Solid-state battery electrode unit

A technology for electrode units and solid-state batteries, applied in electrical components, secondary batteries, solid electrolytes, etc., can solve problems such as lack of continuous transition characteristics, reduced interface resistance, and reduced safety of solid-state batteries, and achieve battery cycle performance and rate Significant decline in performance, reduced interface resistance, and increased interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

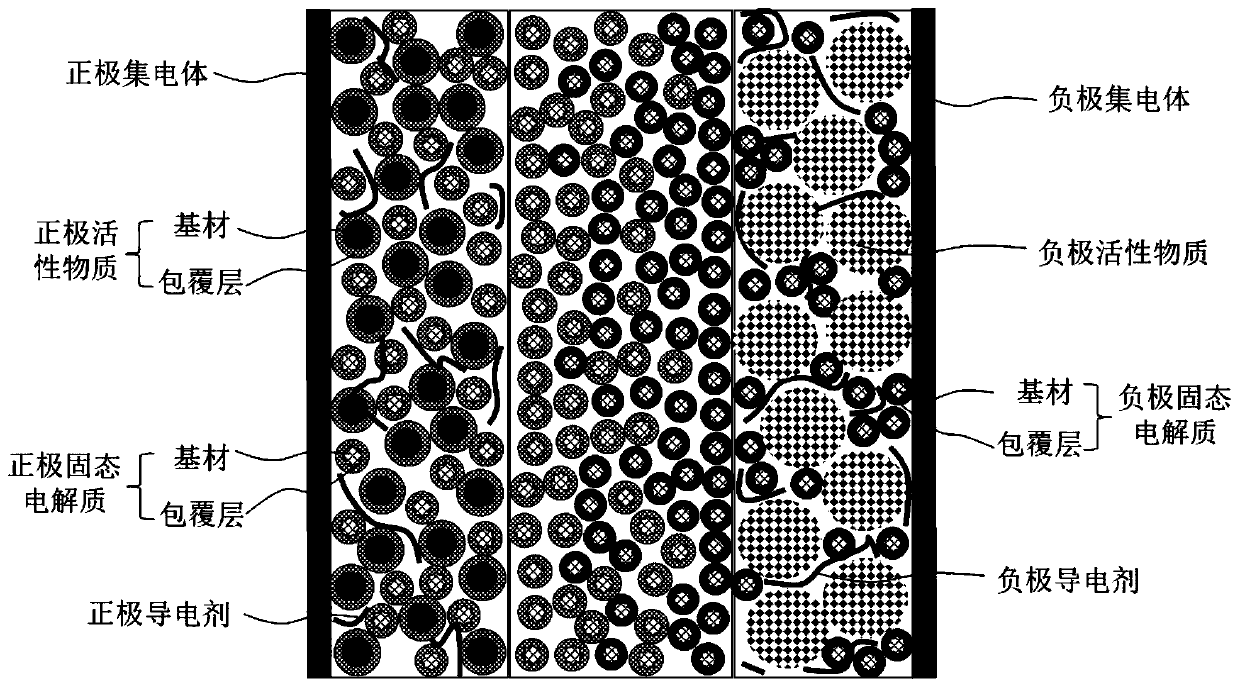

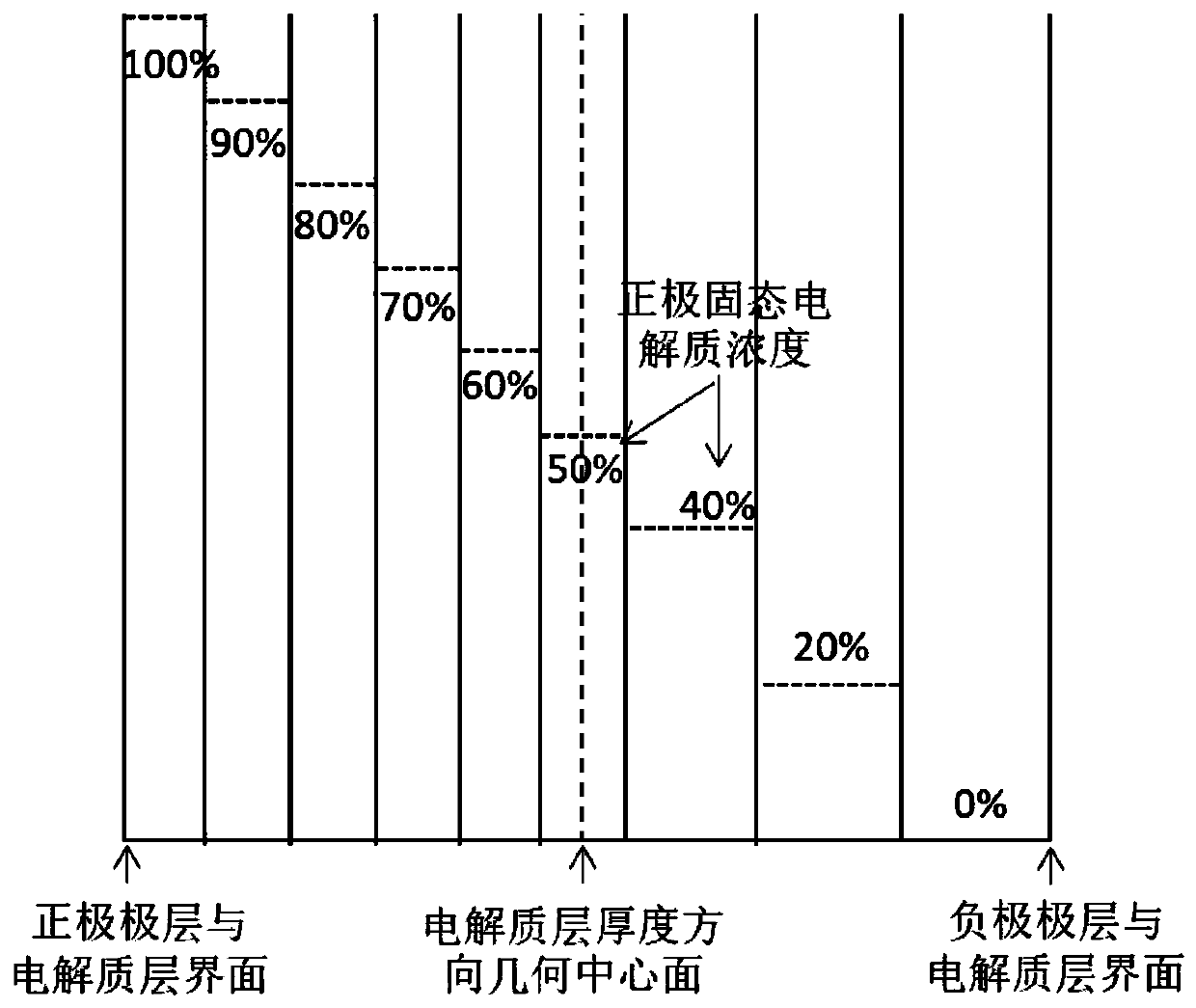

[0068] Positive electrode layer: Aluminum foil is used as the positive electrode collector, nickel-cobalt-aluminate-lithium aluminate coated with aluminum oxide with a thickness of 100nm is used as the positive electrode active material, nano-carbon fiber is used as the positive electrode conductive agent, and polytetrafluoroethylene is used as the positive electrode adhesive. Junction, the surface coating thickness of 5nm Al2O3 Li 7 La 3 Zr 2 o 12 As a positive electrode solid electrolyte; the mass ratio of positive electrode active material, positive electrode conductive agent, positive electrode binder, and positive electrode solid electrolyte is 90:1:2:7;

[0069] Negative electrode layer: Copper foil is used as the negative electrode collector, and SiO is used x / C (the SiO x The preparation process of / C is as follows: mix silicon oxide and glucose at a weight ratio of 1:120, and roast at 600°C for 6 hours to obtain SiO x / C) As the negative electrode active materia...

Embodiment 2

[0073] Positive electrode layer: Aluminum foil is used as the positive electrode collector, nickel cobalt aluminum oxide lithium with a surface coating thickness of 200nm aluminum phosphate is used as the positive electrode active material, carbon nanotubes are used as the positive electrode conductive agent, and polytetrafluoroethylene is used as the positive electrode conductive agent , the surface coating thickness of 50nm Al2O3 Li 1.4 Al 0.4 Ti 1.6 (PO 4 ) 3 As a positive electrode solid electrolyte; the mass ratio of positive electrode active material, positive electrode conductive agent, positive electrode binder, and positive electrode solid electrolyte is 92:2:3:3;

[0074] Negative electrode layer: Copper foil is used as the negative electrode collector, Si / C (carbon-coated structure, wherein the mass ratio of Si:C is 41:10) is used as the negative electrode active material, acetylene black is used as the negative electrode conductive agent, polytetrafluoroethylene...

