Lithium ion battery negative electrode active material, preparation method thereof, negative electrode and battery

A negative electrode active material, lithium ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery cyclability and initial charge-discharge efficiency, low conductivity of silicon carbon negative electrode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Preparation method of the present invention can specifically be as follows:

[0045] Step 1. Combine nano-silicon particles with a particle size of 30nm~300nm, the first additive and the first organic carbon source (the mass ratio of nano-silicon particles, the first organic carbon source, and the first additive is 2:8:1~ 8:2:1) After dispersion by ball milling (the ball milling process was carried out under an inert atmosphere in the experiment, no special instructions will be given later), the ball milling time is 4 hours, and the ball milling speed is 230r / min. Under an inert atmosphere, the temperature was raised at 2°C / min, and the temperature was kept at 500°C~1200°C for 2h. After cooling down to room temperature, it was pulverized by ball milling at 210r / min for 40min to obtain silicon-carbon composite particles with a particle size of 0.5μm~10μm, marked as A.

[0046] Step 2. Combine the second organic carbon source, the second auxiliary agent and the porogen (...

Embodiment 1

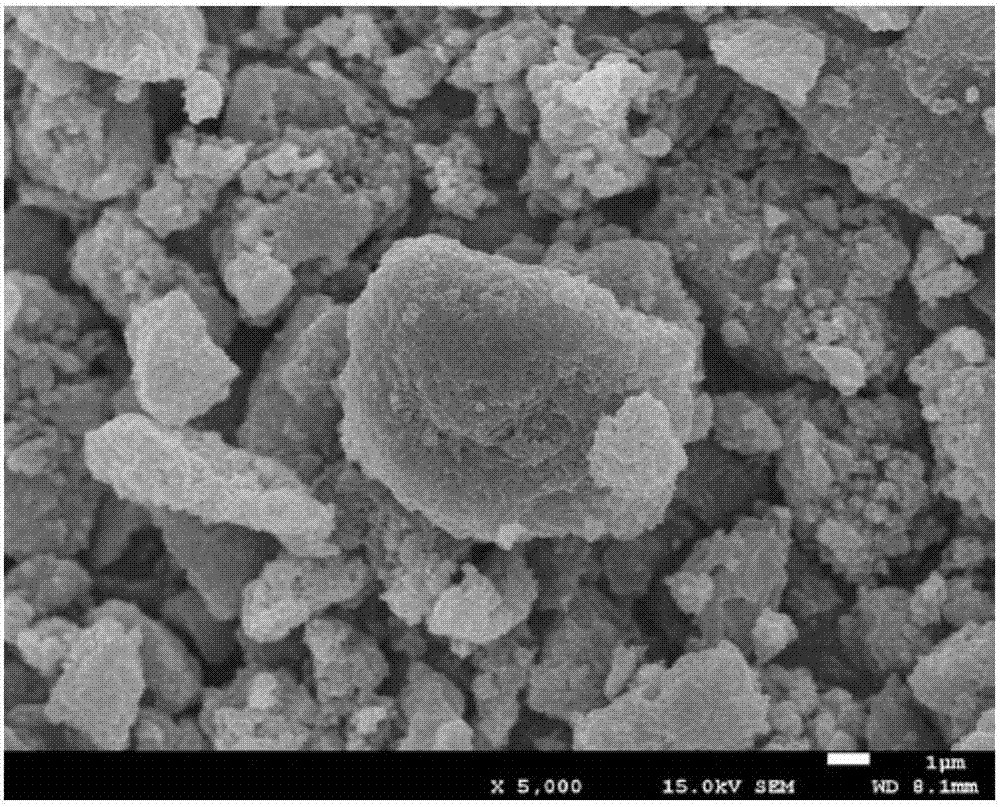

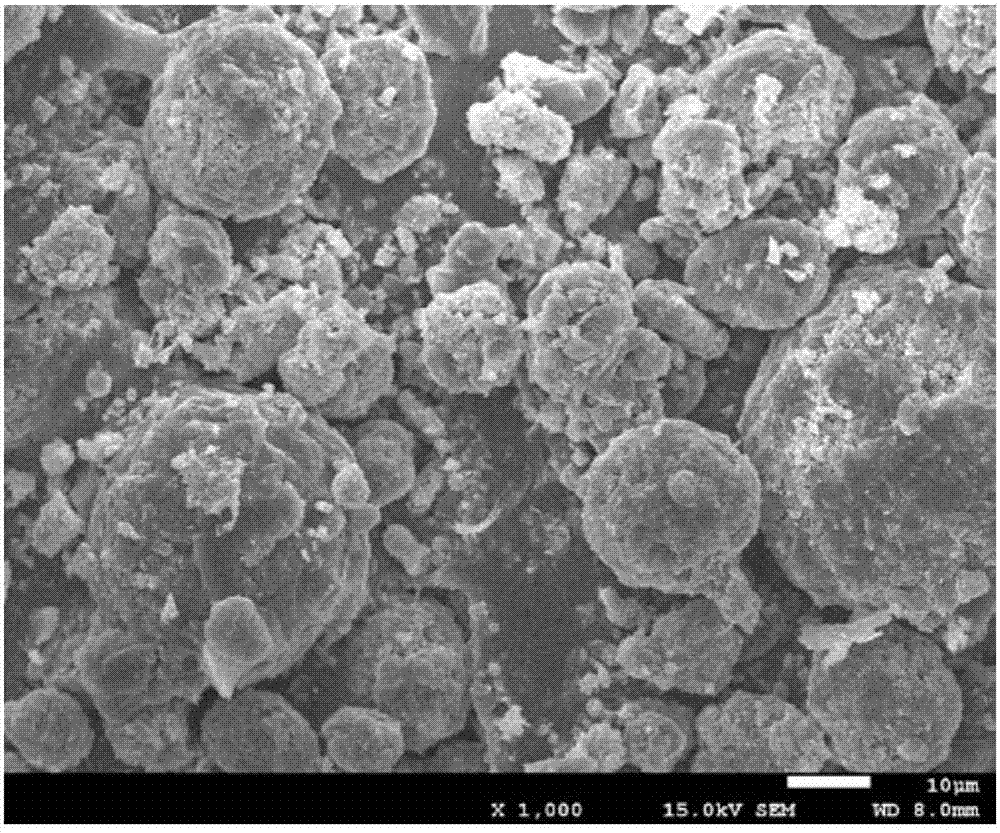

[0055] Step 1, the nano-silicon particles (particle size 100nm), phenolic resin and carbon nanotubes (the mass ratio of nano-silicon particles, phenolic resin, carbon nanotubes is 2:8:1, the total dosage is 165g) through ball milling (in the experiment The ball milling process is all carried out under a nitrogen