Weaving process in three-dimensional conic-casing loom and its product

A fabric and tapered technology, applied in the weaving method of three-dimensional tapered shell fabrics and its products, can solve the problems of long production cycle, high weaving cost, and poor bulkiness of three-dimensional fabrics, and achieve high quality and high damage tolerance , overall good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A linear frusto-conical shell fabric was woven (see Figure 5).

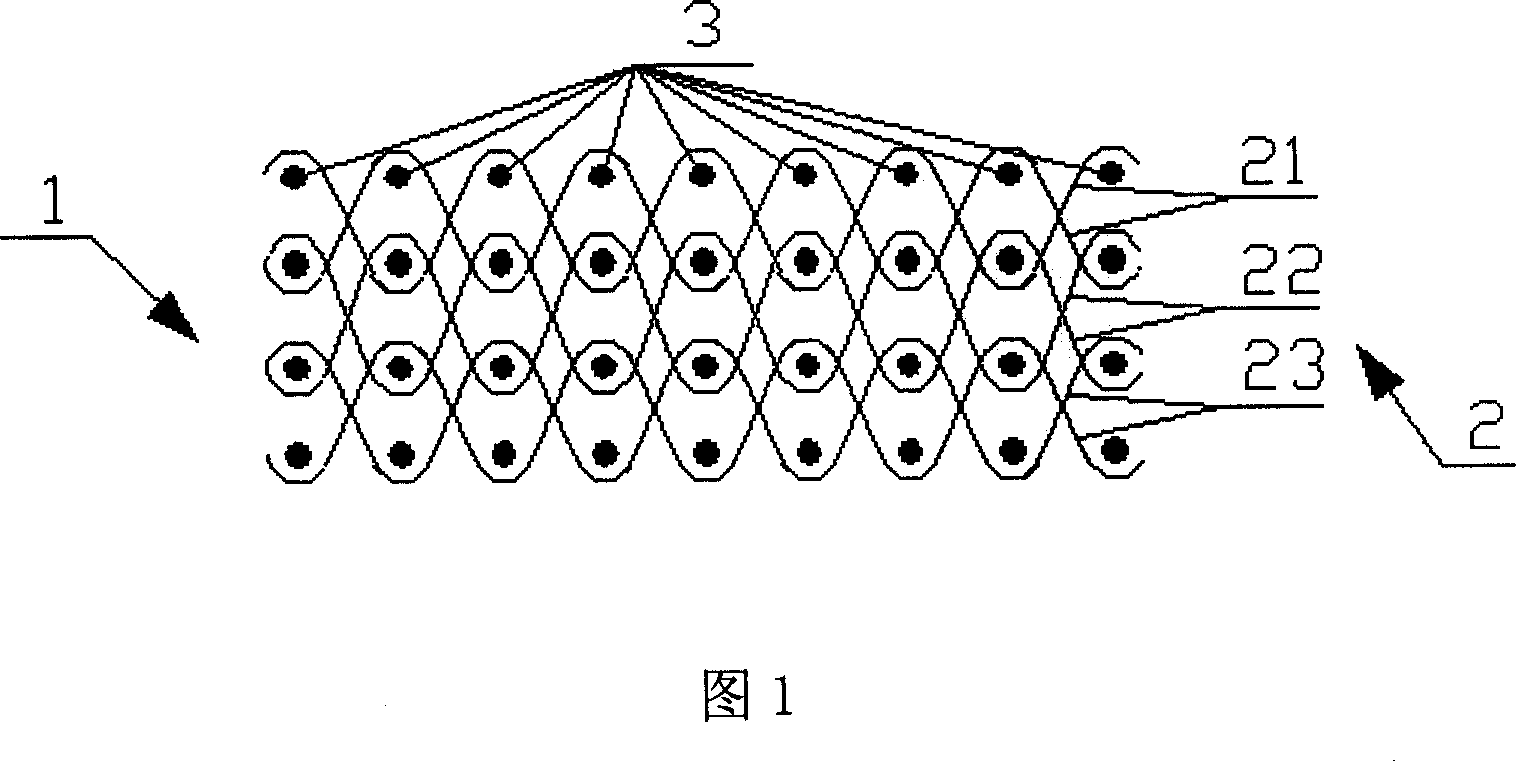

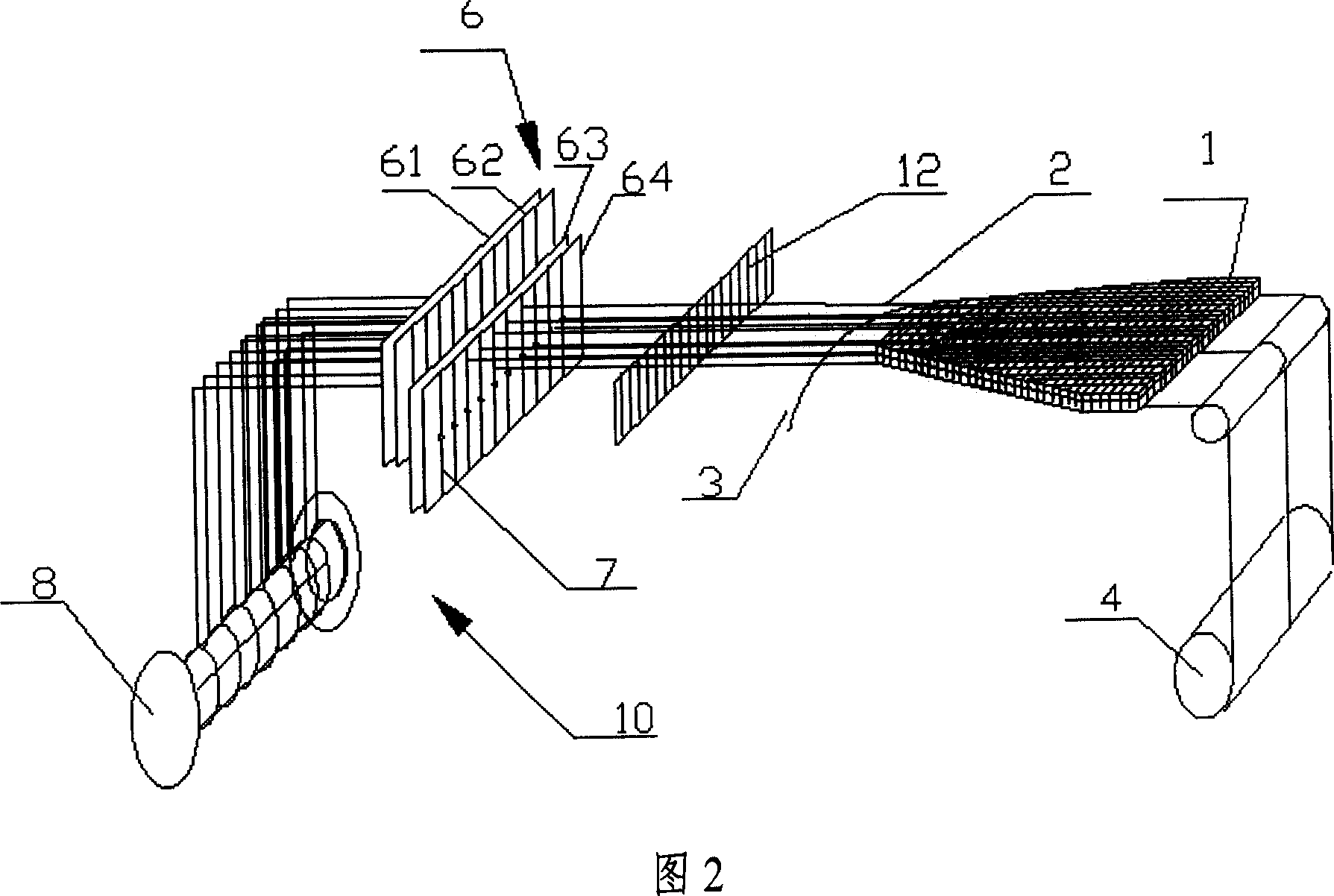

[0030] The diameter of the large end of the linear frustum-conical shell fabric is designed to be 360 mm, the length of the generatrix is 450 mm, the warp yarn density is 500 yarns / 10cm, and the weft yarn density is 300 yarns / cm. According to the size requirements and density requirements of the large end of the shell fabric, the required number of warp yarns is 5652. According to the length of the busbar of the shell, 5652 warp yarns with a length of 900mm are intercepted, and one end of the 5652 yarns is evenly hung on the On the winding shaft 4 (referring to shown in Fig. 2), the other end of these yarns is passed through the reed 12 among Fig. 2 and the heddle 7 respectively to be connected with the warp shaft 8 below the loom 10 again.

[0031] Start the loom 10, the heald frame 7 moves up and down, and the warp yarn 2 forms an upper and lower layer thereupon, forming a passage for introducing the...

