Patents

Literature

97 results about "Electrode adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery, negative plate thereof and preparation method thereof

ActiveCN105304858AImprove low temperature discharge performanceGood high temperature cycle performanceNon-aqueous electrolyte accumulator electrodesElectrical batteryLithium-ion battery

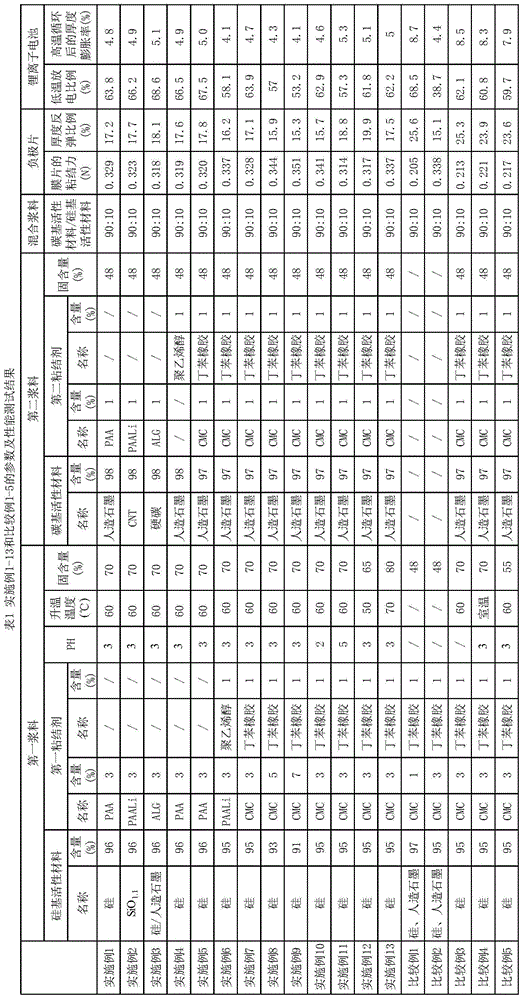

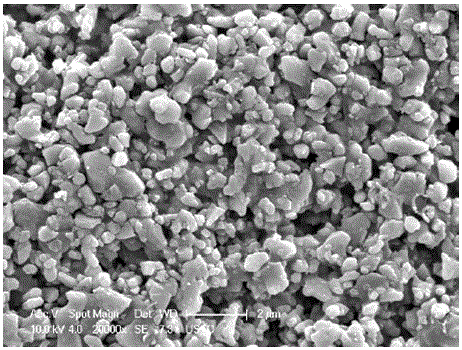

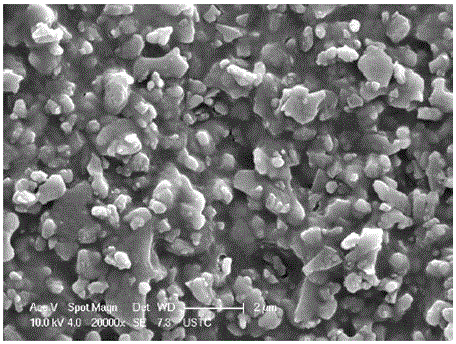

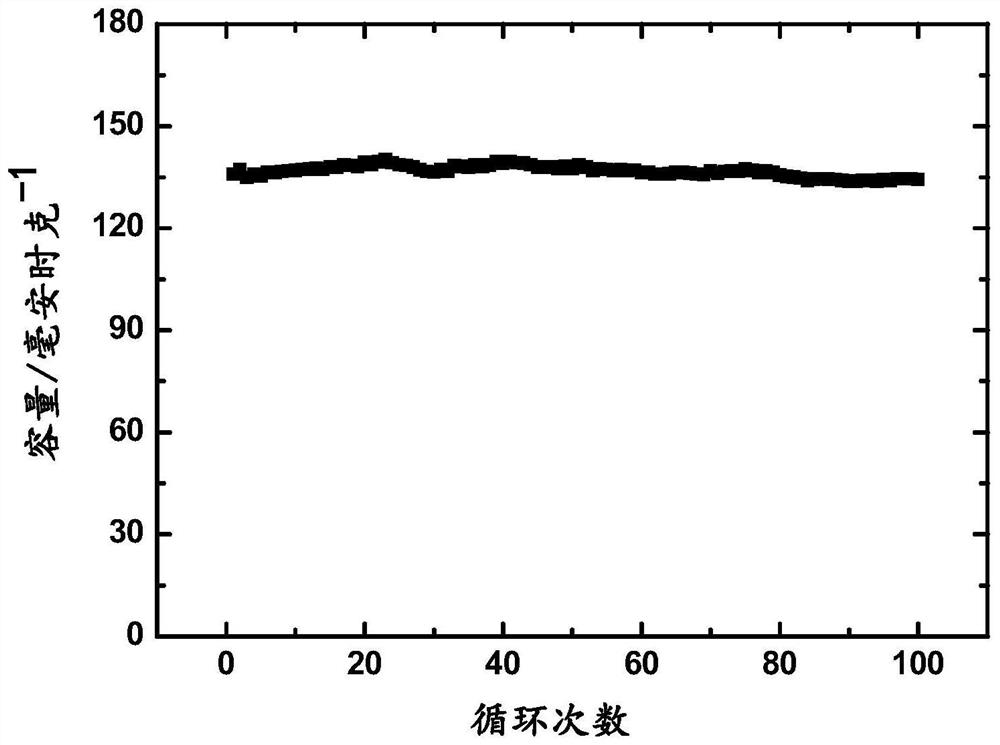

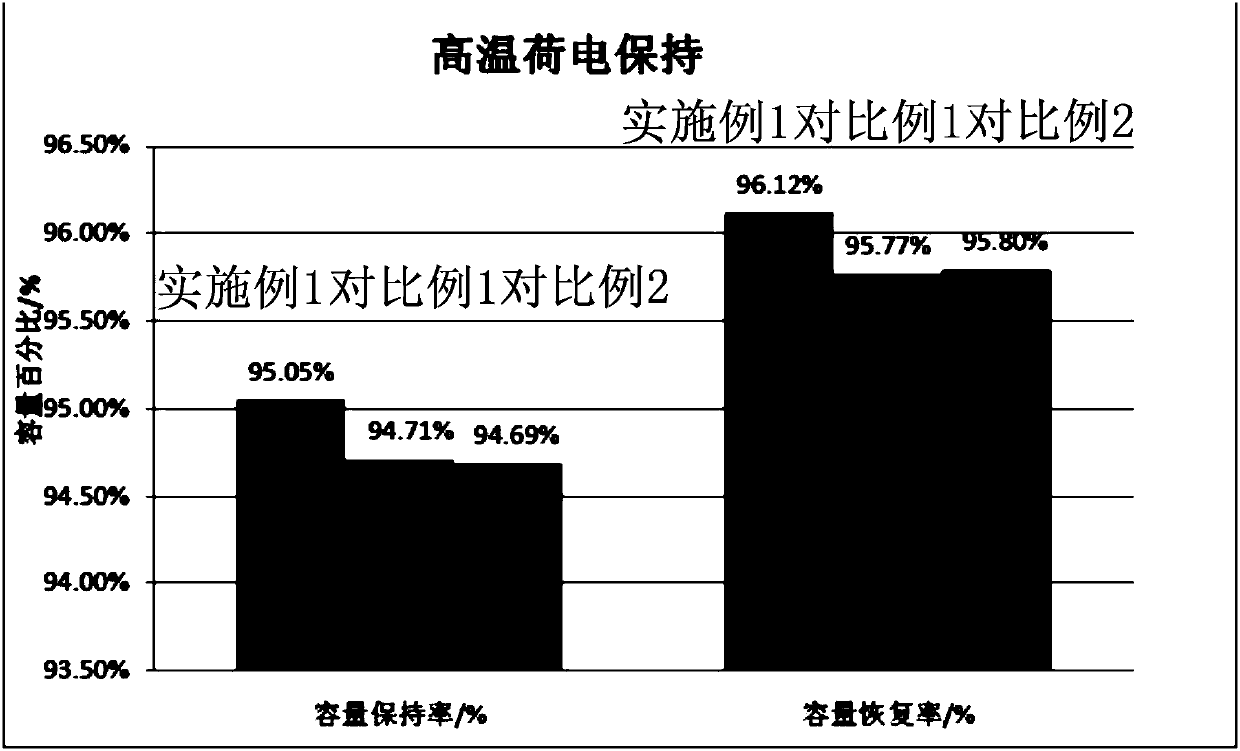

The invention provides a lithium ion battery, a negative plate thereof and a preparation method thereof. The negative plate comprises a negative electrode current collector, and a negative film which is arranged on the negative electrode current collector and comprises a negative electrode active material, a negative electrode adhesive and a conductive agent of the negative electrode. The negative electrode active material comprises a silicon-based active material and a carbon-based active material; the negative electrode adhesive is distributed on the surface of the negative electrode active material; the surface of the silicon-based active material contains -OH; the negative electrode adhesive at least comprises a -COOM adhesive; and the mass ratio of the negative electrode adhesive distributed on the surface of the silicon-based active material to the silicon-based active material is larger than the mass ratio of the negative electrode adhesive distributed on the surface of the carbon-based active material to the carbon-based active material. The negative plate provided by the invention is used for improving the binding power of granules of the silicon-based active material and can solve the problem that the charge and discharge performance of the carbon-based active material is deteriorated due to excessive negative electrode adhesive. The lithium ion battery provided by the invention has good low temperature discharge performance and high temperature cycling performance.

Owner:NINGDE AMPEREX TECH

Sticky ceramic diaphragm and preparation method thereof

InactiveCN105895844AImprove thermal stabilityImprove yield rateCell seperators/membranes/diaphragms/spacersLi-accumulatorsPorous substrateMetallurgy

The invention discloses a preparation method of a sticky ceramic diaphragm. The method comprises the following steps: selecting a porous substrate; dipping the porous substrate into inorganic ceramic slurry and simultaneously stirring the inorganic ceramic slurry to evenly disperse the inorganic ceramic slurry on the surface of the porous substrate; drying the inorganic ceramic slurry to obtain a porous ceramic diaphragm; dipping the porous ceramic diaphragm into a glue solution and simultaneously stirring the glue solution to evenly disperse the glue solution on the surface of an inorganic ceramic coating of the porous ceramic diaphragm; and drying the glue solution to obtain the sticky ceramic diaphragm. The technology is simple. In a dipping manner, the double coated sticky ceramic diaphragm can be simultaneously formed, so that the problems of crimping, wrinkling and the like caused by secondary coating are solved; the thermal stability of the diaphragm is improved; and the yield of the product is improved. Meanwhile, an organic electrode adhesive coating is formed on the surface of a ceramic layer, so that achievement of efficiently automatic assembly is facilitated.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

