TiO2 nanoparticle film and preparation method thereof

A nanoparticle and thin film technology, applied in the field of photocatalysis, can solve the problems of easy cracking and poor substrate adhesion, and achieve the effect of simple and controllable preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] A kind of TiO 2 A method for preparing a nanoparticle film, comprising the steps of:

[0056] Step 1: Put 20×20mm 2 Titanium foils of large and small areas were successively put into 99.7wt% ethanol and deionized water for ultrasonic cleaning for 15 minutes respectively. foil;

[0057] or,

[0058] 20×20mm 2 Ti foils of large and small areas were ultrasonically cleaned in 99.7wt% ethanol and deionized water for 15 minutes, and then put in 40wt% HF, 65-68wt% HNO 3 and H 2 Mixed acid solution of O (the volume ratio is HF:HNO 3 :H 2 O=1:1:2) Immerse for 15s to remove the oxide layer on the surface of the titanium foil to obtain a new titanium surface. After taking it out, rinse it repeatedly with deionized water, and then put the titanium foil into deionized water for ultrasonic cleaning for 10-15min. Thoroughly remove the mixed acid solution to obtain a cleaned titanium foil;

[0059] Step 2: Put the cleaned titanium foil in Step 1 into an oven and dry it at 60-8...

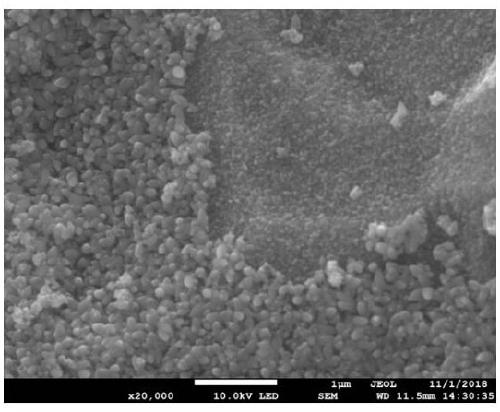

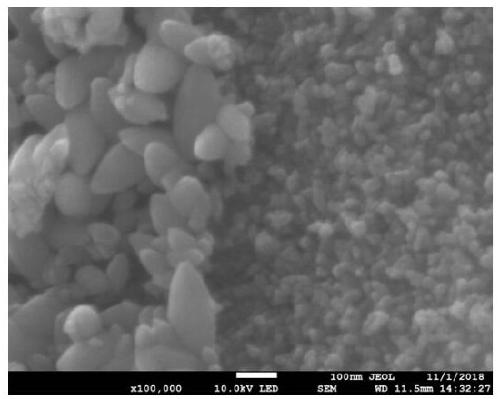

Embodiment 1

[0065] 20×20mm 2 Titanium foils of large and small areas were put into 99.7wt% ethanol and deionized water for ultrasonic cleaning for 15 minutes respectively; then put into 40wt% HF, 68wt% HNO 3 and H 2 Mixed acid solution of O (the volume ratio is HF:HNO 3 :H 2 O=1:1:2) soak for 15s, take it out and rinse it with deionized water, put the titanium foil in deionized water and ultrasonically clean it for 15min to get the cleaned titanium foil; put the cleaned titanium foil into the oven After drying at 70°C for 2 hours, put it into an 80mL reaction kettle; add 5.844g NaCl into deionized water, stir until completely dissolved, and prepare a 50mL NaCl solution with a concentration of 2mol / L; add 10mL of 30wt% H 2 o 2 Add it to the above NaCl solution, stir until it is completely dissolved, and mix the solution evenly to obtain a mixed solution; transfer the mixed solution to an 80mL reaction kettle, and perform a hydrothermal reaction at 160°C for 6h; after the reaction kettl...

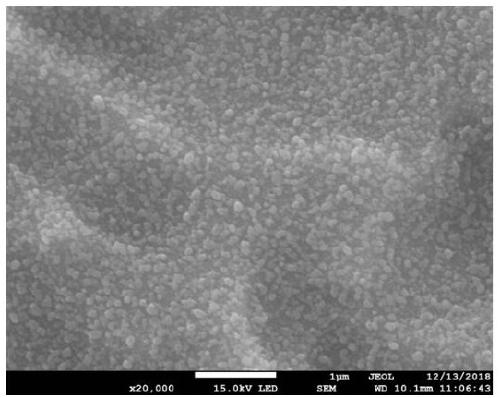

Embodiment 2

[0068] 20×20mm 2 Titanium foils of large and small areas were ultrasonically cleaned in 99.7wt% ethanol and deionized water for 15 minutes respectively; then put in 40wt% HF, 65wt% HNO 3 and H 2 Mixed acid solution of O (the volume ratio is HF:HNO 3 :H 2 O=1:1:2) soak for 15s, take it out and rinse it with deionized water, put the titanium foil in deionized water and ultrasonically clean it for 15min to get the cleaned titanium foil; put the cleaned titanium foil into the oven After drying at 75°C for 2 hours, put it into an 80mL reaction kettle; add 5.844g NaCl into deionized water, stir until completely dissolved, and prepare a 50mL NaCl solution with a concentration of 2mol / L; add 10mL of 30wt% H 2 o 2 Add it into the above NaCl solution, stir until it is completely dissolved, and mix the solution evenly to obtain a mixed solution; transfer the mixed solution to an 80mL reaction kettle, and perform a hydrothermal reaction at 160°C for 8h; after the reaction kettle is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com