Electrostatic dust collector

A technology of electrostatic precipitator and dust collection plate, which is applied in the field of electrostatic precipitator, can solve the problems of weak heat resistance, affecting service life, and affecting dust removal efficiency, etc., and achieves the effect of facilitating neutralization and condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

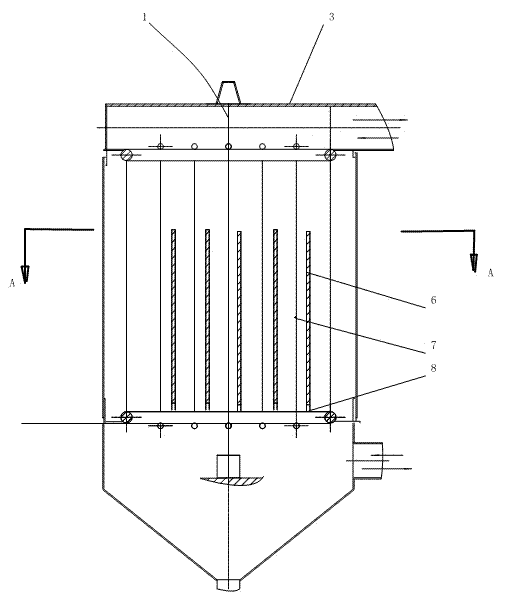

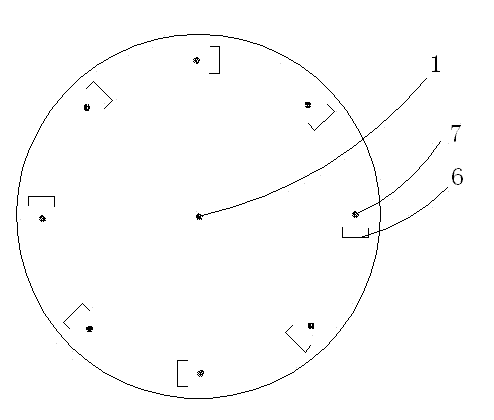

[0039] The electrostatic precipitator of the present embodiment is a cylindrical precipitator, such as figure 1 As shown, it includes a casing 3 , which is cylindrical, and the casing 3 is provided with a cathode 1 , an anode 7 and a dust collecting plate 6 close to the anode 7 . The cathode 1 and the anode 7 of the present embodiment adopt metal wires, the cross section of the dust collection plate 6 is groove-shaped and half surrounds the anode 7, the distance range between the dust collection plate 6 and the anode 7 is 10mm, and the upper and lower sides of the dust collection plate 6 The ends are respectively fixed on the upper and lower ends of the housing 1 through insulators 8.

[0040] In this embodiment, the insulator 8 and the insulator 8 are as Figure 5 and Figure 6 As shown, the material of the insulator 8 is ceramic, mica or tetrafluoroethylene, and the whole is umbrella-shaped. The middle section of the insulator 8 is provided with tooth-shaped protrusions. ...

Embodiment 2

[0045] The electrostatic precipitator of this embodiment is a box-type precipitator, and the difference from Embodiment 1 is that the housing is in the shape of a cuboid box, and the anodes and cathodes are alternately arranged at intervals of a set distance. Fabric in multiple rows.

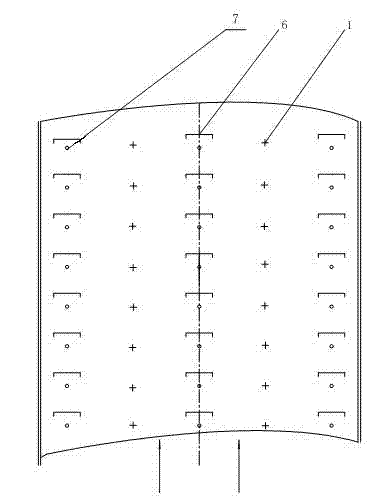

[0046] (1) if image 3 and Figure 4 As shown, the housing 3 of this embodiment is in the shape of a cuboid box, and the anodes 7 and cathodes 6 are alternately arranged in multiple rows at intervals of 500 mm. The dust collecting plate 6 of this embodiment adopts a groove-shaped plastic plate, and the distance between the dust collecting plate 6 and the anode 7 is 80mm.

[0047] (2) The cathode 1 and anode 7 of this embodiment use conductive plastic wires.

[0048] (3) In this embodiment, the insulator 8 is in the shape of a dumbbell, with through holes at both ends, as shown in the figure. The insulators 8 are respectively connected with the dust collecting plate 6 and the housing 1 with p...

Embodiment 3

[0050] This embodiment is an improvement on the basis of Embodiment 2, and the difference from Embodiment 2 is:

[0051] (1) The dust collecting plate 6 is made of arc-shaped metal plate, and the distance between the dust collecting plate 6 and the anode 7 is 150mm; in this embodiment, the dust collecting plate 6 is made of a metal plate to improve the resistance to heat change.

[0052] (2) if Figure 9 As shown, the cathode 1 is provided with buckles 1-2 at intervals along the length direction, and each buckle 1-2 is provided with at least one metal wire 1-1. In this embodiment, the cathode 1 adopts such a structure, which can effectively strengthen the corona discharge.

[0053] (3) The cathode 1 and the anode 7 of this embodiment use conductive rubber wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com