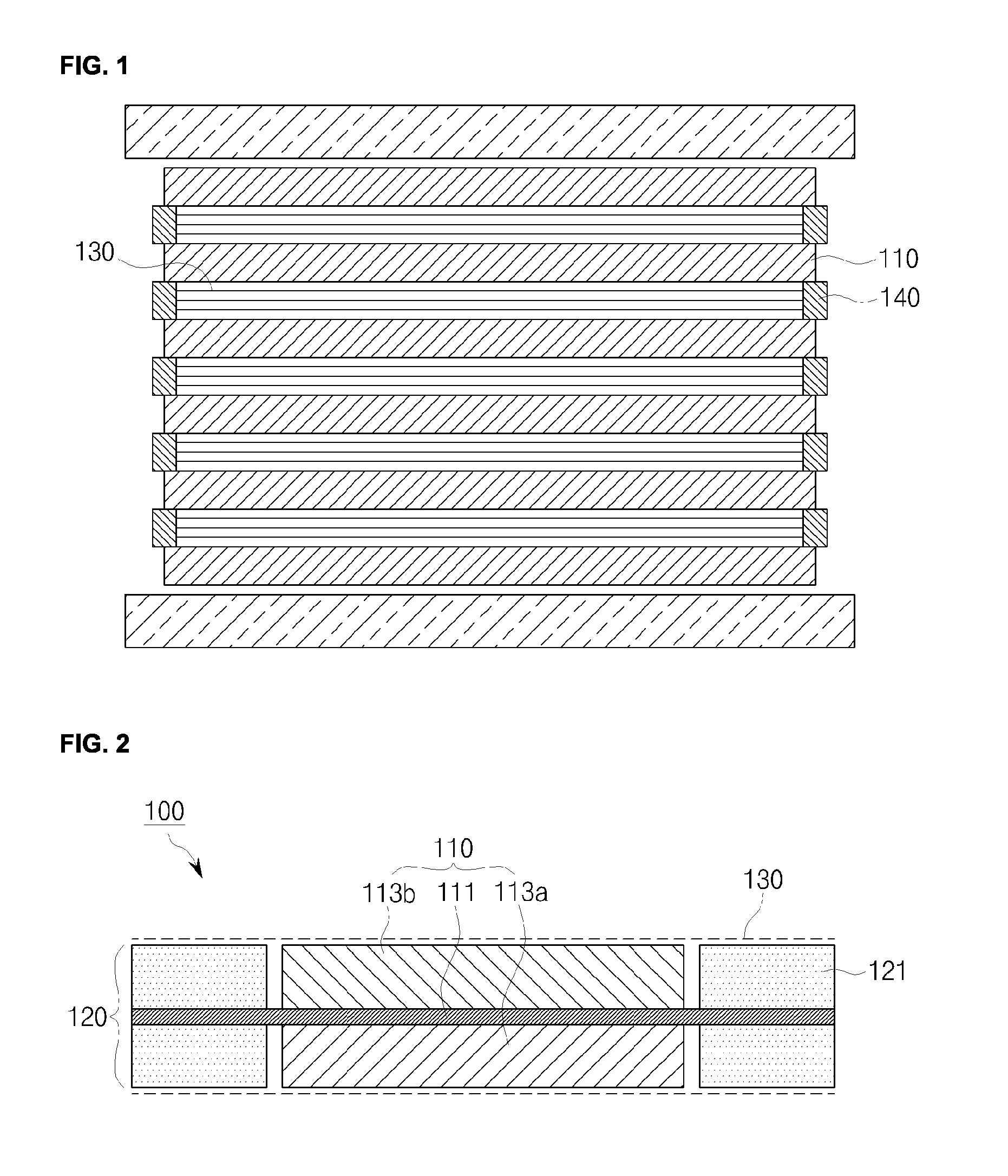

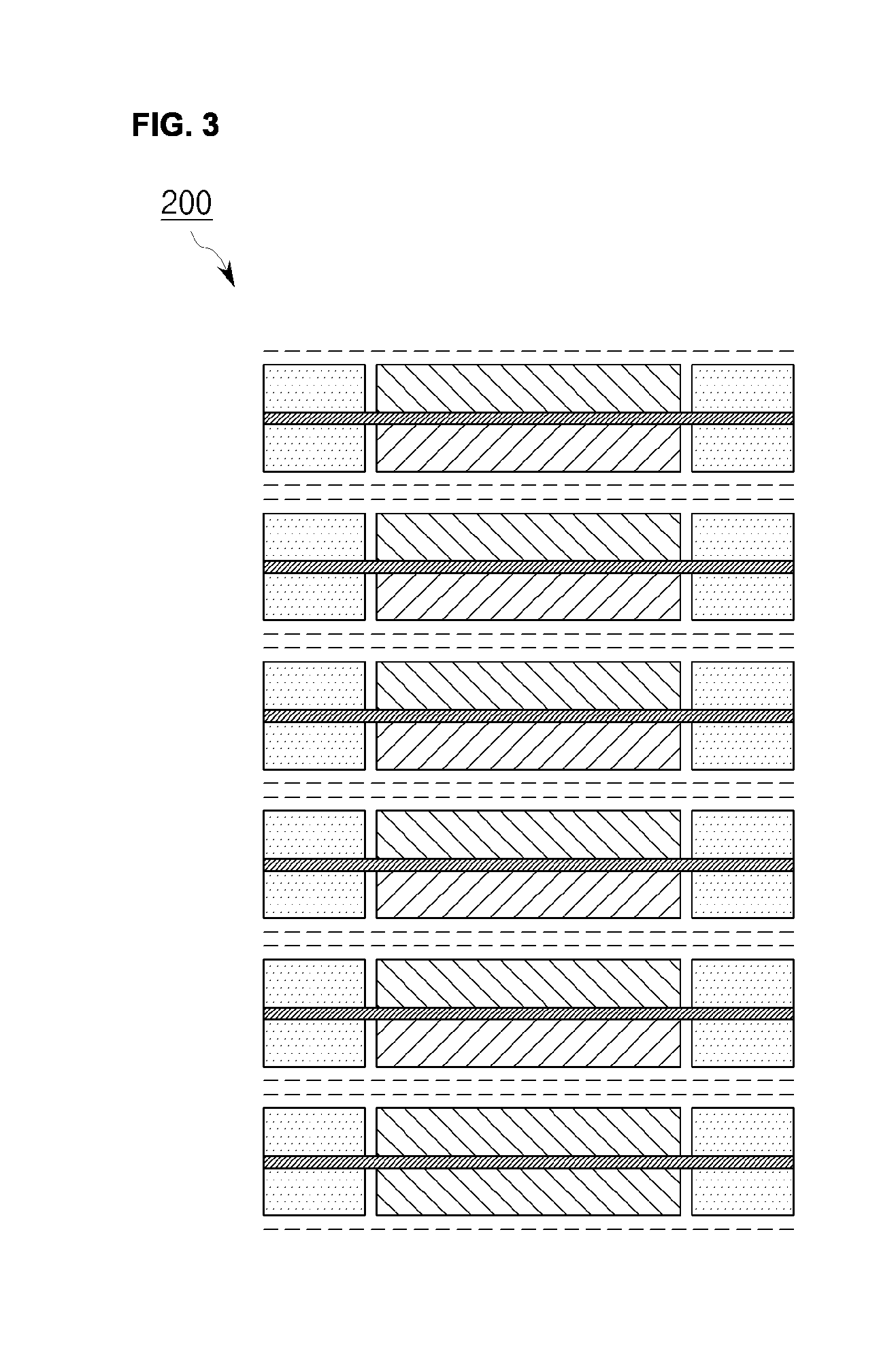

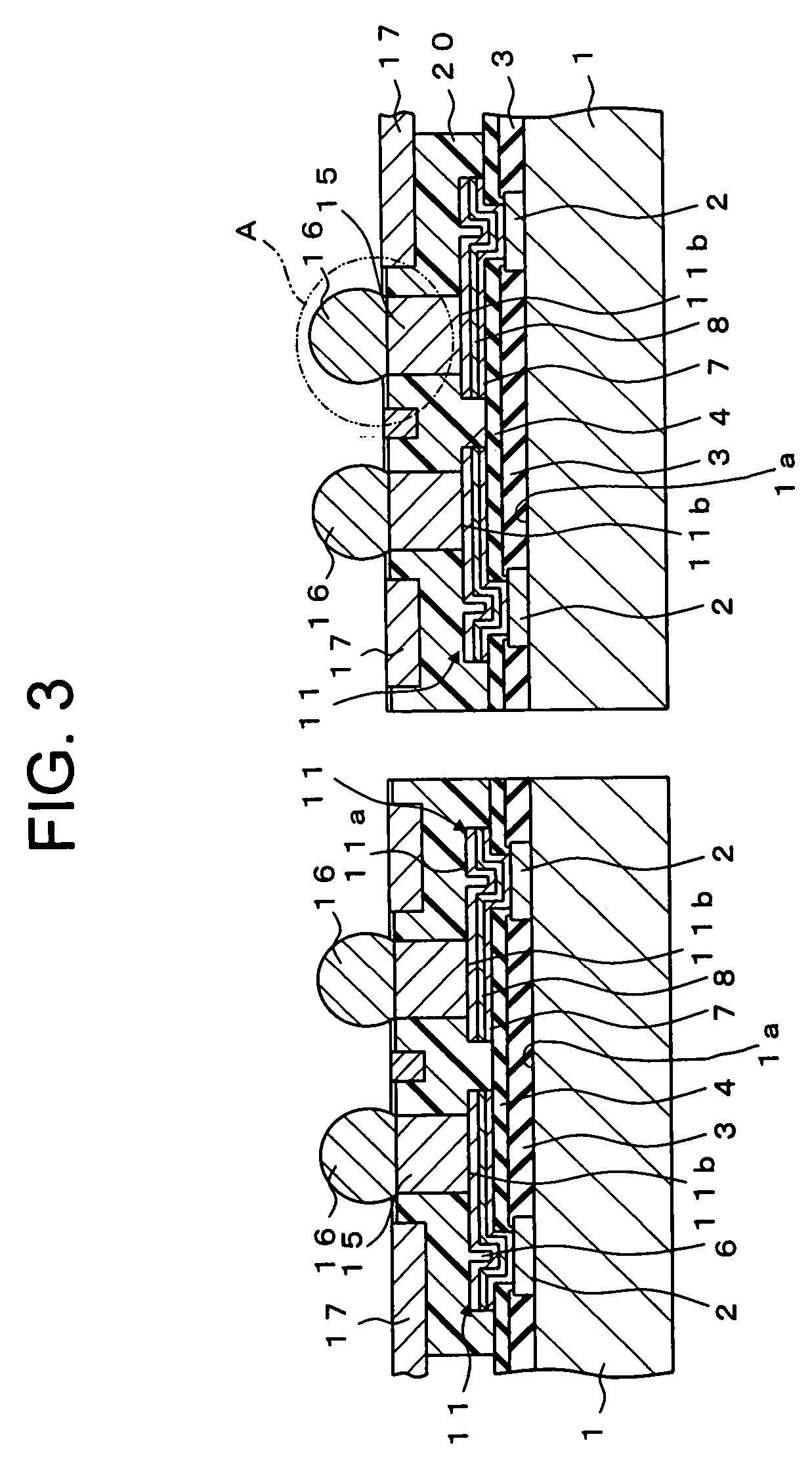

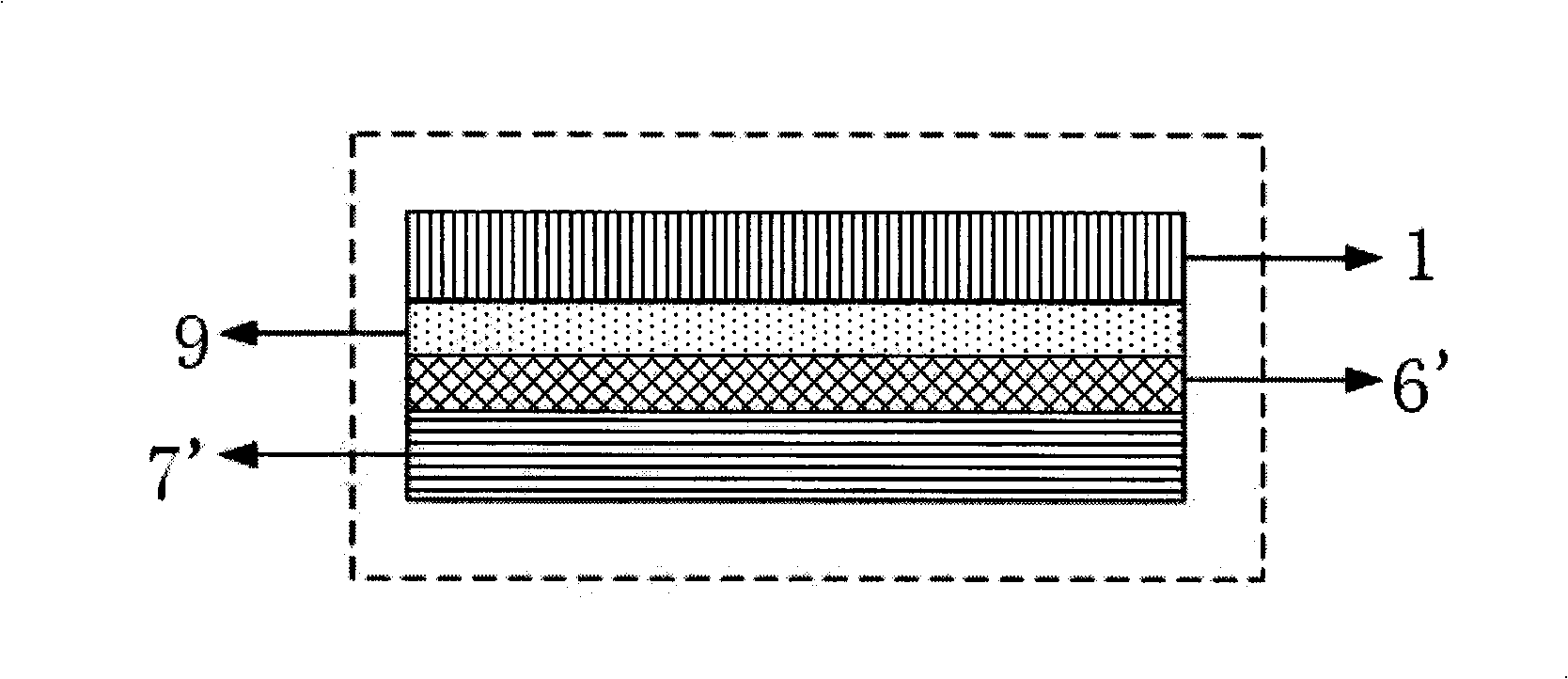

Bipolar electrode/separator assembly, bipolar battery comprising the same and method of manufacturing the same

InactiveUS20110189577A1Facilitate and simplify processSufficient amountElectrode manufacturing processesFuel cells groupingEdge surfaceEngineering

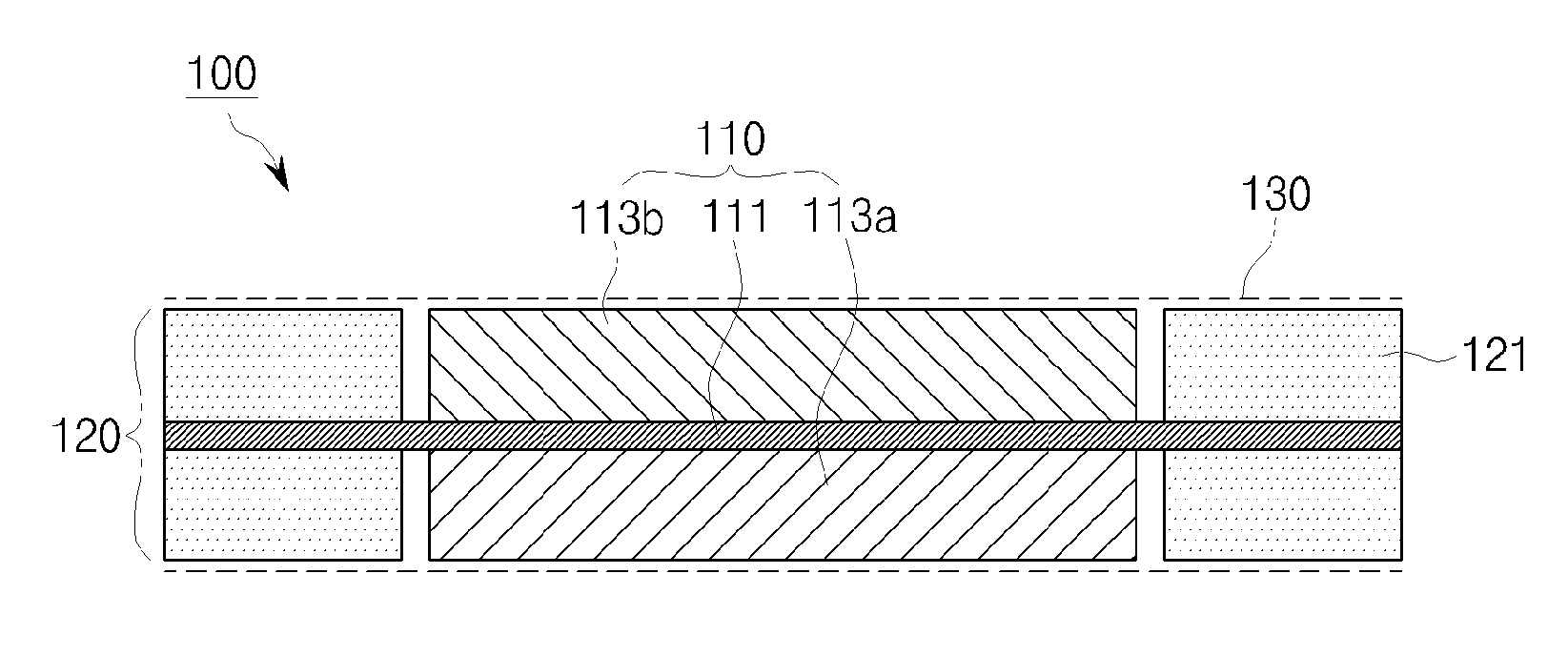

Disclosed is a bipolar electrode / separator assembly including a bipolar electrode-adhesive film assembly including a bipolar electrode holding active materials, having different polarities, on central portions of top and bottom surfaces of a collector, respectively, and adhesive films on both top and bottom surfaces of the collector with respect to at least two of four edge surfaces of the collector on which electrode layers are not coated in the bipolar electrode, and a separator stacked on one or both top and bottom surfaces of the bipolar electrode-adhesive film assembly, wherein the collector and the separator are directly bonded by the adhesive film to thereby seal the bipolar electrode. A bipolar battery including the bipolar electrode / separator assembly and methods of manufacturing the same are also disclosed. A battery having desired capacity and voltage is provided by electrically connecting such bipolar electrode / separator assemblies either in series or in parallel according to usage.

