Lithium-sulfur battery composite positive electrode material and preparation method thereof

A technology of composite materials and lithium-sulfur batteries, which is applied in the fields of battery electrodes, electrolyte storage battery manufacturing, and non-aqueous electrolyte storage batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

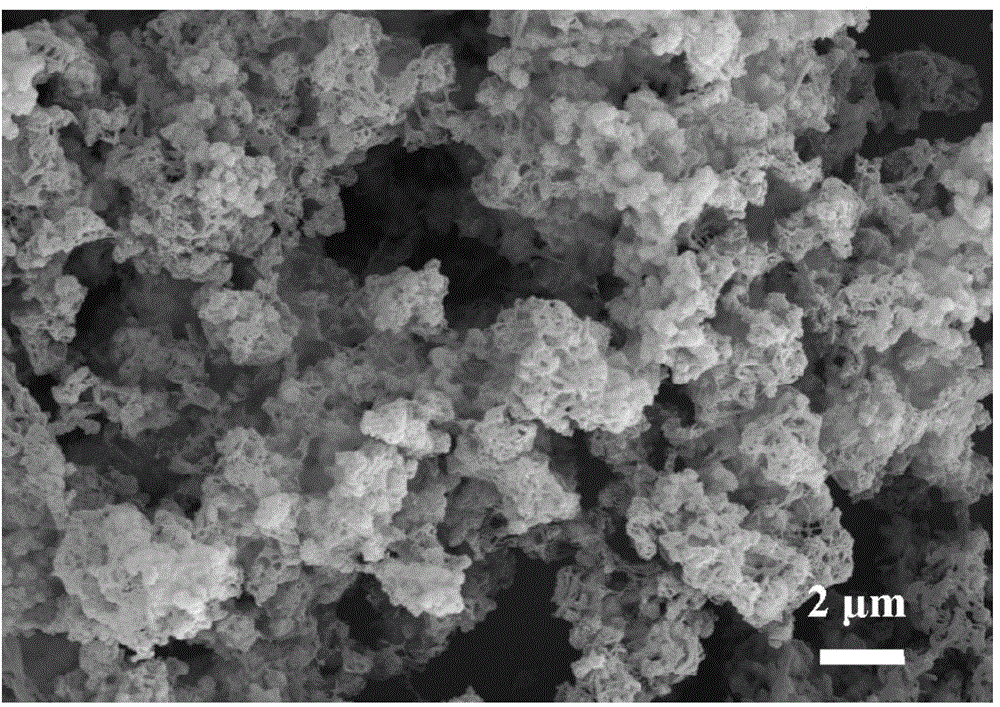

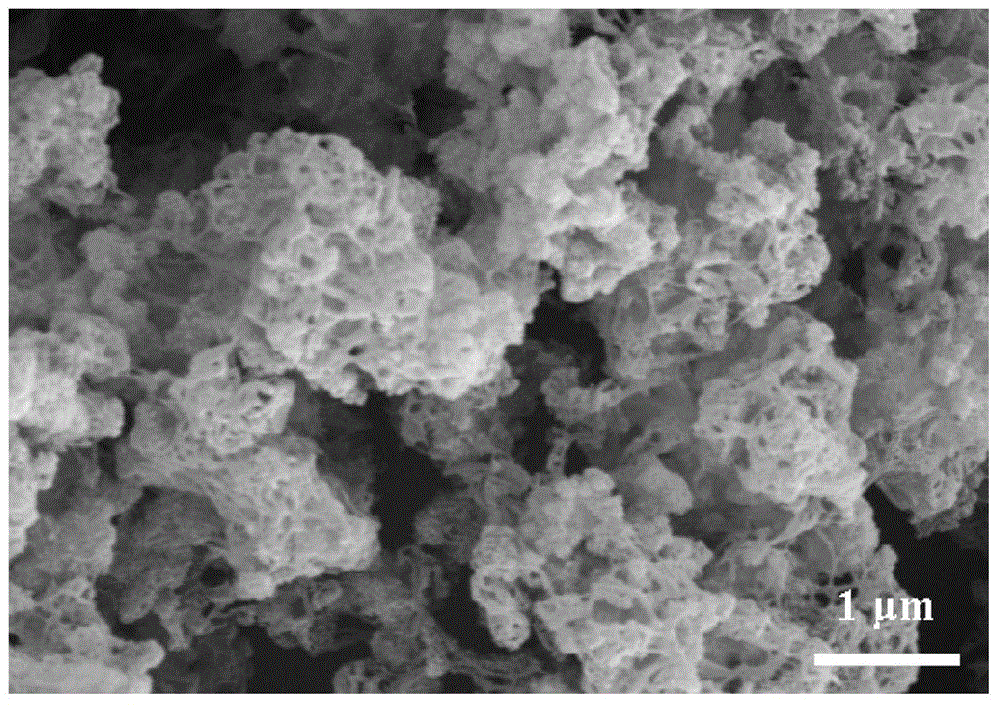

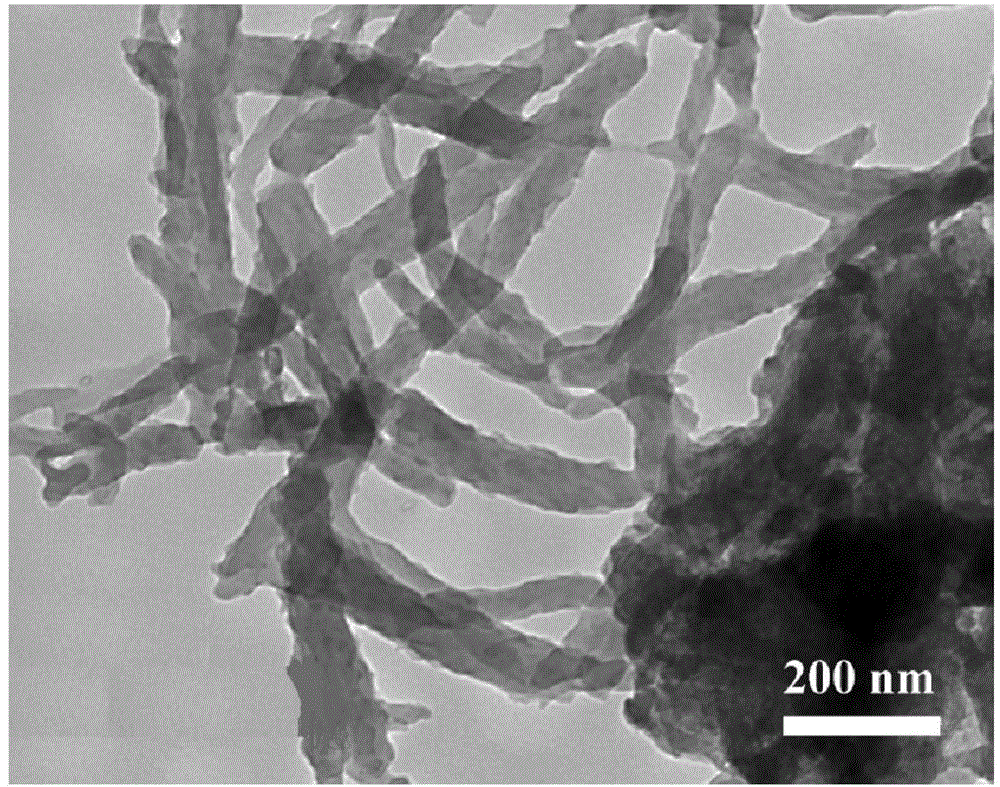

[0029] A lithium-sulfur battery cathode composite material, which comprises oxidized carbon black, conductive polymer and elemental sulfur. Oxidized carbon black particles are the structural core of the positive electrode composite material, and the conductive polymer forms the frame of the positive electrode composite material. The conductive polymer has a spherical network pore structure, and elemental sulfur is deposited on the surface and inside of the spherical network pores. The positive electrode composite material is prepared by multi-step synthesis by in-situ polymerization method and hydrothermal method.

[0030] The preparation method of the conductive polymer composite material of this embodiment includes the following steps:

[0031] (1) Preparation of oxidized carbon black: Dissolve acetylene black in concentrated nitric acid, and apply ultrasonic dispersion method for treatment, and the treatment time is t 0 , 5mins≤t 0 ≤10mins, formulated to a concentration of n 0 S...

Embodiment 2

[0042] The preparation method of the conductive polymer composite material of this embodiment includes the following steps:

[0043] (1) Preparation of oxidized carbon black: Dissolve acetylene black in concentrated hydrochloric acid, and apply ultrasonic dispersion method for treatment, and the treatment time is t 0 , 5mins≤t 0 ≤10mins, formulated to a concentration of n 0 Solution, 0.01g / mL≤n 0 ≤0.05g / mL; put the solution in an autoclave for pressure heating treatment, the pressure is P, 0MPa≤P≤70MPa, and the heating temperature is T 0 ,60℃≤T 0 ≤200℃, processing time is t 1 , 0.5h≤t 1 ≤10h; after that, the solution is washed by ultrasonic centrifugation and the centrifugal speed is v 0 ,1000rad / min≤v 0 ≤8000rad / min; washing times is N 0 , 1≤N 0 ≤8.

[0044] (2) Preparation of monomer solution: the total mass of the battery cathode composite material after drying according to claim 1 is m 0 , Weigh oxidized carbon black m 1 , 0.05m 0 ≤m 1 ≤0.15m 0 , Dispersed at a concentration of n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com