Coupling structure of filter

A coupling structure and filter technology, applied in waveguide devices, electrical components, connecting devices, etc., can solve problems such as ignoring product consistency and stability, and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

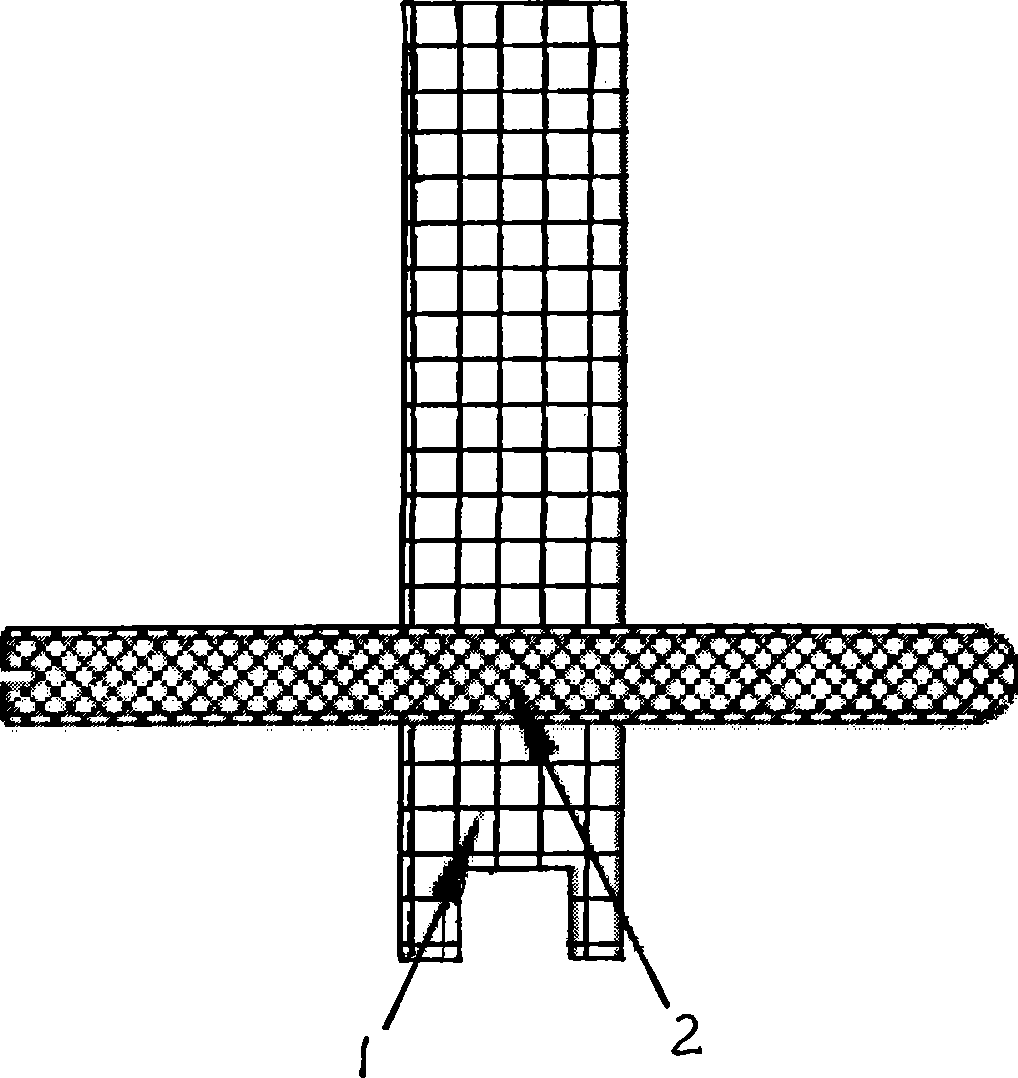

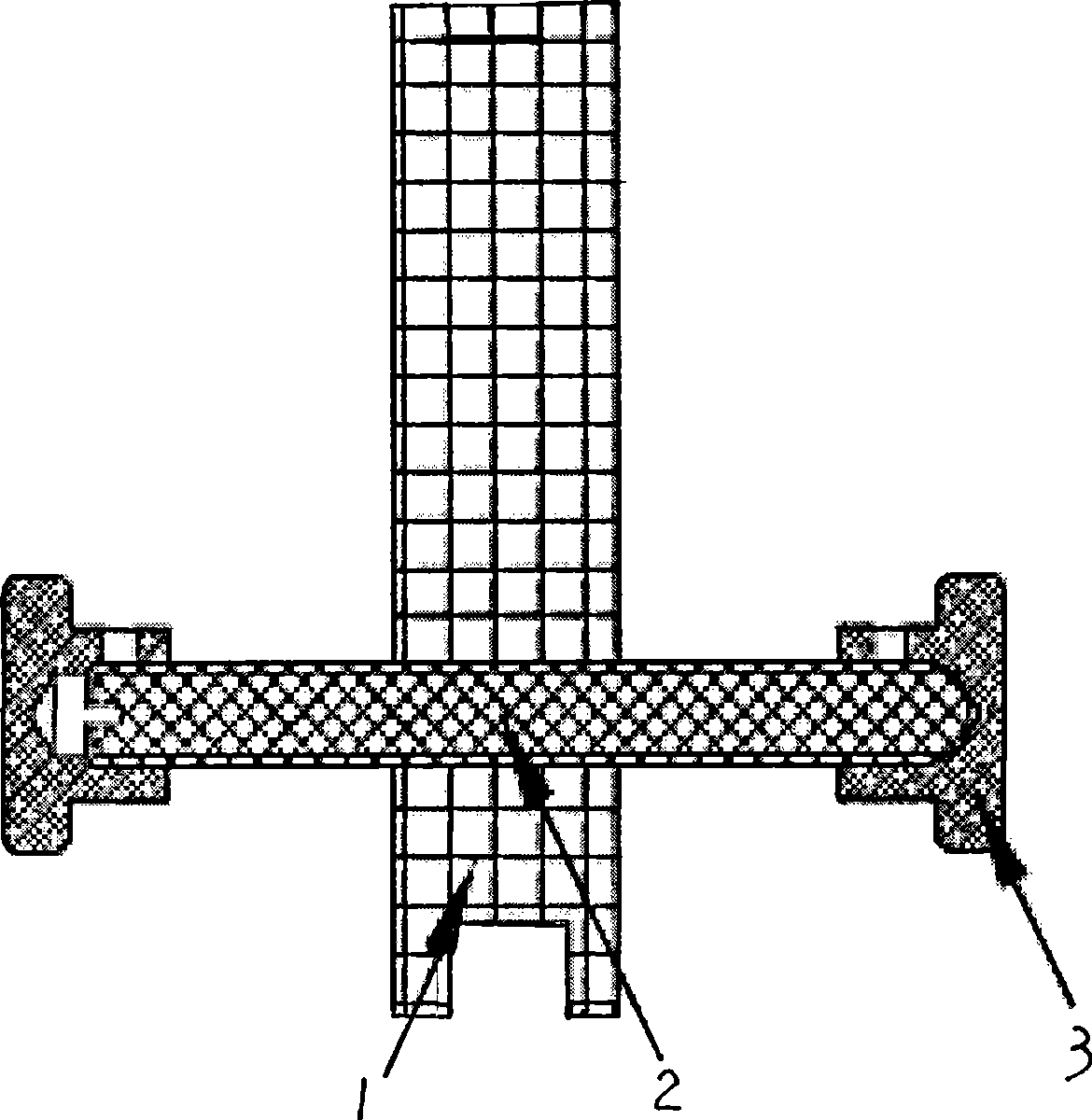

[0028] see figure 1 , figure 2 , The filter coupling structure of the present invention includes a support 1 , an M3 adjusting screw 2 , or two flanges 3 .

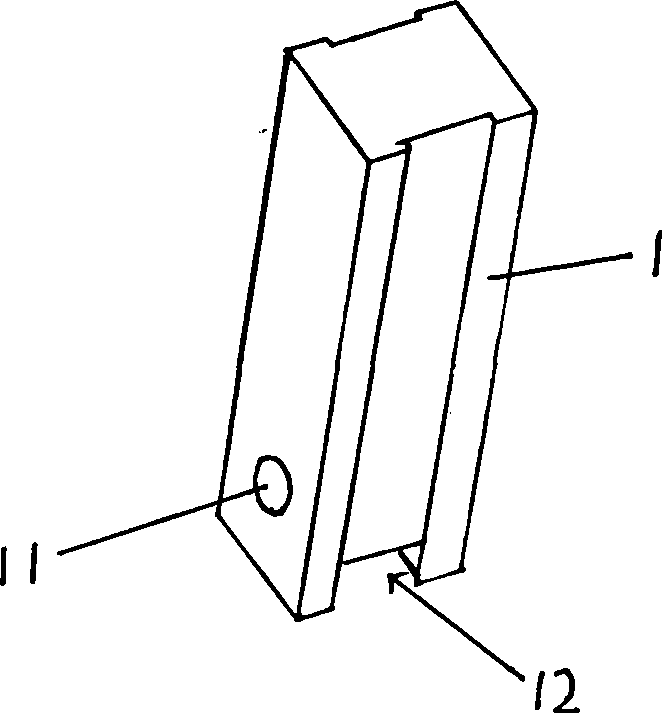

[0029] see image 3 , the support member 1 among the present invention is made of PTFE material, is a rectangular columnar structure, its lower part is provided with the screw hole 11 that runs through two opposite sides, and the side and the bottom surface of the other two without screw holes are provided with the groove 12 that installs. .

[0030] The M3 adjusting screw 2 is made of brass silver-plated material, which passes through the screw hole 11 of the support and is connected to the lower part of the support.

[0031] The two flanges 3 are made of brass silver-plated material, which are respectively connected to the two ends of the M3 adjusting screw to form a dumbbell-shaped structure.

[0032] Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com