atmosphere, and there will be no special instructions in the follow-up) After dispersion, the ball milling time is 4 hours, and the ball milling speed is 230r / min. Place in an atmosphere furnace, bake under the protection of nitrogen, heat up at 2°C / min, and keep at 500°C for 2h. After cooling down to room temperature, it was pulverized by ball milling at 210 r / min for 40 min to obtain silicon-carbon composite particles with a particle size of 5 μm, and the product was marked as A1.

[0056] Step 2. Mix nano-silica (particle size 30~40nm), pitch and carbon nanotubes (the mass ratio of nano-silica, pitch, and carbon nanotubes is 30:10:1, and the total dosage is 155g), a...

Embodiment 2

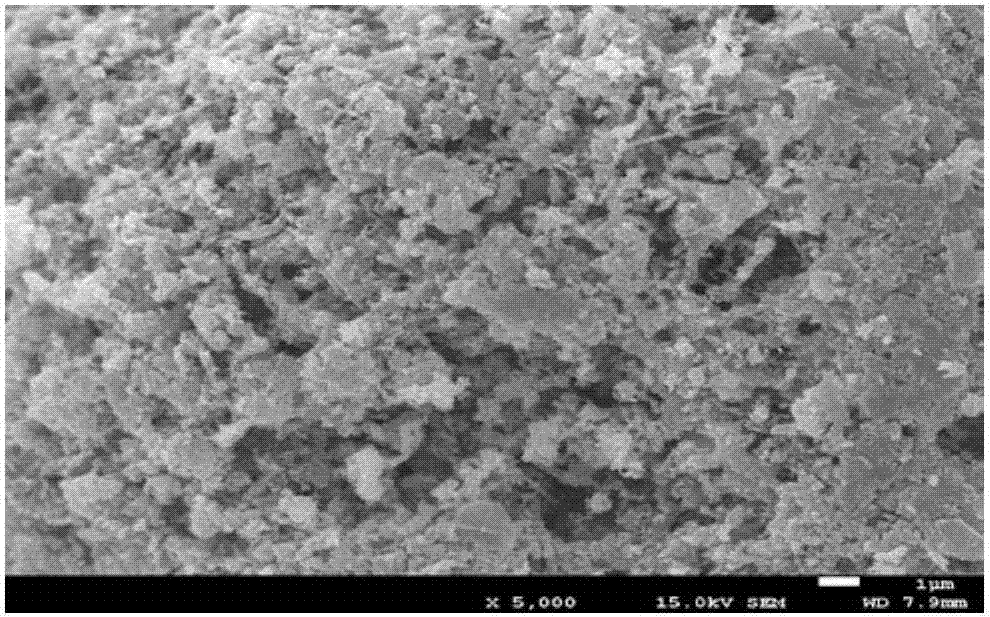

[0064] Step 1, the nano-silicon particles (particle size 100nm), phenolic resin and carbon nanotubes (the mass ratio of nano-silicon particles, phenolic resin and carbon nanotubes is 10:20:1, the total dosage is 165g) through ball milling (in the experiment The ball milling process is all carried out under a nitrogen atmosphere, and there will be no special instructions in the follow-up) After dispersion, the ball milling time is 4 hours, and the ball milling speed is 230r / min. Place in an atmosphere furnace, bake under the protection of nitrogen, heat up at 2°C / min, and keep at 700°C for 2h. After cooling down to room temperature, it was ball milled at 210 r / min for 40 minutes to obtain silicon-carbon composite particles with a particle size of 2 μm, and the product was marked as A2.

[0065] Step 2. After ball milling and dispersing nano-calcium carbonate (particle size 80nm), pitch and carbon nanotubes (the mass ratio of nano-silicon dioxide, pitch, and carbon nanotubes is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com