Adhesive film for organic electronic device and sealing material for organic electronic device comprising same

A technology for organic electronic devices and packaging materials, applied in non-polymer adhesive additives, film/sheet adhesives, circuits, etc., can solve problems such as damage, and achieve the effect of improving life and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

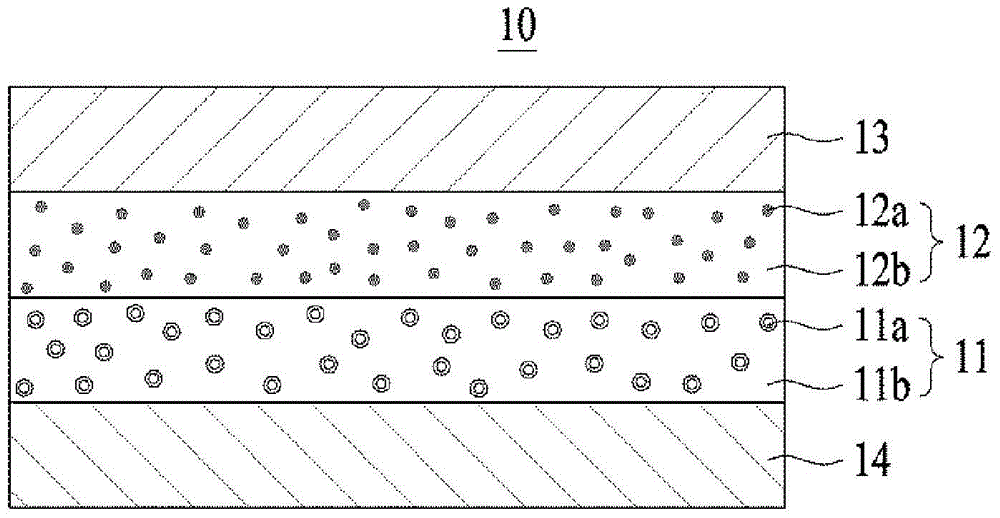

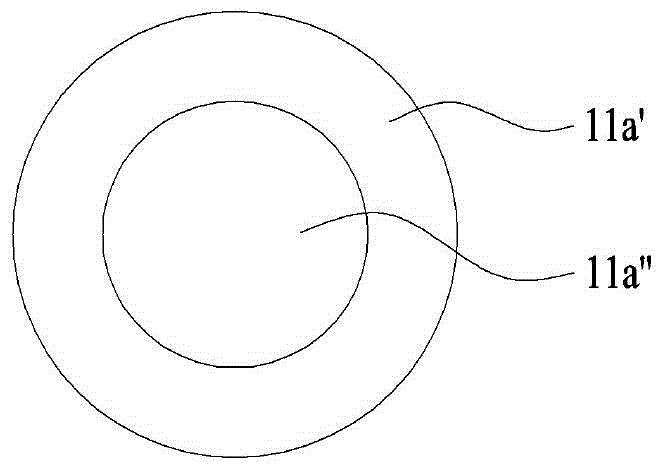

Method used

Image

Examples

Embodiment 1

[0132]First, in order to form the first adhesive layer, 50 weights of high-purity (total chlorine content below 500ppm, n=0) silicon-denatured liquid epoxy (XFR-8628) replaced by a silicon intermediate containing phenyl groups and DCPD-type solid Epoxy (HP-7200L, DIC) 50 weight percent epoxy resin 100 weight parts, drop into phenoxy resin (PKHH, Inchem) 100 weight parts to prepare the first bonding component, and to the first bonding component 100 weight parts, as The solvent contained 150 parts by weight of methyl isobutyl ketone, and was stirred at normal temperature for 2 hours. 1.5 parts by weight of an acid anhydride hardener (B4500, DIC) was added to the above-mentioned agitated material with respect to 100 parts by weight of the above-mentioned first adhesive component, and the dispersion coefficient of the particle size shown in Table 1 was added as a diluent and dispersed by an ultrasonic pulverizer. 25 parts by weight of 25% hollow silica (HS300, Sukkyung), after sti...

Embodiment 2~8

[0136] The same method as in Example 1 was carried out, but as shown in Table 1 below, the type and content of the hygroscopic agent contained in the first adhesive layer and the second adhesive layer were changed to obtain the adhesive film shown in Table 1 below.

experiment example 1

[0140] The following physical properties were measured and described in Table 1 and Table 2 for the adhesive films produced in the above Examples and Comparative Examples.

[0141] 1. Moisture penetration evaluation of adhesive film

[0142] After cutting the test piece into a size of 95mm×95mm, remove the protective film and align it on the 100mm×100mm non-alkali glass, 2.5mm inward from the 4 edges of the glass, and then use a film laminating machine heated to 65°C. attached. After removing the release film on the attached test piece, another 100 mm x 100 mm alkali-free glass was covered and laminated at 65° C. for one minute using a vacuum laminator to prepare a sample without air bubbles. After the laminated samples were hardened in a heating furnace at 100°C for three hours, the lengths were observed using a microscope after water infiltration in units of 100 hours in a reliability chamber set at a temperature of 85°C and a relative humidity of 85%.

[0143] 2. Evaluati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com