Hexagonal flaky titanyl oxalate photocatalyst and preparation method thereof

A technology of titanyl oxalate and photocatalyst, which is applied in the field of photocatalysis, can solve the problems affecting the use of titanyl oxalate photocatalyst, large particle size and different shapes of titanyl oxalate photocatalyst, and achieve good photocatalysis Activity, uniform dispersion, simple and easy-to-control preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of hexagonal plate-shaped titanyl oxalate photocatalyst, comprising the following steps:

[0038] Step 1: 1.25-3.75g titanium sulfate [Ti(SO 4 ) 2 ] was added to 50mL deionized water, and stirred until completely dissolved to obtain a concentration of 0.1-0.3mol / L of Ti(SO 4 ) 2 solution, the titanyl oxalate photocatalyst prepared in this concentration range has a hexagonal plate shape; because when Ti(SO 4 ) 2 When the concentration of the solution is too high, the titanyl oxalate is hydrolyzed, and the hexagonal flake morphology is destroyed to become flocculent particles, which cannot be regrown to form the hexagonal flake morphology in the subsequent reaction process.

[0039] Step 2: To the Ti(SO 4 ) 2 Add 0.358-1.074g ammonium oxalate [(NH 4 ) 2 C 2 o 4 ·H 2 O], stir 20-40min to dissolve completely, it is advisable to not splash on the beaker wall with solution when stirring, make precursor solution, ammonium oxalate [(NH 4 ) 2 C ...

Embodiment 1

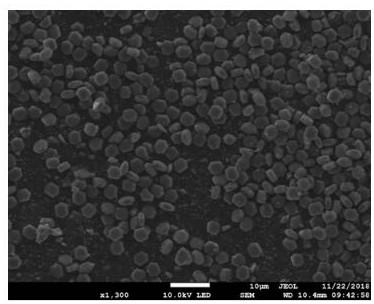

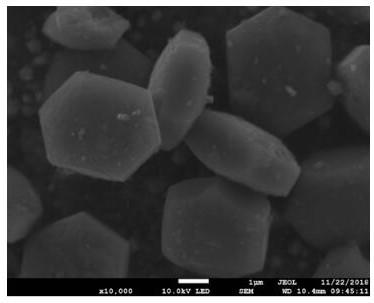

[0044] 2.50g Ti(SO 4 ) 2 Add it into 50mL deionized water, stir until completely dissolved, and prepare a concentration of 0.2mol / L Ti(SO 4 ) 2 solution; 0.716g (NH 4 ) 2 C 2 o 4 ·H 2 O added to Ti(SO 4 ) 2 In the solution, stir for 20 minutes until completely dissolved, as a precursor solution; transfer the precursor solution to a 100mL reactor, and conduct a hydrothermal reaction at 90°C for 5 hours to obtain the reaction product A; after the reaction, the reactor is naturally cooled to room temperature , the reaction product A was centrifuged, washed with deionized water to pH = 7, and then washed 4 times with absolute ethanol to obtain the reaction product B; the reaction product B was dried at 70°C for 3 hours to obtain hexagonal flaky oxalic acid Oxytitanium salt photocatalyst, white powder, hexagonal plate diameter is 4μm, hexagonal plate thickness is 1.5μm.

[0045] refer to figure 1 and figure 2 , the hexagonal flaky titanyl oxalate photocatalyst prepared...

Embodiment 2

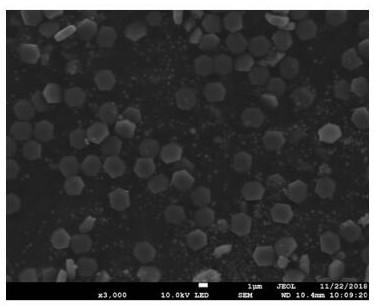

[0047] 1.25g Ti(SO 4 ) 2 Added into 50mL deionized water, stirred until completely dissolved, and prepared Ti(SO 4 ) 2 solution; 0.358g (NH 4 ) 2 C 2 o 4 ·H 2 O added to Ti(SO 4 ) 2 In the solution, stir for 20 minutes until completely dissolved, as a precursor solution; transfer the precursor solution to a 100mL reactor, and conduct a hydrothermal reaction at 90°C for 5 hours to obtain the reaction product A; after the reaction, the reactor is naturally cooled to room temperature , the reaction product A was centrifuged, washed with deionized water to pH = 7, and then washed 4 times with absolute ethanol to obtain the reaction product B; the reaction product B was dried at 70°C for 3 hours to obtain hexagonal flaky oxalic acid The photocatalyst powder of oxytitanium salt is a white powder, the diameter of the hexagonal plate is 3 μm, and the thickness of the hexagonal plate is 0.8 μm.

[0048] refer to image 3 and Figure 4 , the hexagonal flaky titanyl oxalate p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com