Series electric machine with electric braking function

A series-excited motor and electric braking technology, which is applied in the deceleration device of DC motor, electric motor/converter plug, etc. Small braking current, reducing spark effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

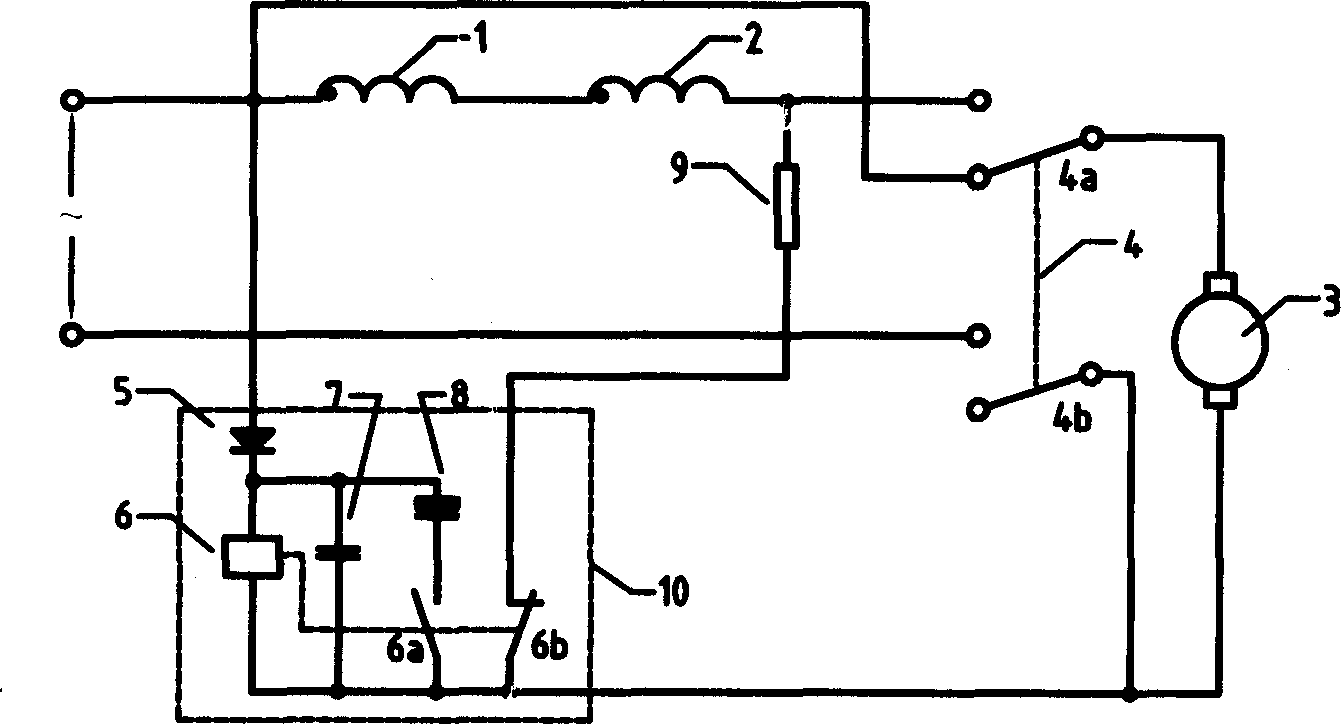

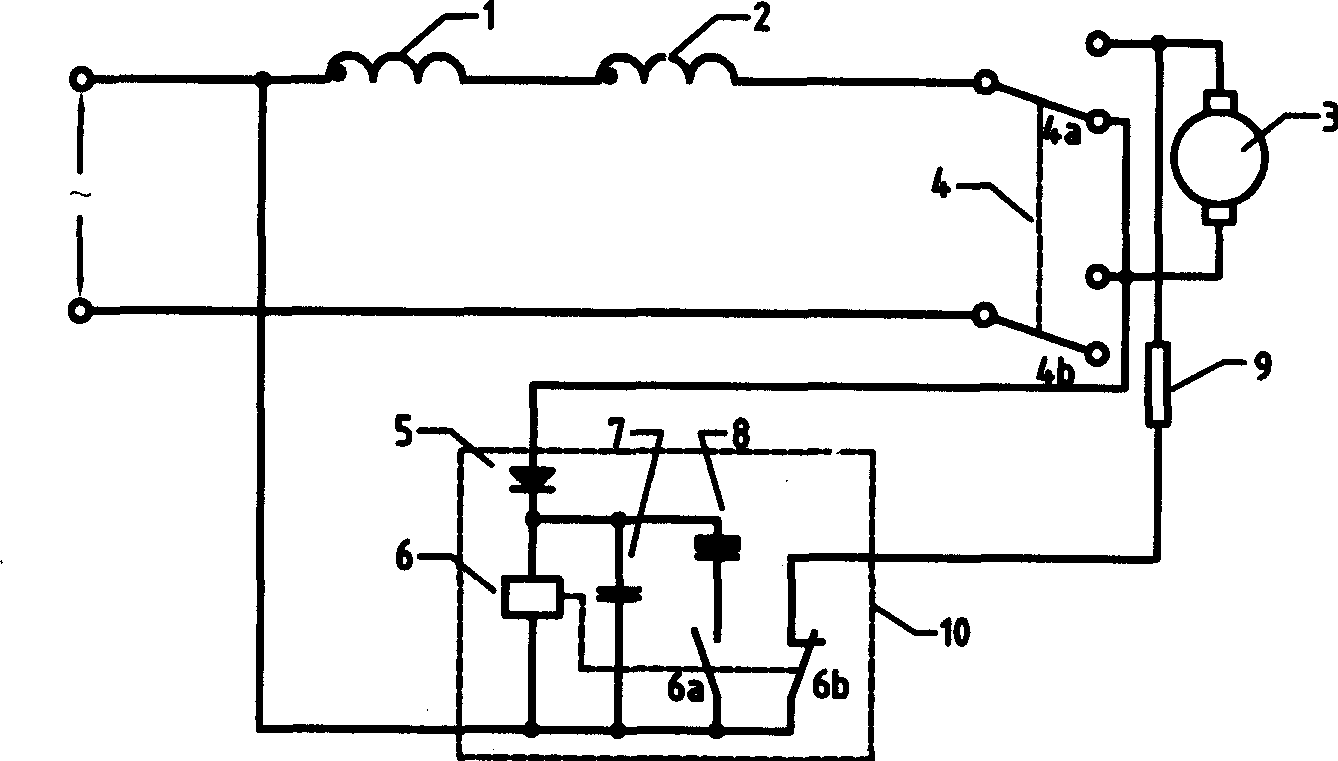

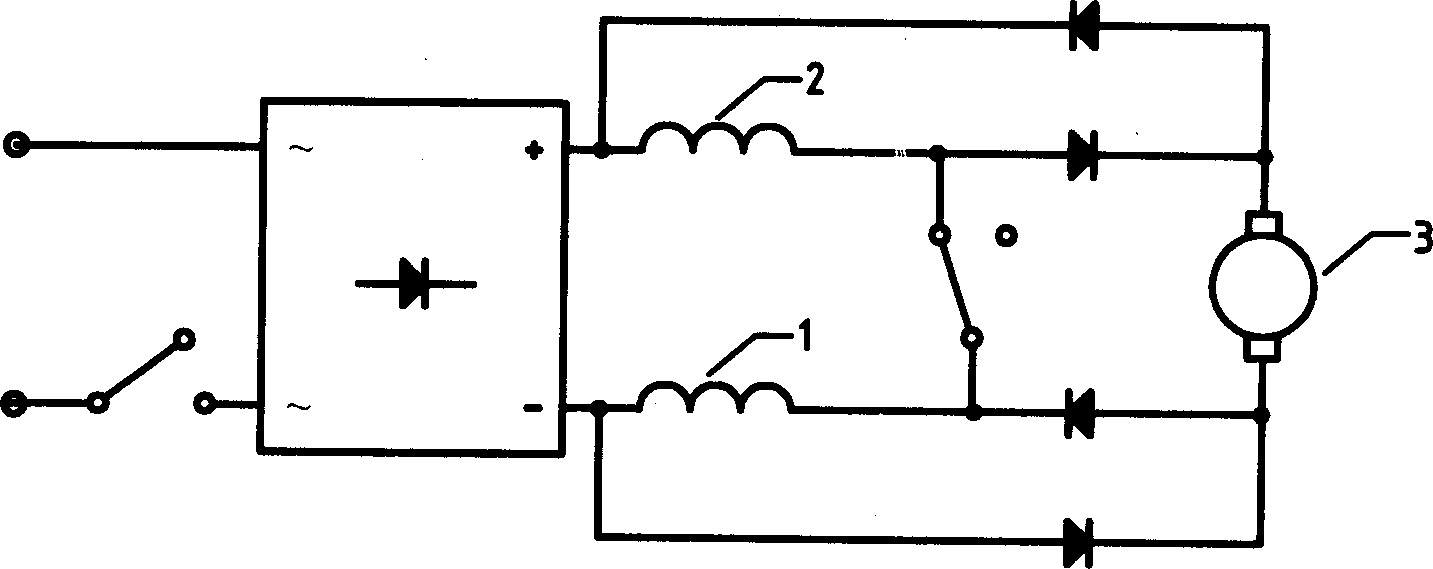

[0015] like figure 1 As shown, the excitation windings 1 and 2 are connected in series, and the open-circuit reverse connection switch 4 is a double-pole double-throw switch, of which one pole 4b is used as a power switch, and the common terminal of the other pole 4a is connected in series with the armature 3, and the two contacts are respectively connected to the series-connected excitation winding The two ends of 1 and 2 are connected, and the delay control device 10 is composed of diode 5, relay 6, filter capacitor 7, and electrolytic capacitor 8. The diode 5 and relay 6 are connected in series, and the filter capacitor 7, electrolytic capacitor 8 and relay 6 are connected in parallel. When the control device 10 is connected to the power supply, when the power supply is turned on, the normally open contact 6a of the relay 6 is closed, the normally closed contact 6b is disconnected, the power supply charges the electrolytic capacitor 8, and when the power supply is disconnect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com