Owner:LG CHEM LTD

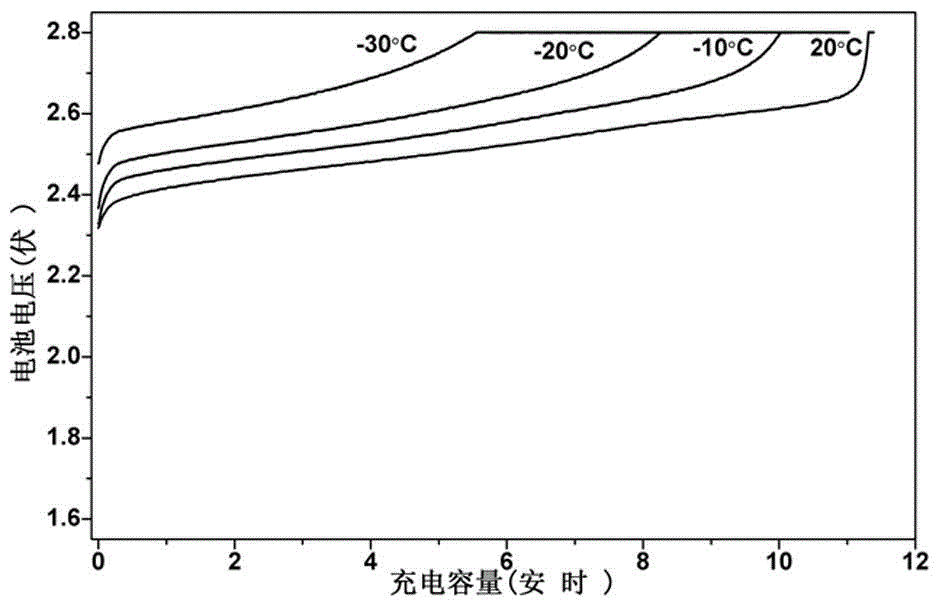

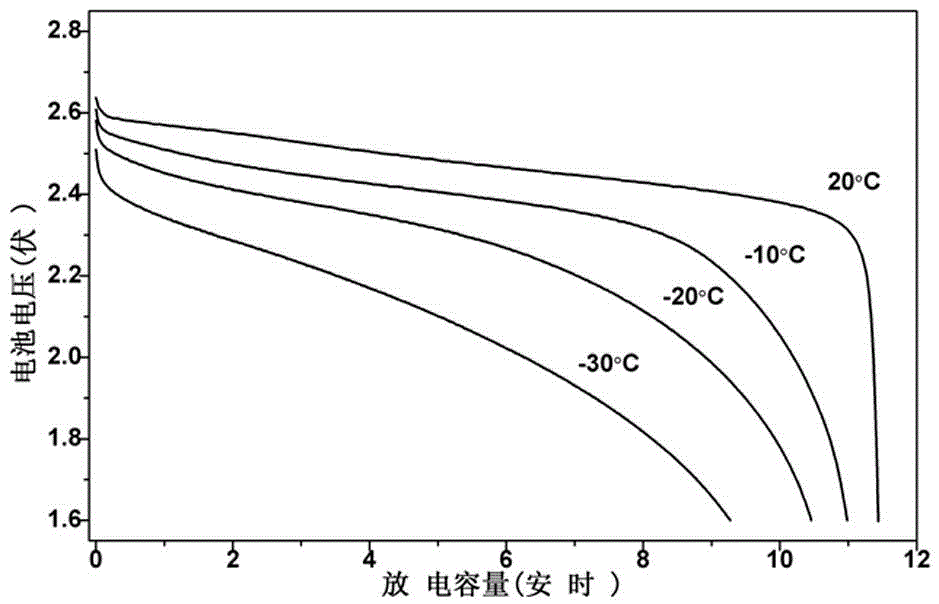

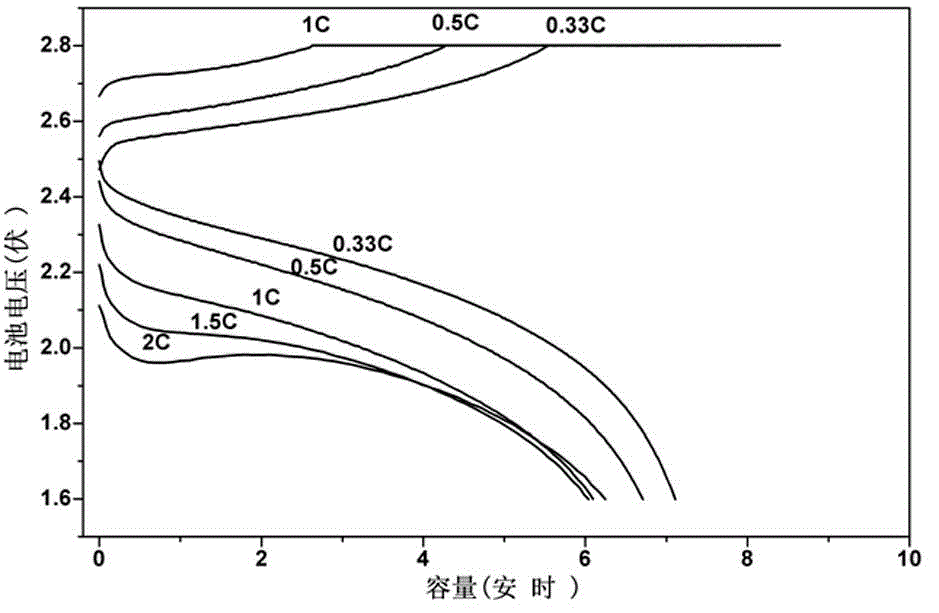

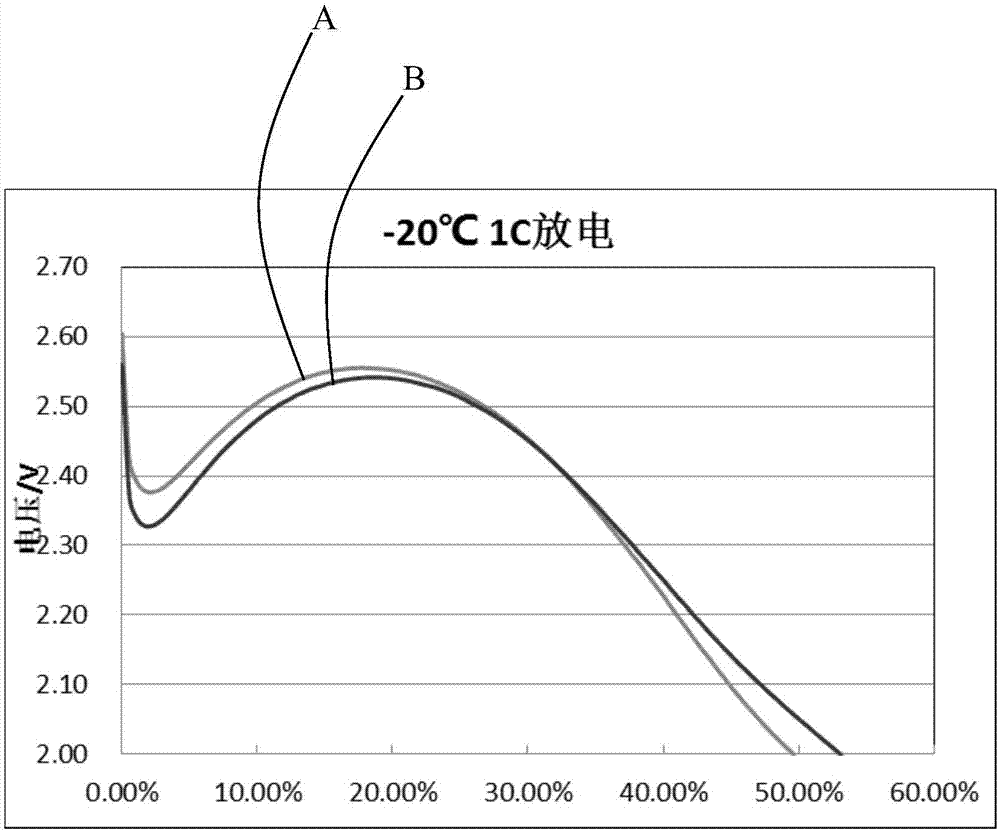

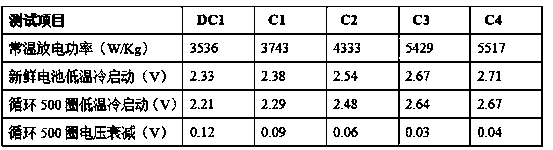

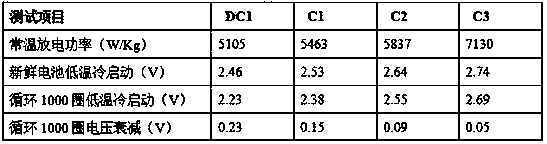

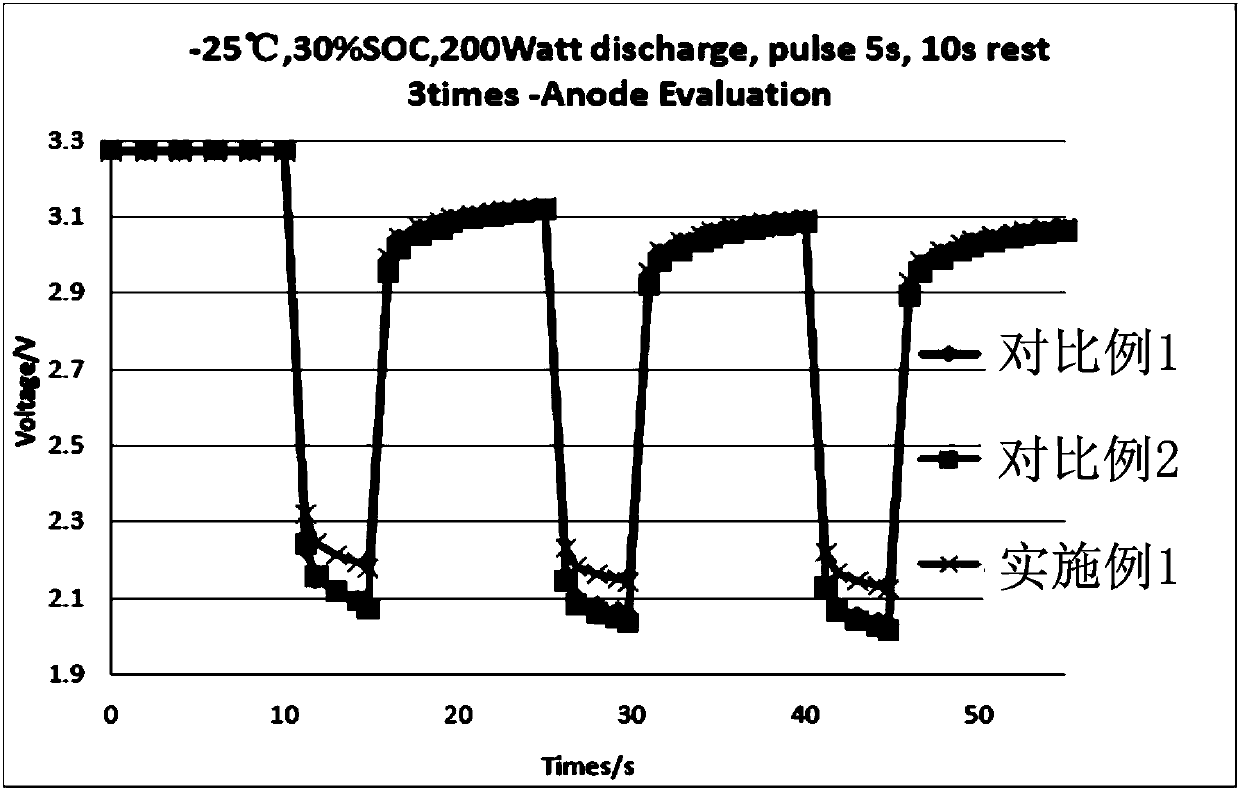

Low-temperature type lithium ion secondary battery

ActiveCN104409767AEnsure safetyLow melting pointFinal product manufactureCell electrodesManganateCarbon nanotube

The invention discloses a low-temperature type lithium ion secondary battery. The low-temperature type lithium ion secondary battery comprises a positive electrode, a negative electrode and an electrolyte, wherein the positive electrode is prepared from the following components including a positive electrode electroactive substance, a positive electrode conductive agent and a positive electrode adhesive; the positive electrode electroactive substance is spinel type lithium manganate, the positive electrode conductive agent is arbitrary more than two of superconductive carbon black, Super-P, KS-6, VGCF or a carbon nano tube, the positive electrode adhesive is polyvinylidene fluoride; the negative electrode is prepared from the following components including a negative electrode electroactive substance, a negative electrode conductive agent and a negative electrode adhesive; the negative electrode electroactive substance is spinel type lithium titanate, the negative electrode conductive agent is arbitrary one or more of the superconductive carbon black, the Super-P, the VGCF or the carbon nano tube, the negative electrode adhesive is the polyvinylidene fluoride; a solvent of the electrolyte is three or more of DMC, EMC, DEC, PC and EA but at least contains the PC and the EA, a solute of the solvent is lithium hexafluorophosphate, the melting point of the electrolyte is smaller than 40 DEG C below zero, and the viscosity is smaller than 3cP. The low temperature type lithium ion secondary battery can be safely charged under the low-temperature condition and is excellent in the charging and discharging cycle performance at low temperature.

Owner:SHANGHAI POWER ENERGY STORAGE BATTERY SYST ENG TECH +1

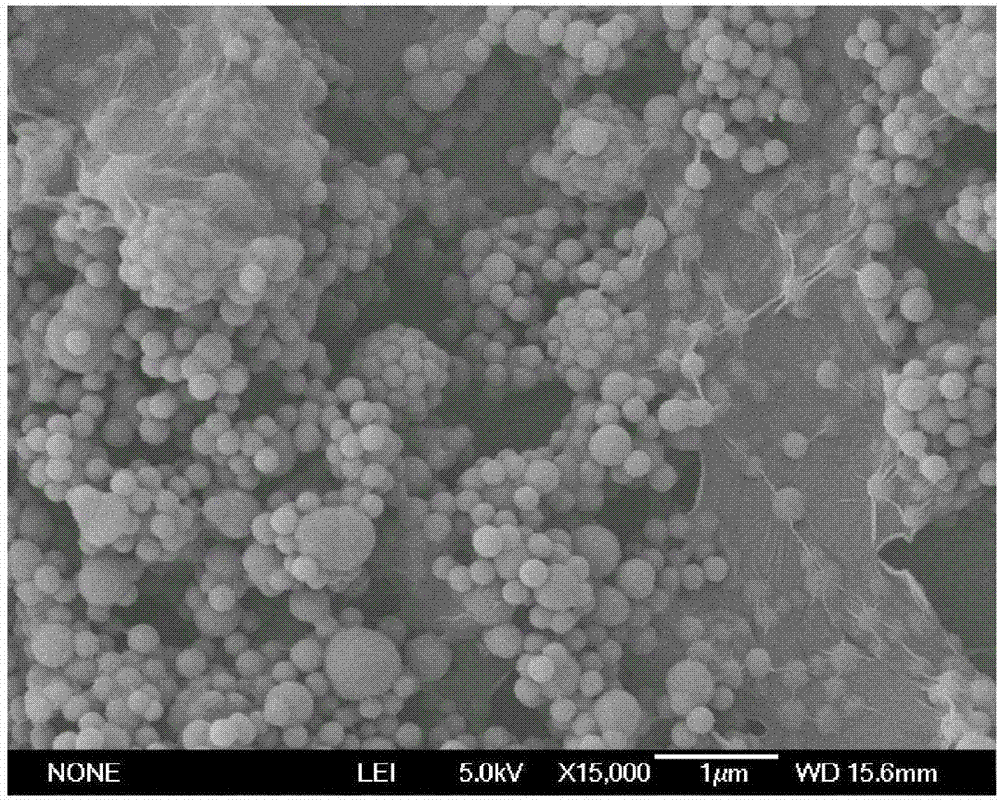

Lithium ion battery silicon-based negative electrode adhesive and preparation method of negative electrode piece with same

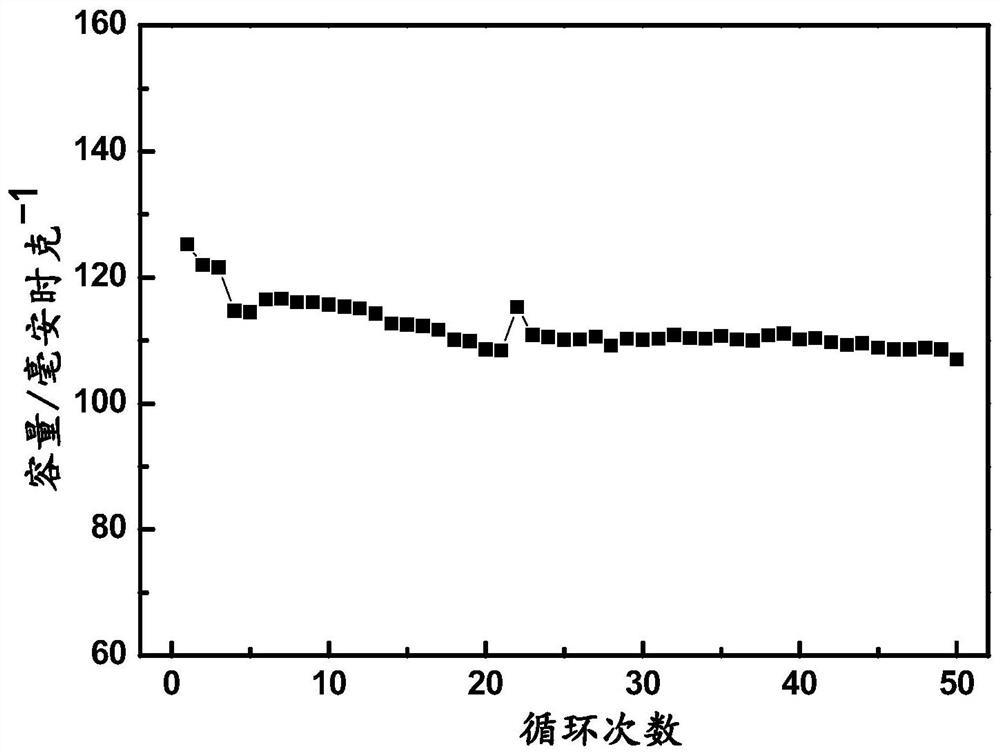

ActiveCN107959027AImprove cycle performanceImprove the first Coulombic efficiencySecondary cellsElectrode collector coatingMass ratioSodium-ion battery

The invention discloses a lithium ion battery silicon-based negative electrode adhesive and a preparation method of the negative electrode piece with the same. The adhesive is prepared according to the method including steps: ultrasonically dispersing graphite oxide into water to obtain graphite oxide (GO) aqueous dispersion in concentration of 0.5-5mg / mL, adding a modified SBR adhesive, and stirring to obtain the lithium ion battery silicon-based negative electrode adhesive (GO / modified SBR), wherein a mass ratio of GO to modified SBR adhesive is 1:10-1:50. By the adhesive, the cycle performance of silicon-based negative electrodes can be improved, and first-time coulomb efficiency of the silicon-based negative electrode materials is improved to a certain extent. Consumption of the conducting agent in a silicon-based negative electrode system is reduced, integral energy density of lithium ion batteries can be improved beneficially, and the method is simple in process and suitable forlarge-scale production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

