Brushless synchronous communicating DC hub motor

A technology of in-wheel motors and commutators, applied in the direction of motors, DC commutators, circuits, etc., can solve the problems of inability to directly apply the electric system of electric vehicles, impracticability, and reduced efficiency, and achieve small sparks, high motor efficiency, and The effect of low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

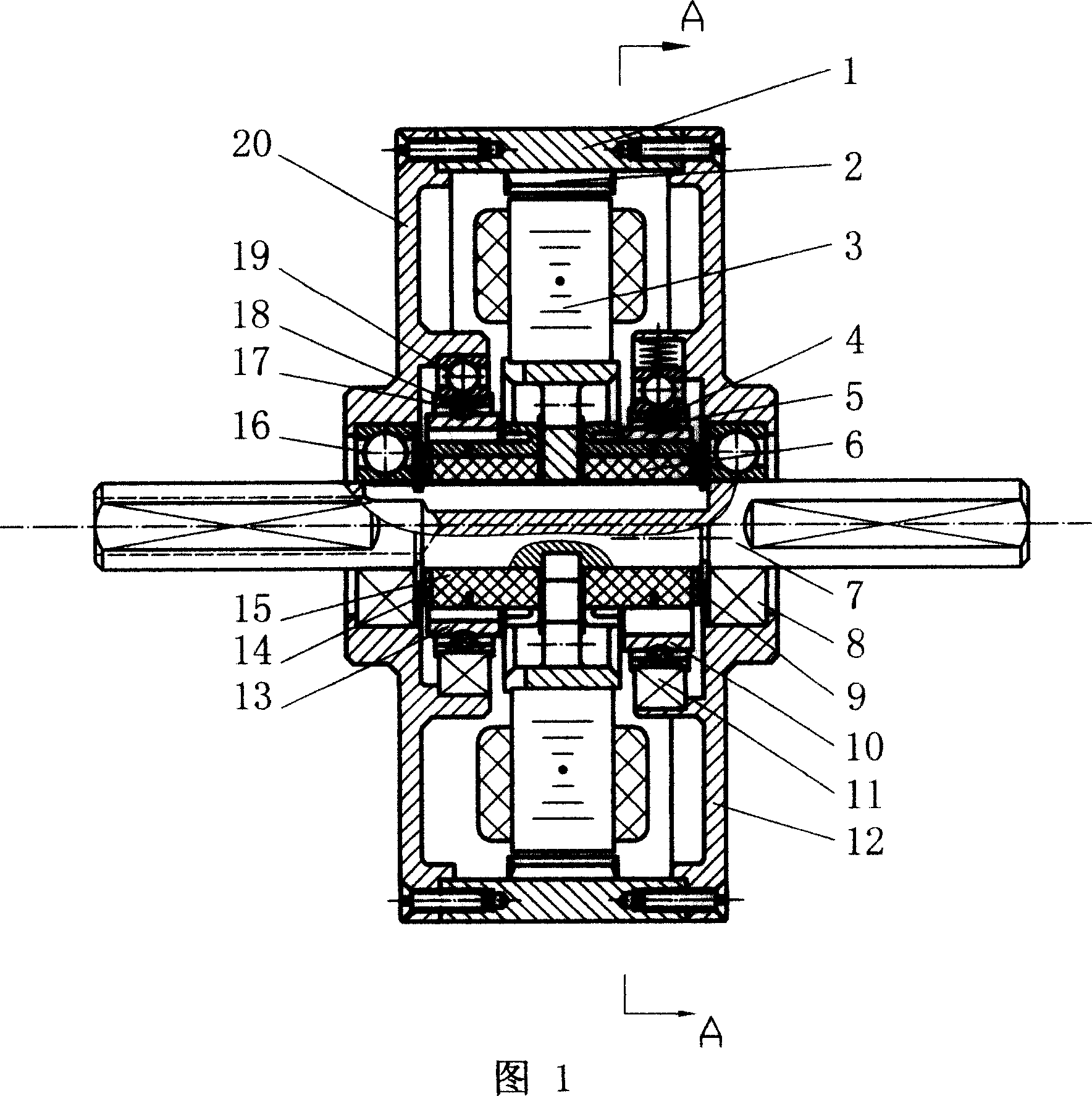

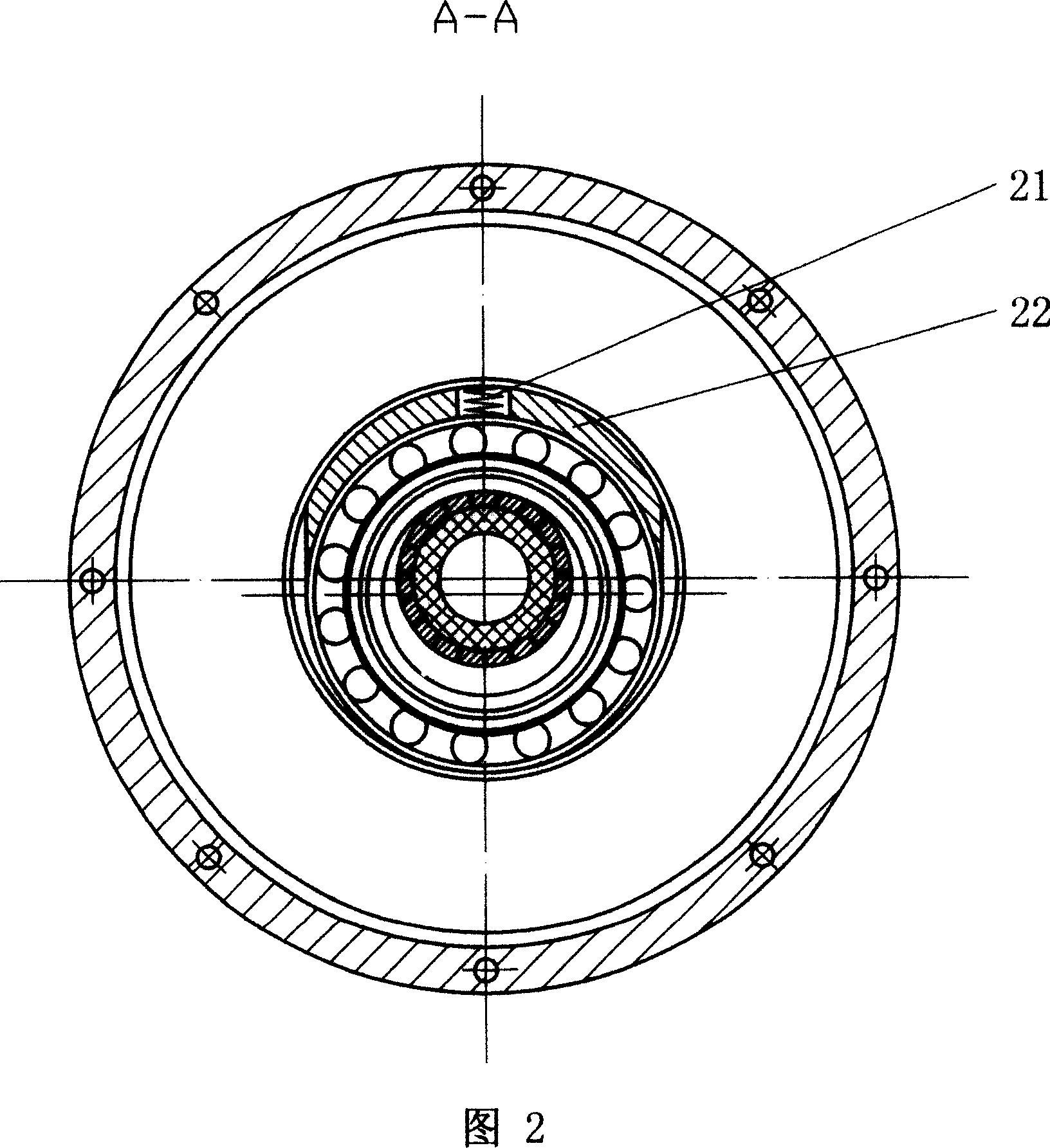

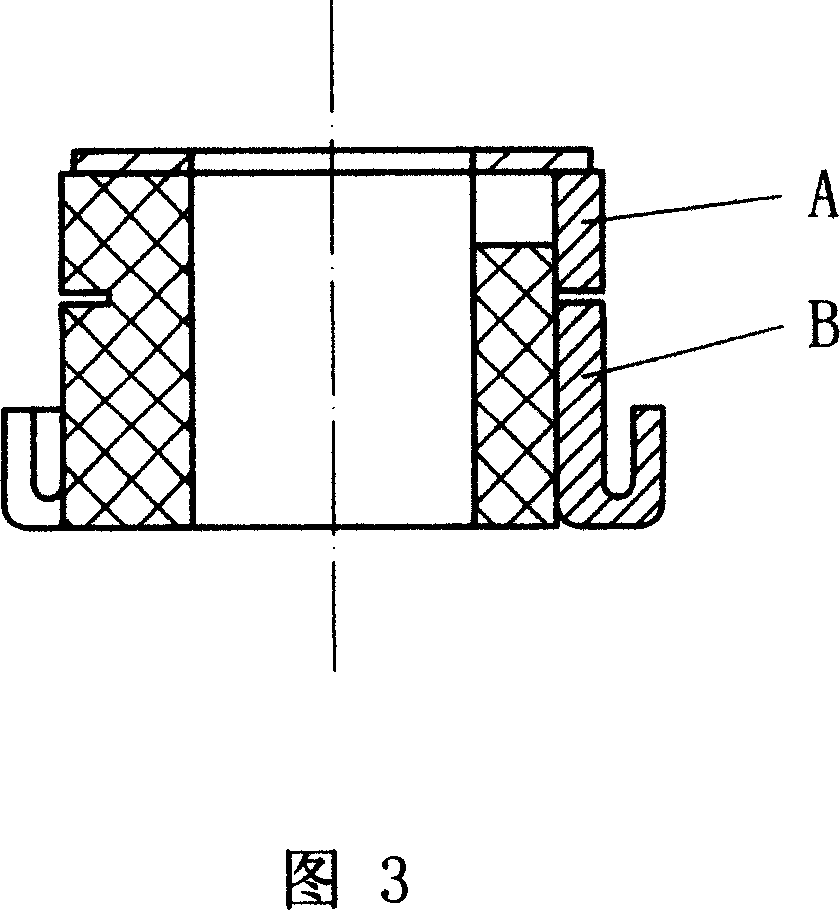

[0032] Referring to Figures 1, 2, and 3, a brushless synchronously commutated DC hub motor includes a main shaft 7, a rotor 2, a stator 3, a left synchronous ring 13, a right synchronous ring 10, a left commutator 15 and a right commutator 6 . The stator 3 is located in the middle of the housing 1 and is fixed on the main shaft 7, and a left commutator 15 and a right commutator 6 are arranged on both sides. The commutator is composed of a power supply ring A and a commutator piece B. The left commutator 15 is tangent to the left synchronous ring 13 through the left synchronous spring and the left synchronous balance weight. Tangent to the right synchronous ring 10. The left insulating ring 18 is sleeved on the inner bearing 19 of the left end cover, the left synchronous ring 13 is rollingly fitted with the left commutator 15, and a left flexible universal ring 17 is arranged between the left insulating ring 18 and the left synchronous ring 13; the right insulating ring 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com