Coiling-type germanium nanomaterial and preparation method thereof

A technology of nanomaterials and coils, which is applied in the field of electrochemistry, can solve the problem that the volume expansion effect is not very obvious, and achieve the effects of short transmission length, improved work efficiency, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of embodiment 1 coil shape germanium nanomaterial

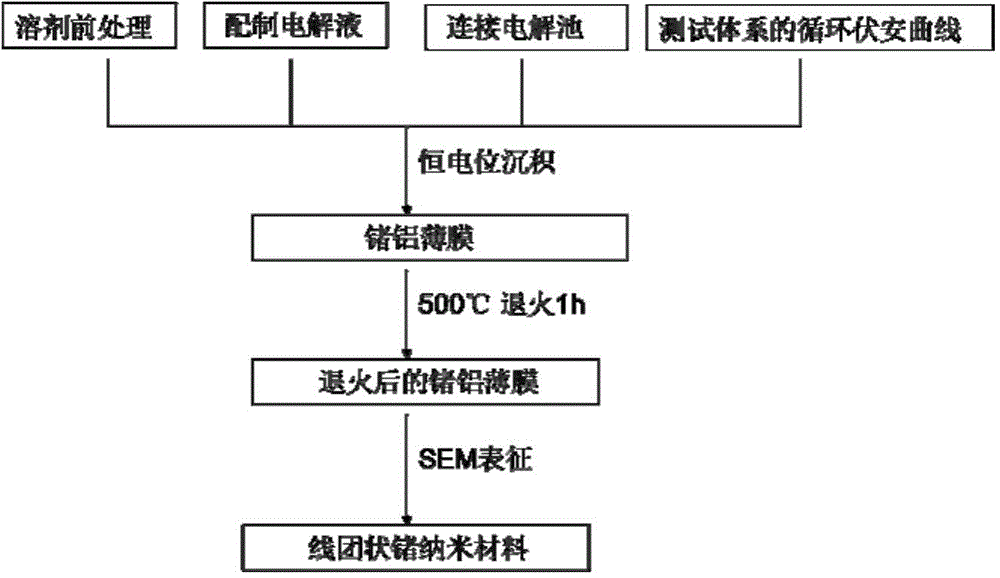

[0021] The specific process for preparing coiled germanium nanomaterials is as follows: figure 1 As shown, the experimental part is mainly divided into two parts: ionic liquid electrodeposition experiment and annealing experiment.

[0022] 1. Electrodeposition of germanium and aluminum thin films by ionic liquid

[0023] (1) Pretreatment of experimental reagents

[0024] The ionic liquid EmimTf 2 N was placed in a glove box and distilled at 100°C for 24 hours to remove the moisture in the ionic liquid to make the water content less than 2ppm, and put it in the glove box for later use.

[0025] (2) Preparation of electrolyte

[0026] Prepare 0.1mol / L GeCl in the glove box 4 , 2.5mol / L AlCl3 EmimTf 2 N solution, after stirring evenly, was placed in the glove box for later use.

[0027] (3) Connect the electrolytic cell

[0028] The deposition experiment was carried out using a three-electrode syst...

Embodiment 2

[0035] Morphological characterization of embodiment 2 germanium nanomaterials

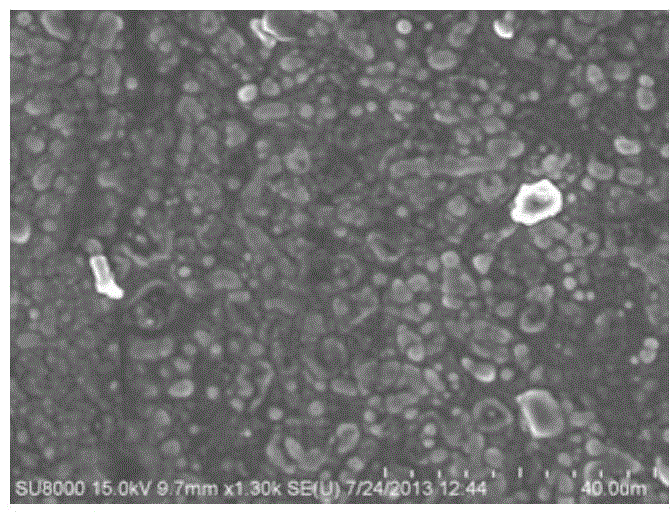

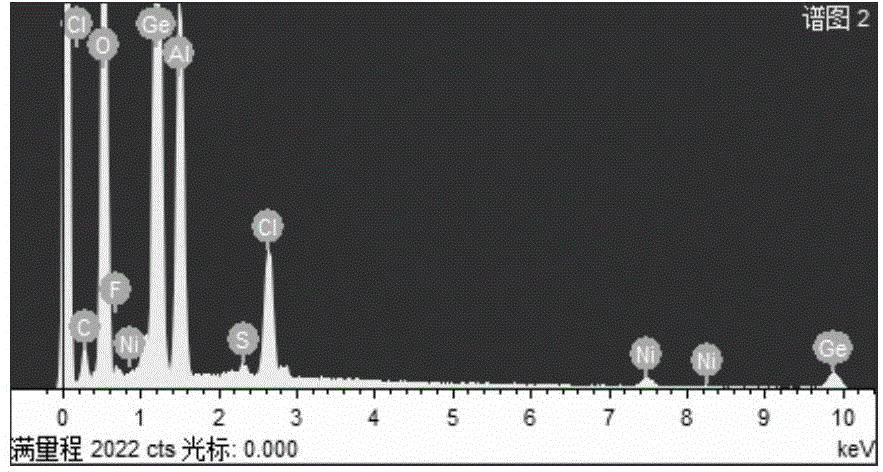

[0036] Through SEM characterization, we can intuitively see the microscopic morphology of the product, figure 2 The SEM image of the germanium-aluminum film electrodeposited by ionic liquid, we can see from the figure that the film directly electrodeposited is formed by the aggregation of small grains, from the EDS analysis ( image 3 ) It can be seen that the film mainly contains germanium and aluminum elements, of which a small amount of Cl, S, and F are the constituent elements of the ionic liquid, while the Ni element is the matrix material, and O and C are adsorbed during the preparation and characterization of the material. Yes, the O element may also be generated due to a small portion of the material being oxidized during the characterization process. However, after annealing, the morphology of the material has changed significantly due to the metal-induced effect. Figure 4 It is the SE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com