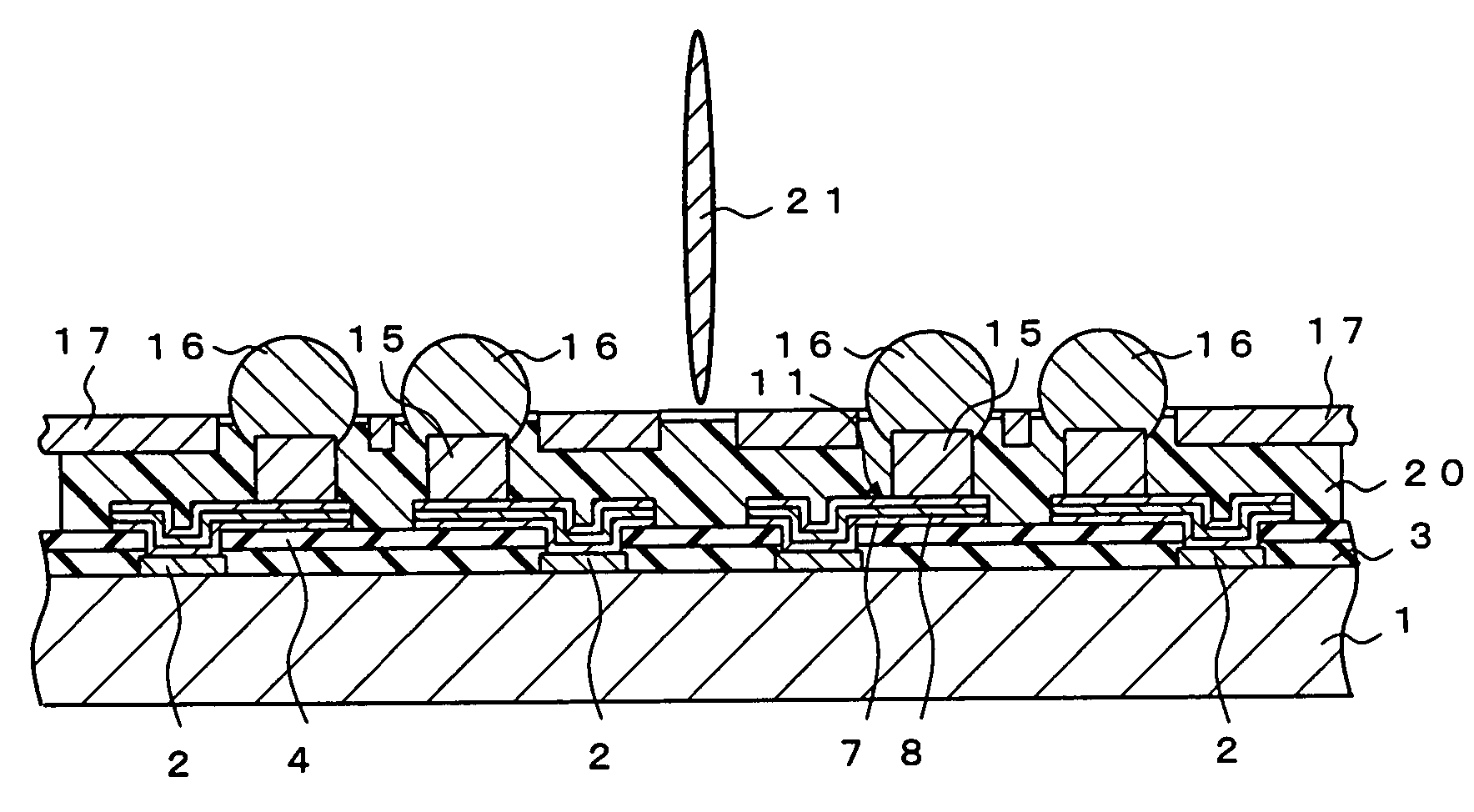

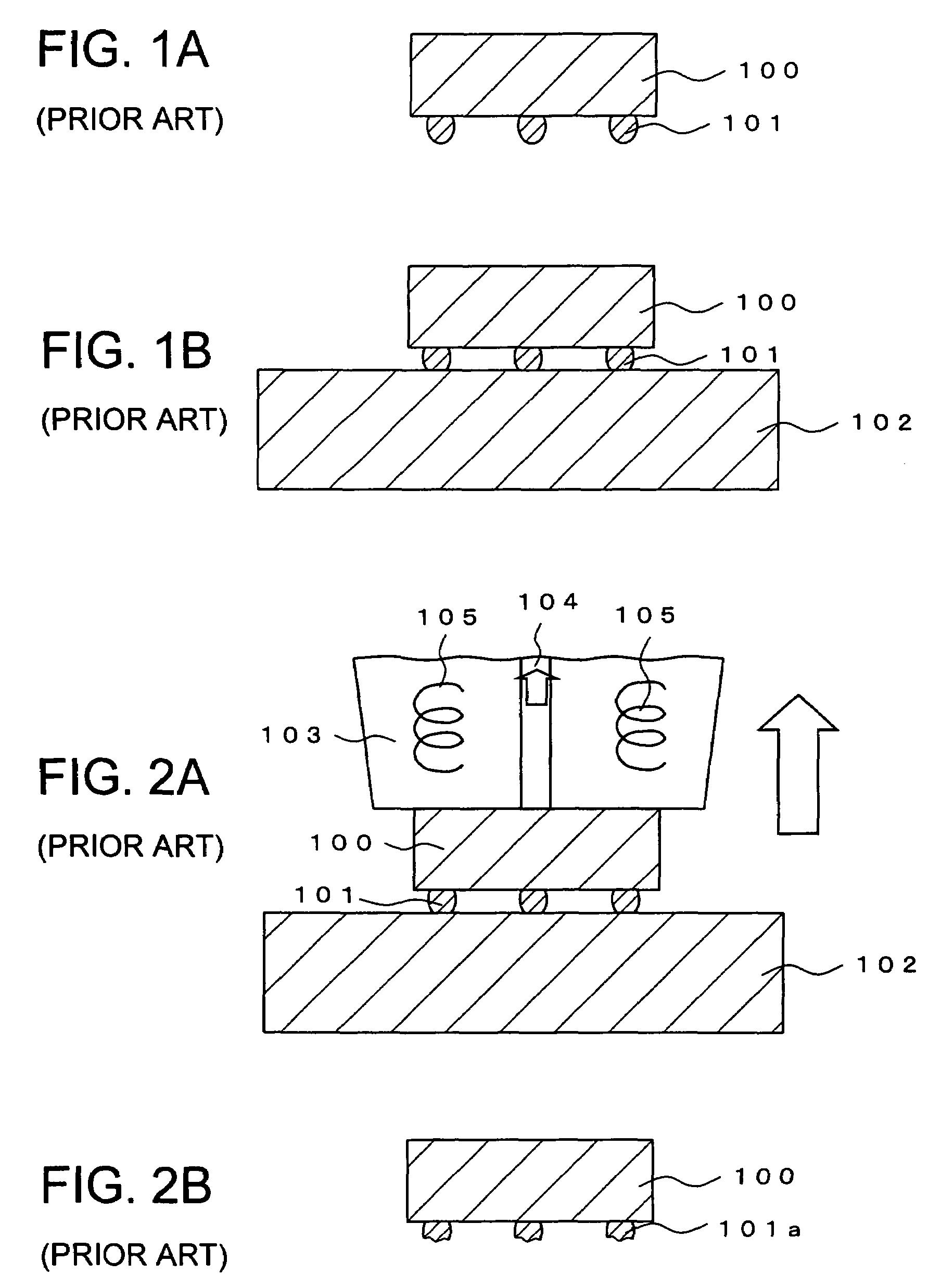

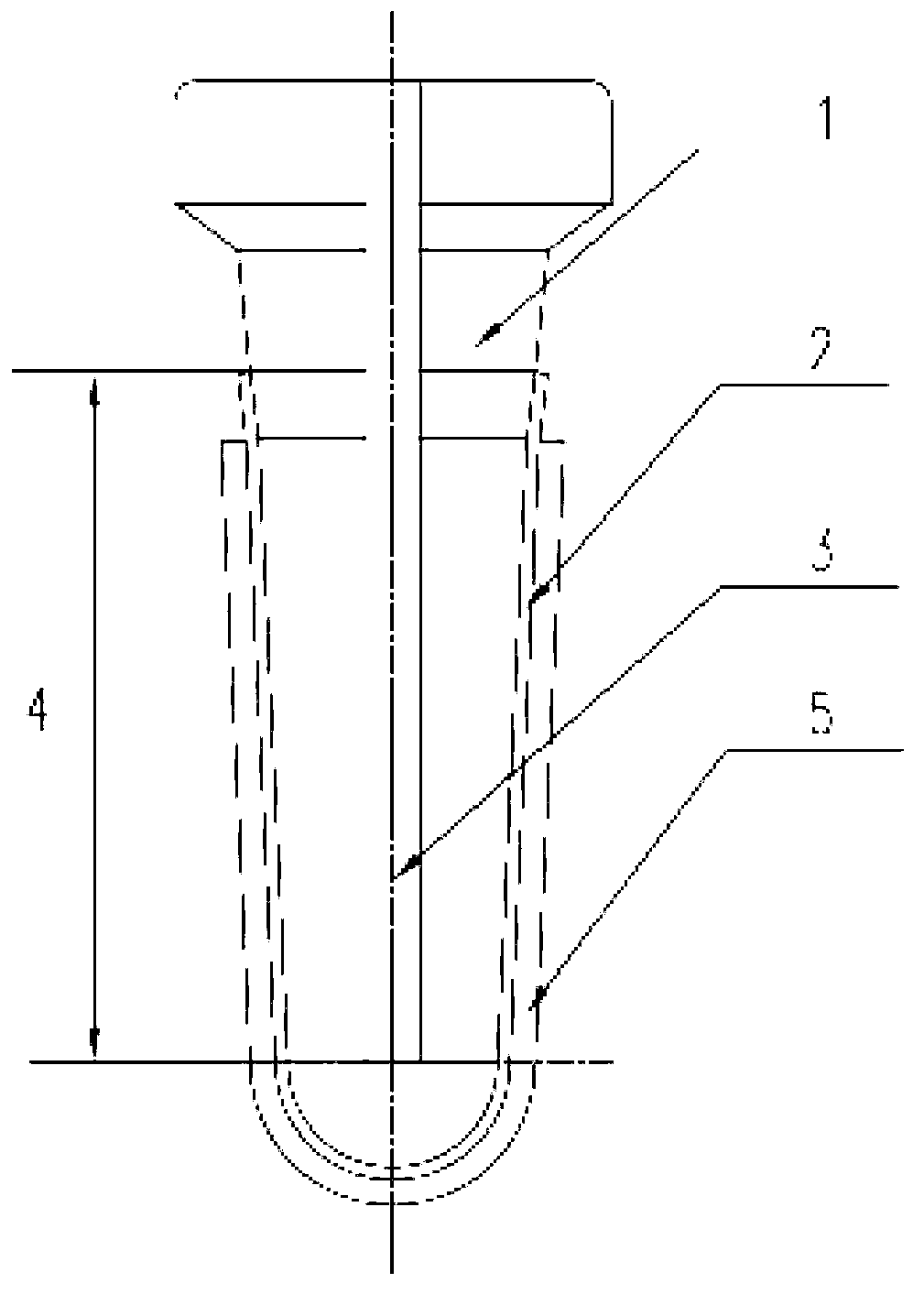

Flip-chip type semiconductor device and method of manufacturing the same

InactiveUS7074650B2Improve reliabilityReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrode adhesive

In a flip-chip type semiconductor device, a pad electrode and a passivation film are formed on a semiconductor substrate. An insulating resin layer is formed on the passivation film, and an opening is formed above the electrode. A pad electrode adhesive metal film is formed on the substrate like a re-wiring pattern, and a plating feed layer metal film and a Cu plating layer are sequentially formed on the metal film to form a wiring layer. A metal post electrode is formed on the wiring layer. A solder bump is formed on the post electrodes, a support plate in which holes each having a diameter larger than the diameter of the solder bump are formed at positions adjusted to the solder bumps is arranged, and an insulating resin layer is formed between the support plate and the semiconductor substrate. Therefore, a stress acting on the solder bump is moderated.

Owner:RENESAS ELECTRONICS CORP

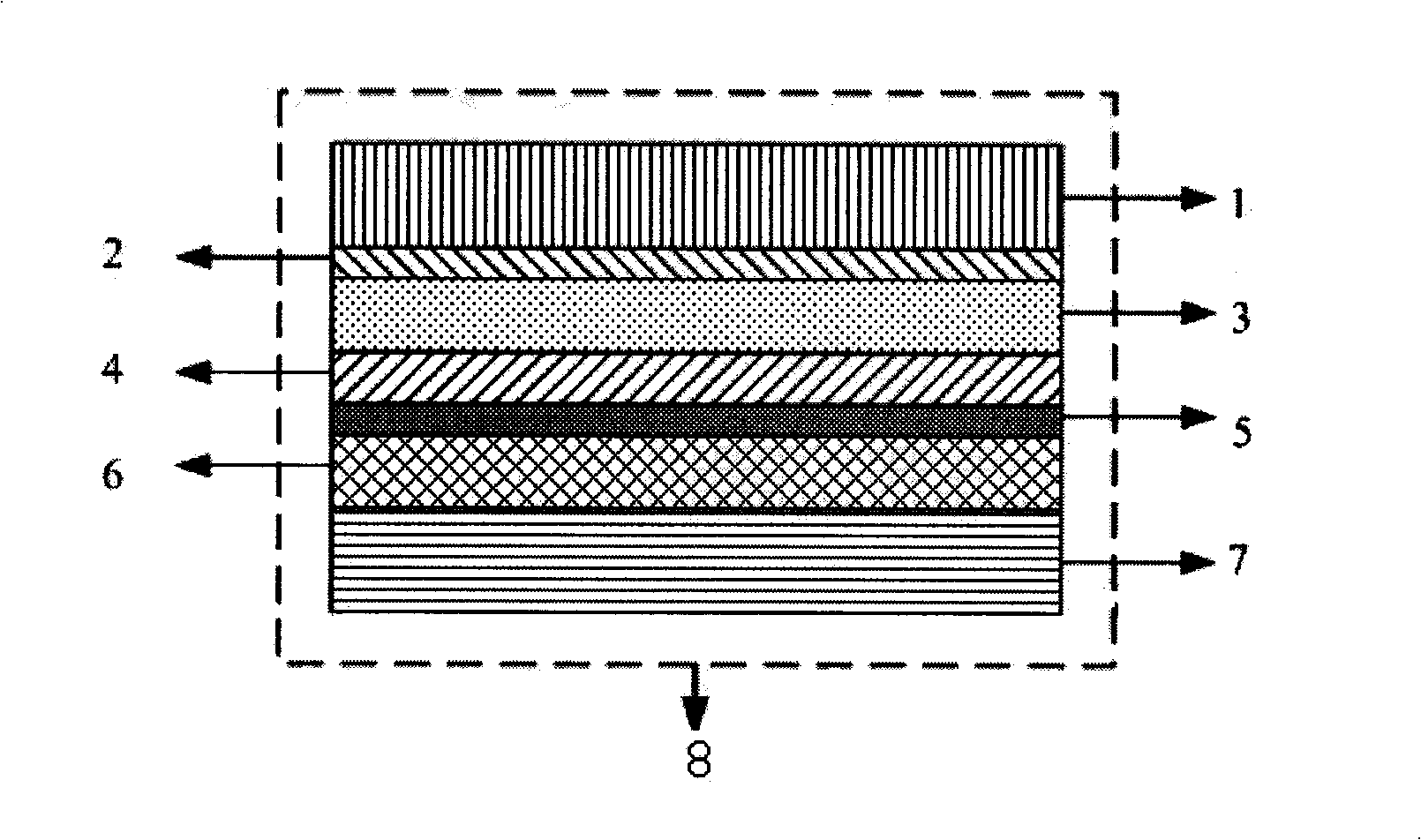

Fabricating method of electrode adhesive bicell

InactiveUS20080038447A1Increase energy densityLong lastingFinal product manufactureElectrode carriers/collectorsPolymer adhesivePolymer science

A method for manufacturing an electrode adhesive bicell comprises steps of forming a solid state positive electrode film; forming a solid state negative electrode film; mixing polymer adhesive, a filler and two solvents of different boiling points as a mixing material; the mixing material being coated upon two opposite surfaces of a porous membrane as a coated object; the coated object being then dried as a separator membrane; the two solvents of different boiling points serving to solving the polymer adhesive, after the solvent of lower boiling point is evaporated, the other solvent of high boiling point is retained so that the separator membrane is retained as a gel with good adhesive and plasticity for the combination of solid state positive electrode film and solid state negative electrode film.

Owner:VISTA ADVANCE TECH

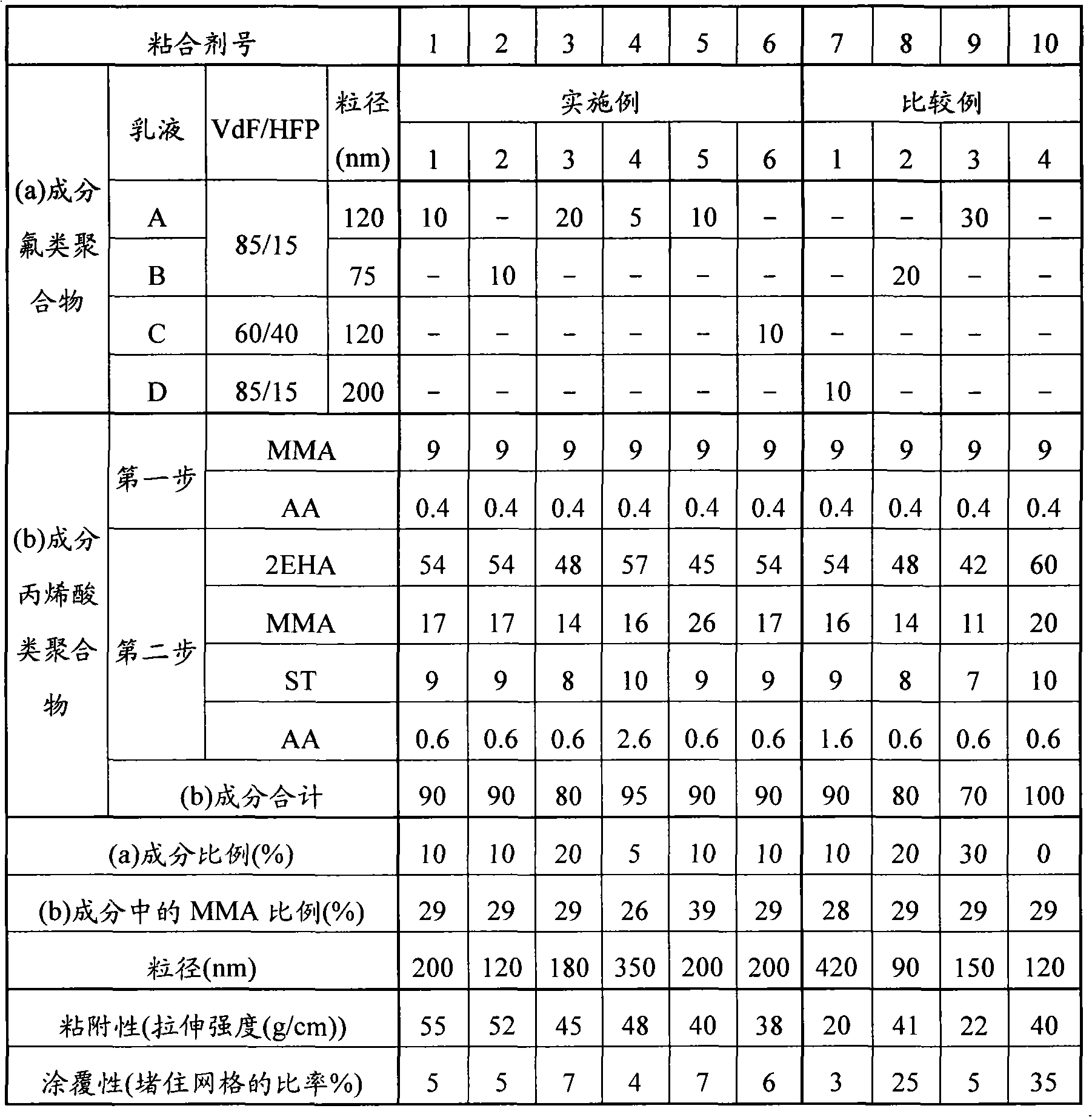

Combination for capacitor electrode adhesive

ActiveCN101550322ANot easy to blockBasic electrochemical stabilityHybrid capacitor electrodesCell electrodesHydrogen atomSlurry

The invention relates to a combination for capacitor electrode adhesive, capable of providing the serum with excellent electrochemistry stability and adhesive ability of afflux body for forming the electrode and uniformity of coating when the afflux body is porous and the serum unable of blocking the afflux body grid. The combination for capacitor electrode adhesive comprises the polymer combination comprising (a) component: fluorine polymer 5-20 weight% and (b) component: (methyl) acrylics polymer 80-95 weight% containing the structure unit of the monomer represented by the general formula (1), namely granular polymer combination with number-average grain size of 0.1-0.4 Mum, general formula (1) CH2=CR1COOR2, in the general formula (1), R1 represents hydrogen atom or methyl, R2 represents alkyl or cycloalkyl of carbon atom number 1-18.

