Negative electrode material of flexible sodium metal battery and preparation method thereof

A battery negative electrode and sodium metal technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high quality, hard carbon without good flexibility, and low energy density of composite electrodes, so as to solve volume expansion and high utilization rate , the effect of inhibiting the growth of sodium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a flexible sodium metal battery negative electrode material, the steps of the method are as follows:

[0045] 40mg (2.5mg / ml) of graphene oxide (the mass ratio of C and O is 1.95:1) was ultrasonically dispersed for 120min, and 120mg of ascorbic acid was added, stirred for 30min, and then placed in a water bath at 50°C for 6h to obtain an intermediate product, which was used to Wash the intermediate product repeatedly with ionic water, then put the intermediate product into a freeze dryer, and freeze-dry it at -181°C for 24 hours at 10 MPa to obtain graphene airgel. After slicing, punch the graphene airgel into Ф= The 10mm disc was transferred to a glove box, and 6mg of liquid metal sodium was adsorbed at 300°C to obtain a flexible sodium metal battery negative electrode material.

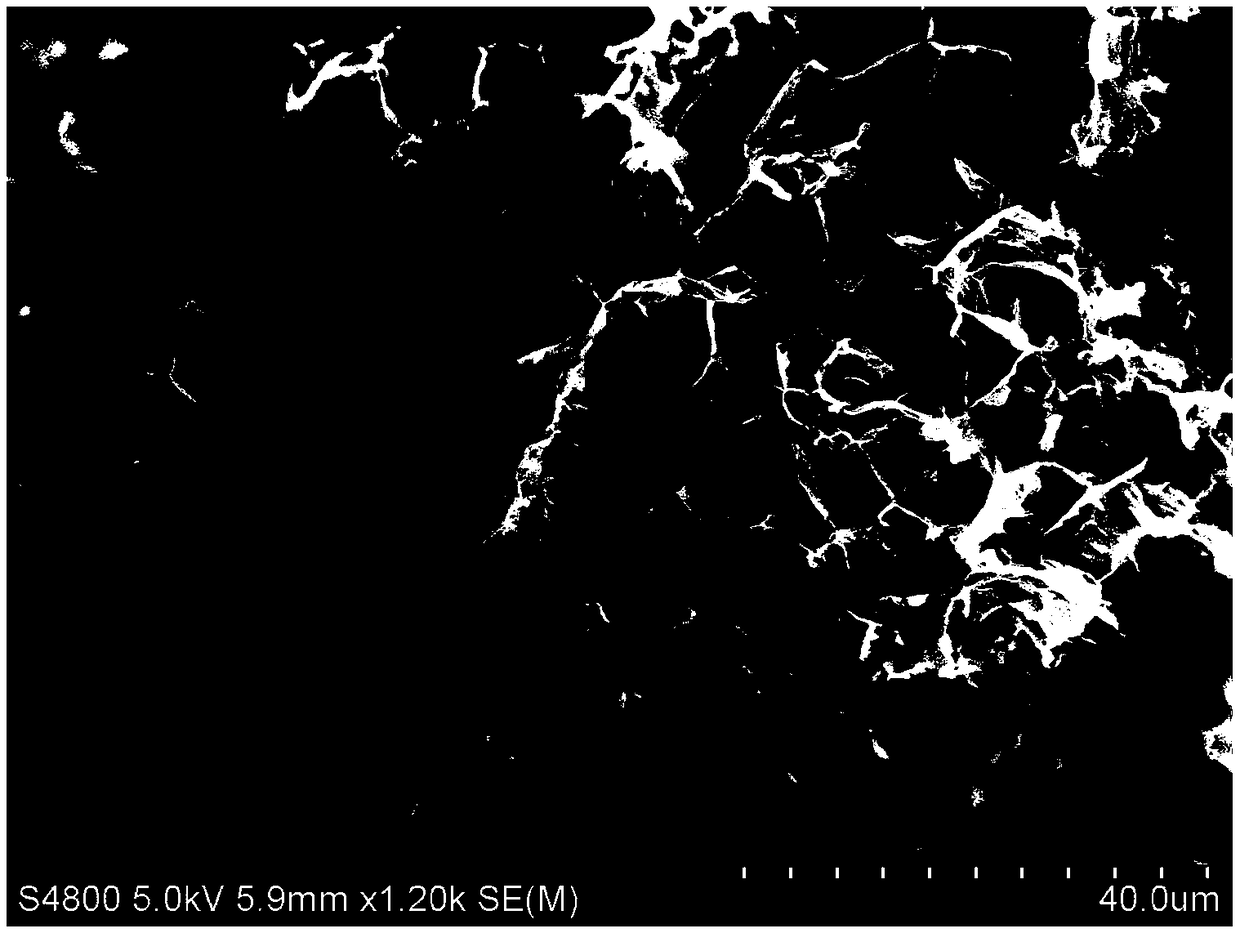

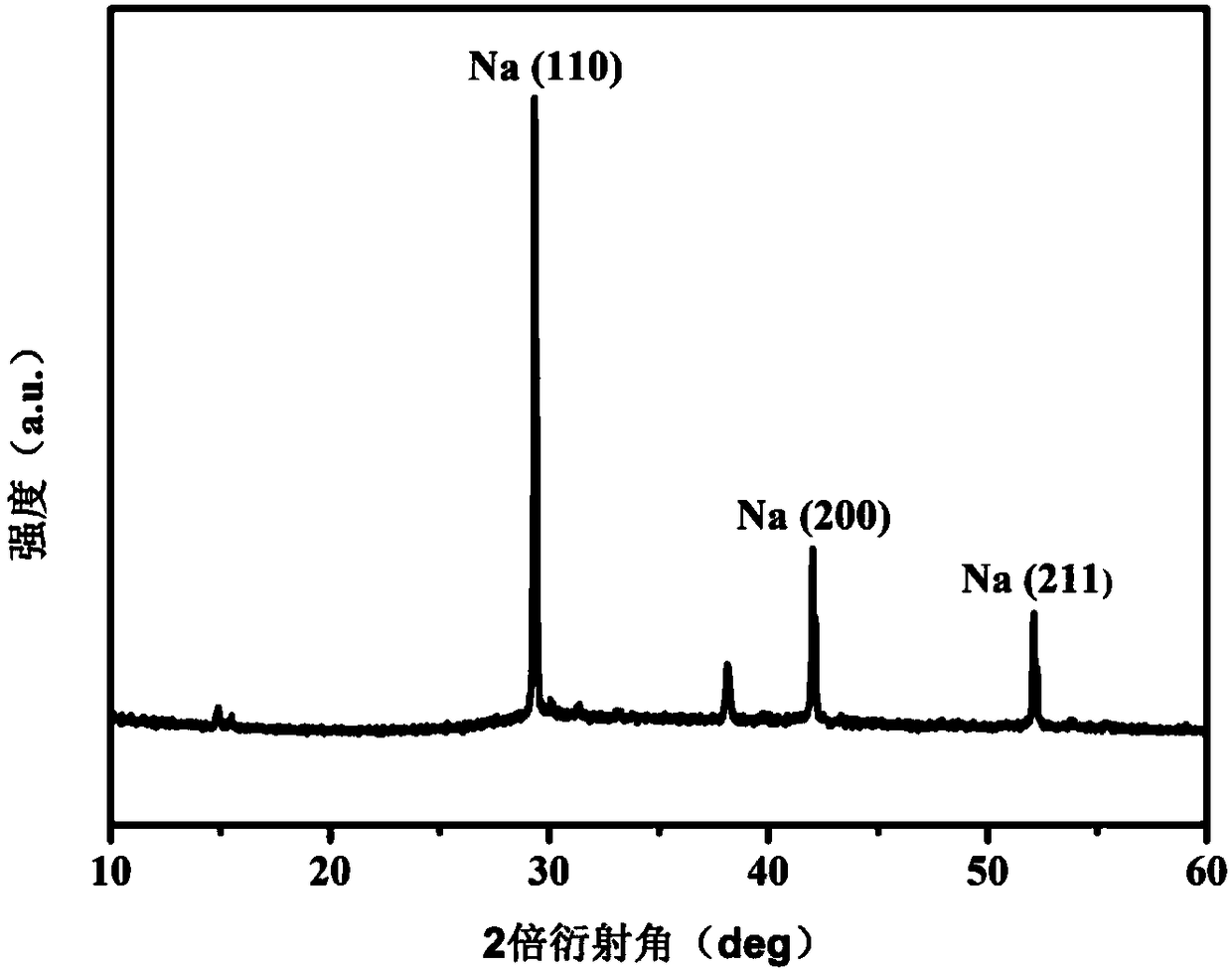

[0046] Scanning electron microscopy results of graphene aerogels as figure 1 As shown, the stacked pore-like structures constitute a compact 3d conductive framework wi...

Embodiment 2

[0051] A method for preparing a flexible sodium metal battery negative electrode material, the steps of the method are as follows:

[0052] 40mg (2.5mg / ml) of graphene oxide (the mass ratio of C and O is 2.5:1) was ultrasonically dispersed for 120min, and 120mg of ascorbic acid was added, stirred for 30min, and then placed in a water bath at 50°C for 6h to obtain an intermediate product, which was used to Wash the intermediate product repeatedly with ionic water, then put the intermediate product into a freeze dryer, and freeze-dry it at -181°C for 24 hours at 10 MPa to obtain graphene airgel. After slicing, punch the graphene airgel into Ф= The 10mm disc was transferred to a glove box, and 6mg of liquid metal sodium was adsorbed at 300°C to obtain a flexible sodium metal battery negative electrode material.

[0053] The scanning electron microscopy results of graphene airgel show that the stacked pore-like structure constitutes a compact 3D conductive framework with a pore ...

Embodiment 3

[0058] A method for preparing a flexible sodium metal battery negative electrode material, the steps of the method are as follows:

[0059] 40mg (2.5mg / ml) of graphene oxide (the mass ratio of C and O is 1.95:1) was ultrasonically dispersed for 120min, and 120mg of ascorbic acid was added, stirred for 30min, and then placed in a water bath at 120°C for 6h to obtain an intermediate product, which was used to Wash the intermediate product repeatedly with ionic water, then put the intermediate product into a freeze dryer, and freeze-dry it at -181°C for 24 hours at 10 MPa to obtain graphene airgel. After slicing, punch the graphene airgel into Ф= The 10mm disc was transferred to a glove box, and 6mg of liquid metal sodium was adsorbed at 300°C to obtain a flexible sodium metal battery negative electrode material.

[0060] The scanning electron microscopy results of graphene airgel show that the stacked pore-like structure constitutes a compact 3D conductive framework with a por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com