Nickel-based multiple components cathode material and its preparation method

A positive electrode material, nickel-based technology, applied in the field of nickel-based multi-element positive electrode materials for lithium-ion secondary batteries and its preparation, can solve the problems of affecting the capacity of positive electrode materials, poor conductivity of the coating layer, poor safety performance, etc., to achieve Prevents direct contact, improves electrical conductivity, and suppresses heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

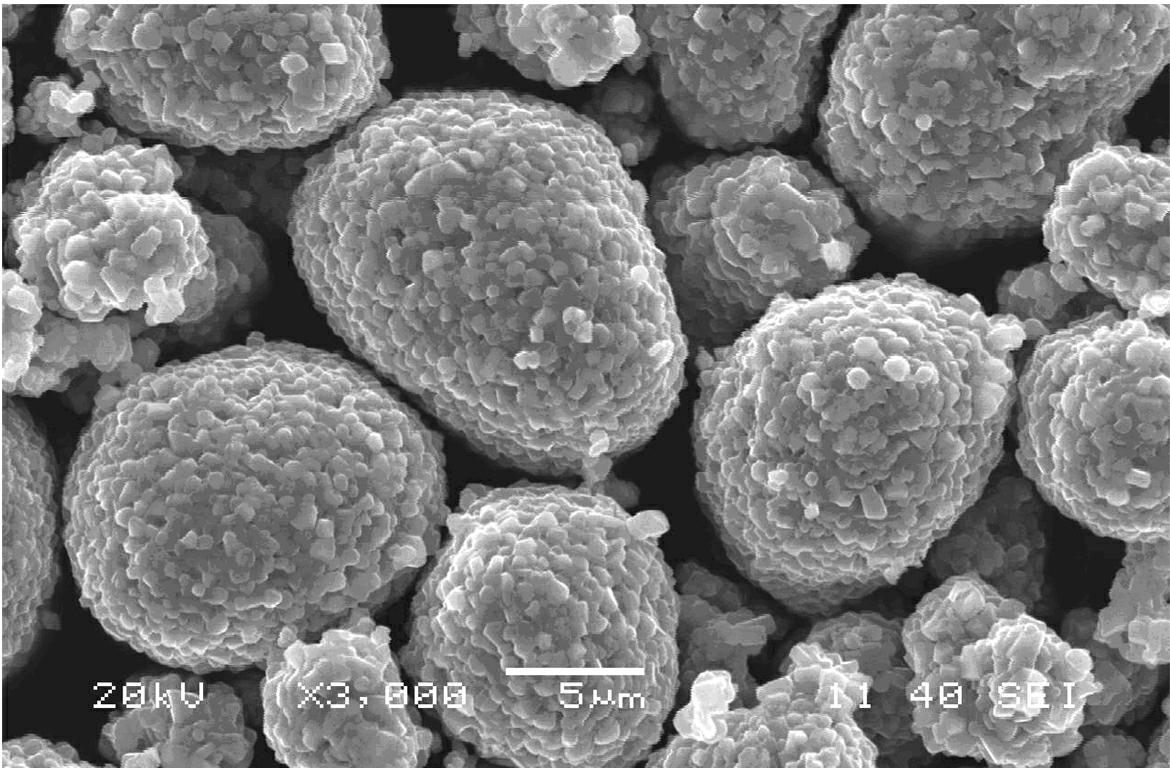

[0024] The nickel-based multi-element positive electrode material of the present embodiment, its chemical formula is

[0025] Li 1.04 Ni 0.75 co 0.15 al 0.10 o 2 / (0.4Li 3 PO 4 0.6Al 2 o 3 ) 0.003 , in powder form.

[0026] Its preparation method:

[0027] (1) Weigh Ni 0.75 co 0.15 al 0.10 (OH) 2 The indicated nickel-based compound (average particle size D50=10.0μm measured by laser particle size analyzer, tap density is 2.05g / cm 3 , powder particles are spherical) 280.00g and lithium hydroxide monohydrate (purity 95%) 144.7g, mix, put the mixture in a muffle furnace, pre-fire at 500°C for 6h, then heat up to 700°C for sintering for 12h, After cooling, it is crushed and sieved to obtain a chemical formula of Li 1.04 Ni 0.75 co 0.15 al 0.10 o 2 represented by Compound A;

[0028] (2) Weigh 0.28g of lithium carbonate, 0.29g of ammonium dihydrogen phosphate, add 30g of water, and prepare Li 3 PO 4 Suspension B;

[0029] (3) Weigh 2.85 g of aluminum nitrate...

Embodiment 2

[0034] The nickel-based multi-element positive electrode material of the present embodiment, its chemical formula is

[0035] Li 1.08 Ni 0.8 co 0.1 mn 0.1 o 2 / (0.5Li 3 PO 4 0.5ZrO 2 ) 0.010 , in powder form.

[0036] Its preparation method:

[0037] (1) Weigh Ni 0.8 co 0.1 mn 0.1 (OH) 2 Represented nickel-based compound (average particle size D50=8.0μm measured by laser particle size analyzer, tap density 1.8g / cm 3 , powder particles spherical) 280.00g and lithium hydroxide monohydrate (purity 95%) 143.1g, mix, put the mixture in a muffle furnace, pre-fire at 400°C for 4h, then heat up to 800°C for sintering for 4h, cool After crushing and sieving, the chemical formula obtained is Li 1.08 Ni 0.8 co 0.1 mn 0.1 o 2 represented by Compound A;

[0038] (2) Weigh 1.35g lithium hydroxide monohydrate (purity 95%), 1.35g diammonium hydrogen phosphate, add 30g water, and prepare Li 3 PO 4 Suspension B;

[0039] (3) Weigh 4.39 g of zirconium nitrate pentahydrate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com