Owner:株式会社引能仕材料

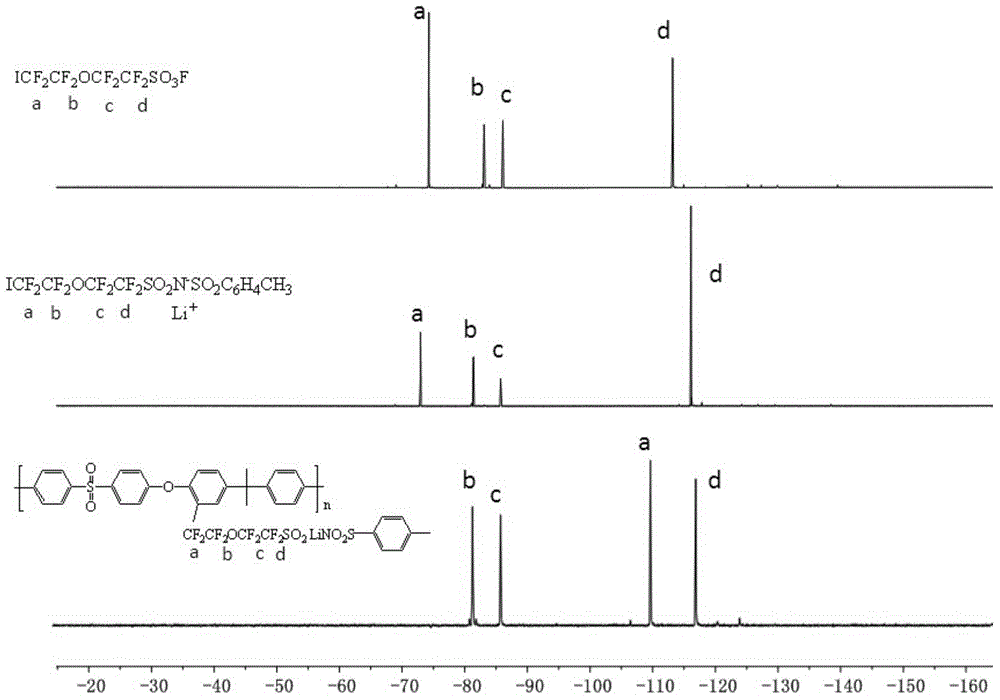

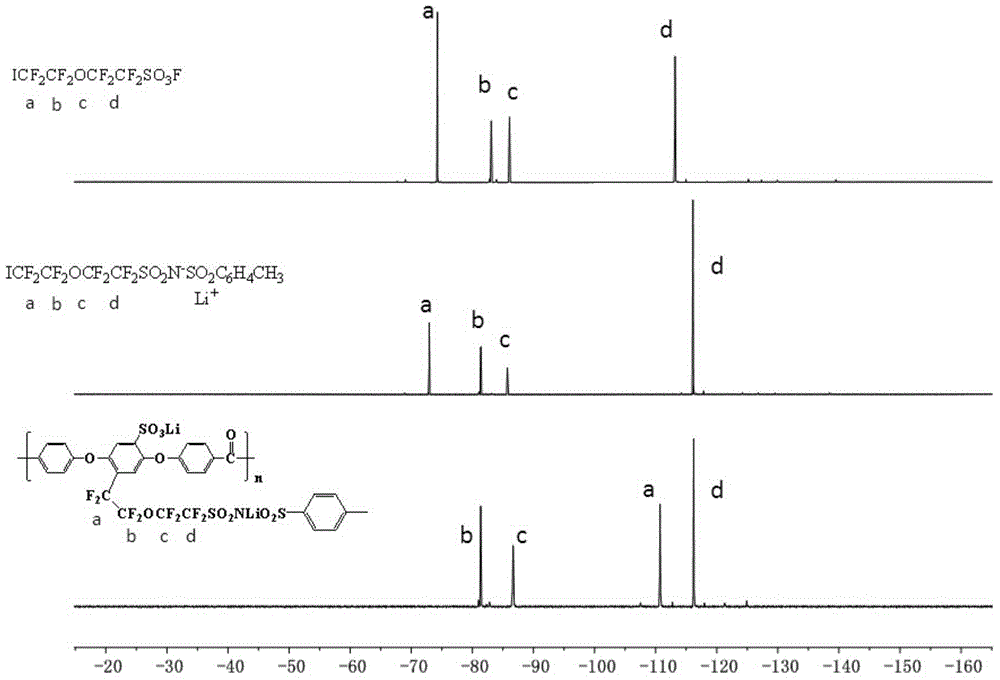

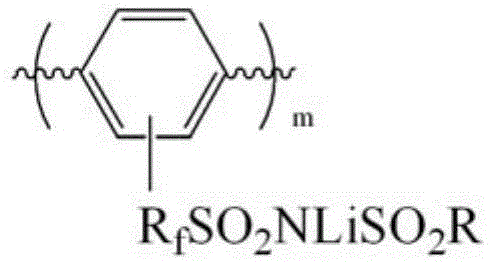

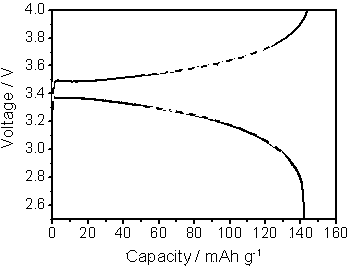

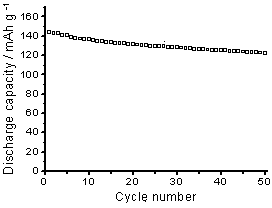

An electrode adhesive for a lithium ion battery, and preparing and using methods thereof

InactiveCN105449218ALower dissociation energyImprove conductivityCell electrodesSecondary cellsHigh rateAluminium-ion battery

The invention provides an electrode adhesive for a lithium ion battery. The adhesive is a lithium ion polymer adopting an aromatic benzene ring as a main chain and adopting fluorine-containing lithium sulfimide as a side chain. Compared with the prior art, the adhesive can form co-complexation bridging with high-energy-density active compounds such as nanometer silicon, is good in adhesiveness, and can adapt to stress influences generated by volume changes of active compounds in charge and discharge processes. The adhesive is good in lithium ionic conductivity, thus overcoming problems that charge-discharge properties of lithium ion batteries are influenced and battery capacity rapidly decreases during high-rate charging and discharging in particular, which are caused by low lithium ionic conductivity of adhesives at present. The adhesive has a good application prospect in all-solid-state polymer lithium ion batteries, gel state polymer lithium ion batteries, integrated polymer lithium ion batteries, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

