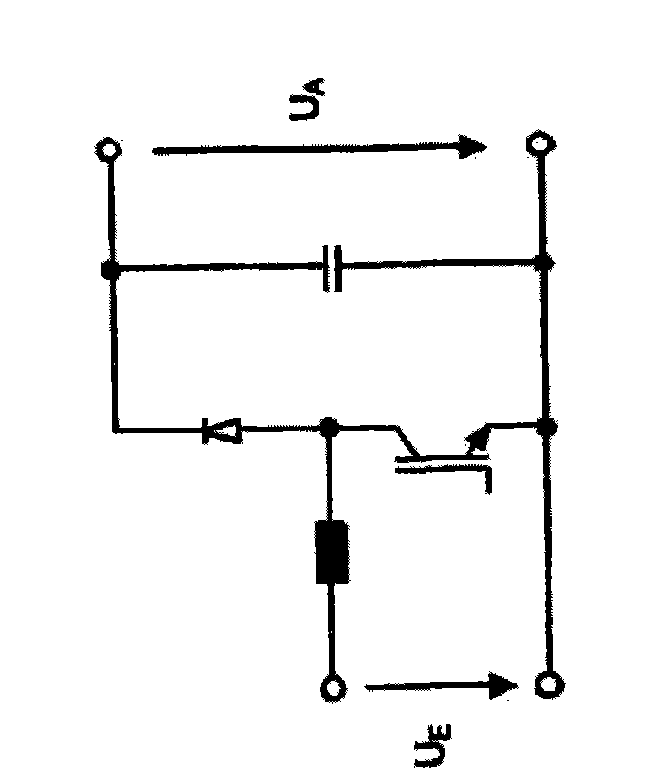

[0021] exist figure 1 The boost converter switching circuit is shown in , which operates from a relatively low input voltage U E generate a higher output voltage U A . The boost converter switching circuit basically consists of an inductor in the form of a coil, a diode and an energy storage capacitor. The inductance can be temporarily grounded by means of bipolar transistors, MOSFETs or IGBTs. When the switch is open, the inductor tries to maintain the current flow. The voltage thus rises until it exceeds the output voltage U across the capacitor A and the diode conducts. Thereafter at a first instant the current flows unchanged and charges the capacitor. At this point the magnetic field of the inductor weakens, transferring its energy to the capacitor and possibly a downstream load. The problem with this type of circuit is that the transistor has to be turned on under load, which causes corresponding switching losses.

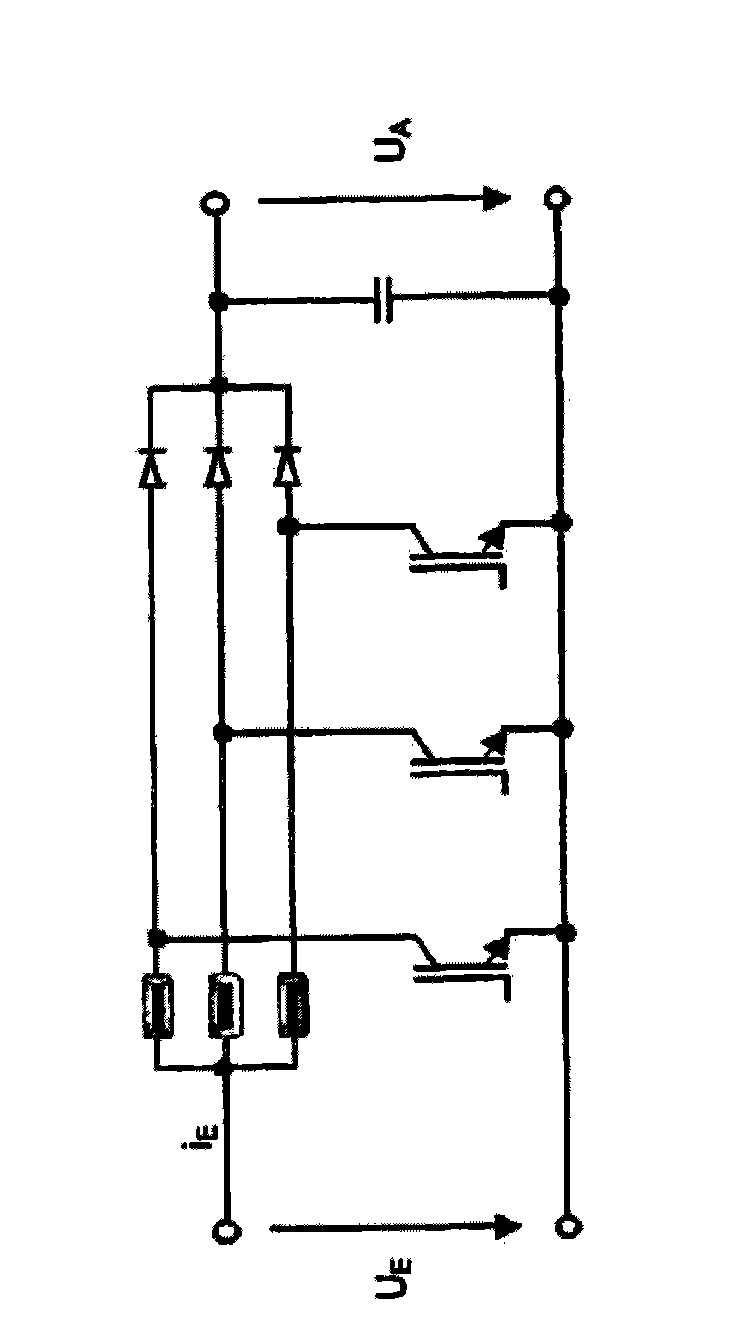

[0022] figure 2 shown with figure 1 power el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com