Method for producing a high damage tolerant aluminium alloy

a technology of high damage tolerance and alloy, which is applied in the field of high damage tolerance aluminium alloy production, can solve the problems that aa2000 and aa6000 series alloys are generally unsuitable for the design of commercial aircraft, and achieve the effects of improving fatigue crack growth resistance, improving toughness, and maintaining strength levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0052] In a first preferred embodiment of the present invention, two conventional alloys (AA6013 and AA6056) were cast and processed to a sheet product. Here, two processing variants were used:

[0053] Route 1. A normal processing route by lab-casting ingots of conventional AA6013 and AA6056-alloy compositions was used. Blocks of 80×80×100 mm were sawn, homogenised, preheated and hot rolled to 4.5 mm sheet. After hot rolling the hot rolled products were conventionally cooled to ambient temperature by allowing the sheet to cool to ambient air to room temperature, fed to the cold rolling station, cold rolled to 2 mm and heat treated for 20 min at 550° C., thereafter quenched and aged to a T6-temper for 4 hours at 190° C.

[0054] Route 2. Ingots of conventional AA6013 and AA6056-alloy compositions were lab-cast and sawn to a size of 80×80×100 mm. These blocks were homogenised, pre-heated and hot rolled to 4.5 mm. A simulation of the hot coiling in an industrial scale was incorporated by ...