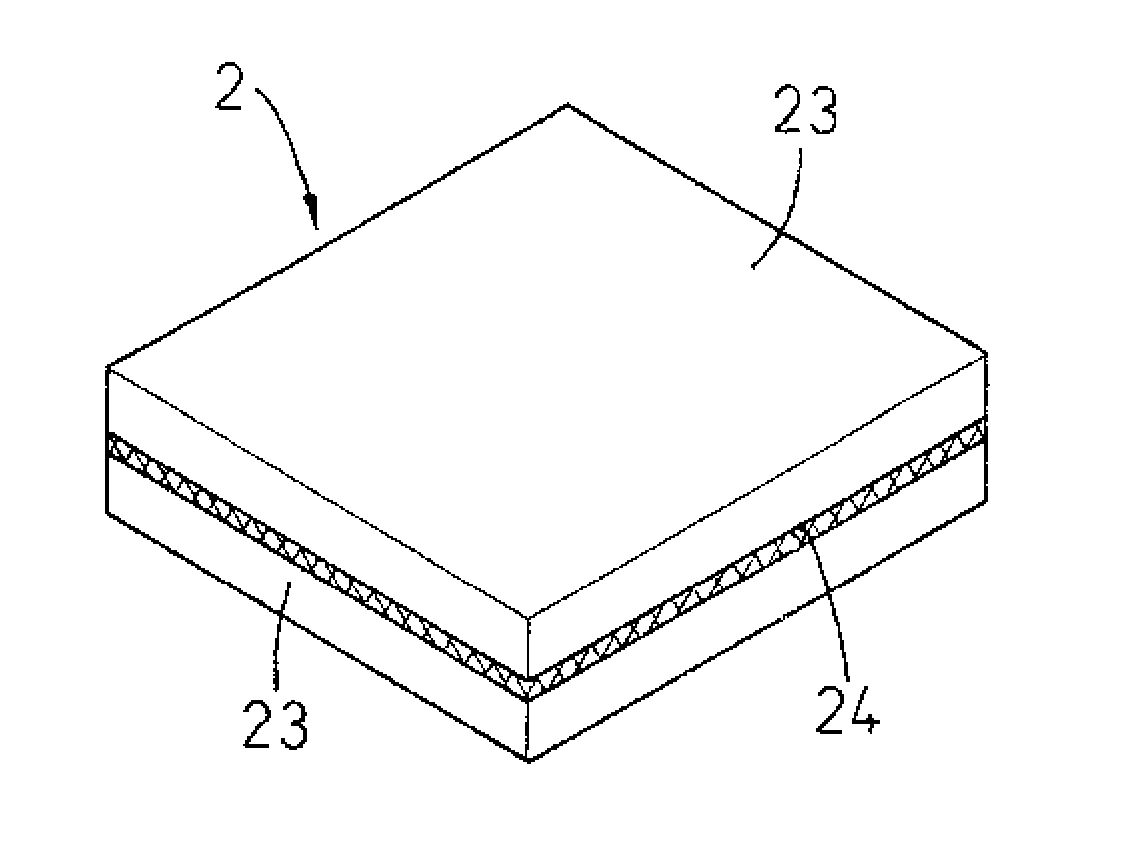

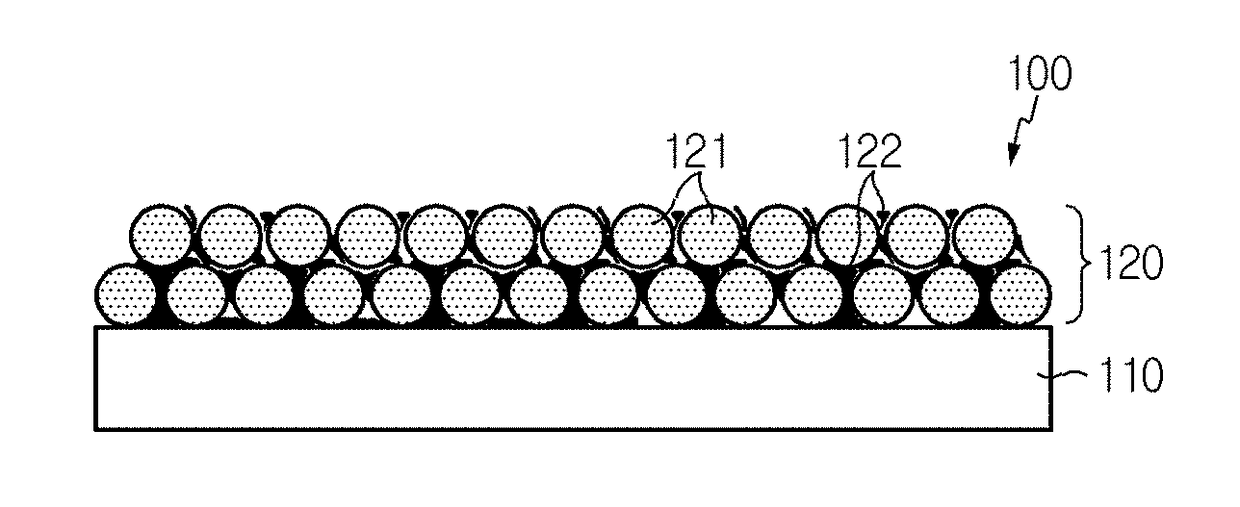

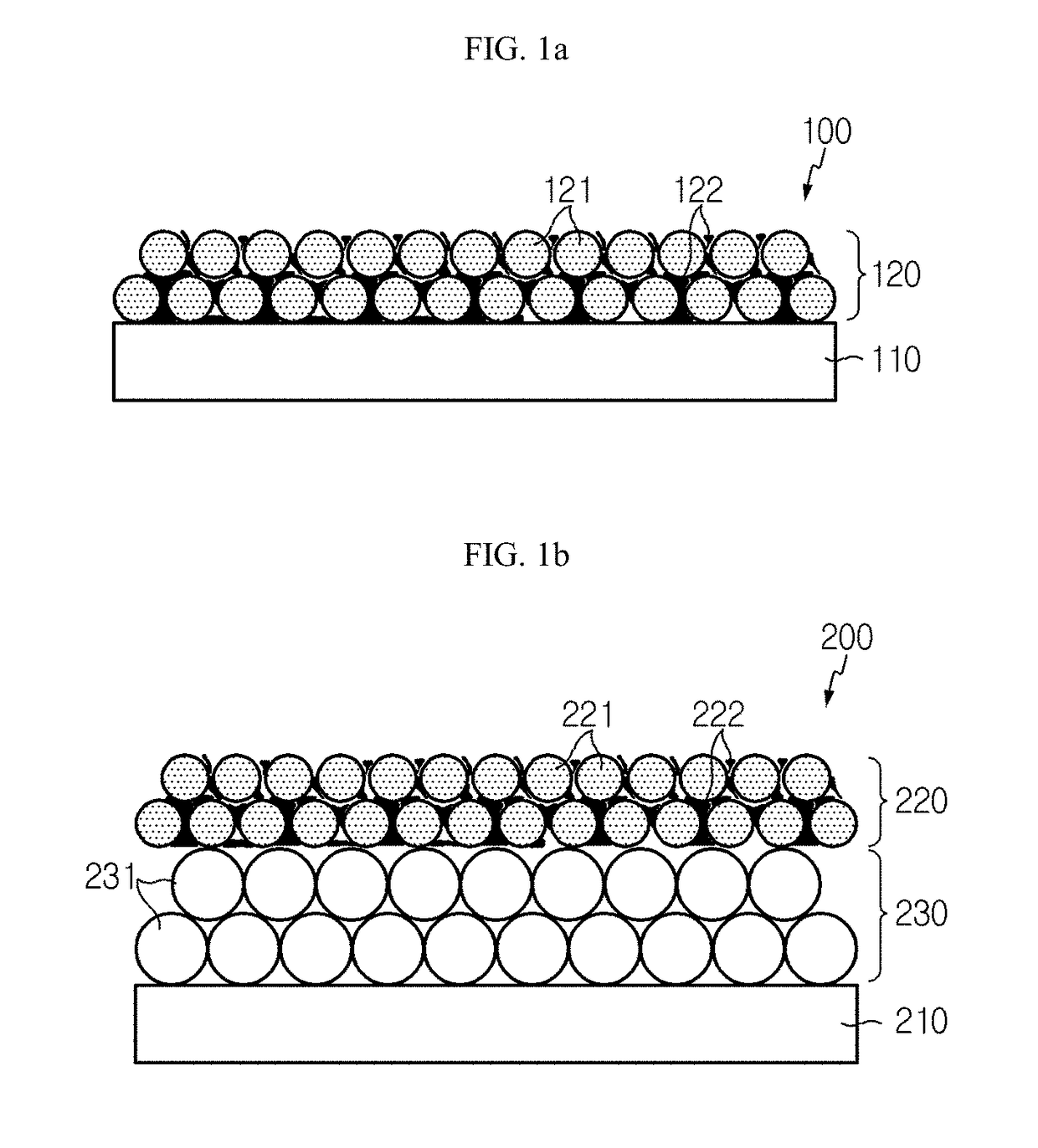

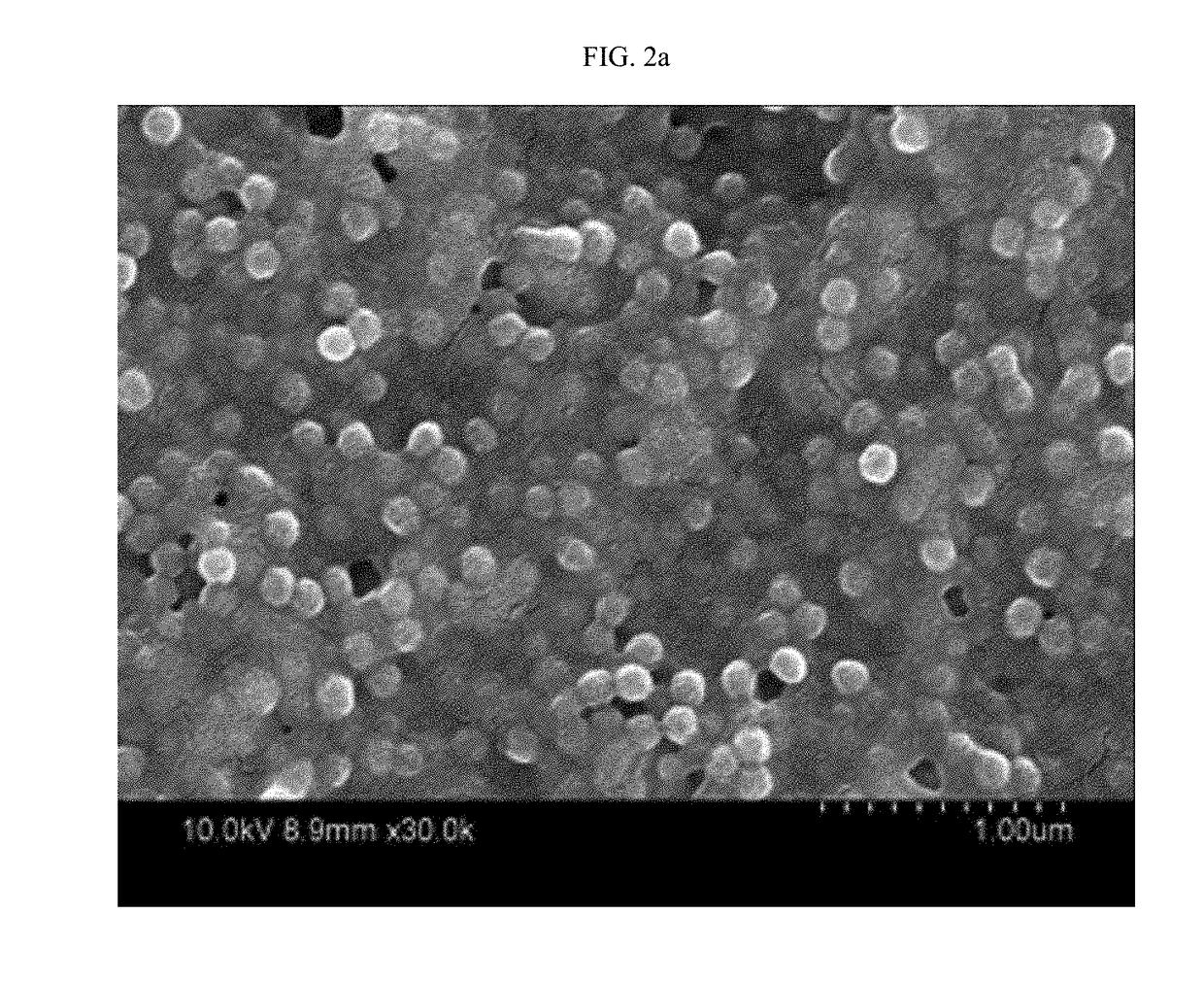

Method for manufacturing separator for lithium secondary battery, separator manufactured by method, and lithium secondary battery comprising same

ActiveCN105556702ASpeed up preparationLow costCell seperators/membranes/diaphragms/spacersFinal product manufactureElectrical batteryPolymer substrate

The present invention relates to a method for manufacturing a separator for a lithium secondary battery, a separator manufactured by the method, and a lithium secondary battery comprising the same, the method comprising: a charging step (S1) for charging polymer particles and forming the charged polymer particles; a laminating step (S2) for laminating the charged polymer particles on at least one side of a porous polymer substrate and forming an electrode adhesive layer in such a manner that, relative to the entire surface area of the porous polymer substrate, the formation surface area of the electrode adhesive layer is 1 to 30% thereof; and a fixing step (S3) for fixing the electrode adhesive layer by means of heat and pressure. According to the present invention, the method for manufacturing a separator for a lithium secondary battery, introducing an electrode adhesive layer by using static electricity, not by slurry coating comprising a solvent, does not require a solvent due to polymer particles being applied in a laser printing technique, thereby generating a cost-saving effect due to there being no burden for handling and storage, and does not require a step for drying the solvent, thereby being capable of rapidly manufacturing a separator for a lithium secondary battery. Furthermore, it is possible to prevent the resistance increase of a lithium secondary battery by coating only a certain surface area, not the entire surface area, of the electrode adhesive layer.

Owner:LG ENERGY SOLUTION LTD

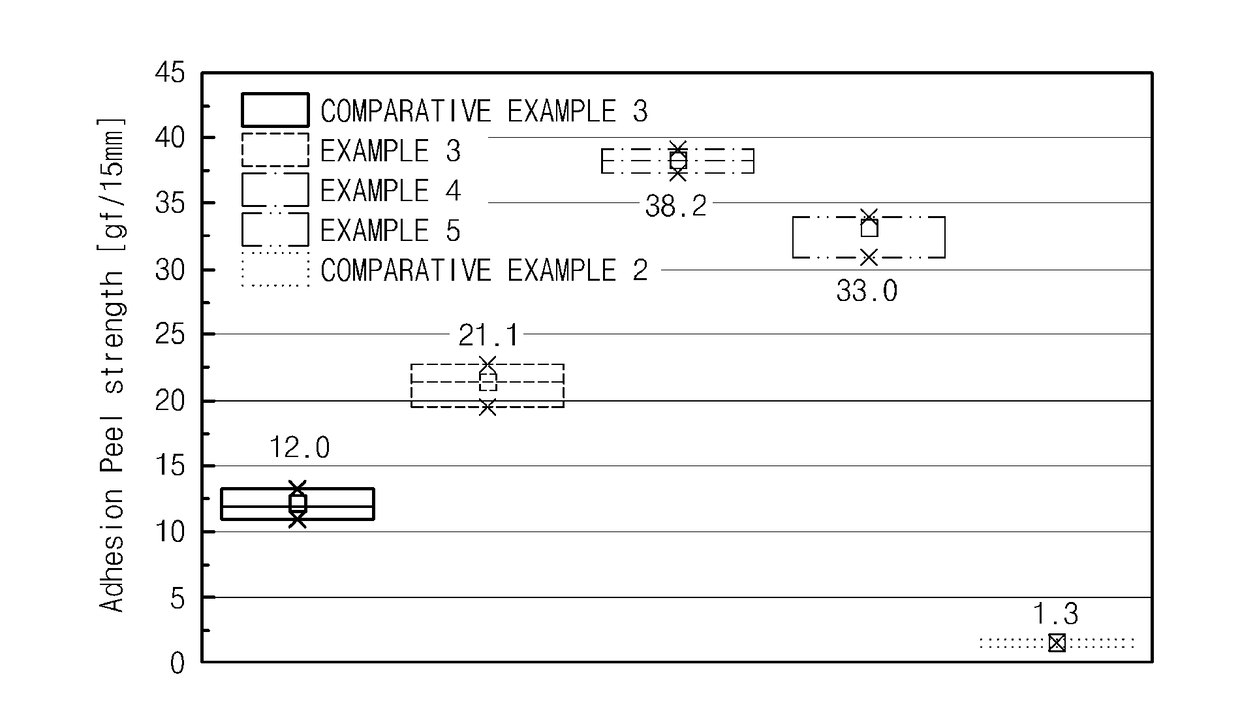

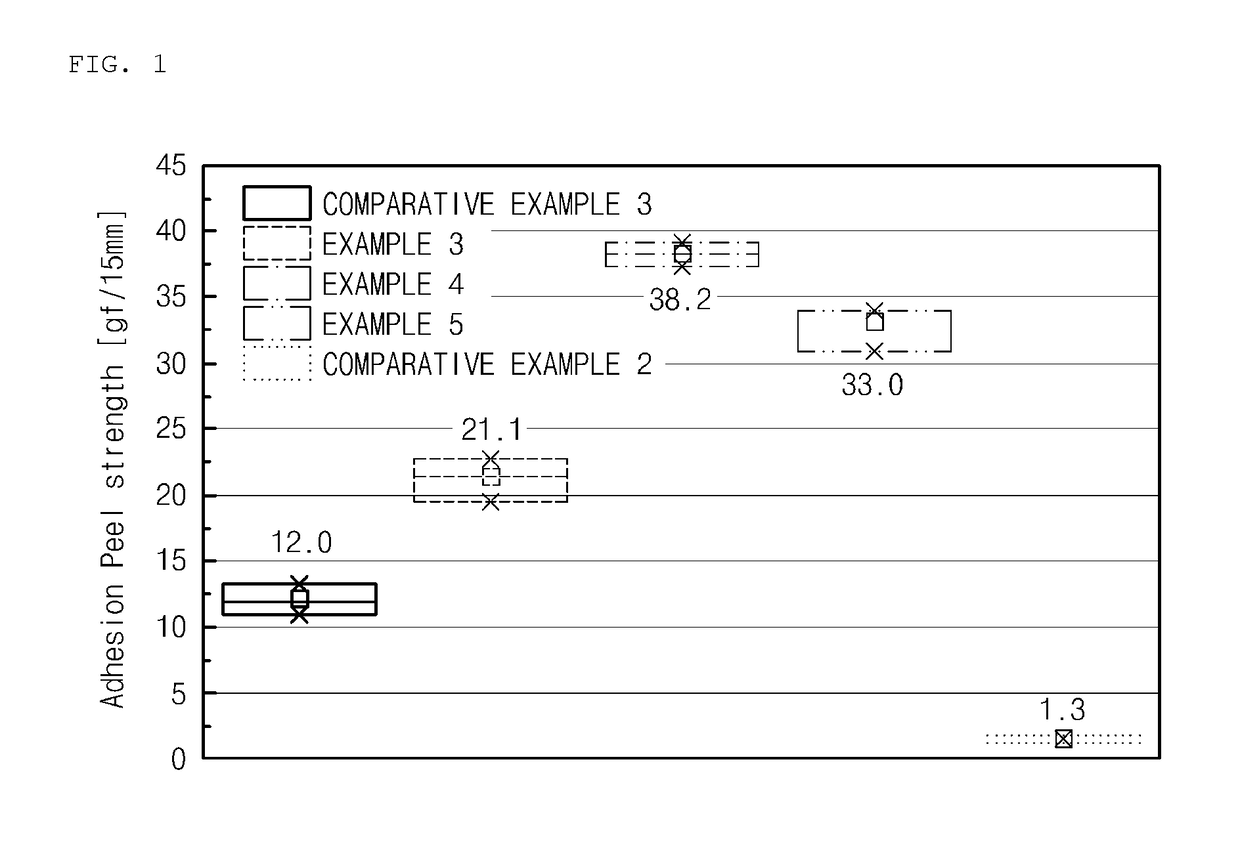

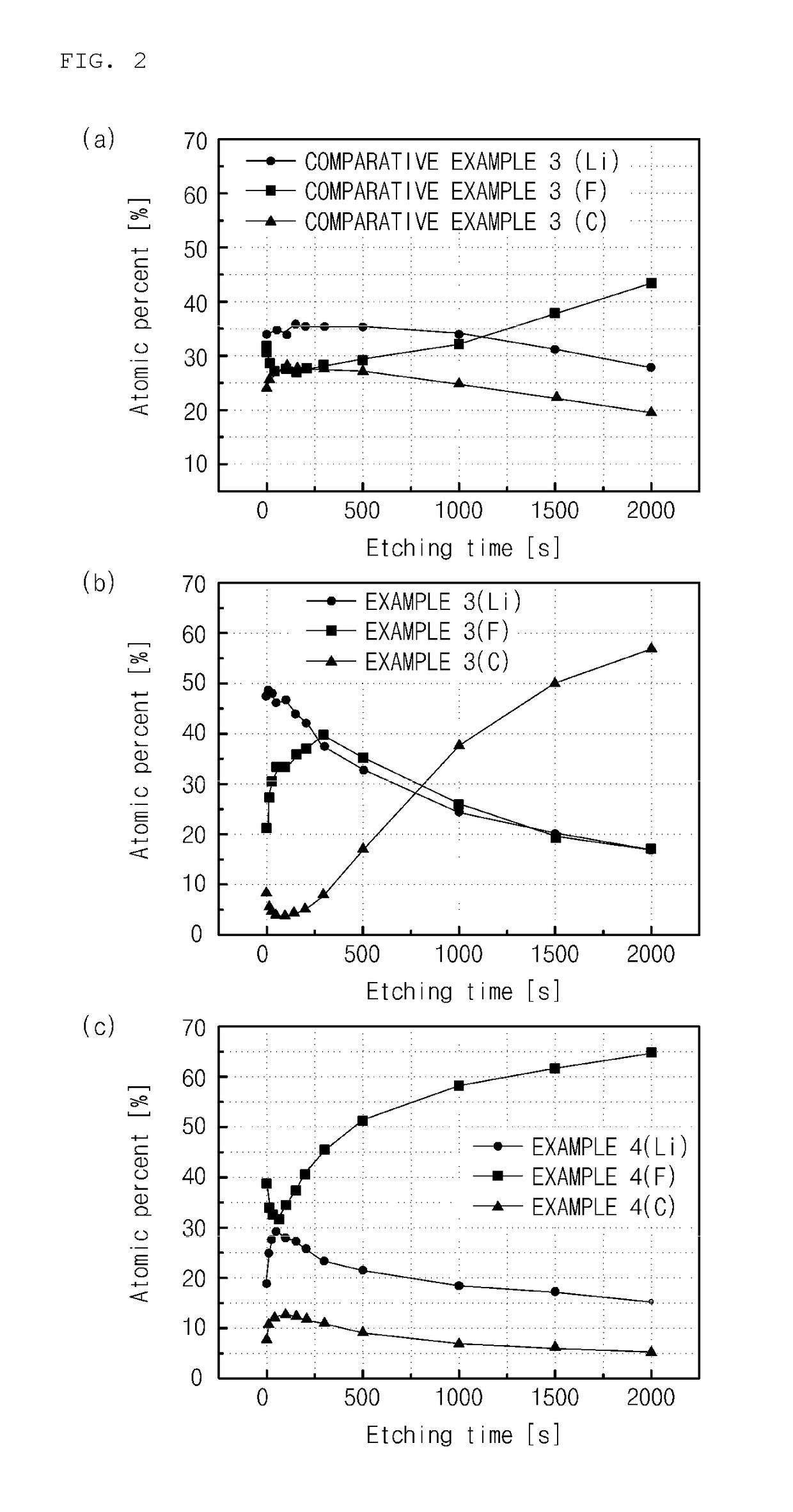

Separator having electrode adhesive layer and electrochemical device including the same

ActiveUS20180315971A1Improve adhesionImprove securityLi-accumulatorsCell component detailsPorous coatingAcrylic resin

Disclosed are a separator having an electrode adhesive layer and an electrochemical device including the same. The electrode adhesive layer includes organic particles and an acrylic resin binder. Preferably, the acrylic resin binder is present in an amount of 30 wt % or more, so that a film-shaped electrode adhesive layer can be formed even when the organic particles have a particle diameter smaller than that of the pores of the underlying substrate or voids of the underlying porous coating layer.

Owner:LG ENERGY SOLUTION LTD

Preparation method of lithium battery negative electrode slurry

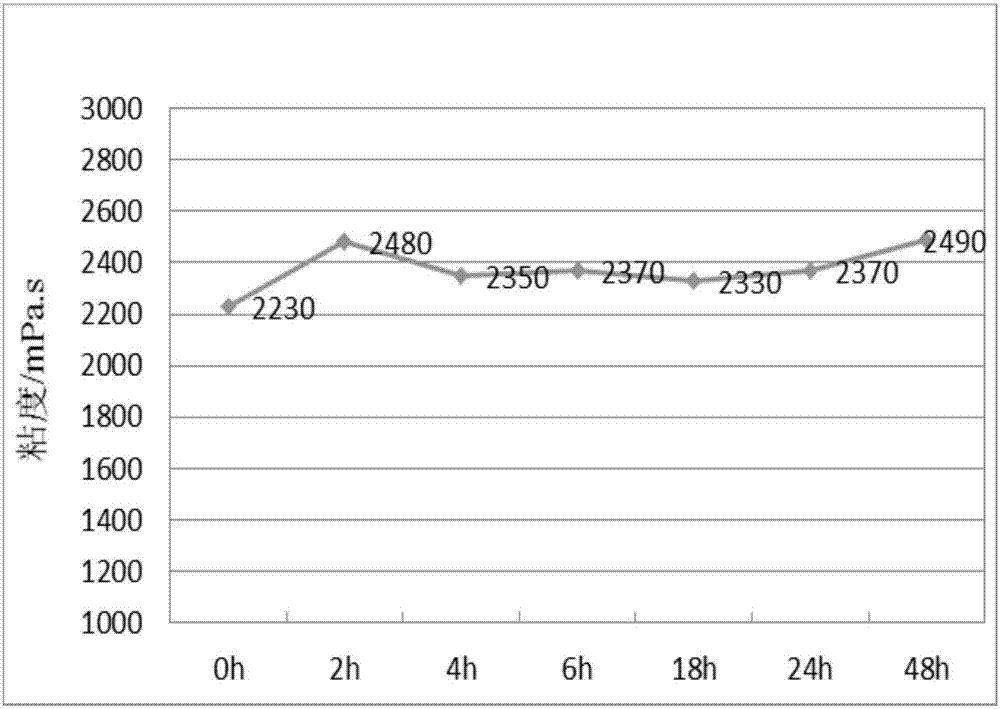

InactiveCN107240674AGood dispersionEasy to makeElectrode manufacturing processesSecondary cellsMass ratioSlurry

The invention discloses a preparation method of lithium battery negative electrode slurry. The preparation method comprises the following steps: step one, weighing graphite, a conductive agent and sodium carboxymethylcellulose dry powder in a mass ratio of (93 to 96): (2 to 5): (1.8 to 2.5), then adding the graphite, the conductive agent and partial sodium carboxymethylcellulose dry powder with the solid content of 30% to 70% into a stirring tank, and starting roatation and revolution of the stirring tank for first stirring; step two, adding partial deionized water with the solid content of 20% to 60% in deionized water with the solid content of 45% to 50% for second stirring; step three, adding remaining partial sodium carboxymethylcellulose dry powder with the solid content of 70% to 30% for third stirring; step four, adding remaining partial deionized water with the solid content of 80% to 40% for fourth stirring; step five, adjusting the rotation of the stirring tank for fifth stirring, and connecting circulating cooling water; step six, adding a negative electrode adhesive, and then adjusting the rotation of the stirring tank again for sixth stirring; and step seven, stopping the rotation of the stirring tank, then adjusting the revolution of the stirring tank for seventh stirring to obtain a product, and carrying out vacuum defoamation on the product.

