Silicon-based slurry and preparation method and application thereof

A technology of silicon-based materials and slurries, which is applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve problems such as the complexity of the preparation process, achieve the effects of reducing the overall expansion rate, ensuring strength, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

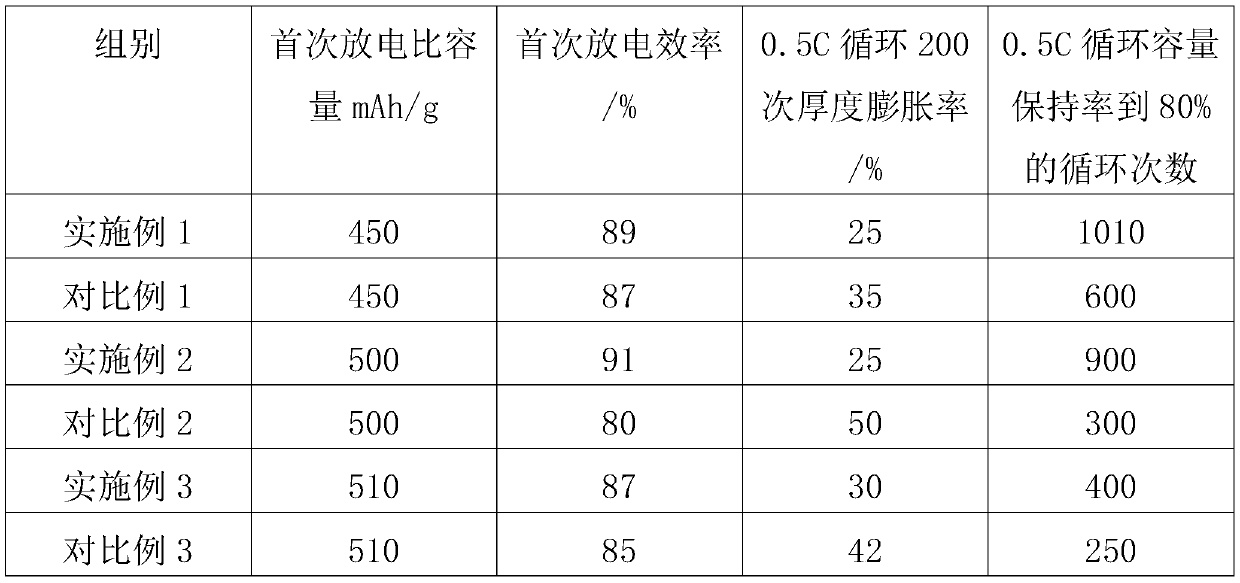

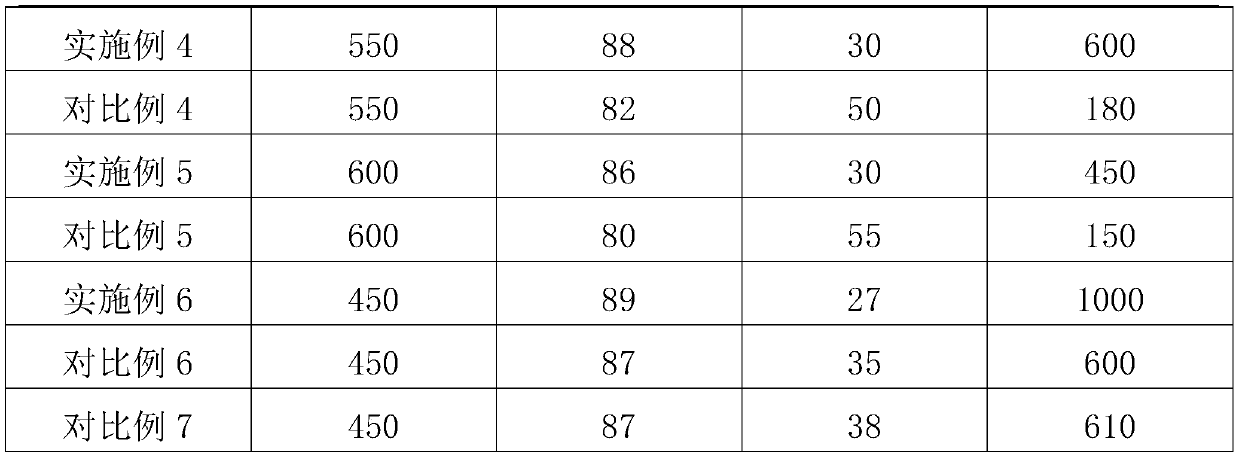

Examples

Embodiment 1

[0030] A silicon-based slurry, comprising the following components by weight: 10 parts of silicon-based material silicon oxide SiO, non-silicon-based ceramic material Al 2 o 3 0.5 parts of aluminum oxide, 0.5 parts of multi-walled carbon nanotubes of carbon material, 8 parts of acrylic resin PAA as a curing agent, 0.1 part of polyvinylpyrrolidone PVP as a dispersant, 0.1 part of isopropanol as a defoaming agent, and 100 parts of solvent water.

[0031] The preparation method of silicon-based slurry in the present embodiment comprises the following steps:

[0032] (1) Add part of the solvent into the first container, then add the curing agent, defoamer, part of the dispersant and the ground carbon material powder therein, and disperse in the high-pressure homogenizer to obtain the first mixed solution;

[0033](2) Add the remaining solvent into the second container, then add silicon-based materials, non-silicon-based ceramic materials and remaining dispersant, and stir to obta...

Embodiment 2

[0040] A silicon-based slurry, comprising the following components by weight: silicon-based material lithium disilicate Li 2 Si 2 o 5 17 parts, non-silicon-based ceramic material Li 7 La 3 Zr 2 o 12 2 parts, 0.2 parts of carbon material single-walled carbon nanotubes, 10 parts of curing agent acrylic resin PAA, 2 parts of hydrogenated nitrile rubber, 0.2 parts of dispersant polyvinylpyrrolidone PVP, 0.1 part of defoaming agent acetone, 100 parts of solvent water.

[0041] The preparation method of silicon-based slurry in the present embodiment comprises the following steps:

[0042] (1) Add part of the solvent to the first container, then add the curing agent, defoamer, part of the dispersant and the ground carbon material powder therein, and ultrasonically disperse to obtain the first mixed liquid;

[0043] (2) Add the remaining solvent into the second container, then add the silicon-based material, non-silicon-based ceramic material and remaining dispersant, and stir...

Embodiment 3

[0050] A silicon-based slurry, comprising the following components by weight: 16 parts of silicon-based material silicon oxide SiO, lithium silicate Li 2 SiO 3 1 part, 1 part of silicon simple substance Si, 5 parts of non-silicon-based ceramic material LiTFSI, 1 part of carbon material nano-carbon black, 12 parts of curing agent polyacrylonitrile PAN, 3 parts of polyethylene oxide PEO, dispersant dodecylbenzenesulfonate 0.1 part of sodium bicarbonate, 0.1 part of acetone as an antifoaming agent, and 150 parts of N-methyl pyrrolidone as a solvent.

[0051] The preparation method of silicon-based slurry in the present embodiment comprises the following steps:

[0052] (1) Add part of the solvent into the first container, then add the curing agent, defoamer, part of the dispersant and the ground carbon material powder, and grind it with a sand mill at a speed of 20000r / min to obtain the first mixed liquid;

[0053] (2) Add remaining solvent to the second container, then add s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com