Modified lithium-based composite negative material for solid state battery and preparation and application of material

A negative electrode material and solid-state battery technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as difficult large-scale production and expensive methods, achieve inhibited growth, increase limit current density, and reduce interface impedance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

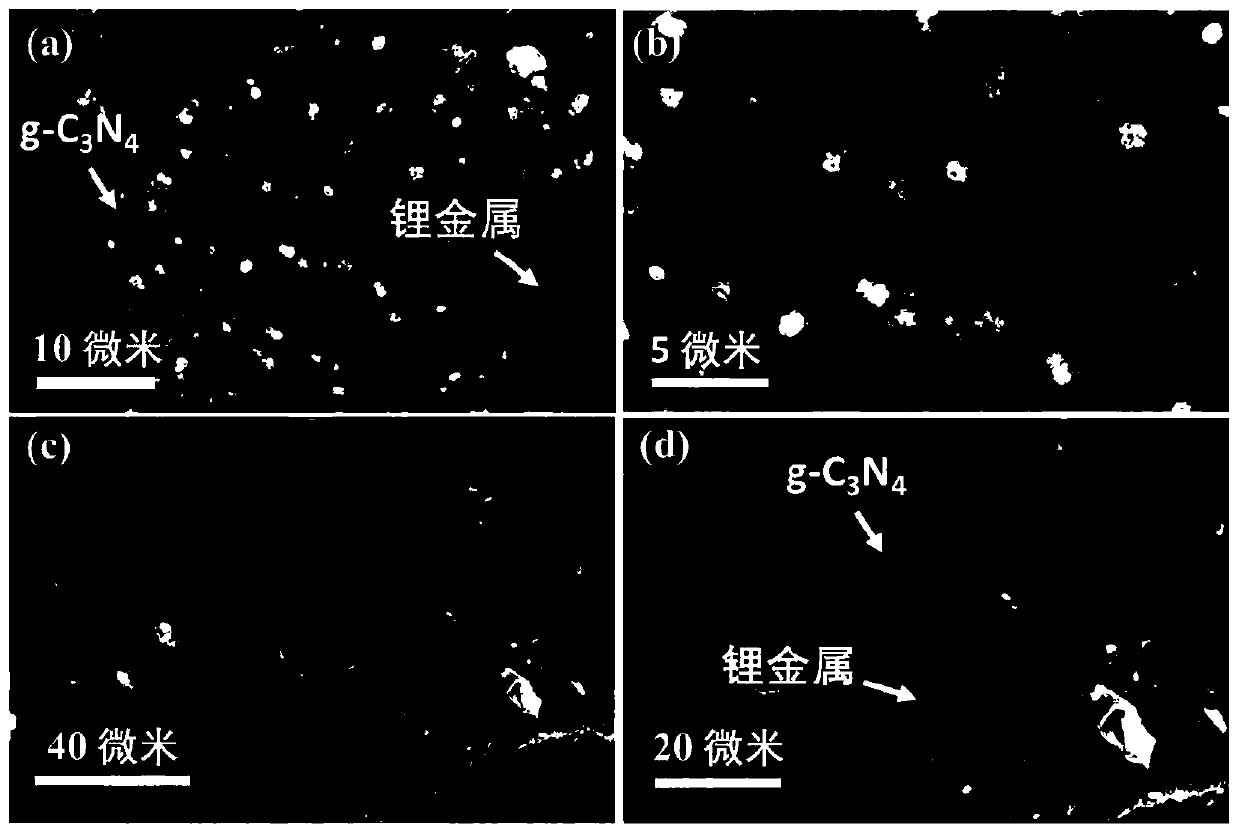

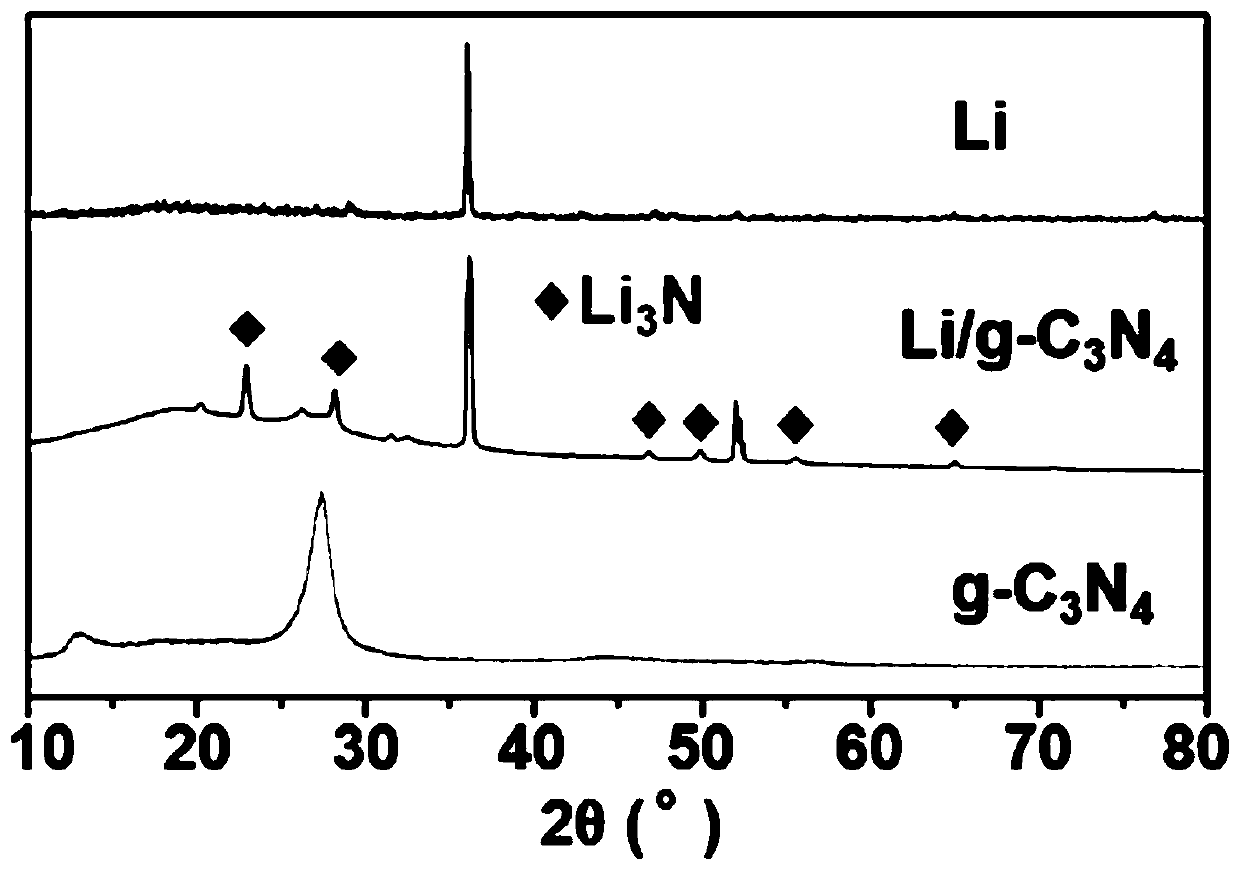

[0038] Commercial melamine powder was pyrolyzed at 550 °C in air for 4 hours to obtain graphitized carbon nitride (g-C 3 N 4 ) powder, where the heating rate is 5°C / min.

[0039] In a high-purity argon atmosphere, lithium metal with a purity of battery grade and pyrolyzed g-C 3 N 4 The powder is mixed according to the mass ratio of 9:1 and placed in a high-temperature stirrer. The high-temperature stirrer is heated to 280°C to melt the metal lithium. At a constant temperature, the molten metal lithium is continuously stirred to fully mix with the carbon nitride powder. The stirring speed is 60r / min, and the time is 40min.

