Preparation and application method of graphene-coated porous silicon composite anode material

A graphene-coated, negative electrode material technology, applied in graphene, battery electrodes, electrical components, etc., can solve the problems of limiting the practical application of silicon materials, the capacity decay of silicon electrodes, and the large volume expansion rate, so as to improve the first charge and discharge. Efficiency, prevention of volume expansion, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

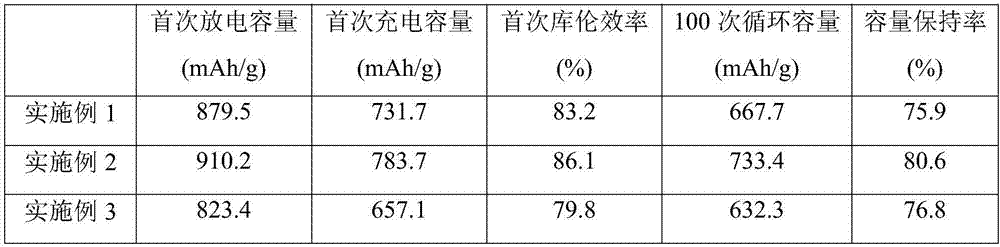

Embodiment 1

[0037] (1) Weigh 60g of 2, 4, and 8mm diameter grinding balls, 5g of smelted aluminum-silicon alloy and 3ml of acetone solution in a glove box and add them to a 150ml ball milling tank. The ball milling jar was placed on a planetary ball mill with a rotation speed of 500 rpm for 12 hours. In order to prevent local temperature from being too high, the sample was ball milled for 10 minutes and then suspended for 6 minutes.

[0038] (2) Dissolve the obtained small particles of aluminum-silicon alloy with deionized water, ultrasonically disperse for 20 minutes, then clean it three times, and dry it in an oven for 12 hours at a temperature of 100°C.

[0039] (3) Measure 50ml of 5% dilute nitric acid and 100ml of 10% dilute sulfuric acid respectively, mix well and pour it into a 300ml beaker, and gradually add the aluminum-silicon alloy under vigorous stirring until it is completely dissolved. Then ultrasonic 60min, placed on a magnetic stirrer to stir for 6h. It was washed 5 times with...

Embodiment 2

[0045] (1) Weigh 60g of zirconia balls with a diameter of 4mm, 6g of smelted aluminum-silicon alloy and 5ml of absolute ethanol in a glove box and add them to a 100ml ball mill tank. The ball milling jar was placed on a planetary ball mill with a rotation speed of 200 rpm for 24 hours. In order to prevent local temperature from being too high, the sample was ball milled for 20 minutes and then suspended for 10 minutes.

[0046] (2) Dissolve the obtained small particles of aluminum-silicon alloy with alcohol, ultrasonically disperse for 30 minutes, then clean it three times, and dry it in an oven for 6 hours at a temperature of 60°C.

[0047] (3) Measure 200 ml of 10% hydrofluoric acid and pour it into a 400 ml beaker, and slowly add the aluminum-silicon alloy under vigorous stirring until it is completely dissolved. Then ultrasonic for 30min, put on a magnetic stirrer and stir for 8h. It was cleaned three times with deionization and alcohol, and dried in a vacuum drying oven at 60...

Embodiment 3

[0053] (1) Weigh 50g of zirconia balls (mass ratio 1:1) with diameters of 2 and 4mm respectively, 5g of metallurgical aluminum-silicon alloy and 20ml of n-hexane solution in a glove box and add them to a 100ml ball mill tank. The ball milling jar was placed on a planetary ball mill with a rotation speed of 500 rpm for 12 hours. In order to prevent local temperature from being too high, the sample was ball milled for 15 minutes and then suspended for 8 minutes.

[0054] (2) Dissolve the obtained small particles of aluminum-silicon alloy with deionized water, ultrasonically disperse for 1 hour, and then clean it with deionized water three times, and place it in an oven to dry for 12 hours at a temperature of 120°C.

[0055] (3) Measure 150 ml of 15% hydrochloric acid and pour it into a 400 ml beaker, and slowly add the aluminum-silicon alloy under vigorous stirring until it is completely dissolved. Then ultrasonic for 30min, put on a magnetic stirrer and stir for 4h. It was cleaned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com