Independently-targeted hole-free socket

A split-type, socket technology, applied in electrical components, coupling devices, circuits, etc., can solve problems such as loss of elasticity, spark flashover, virtual connection floating, etc., to increase power consumption, improve safety performance, and avoid jacks. relaxing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The detailed structure of the present invention is described below in conjunction with embodiment and accompanying drawing thereof, but the present invention is not limited to following embodiment, and various combinations are implemented in the design frame of the present invention, all within the scope of effective protection.

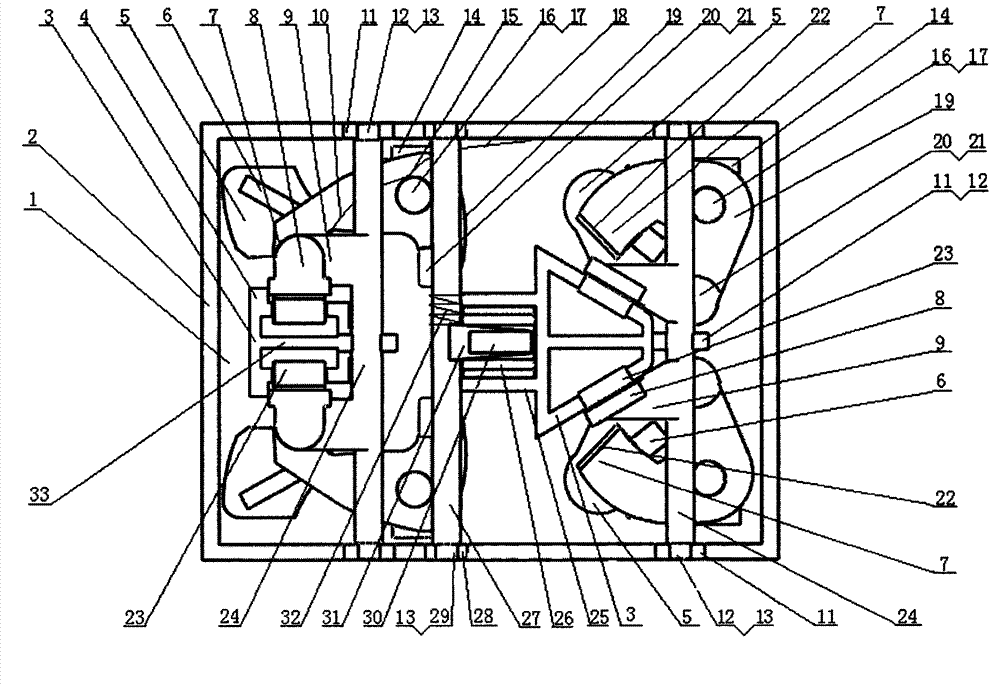

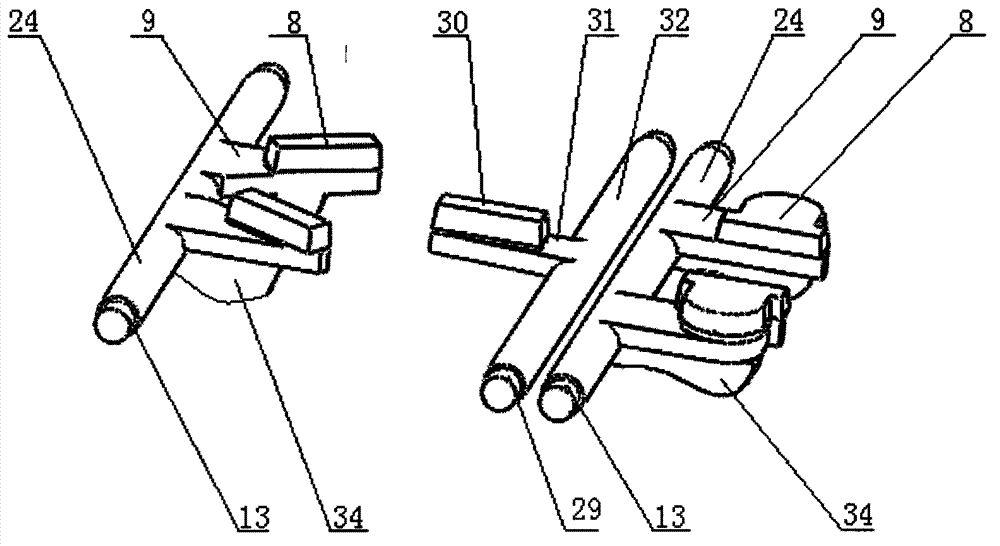

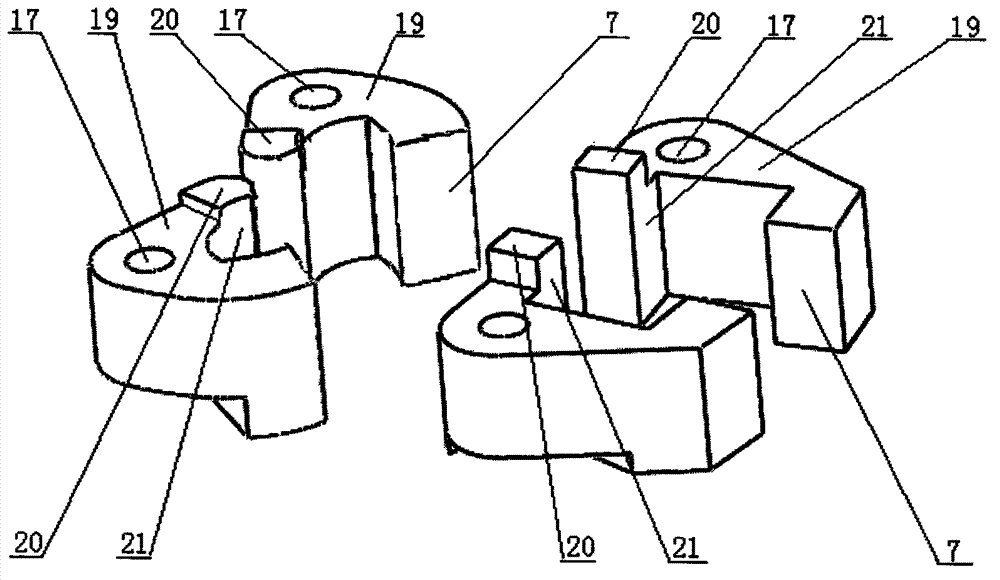

[0037] figure 1 Described is a kind of sub-guide non-porous socket, and the present invention includes: fixed conductive sheet installation device, rotating conductive sheet installation device, protective door device, socket base 1, socket cover 40, it is characterized in that: said protective door device Including, protecting door shaft 24 (see figure 2 ), protection door shaft frame 11, protection door 9, hole blocking plate 8, cam 34, driving lever 72, oblique stay rod 79, oblique spring 76, oblique stay box 77, and said rotating conducting sheet 22 installation devices include: Frame 19, (see image 3 ) Rotary frame head 7, rotary fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com