Probe card, test equipment comprising probe card, and test method

A technology for testing equipment and probe cards, applied in the field of probe cards, can solve problems such as low test accuracy, damage to semiconductor chips, ignition of semiconductor chips, etc., to avoid the phenomenon of ignition, ensure safety, and improve test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

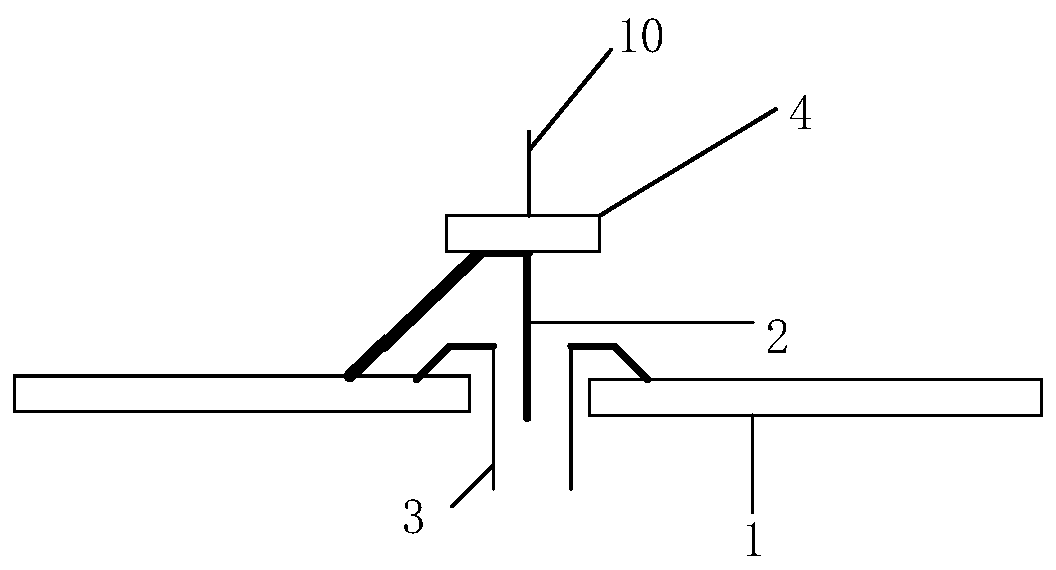

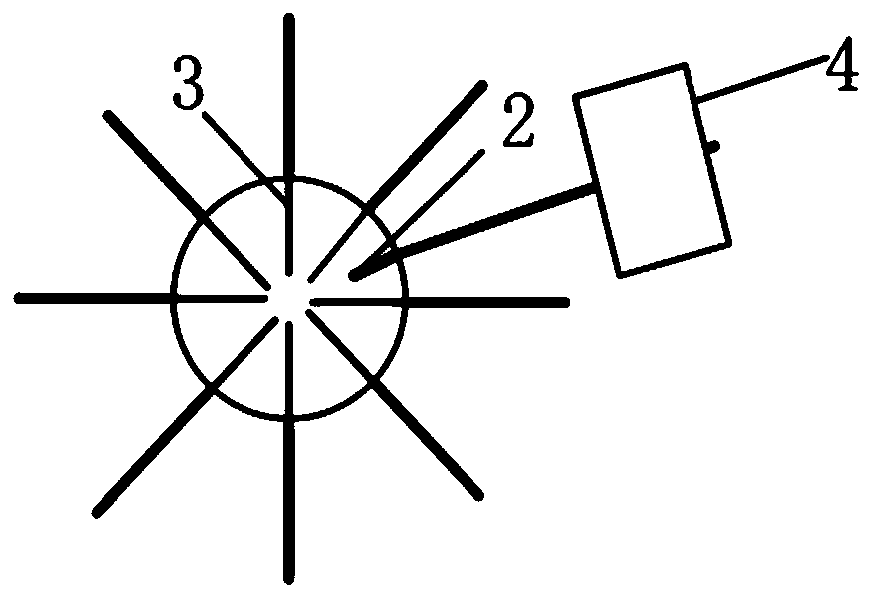

[0046] Embodiment 1 of the present invention provides a probe card, its cross-sectional view and top view are as follows figure 1 and figure 2 As shown, the probe card includes a PCB board 1, a hollow needle 2 and a probe 3; the hollow needle 2 and the probe 3 are respectively connected to the PCB board 1, and the hollow needle 2 and the probe 3 are adjacently arranged; the hollow needle 2 is used for For spraying the flame retardant gas, the flame retardant gas in Embodiment 1 of the present invention can be nitrogen.