Embodiment 3

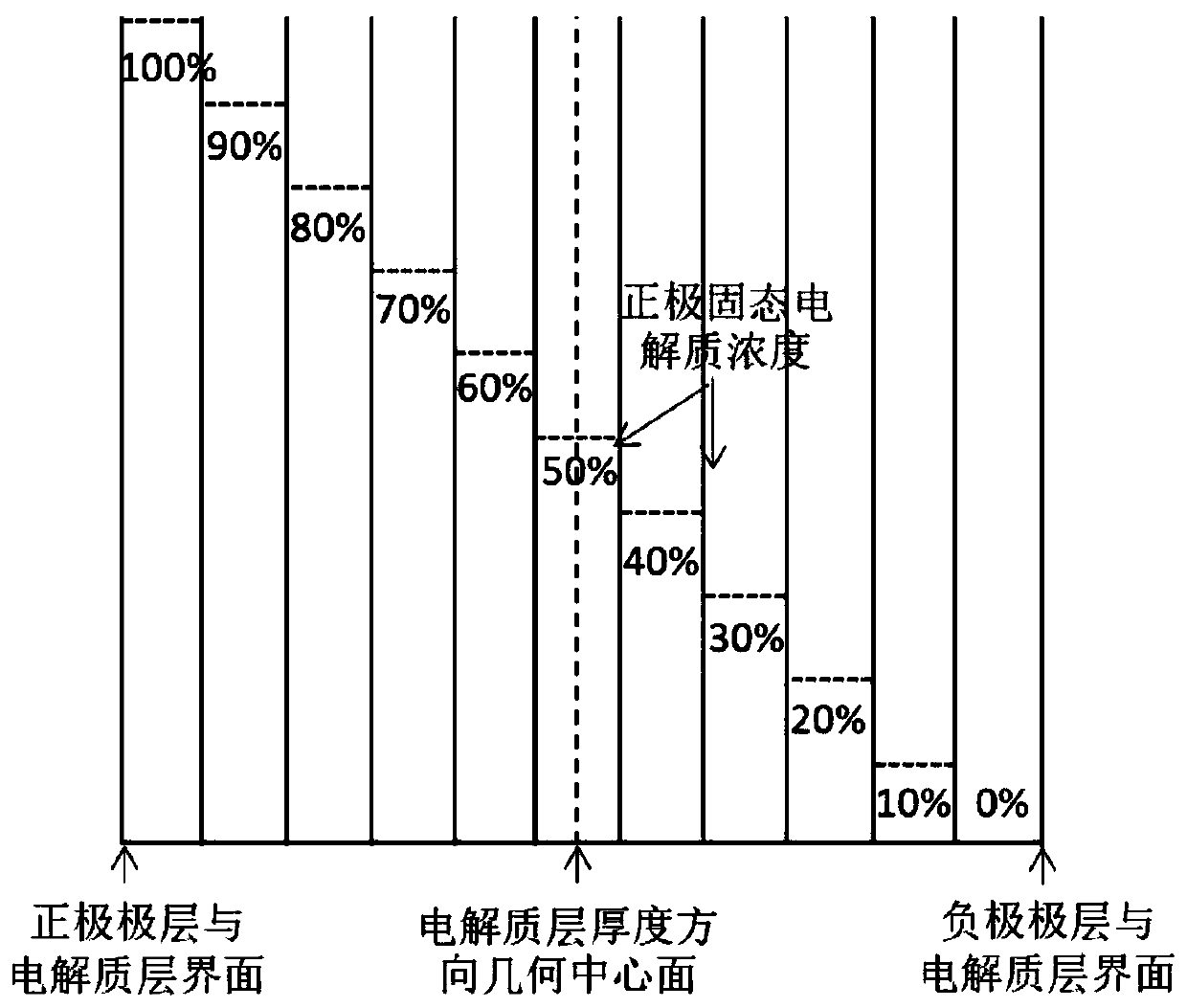

[0078] The difference from Example 1 is that the concentration of the positive electrode electrolyte on the surface near the positive electrode layer to the surface near the negative electrode layer is 100%, 90%, 80%, 70%, 60% (geometric center in the thickness direction), 30%, 0% % (near the side surface of the negative electrode layer).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com