Composite quasi-solid-state electrolyte and preparation method thereof, and lithium battery or lithium ion battery containing composite quasi-solid-state electrolyte

A solid electrolyte, quasi-solid-state technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, lithium battery, etc., can solve the problems of fragile electrolyte membrane, poor air stability, poor mechanical flexibility, etc., achieve good interface wettability, prevent Effect of volume expansion, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

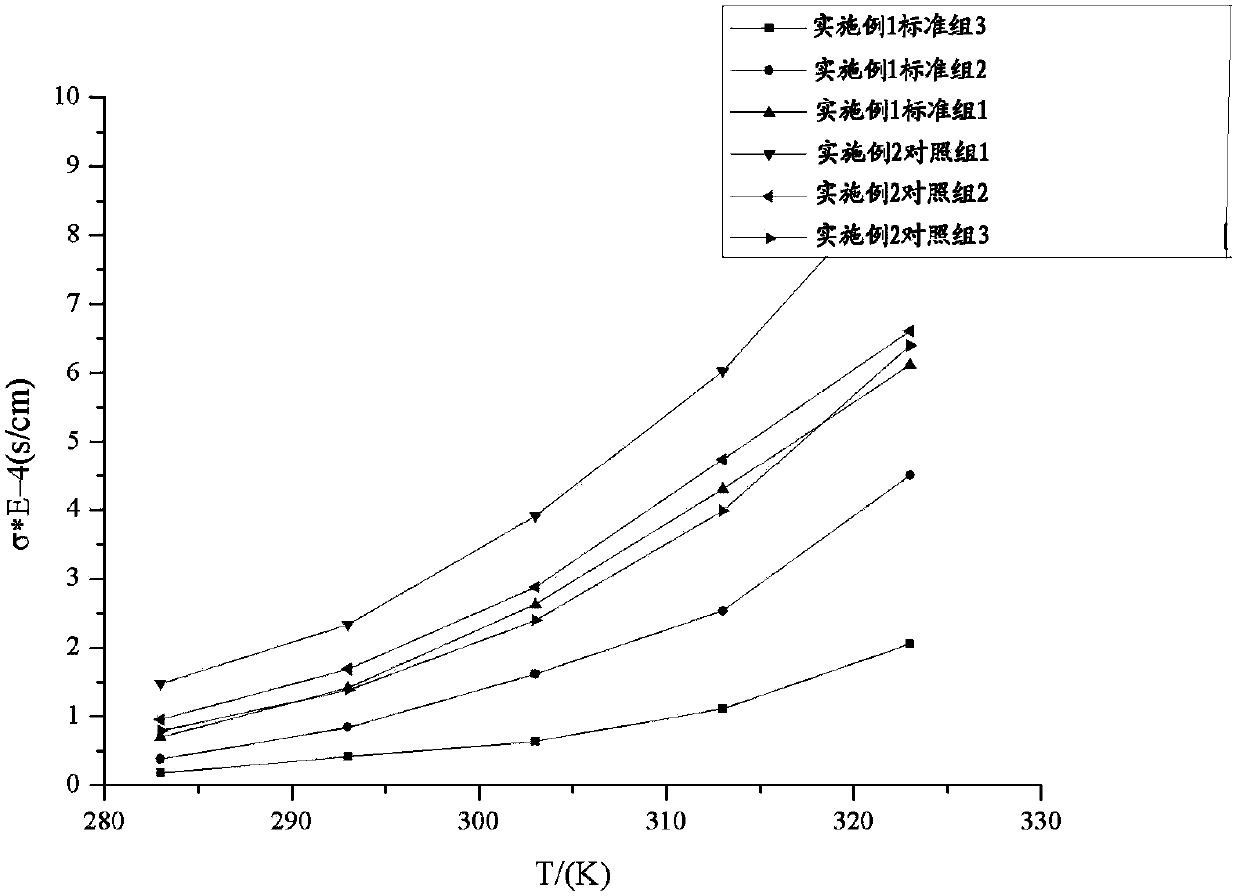

[0073] Comparative example without adding solid electrolyte

[0074] In this example, the quasi-solid electrolyte membrane was prepared by the second embodiment of the method of the present invention, but in this comparative example, no solid electrolyte was added. Specifically, the quasi-solid electrolyte membrane is prepared in an anhydrous atmosphere at a temperature of 20° C. and a dew point of 30° C. to 50° C. In this comparative example, three quasi-solid electrolyte membranes without solid electrolyte were prepared using the ingredients and contents listed in standard group 1, standard group 2 and standard group 3.

[0075] Standard group 1: 3.3g nano fumed silica (particle size is 7nm), 4.48g LiG3TFSI and binder PTFE powder (0.324g); Wherein, by the total mass of quasi-solid electrolyte composition, the mass fraction of LiG3TFSI is 55.28% (the corresponding volume fraction is 70%; the volume fraction is based on the sum of the volumes of the components before mixing...

Embodiment 2

[0086] In this example, the composite quasi-solid electrolyte membrane is prepared using the second embodiment of the method of the present invention. In this example, a solid electrolyte is added to the composite quasi-solid electrolyte. Specifically, the composite quasi-solid electrolyte membrane is prepared in an anhydrous atmosphere with a temperature of 20°C and a dew point of 30°C to 50°C. In this example, three composite quasi-solid electrolyte membranes containing solid electrolytes were prepared using the components and contents listed in Control Group 1, Control Group 2, and Control Group 3.

[0087] Control group 1 (corresponding to the standard group 1 in embodiment 1): 2.2g nano fumed silica (particle diameter is 7nm), 5.12g LiG3TFSI, 2.5g Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 , Binder PTFE powder (0.41g). Based on the total mass of the composite quasi-solid electrolyte components, the mass fraction of nano fumed silica is 21%, the mass fraction of LiG3TFSI is 50% (...

Embodiment 3

[0105] The preparation method of the composite quasi-solid electrolyte membrane of this embodiment is the same as that of Embodiment 2.

[0106] Control group 4: 2.2g nano fumed silica (particle size is 7nm), 5.12g LiG3TFSI, 3.5gLi 6.75 La 3 Zr 1.75 Ta 0.25 o 12 , Binder PTFE powder (0.45g). Based on the total mass of the composite quasi-solid electrolyte components, the mass fraction of nano fumed silica is 19.5%, the mass fraction of LiG3TFSI is 45% (the corresponding volume fraction is 70%), Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 The mass fraction of the binder PTFE powder is 31.5%, and the mass fraction of the binder PTFE powder is 4%.

[0107] Control group 5: 2.2g nano fumed silica (particle size is 7nm), 5.12g LiG3TFSI, 8.2gLi 6.75 La 3 Zr 1.75 Ta 0.25 o 12 , Binder PTFE powder (0.646g). Based on the total mass of the composite quasi-solid electrolyte components, the mass fraction of nano fumed silica is 13.6%, the mass fraction of LiG3TFSI is 31.7% (the corre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com