Owner:SHENZHEN ANDING NEW ENERGY TECH DEV CO LTD

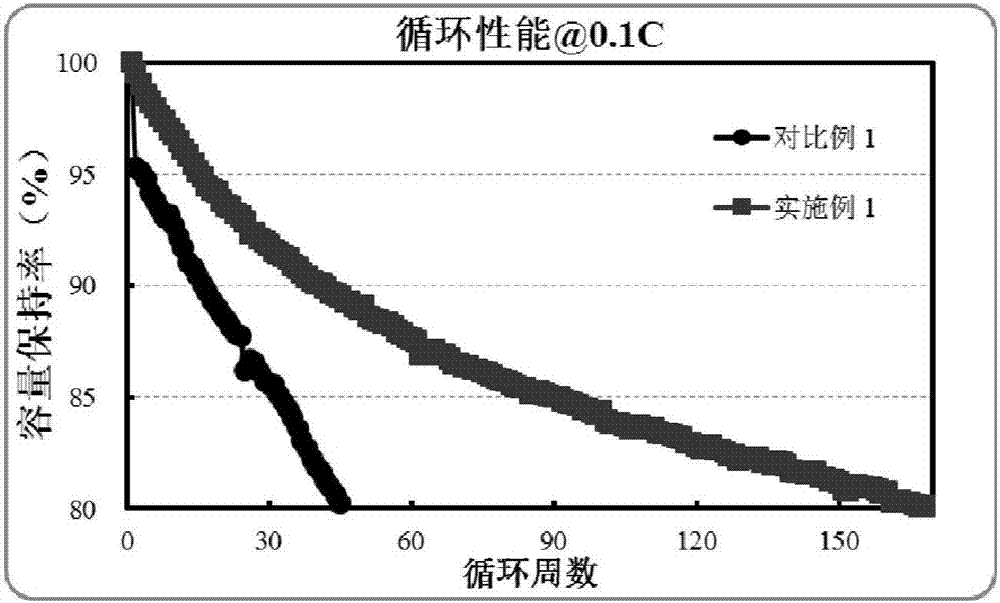

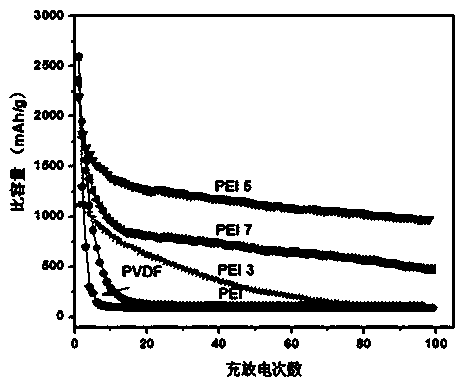

Preparation method of lithium ion battery negative electrode adhesive and method for preparing lithium ion battery negative electrode material

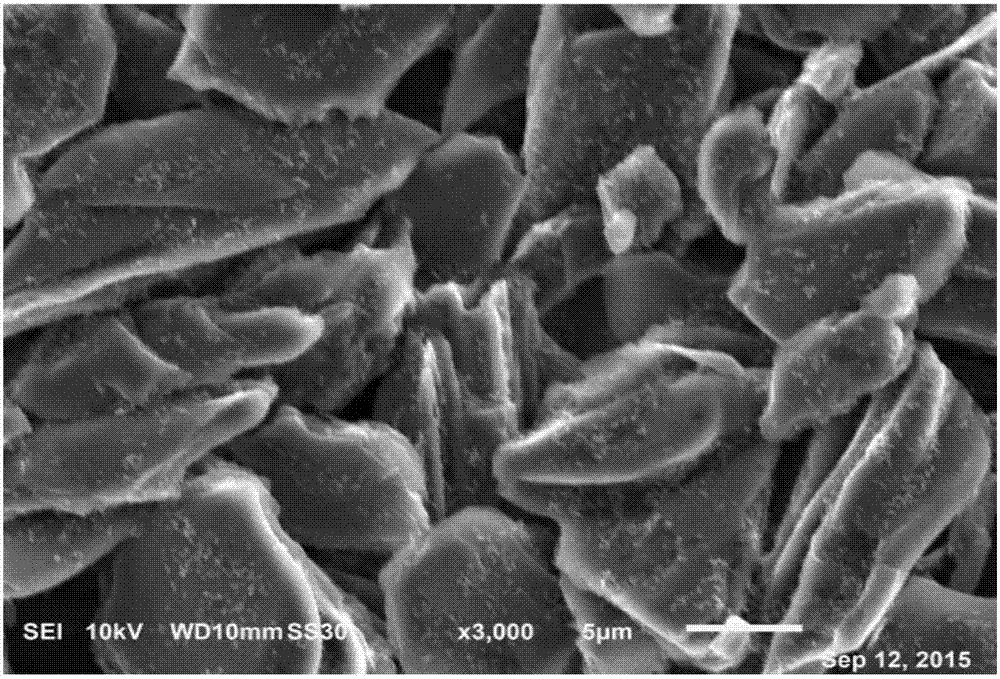

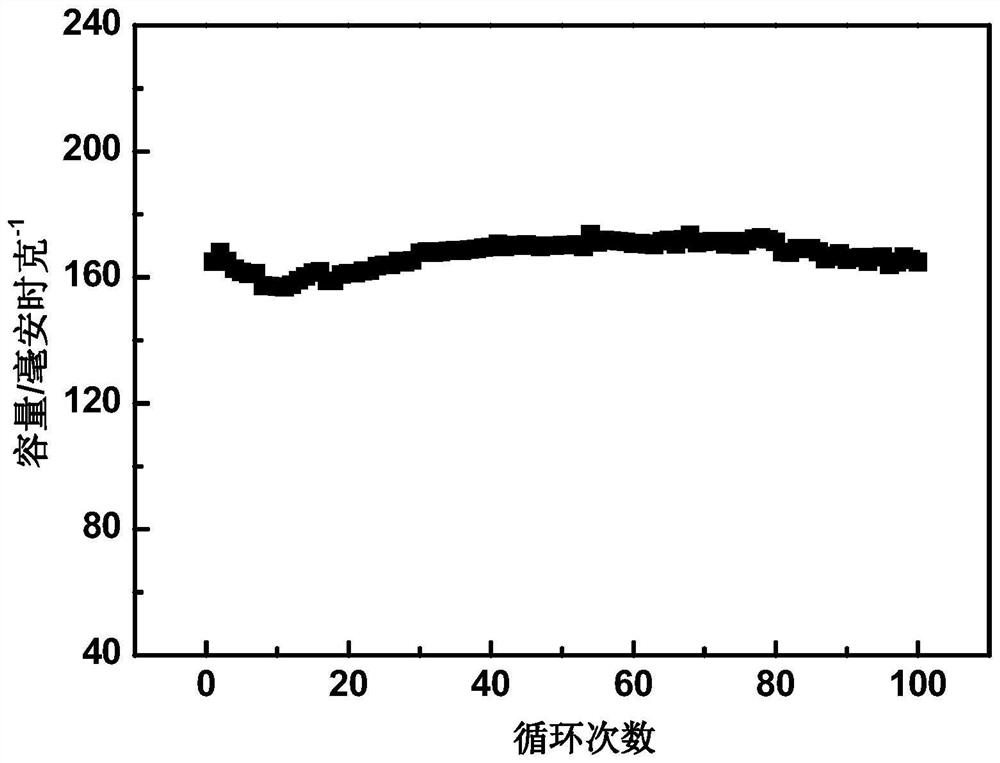

ActiveCN108899548AImproved rheological propertiesImprove charge and discharge cycle stabilityCell electrodesSecondary cellsCross-linkPolyetherimide

The invention provides a preparation method of a lithium ion battery negative electrode adhesive and a method for preparing the lithium ion battery negative electrode material. A cross-linked PEI (Polyetherimide) adhesive prepared according to the invention is water-soluble, low in toxicity, nonflammable, green, environment-friendly and capable of realizing industrial production, the prepared cross-linked PEI adhesive has a hyperbranched network structure, and the structure can form multi-dimensional strong hydrogen bonds with silicon, so that silica nanoparticles are firmly coated. The flexible hyperbranched PEI molecular chain is capable of effectively buffering stress generated by silicon volume expansion, and flows to the damage surface while shrinking the silicon volume to form hydrogen bonds again, and the self-repairing effect is effectively achieved; movement of the silicon can be effectively limited by the network structure, deformation resistance of the electrode is improved,the integrity of the electrode is ensured, and the volume effect problem of the silicon negative electrode can be effectively solved, so that the cycling stability of the silicon negative electrode is greatly improved, the requirements of electric vehicles and other large energy storage devices on high-specific capacity cells are further met, and the development prospects are wide.

Owner:JIAXING UNIV

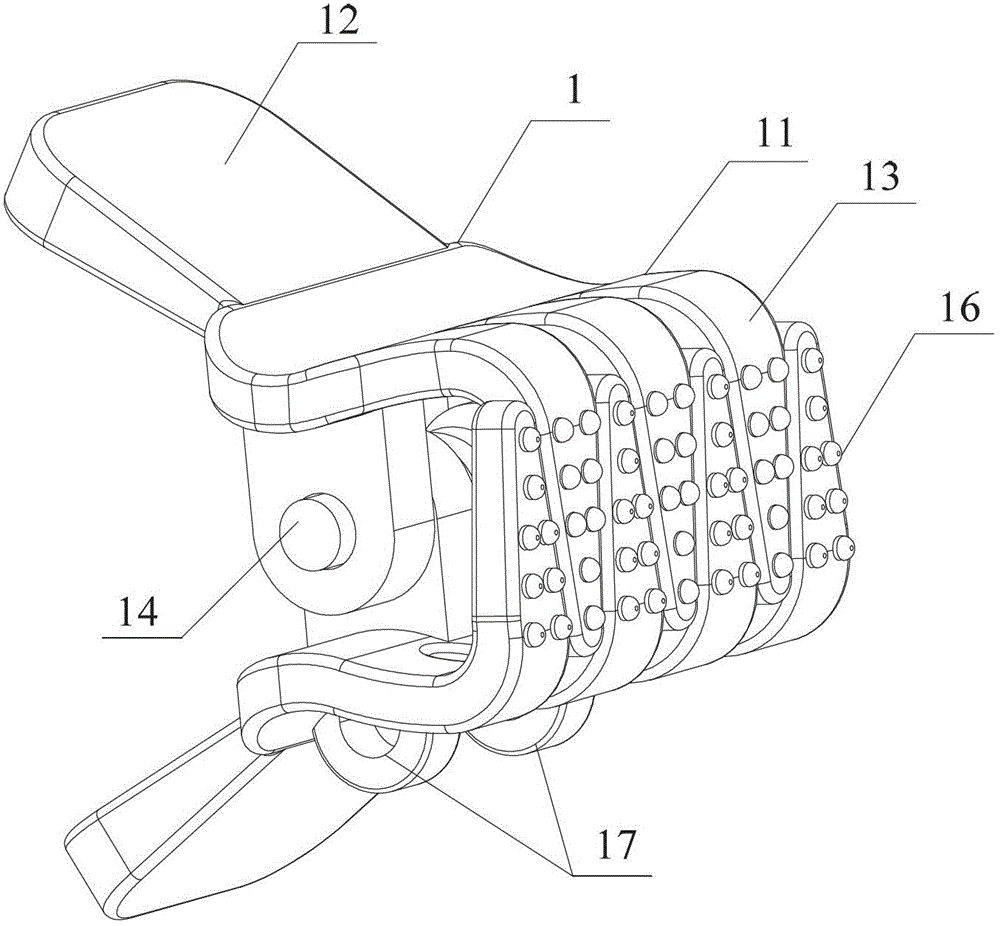

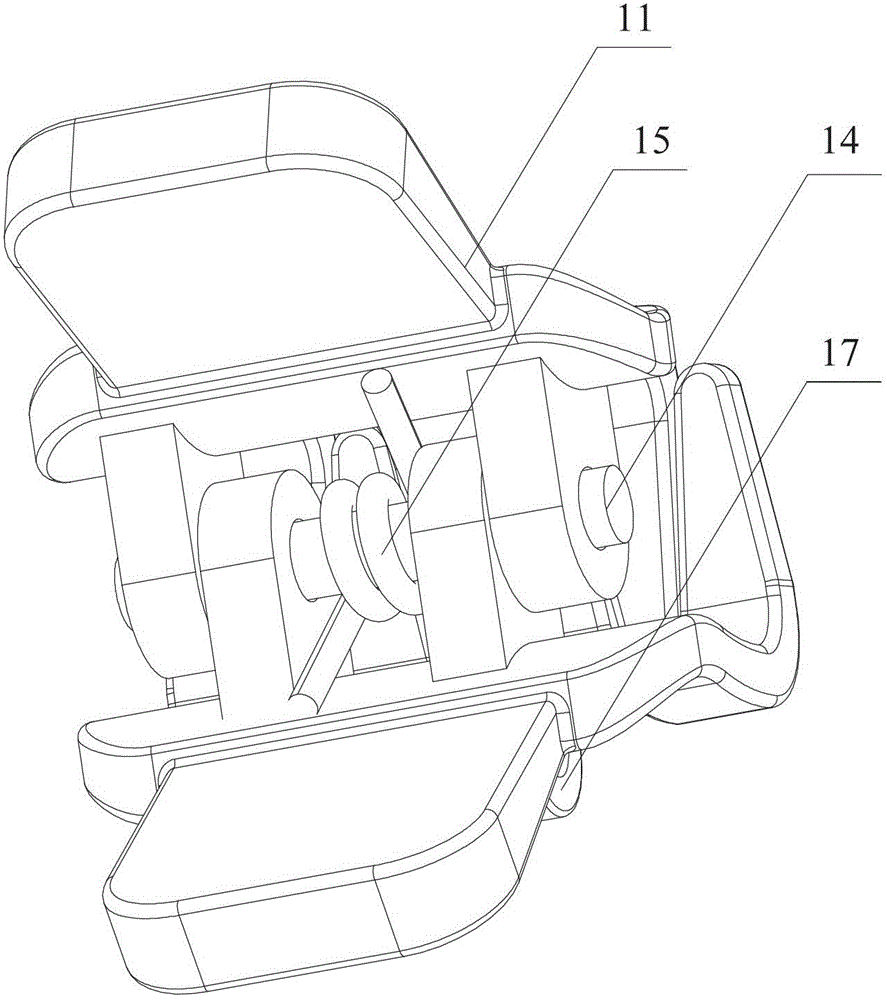

Dry type medical electrode

ActiveCN102908139AReduce contact resistanceIncrease coefficient of frictionDiagnostic recording/measuringSensorsClipping hairContact impedance

The invention discloses a dry type medical electrode. The electrode is an elastic-clip-shaped electrode formed by a pair of conductive clips which are symmetric by two edges and crossed in tooth shape. A plurality of projections contacting with scalp are arranged at the bottoms of the conductive clips. By adopting the elastic clip-shaped electrode formed by a pair of the conductive rubber clips which are symmetric by two edges and crossed in tooth shaped, hairs are separated by the conductive tooth-shaped elastic clips, the conductive electrode fixed by the clipped hair can directly contact with the scalp, and meanwhile, rough projections are arranged on the surface of the bottom of the tooth-shaped electrode and can directly contact with the scalp, so that the skin of the scalp can be pressed to be rough, friction coefficient between the electrode and the scalp is increased, contact surface of the electrode and the scalp is enlarged, and contact impedance of the electrode and the scalp is reduced without hurting the hairs and the scalp. The dry type medical electrode is convenient to operate, and many problems caused by using of electrode adhesives (paste) in the prior art are avoided.