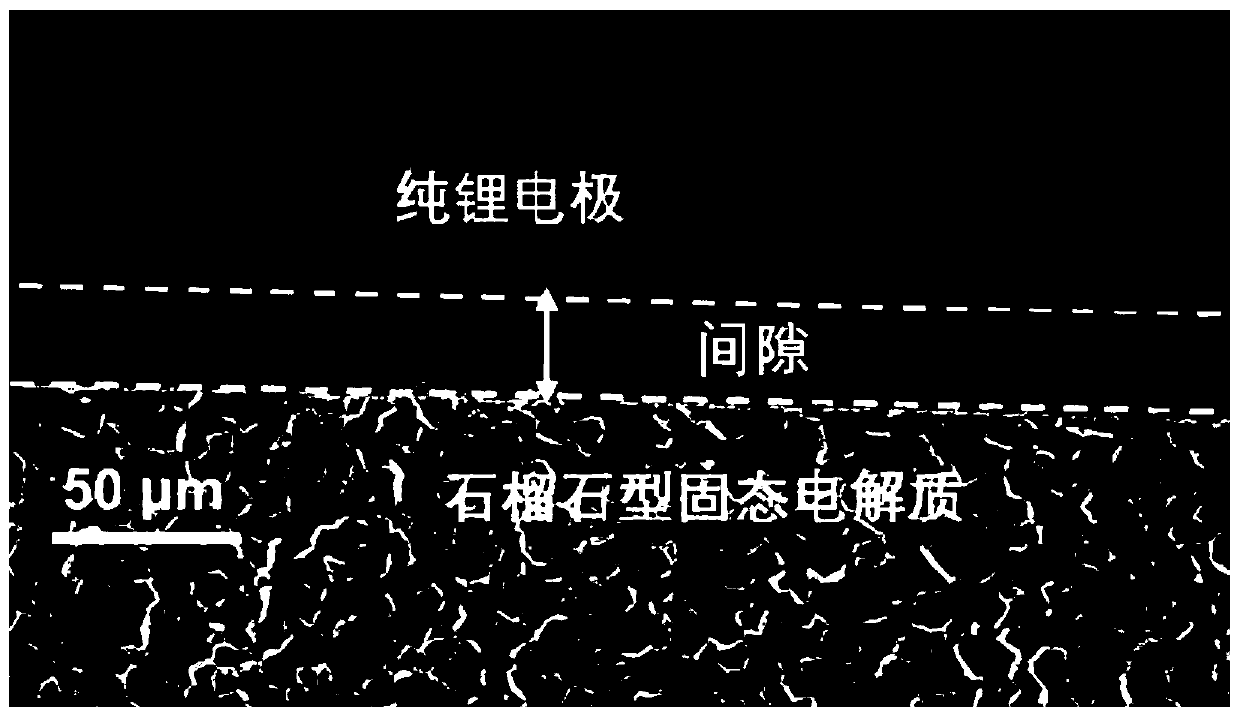

[0040] Lithium metal and g-C 3 N 4 After the powder is mixed evenly, preheat the polished lithium lanthanum zirconium oxide ceramic sheet to 280°C, and then evenly coat the above-mentioned modified lithium-based composite negative electrode material on the ceramic sheet, place it at room temperature, and let it cool down and solidify .

[0041] The a...

Embodiment 2

[0051] In a high-purity argon atmosphere, mix battery-grade lithium metal and commercial boron nitride powder in a mass ratio of 9:1 and put them in a high-temperature stirrer. After the temperature is heated to 300°C to melt the lithium metal, control Constant temperature, under the action of mechanical stirring of stainless steel stirrer, the rotating speed is 80r / min, and the time is 60min. After the constant temperature stirring is completed, the heat supply of the high temperature stirrer is stopped, so that the lithium-boron nitride composite negative electrode material is gradually cooled down to room temperature.

[0052] The solidified composite negative electrode material is rolled and thinned by using a roller press, and the porous copper foil is used as a metal current collector, and the thinned lithium-boron nitride composite negative electrode material is transferred to the porous copper foil.

[0053] The selected porous copper foil is 200 mesh, the thickness is...

Embodiment 3

[0056] In a high-purity argon atmosphere, mix battery-grade lithium metal and commercial aluminum nitride powder in a mass ratio of 8:2 and put them in a high-temperature stirrer. After the temperature is heated to 250°C to melt the lithium metal, control Constant temperature, under the action of mechanical stirring of stainless steel stirrer, the rotating speed is 90r / min, and the time is 20min. After the constant temperature stirring is completed, the heat supply of the high temperature stirrer is stopped, so that the lithium-aluminum nitride composite negative electrode material is gradually cooled and solidified.

[0057] After preheating the polished lithium lanthanum zirconium oxide ceramic sheet to 250°C, the uniformly stirred lithium-aluminum nitride compound is evenly coated on the ceramic sheet, and placed at room temperature to cool down and solidify.

[0058] The amount of coating on the ceramic sheet is based on the coated lithium-aluminum nitride composite powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com