Main shaft brake lining of wind-driven generator and preparation method thereof

A technology of wind turbines and liners, which is applied in the direction of mechanical equipment, friction linings, gear transmission mechanisms, etc., can solve the problems of yaw nodding instability in the main engine cabin, only 1890 hours, and affect the normal power generation of wind turbines, and achieve dual wear The effect of small size, long service life and stable friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

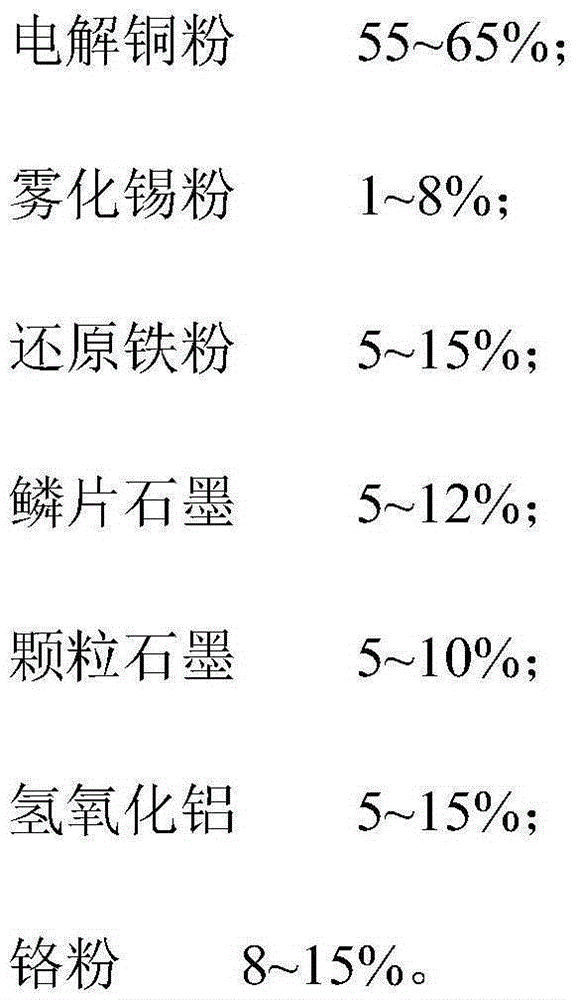

[0025] Wind turbine main shaft brake pad, the brake pad formula is:

[0026]

[0027]

[0028] The particle size of electrolytic copper powder is 200 mesh, the particle size of atomized tin powder is 300 mesh, the particle size of reduced iron powder is 100 mesh, the particle size of flake graphite is 80 mesh, the particle size of granular graphite is 40 mesh, and the particle size of aluminum hydroxide is 80 mesh, the particle size of chromium powder is 200 mesh.

[0029] The purity of copper powder in electrolytic copper powder is ≥99.8%, and the purity of tin powder in atomized tin powder is ≥98%.

[0030] The preparation method of the brake liner of the main shaft of the wind power generator comprises the following steps:

[0031] (1) Ingredients: Weigh each component material according to the ratio: electrolytic copper powder, atomized tin powder, reduced iron powder, flake graphite, aluminum hydroxide and chromium powder;

[0032] (2) Mixing: Put the weighed mate...

Embodiment 2

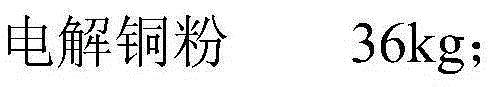

[0037] Wind turbine main shaft brake pad, the brake pad formula is:

[0038]

[0039] The particle size of electrolytic copper powder is 250 mesh, the particle size of atomized tin powder is 250 mesh, the particle size of reduced iron powder is 90 mesh, the particle size of flake graphite is 9 mesh, the particle size of granular graphite is 50 mesh, and the particle size of aluminum hydroxide is 90 mesh, the particle size of chromium powder is 250 mesh.

[0040] The purity of copper powder in electrolytic copper powder is ≥99.8%, and the purity of tin powder in atomized tin powder is ≥98%.

[0041] The preparation method of the brake liner of the main shaft of the wind power generator comprises the following steps:

[0042] (1) Ingredients: Weigh each component material according to the ratio: electrolytic copper powder, atomized tin powder, reduced iron powder, flake graphite, aluminum hydroxide and chromium powder;

[0043] (2) Mixing: Put the weighed materials into a d...

Embodiment 3

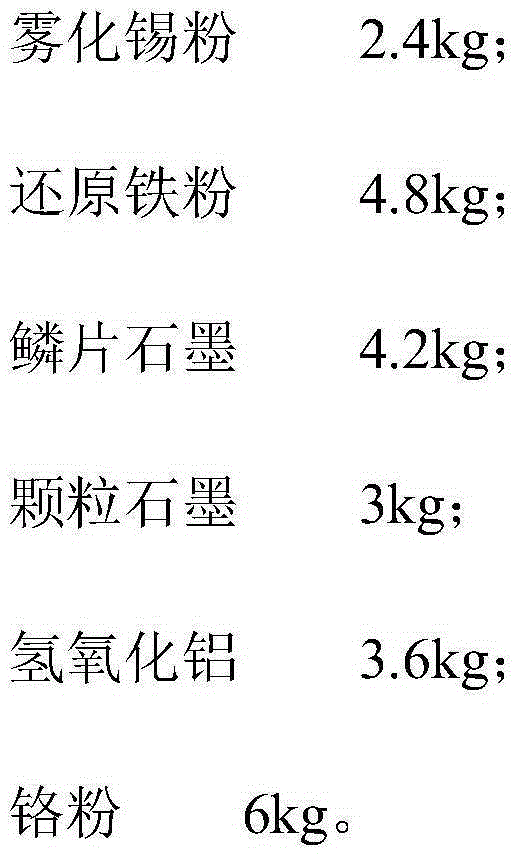

[0048] Wind turbine main shaft brake pad, the brake pad formula is:

[0049]

[0050] The particle size of electrolytic copper powder is 300 mesh, the particle size of atomized tin powder is 300 mesh, the particle size of reduced iron powder is 100 mesh, the particle size of flake graphite is 100 mesh, the particle size of granular graphite is 60 mesh, and the particle size of aluminum hydroxide is 100 mesh, the particle size of chromium powder is 300 mesh.

[0051] The purity of copper powder in electrolytic copper powder is ≥99.8%, and the purity of tin powder in atomized tin powder is ≥98%.

[0052] The preparation method of the brake liner of the main shaft of the wind power generator comprises the following steps:

[0053] (1) Ingredients: Weigh each component material according to the ratio: electrolytic copper powder, atomized tin powder, reduced iron powder, flake graphite, aluminum hydroxide and chromium powder;

[0054] (2) Mixing: Put the weighed materials into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com