Preparation method of three-dimensional porous graphene

A three-dimensional porous, graphene technology, applied in graphene, nano-carbon and other directions, can solve the problems of unsatisfactory graphene sheet bonding and poor electrical conductivity, and achieve the effects of reducing interface resistance, easy process, and excellent electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of graphene oxide aqueous solution: Prepare graphene oxide aqueous solution with a concentration of 3 mg / ml by modified Hummers method; preparation of toluene soluble asphalt: mix mesophase pitch powder with toluene at a ratio of 1 g: 40 ml, at 75 ° C Dissolve under heat for 4 hours, separate the toluene soluble part of pitch;

[0036] Graphene oxide reduction repair: Mix 30ml of the 3mg / ml above-mentioned graphene aqueous solution with 3ml of asphalt toluene solubles and stir for 30 minutes, put the mixed solution into a 45ml hydrothermal reactor, and react at 240°C for 15 hours. Take out the sample and cool it to room temperature, wash the sample several times with deionized water, and then freeze-dry;

[0037] Graphene heat treatment: heat-treat the dried sample at 1000°C for 0.5-3 hours under argon protection to obtain the final sample.

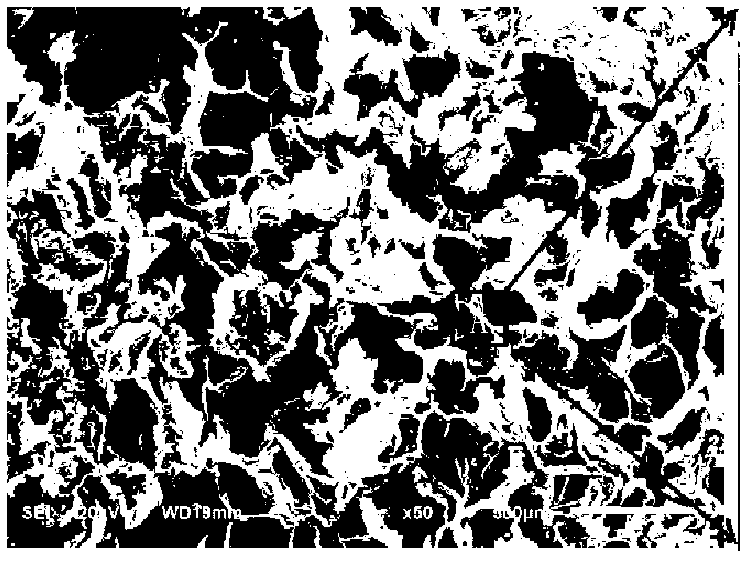

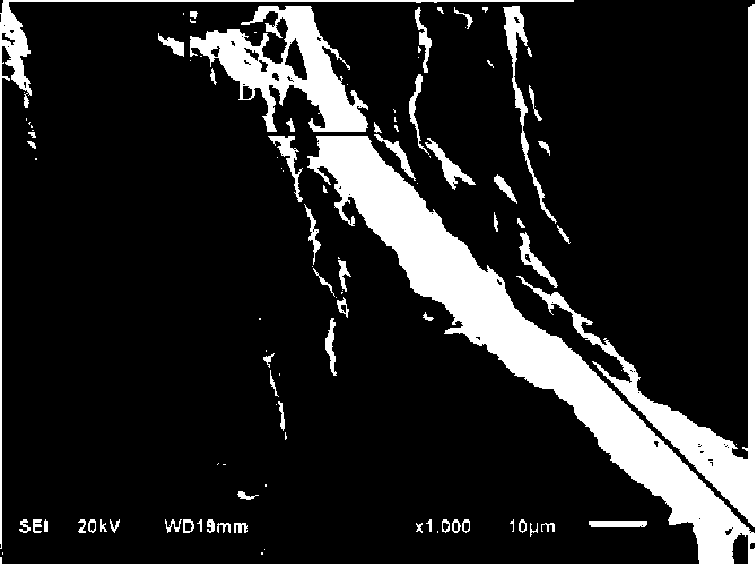

[0038] Obtain cylindrical solid three-dimensional graphene, its SEM photograph sees Figure 2A-2C , macro photo see...

Embodiment 2

[0040] The preparation process and steps in this example are basically the same as those in Example 1 above. The difference is: 30ml of 3mg / ml above-mentioned graphene aqueous solution and 5ml of asphalt toluene solubles are mixed and stirred. Obtain cylindrical solid three-dimensional graphene, its macroscopic photograph sees image 3 In c, it can be seen that the prepared graphene is a three-dimensional porous structure. The sheet resistance prepared in this embodiment is 3Ω sq. -1 .

Embodiment 3

[0042] The preparation process and steps in this example are basically the same as those in Example 1 above. The difference is: 30ml of 3mg / ml above-mentioned graphene aqueous solution and 10ml of asphalt toluene solubles are mixed and stirred. Obtain cylindrical solid three-dimensional graphene, its macroscopic photograph sees image 3 d in The sheet resistance prepared by this embodiment is 6Ω sq -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com