[0047] The probe card provided by Embodiment 1 of the present invention also includes a pressure chamber 4 ; the needle tail of the hollow needle 2 is placed in the pressure chamber 4 .

[0048] The probe card provided by Embodiment 1 of the present invention also includes a first support arm and a second support arm; the hollow needle 2 is connected to the contact point provided on the PCB board 1 through the first support arm, and the probe 3 is connected ...

Embodiment 2

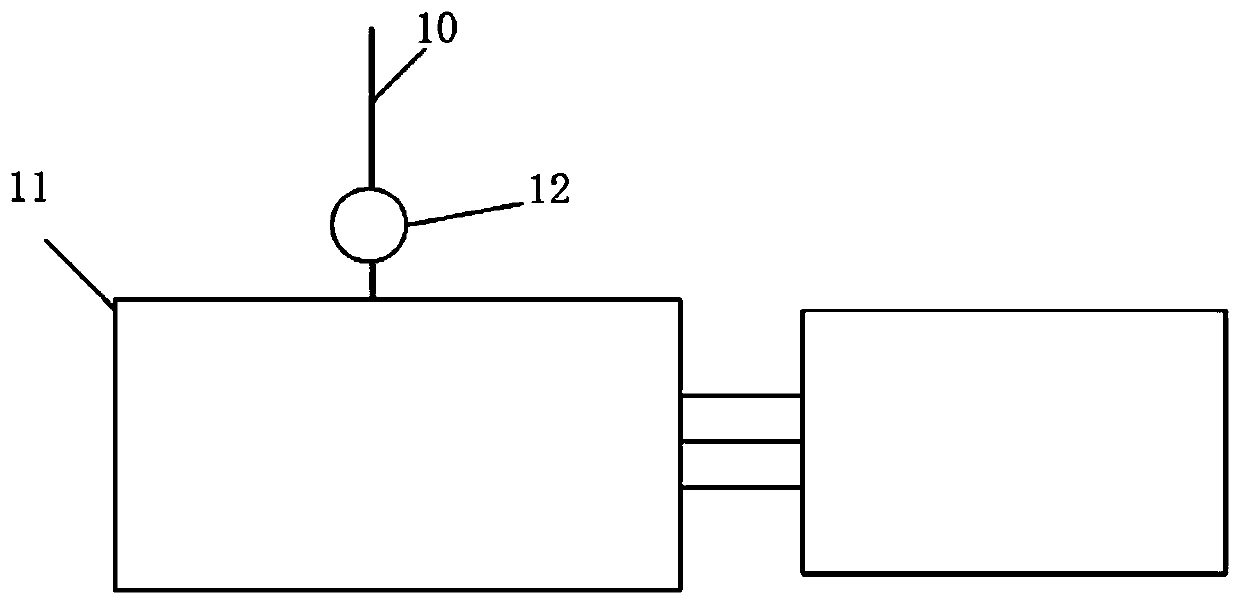

[0057] Embodiment 2 of the present invention provides a test device, including a probe card, a pipeline 10 and a high-pressure test device 11; the specific connection relationship is: the pressure chamber 4 of the probe card is connected to the nitrogen pipeline 10, and the probe card passes through the interface Insert the high-voltage testing device 11, and the pipeline 10 is filled with flame-retardant gas.

[0058] The pipeline 10 is provided with a pressure regulating valve 12 for adjusting the pressure of the flame retardant gas according to the conditions of the tested products.

[0059] The above-mentioned high-voltage test device 11 includes a high-voltage direct current source, a detection device and a slide table; the high-voltage direct current source is connected to the detection device to provide power for the detection device; the detection device is provided with a card slot, and the probe card is inserted into the card slot through the interface The slide table ...

Embodiment 3

[0061] Embodiment 3 of the present invention provides a method for testing a semiconductor chip to be tested by using the test device of Embodiment 2. The specific process is as follows:

[0062] S101: placing the probe card in the high voltage testing device 11;

[0063] S102: placing the semiconductor chip to be tested on the carrier stage of the high voltage testing device 11;

[0064] S103: Open the pressure regulating valve 12, and adjust the pressure of the flame retardant gas in the pipeline 10 to a preset pressure value (such as 0.01mpa) according to the demand of the semiconductor chip to be tested;

[0065] S104: Adjust the height of the slide table so that the probe 3 of the probe card is in contact with the semiconductor chip to be tested;

[0066] S105: Turn on the high voltage testing device 11 to test the static parameters of the semiconductor chip to be tested.

[0067] For the convenience of description, each part of the device described above is divided int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com