Embodiment 2

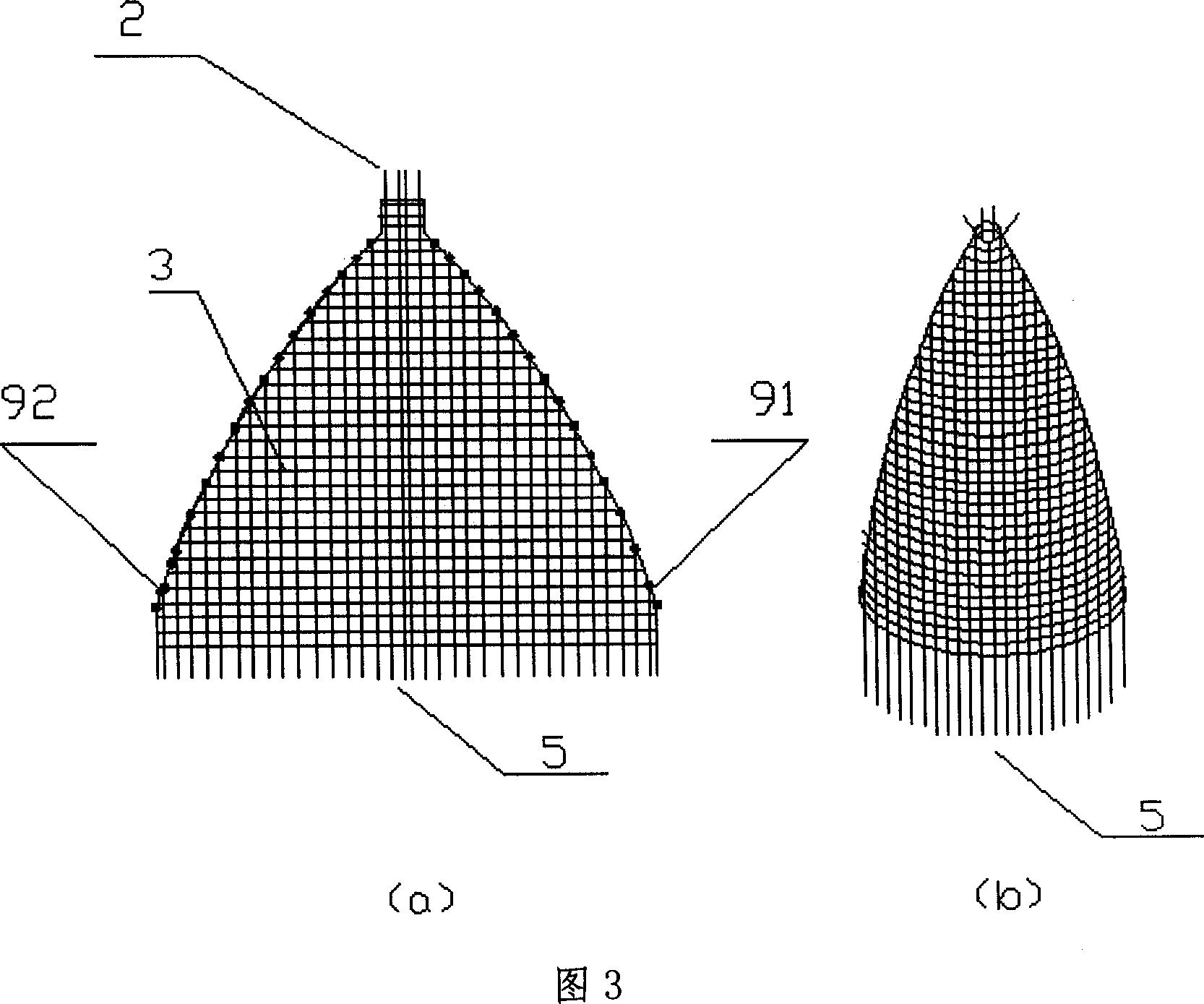

[0035] Weave the curved frusto-conical shell fabric (see Figure 3).

[0036] The weaving process of the curved frustoconical shell fabric is basically the same as the weaving process of the linear frustoconical shell fabric described in Example 1. The difference is that the number of warp yarns cut each time in weaving the same fabric is no longer a constant, but changes in order to obtain the required curve shape. In this embodiment, at the initial stage of weaving, each warp-cutting operation cuts off 4 warp yarns on both sides of the fabric; after the fabric length reaches 3 cm, each warp-cutting operation cuts off 6 warp yarns on both sides of the fabric; After the length reaches 5cm, each warp-cutting operation cuts off 9 warp yarns on both sides of the fabric, and so on until the overall profiling weaving of the fabric is completed.

Embodiment 3

[0038] A cylindrical shell fabric is woven (see Figure 6).

[0039] The weaving method of the cylindrical shell fabric is also basically the same as the weaving method described in Example 1, but it is simpler: the weaving process does not need yarn cutting operation from beginning to end. Strictly speaking, the cylindrical shell fabric is a special case of the three-dimensional tapered shell fabric of the present invention (taper = 0).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com