Light absorbing material and preparation method thereof

A light-absorbing material and ultraviolet light technology, applied in chemical instruments and methods, vanadium oxide, metal/metal oxide/metal hydroxide catalysts, etc. Complicated methods and other issues, to achieve the effects of wide and cheap raw material sources, degradation of air pollutants, and enhanced catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the light absorbing material of the present invention comprises the following steps:

[0045]1) Mixing materials: mix the oxalic acid solution and the vanadium-containing precursor, and fully stir to obtain a sol; wherein, the molar ratio of the vanadium in the vanadium-containing precursor to the carbon in the oxalic acid is 1: (1.5~3.5); The vanadium precursor includes any one of vanadium pentoxide and ammonium metavanadate;

[0046] 2) Hydrothermal reaction: react the sol obtained in step 1) at 220-250°C for 24-72 hours to obtain a crude product;

[0047] 3) Post-reaction treatment: washing and drying the crude product to obtain a light-absorbing material.

[0048] The inventive method, according to preset V:C mol ratio, in oxalic acid (H 2 C 2 o 4 ) into the deionized aqueous solution containing vanadium, and the sol was obtained after stirring evenly, and the sol was transferred to a hydrothermal kettle for hydrothermal reaction to obt...

Embodiment 1

[0060] (1) Preparation of sol: get 30mmol of H 2 C 2 o 4 Add it to 80mL of deionized water, stir evenly until completely dissolved; then take 10mmol of V 2 o 5 Dissolve in the above solution and stir evenly until completely dissolved to obtain a sol.

[0061] (2) Hydrothermal reaction: Clean the liner of the hydrothermal reaction kettle with deionized water and absolute ethanol, pour the sol prepared in step 1) into a 100mL liner of the hydrothermal reaction kettle, and react at 240°C for 48 hours, after cooling to room temperature, the product was alternately washed 3 times with water and absolute ethanol, and dried in an oven at 100°C for 10 hours to obtain the black product VO x Powder light absorbing material.