example 2

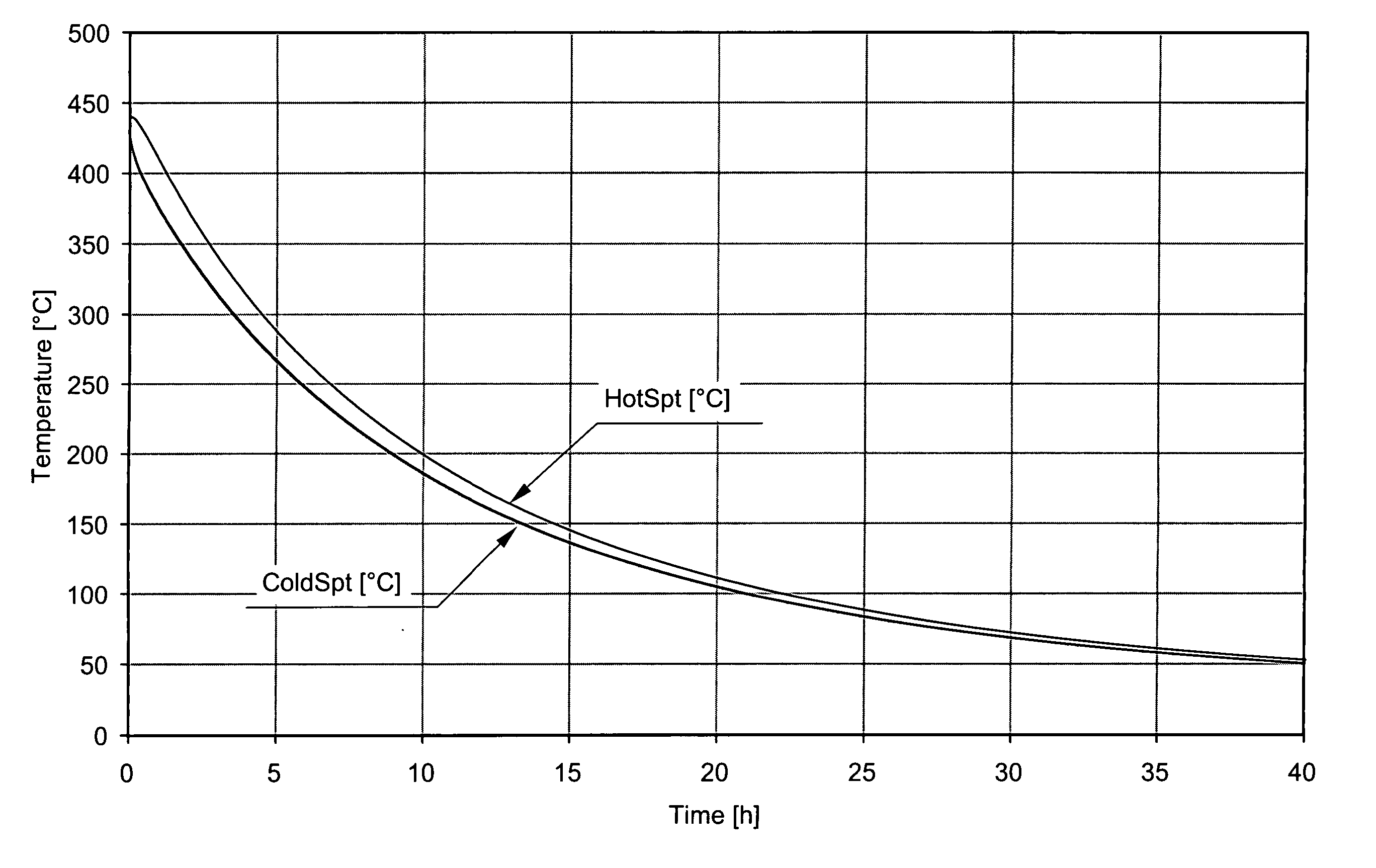

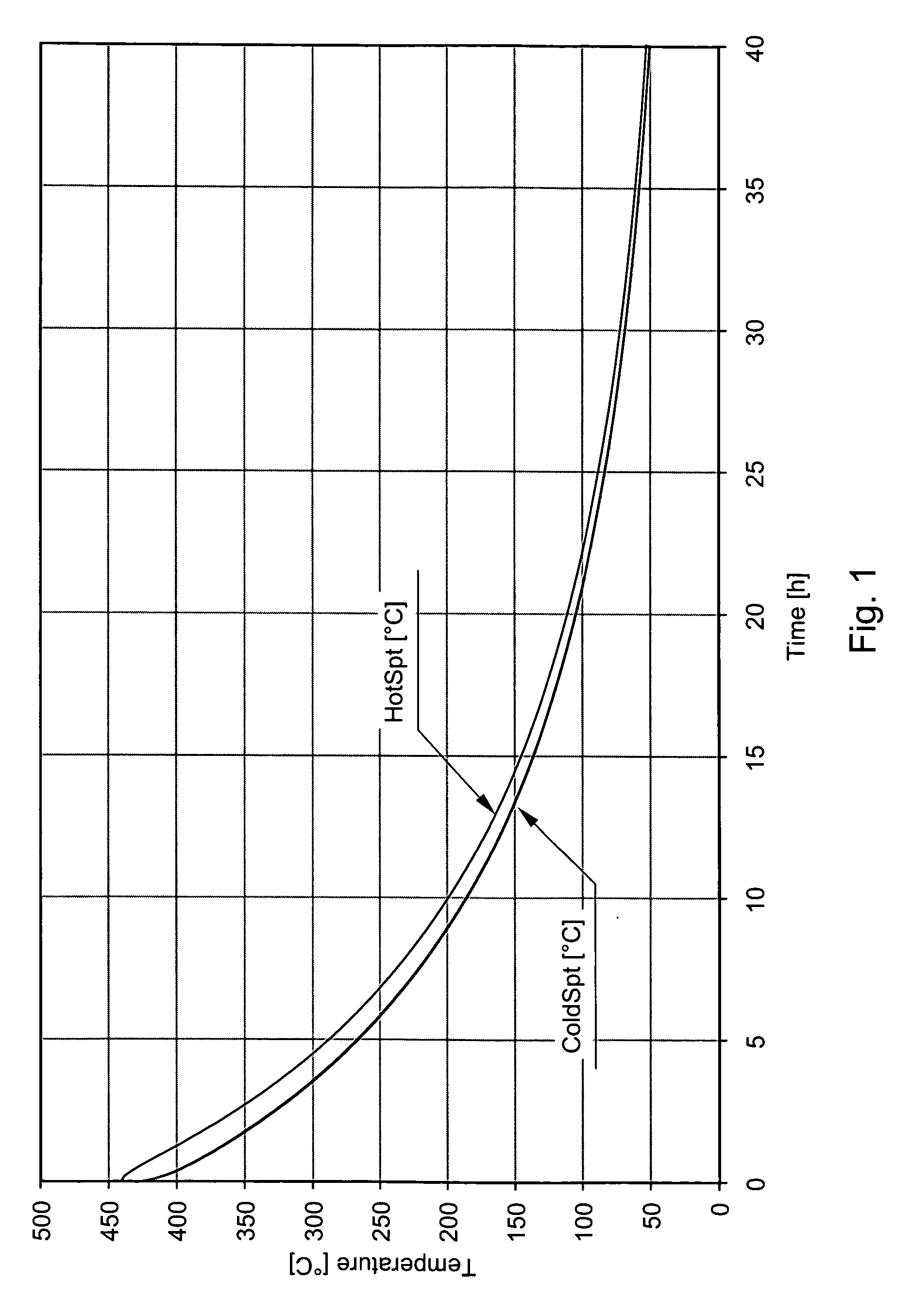

[0078]FIG. 1 shows a typical continuous cooling down curve for an aluminium AA7050 alloy when cooled down from a hot-mill exit temperature of 440° C. to a temperature below 150° C., whereby the metal sheet has a gauge of 4.5 mm and being immediately coiled when leaving the hot-mill in accordance with an embodiment of the method of this invention. The width of the coil was 1.4 meter. The temperatures of the coil as function of time is also given in Table 7 for the hottest spot of a coil (being the centre, and indicated as HotSpt in FIG. 1) and the coldest spot (being the edge of a coil, and indicated as ColdSpt in FIG. 1)). Table 7 provides also the temperatures in case a coil having a width of 2.8 meter.

[0079] For the shown cooling curve in FIG. 1 the α is about −0.084 hrs−1.

[0080] In case a sheet with a gauge of about 4.0 to 4.5 mm was allowed to cool down from the hot-mill exit temperature to below 150° C. using conventional cooling practice, viz. leaving the plate to cool in no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com