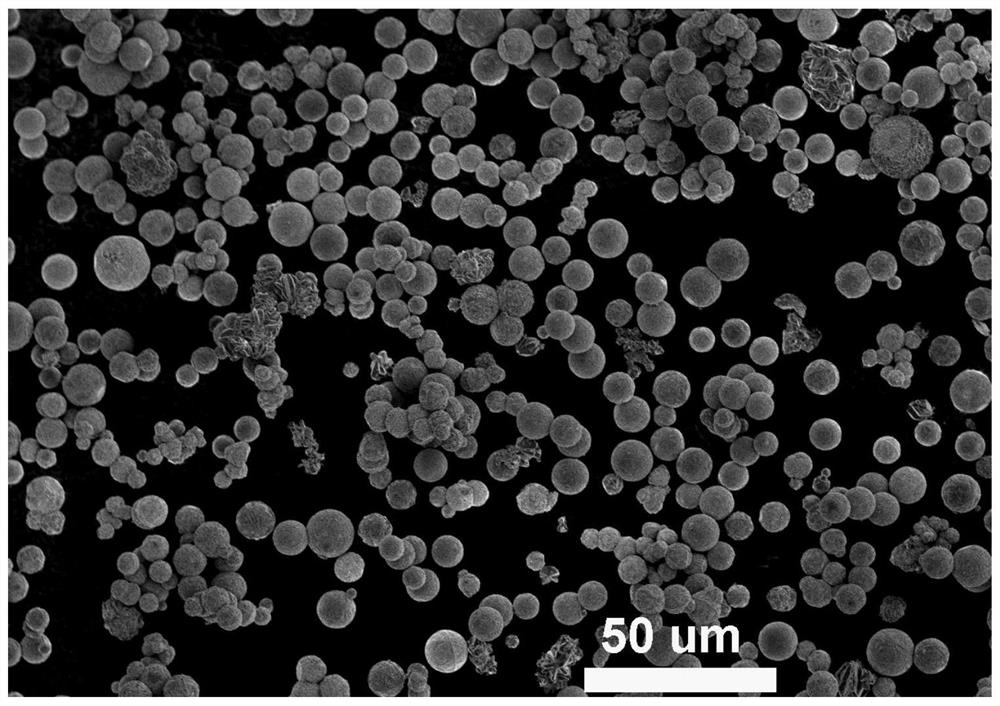

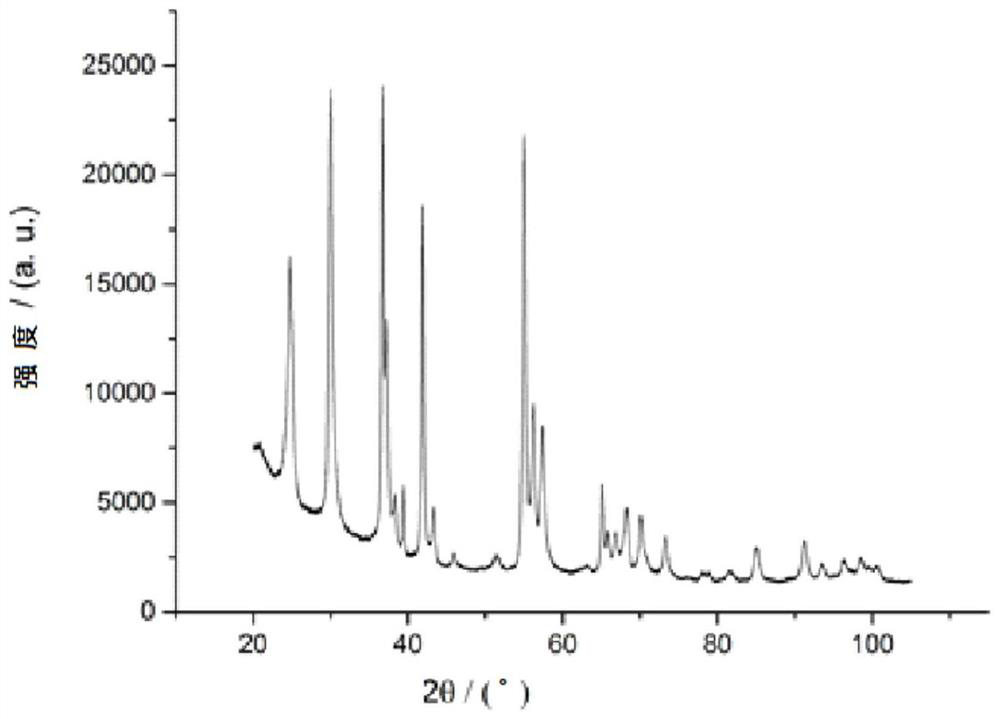

[0062] VO prepared in this embodiment x The powder scanning electron microscope picture is as follows figure 1 As shown, the morphology of the sample is similar to that of a spherical structure. The XRD pattern of the sample is as follows figure 2 As show...

Embodiment 2

[0064] (1) Preparation of sol: get 30mmol of H 2 C 2 o 4 Add to 80mL of deionized water, stir evenly until completely dissolved; then take 20mmol of NH 4 VO 3 Dissolve in the above solution and stir evenly until completely dissolved to obtain a sol.

[0065] (2) Hydrothermal reaction: Clean the liner of the hydrothermal reaction kettle with deionized water and absolute ethanol, pour the sol prepared in step 1) into a 100mL liner of the hydrothermal reaction kettle, and react at 240°C for 48 hours, after cooling to room temperature, the product was alternately washed 3 times with water and absolute ethanol, and dried in an oven at 150°C for 6 hours to obtain the black product VO x Powder light absorbing material.

[0066] The VO x The XRD pattern of the powder is shown in Figure 7 , similar to figure 2 , shown as the novel VO of the present invention x Crystal structure. Its reflection spectrum see Figure 8 , which proves that it has very strong absorption in ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com