Owner:SHENZHEN YINGZHI TECH

High-temperature resistance lithium ion secondary battery adhesive and preparation method thereof

The invention discloses a high-temperature resistance lithium ion secondary battery adhesive and a preparation method thereof. The preparation method adopts 2-acrylamide-2- methylsulfonate, itaconate, dimethyl itaconate, maleic anhydride, and fumarate as the initial monomer, and carboxymethyl cellulose salt as the auxiliary agent. The reactants polymerize under the inducing of persulfate thermal free radical initiator, so as to produce homogeneous and stable electrode adhesive. The electrode adhesive prepared according to the preparation method has the advantage of high-temperature resistance, and is suitable for being applied to high power-density and high energy-density lithium ion battery.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparation method for positive electrode for lithium iron phosphate secondary battery and lithium ion battery

InactiveCN109817896AGood adhesionImprove ionic conductivityElectrode manufacturing processesElectrode carriers/collectorsHigh rateLithium iron phosphate

The invention discloses a preparation method of a positive electrode for a lithium iron phosphate secondary battery and a lithium ion battery, and belongs to the technical field of lithium ion batteries. The invention aims to solve the problem that the rate capability and the low-temperature performance of the existing lithium iron phosphate battery are not ideal. The method specifically comprisesthe following steps: opening a stirring tank, adding a conductive agent, lithium iron phosphate, a positive electrode adhesive and NMP according to the mass ratio of a formula design, performing uniform stirring and dispersing at the revolution rotating speed of 20-60 rpm when the rotating speed of a dispersing disc is 200-2, 000 rpm, adjusting the revolution rotating speed to 10-30 rpm, taking out the material, measuring the solid content, opening a vacuum pump, and keeping the vacuum degree of -0.08 to -0.09 MPa, performing stirring for 30 minutes, discharging vacuum to obtain positive electrode slurry, and arranging the positive electrode slurry on a positive electrode current collector in a coating manner to obtain the positive electrode. The positive electrode prepared by the invention has good adhesive strength and high ionic conductivity, and can realize high-rate rapid charging and discharging of the lithium ion battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

Lithium battery electrode adhesive and preparation method thereof

ActiveCN108832130AImprove stabilityImprove electrolytic resistanceCell electrodesLi-accumulatorsCyclohexanoneElectrolysis

The invention discloses a lithium battery electrode adhesive and a preparation method thereof. The lithium battery electrode adhesive is prepared from the following raw materials in parts by weight: 600-800 parts of acrylic ester, 40-80 parts of acrylate monomer, 200-300 parts of acrylic ester polyhydric alcohol, 1-5 parts of cyclohexanone 1,2-propylene glycol ketal, 0.5-3 parts of carbon nanotubeand 0.01-0.1 part of azo-bis-iso-heptonitrile. The lithium battery electrode adhesive prepared by the preparation method has a good protection function on the lithium battery electrode, can be dust-proof and water-proof, does not crack at low temperature, and has excellent adhesive property. The acrylic ester polyhydric alcohol and the carbon nanotube are added to be favorable for improving the discharging stability of the lithium battery, improving electrolysis resistance and prolonging the service life of the lithium battery.

Owner:NINGBO NENGZHIGUANG NEW MATERIALS TECH

Solid-state battery based on plastic crystal modified positive electrode and preparation method of solid-state battery

ActiveCN114335536AFully playImprove compatibilityFinal product manufactureCell electrodesPlastic crystalElectrical battery

The invention belongs to the technical field of solid-state batteries, and particularly relates to a solid-state battery based on a plastic crystal modified positive electrode and a preparation method thereof.The preparation method of the solid-state battery based on the plastic crystal modified positive electrode comprises the following steps that firstly, plastic crystal, lithium salt, a polymer and inorganic filler are heated and mixed, and the plastic crystal melted into a liquid state serves as a solvent; 2, mixing positive electrode material powder, a conductive agent, the plastic crystal-based composite positive electrode adhesive obtained in the step 1 and an organic solvent, and coating a current collector with the mixture; and 3, preparing a plastic crystal-based positive electrode surface treatment liquid, coating or spraying the plastic crystal-based positive electrode surface treatment liquid on the surface of the positive electrode layer obtained in the step 2, and carrying out in-situ polymerization by adopting heating or irradiation. According to the solid-state battery based on the plastic crystal modified positive electrode and the preparation method of the solid-state battery, the interface compatibility and the compatibility with a high-specific-energy electrode material are improved, and the problem that the battery performance cannot be brought into full play due to poor battery interface contact and low material conductivity is solved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Conductive slurry and preparation method thereof, electrode plate coated with conductive slurry, and lithium ion battery

InactiveCN105932222AImproved high-magnification performanceImprove cycle stabilityCell electrodesSecondary cellsSlurryLithium-ion battery

The invention relates to the technical field of lithium ion batteries, and in particular relates to conductive slurry for a lithium ion battery. The conductive slurry comprises positive electrode conductive slurry coated on a positive electrode plate and negative electrode conductive slurry coated on a negative electrode plate; according to mass percent, the positive electrode conductive slurry comprises 92.5%-95.5% of positive electrode active materials, 0.5%-3.5% of positive electrode adhesives and 2.5%-5.5% of conductive agents; and the negative electrode conductive slurry comprises 93%-96% of negative electrode active materials, 1.4%-3.4% of negative electrode adhesives, 0.9%-3.9% of conductive agents and 0.2%-2.2% of thickening agents. The prepared conductive slurry is stable in conductivity, good in dispersion effect and hard in settlement. The invention further relates to a preparation method of the conductive slurry, an electrode plate containing the conductive slurry, and the lithium ion battery.

Owner:DONGGUAN JOYSUN NEW ENERGY

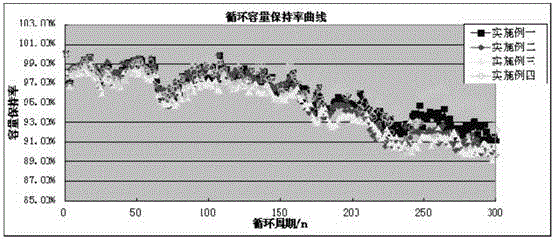

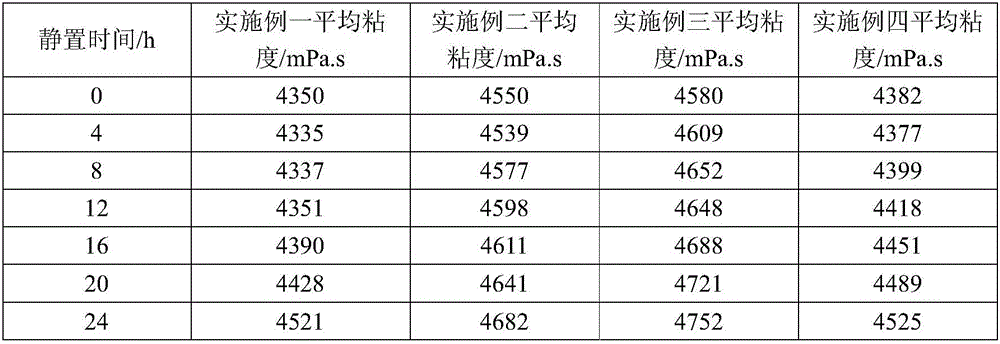

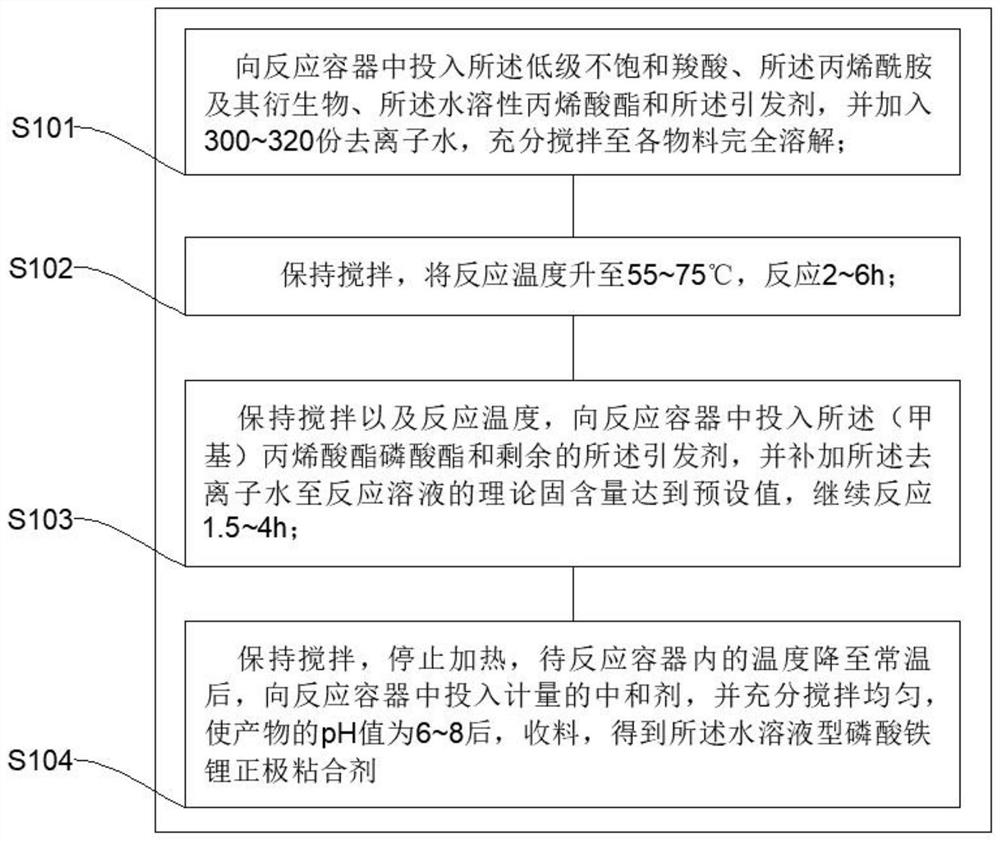

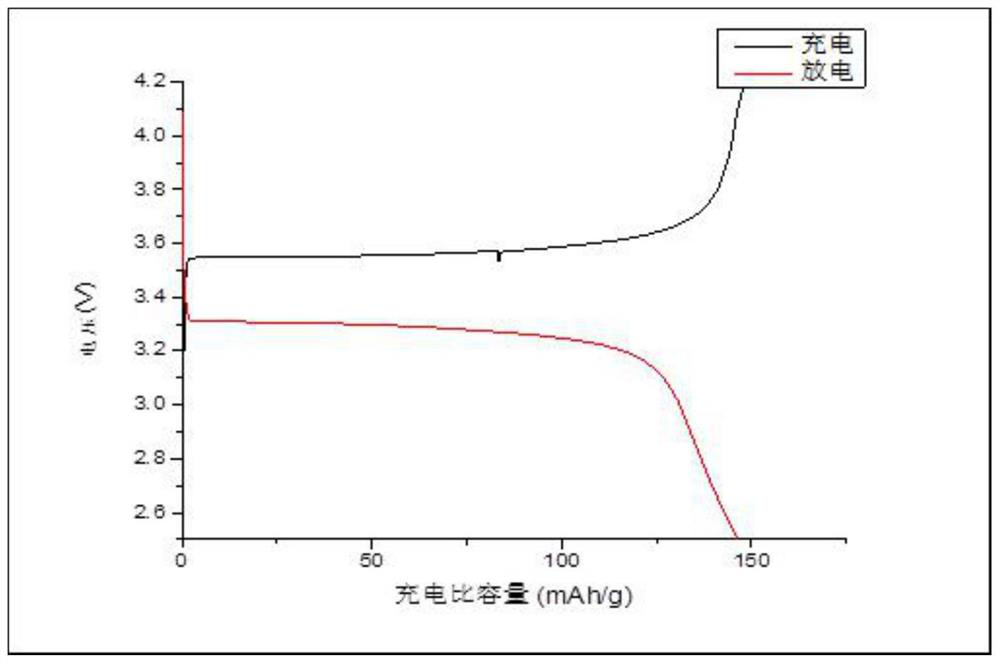

Aqueous solution type lithium iron phosphate positive electrode adhesive and preparation method and application thereof

PendingCN112467142AImprove thermal stabilityGood storage stabilitySecondary cellsPositive electrodesMethacrylatePhosphoric Acid Esters

The invention discloses an aqueous solution type lithium iron phosphate positive electrode adhesive, and a preparation method and application thereof. The aqueous solution type lithium iron phosphatepositive electrode adhesive is an aqueous solution, and the solid content is 3-15%; at 25 DEG C, the viscosity of the aqueous solution type lithium iron phosphate positive electrode binder is 5000-100000 cp, and the pH value is 6-8; the aqueous solution type lithium iron phosphate positive electrode adhesive comprises the following components in parts by mass: 10-20 parts of low-grade unsaturatedcarboxylic acid, 8-15 parts of acrylamide and derivatives thereof, 5-20 parts of water-soluble acrylate, 5-10 parts of (methyl) acrylate phosphate ester, and 0.1-0.4 part of initiator. Compared with the prior art, a single-component aqueous solution system is adopted, compared with a multi-component blending solution, the storage and use stability is better, the formula is simpler, and preparationis easy and convenient; in the aspect of components, acrylic acid, acrylate, acrylamide and other monomers are adopted for copolymerization, and the product has better thermal stability than polyvinyl alcohol, CMC and other water-soluble polymers.

Owner:湖南高瑞电源材料有限公司

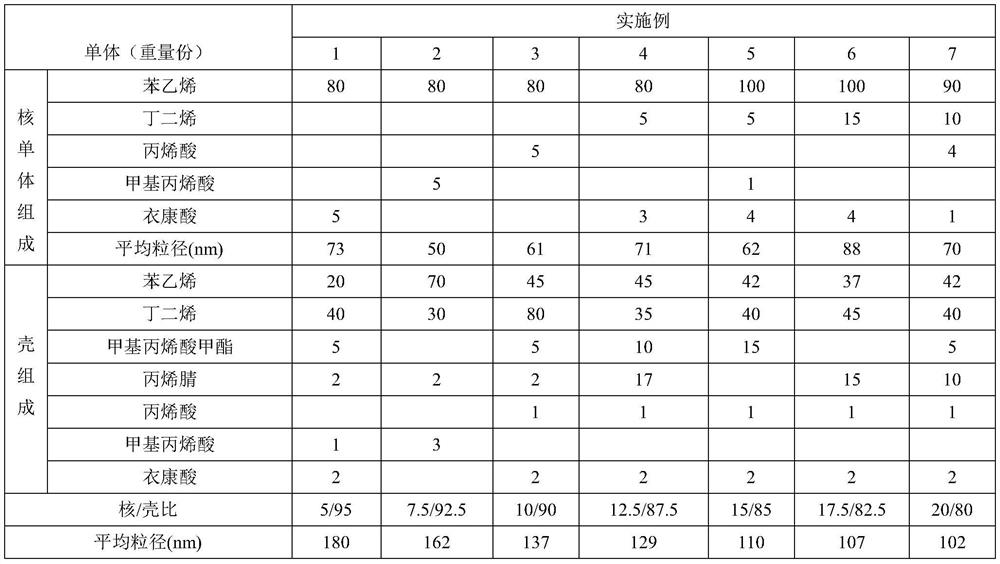

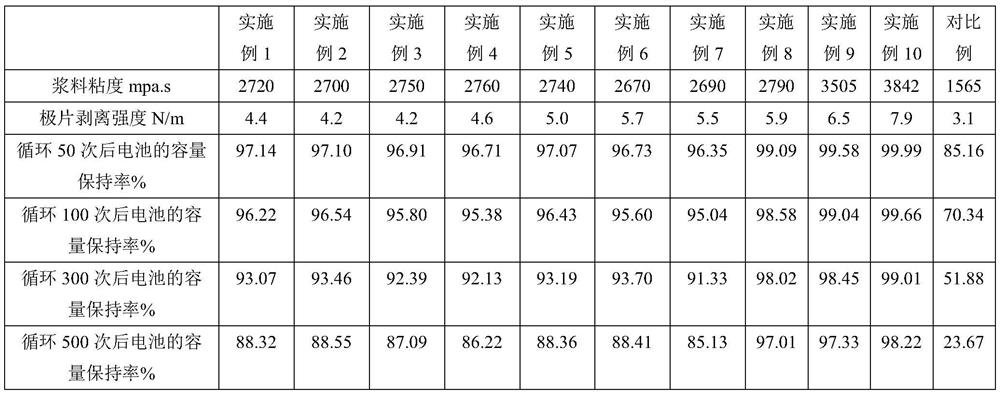

Copolymer latex for negative electrode of lithium ion secondary battery, preparation method and application

ActiveCN111825804AReduce dosageIncrease polarityCell electrodesSecondary cellsElectrolytic agentButadiene Dioxide

The invention discloses copolymer latex for a negative electrode of a lithium ion secondary battery. Firstly, styrene, butadiene and unsaturated carboxylic acid monomers are copolymerized to prepare ahard core, and butadiene, styrene and vinyl unsaturated monomers are copolymerized to prepare a soft shell so that a latex product with a hard core and soft shell structure is prepared, and the latexproduct is particularly suitable for a lithium ion secondary battery negative electrode adhesive. Research finds that the copolymer latex with the polymer particles with the hard-core and soft-shellstructures can improve the cohesiveness so that the dosage of the adhesive is reduced, and the influence of the adhesive on the internal resistance of the battery is reduced. The functional group introduced by copolymerization can change the polarity and dielectric properties of the polymer, thereby improving the electrolyte swelling resistance of the adhesive and the influence on the internal resistance of the battery.

Owner:RIZHAO GUANGDA BUILDING MATERIALS

Preparation method for positive electrode of ternary power lithium ion battery and lithium ion battery

InactiveCN109888189AGood adhesionImprove ionic conductivityElectrode manufacturing processesElectrode carriers/collectorsAluminium-ion batteryHigh rate

The invention relates to a preparation method for a positive electrode of a ternary power lithium ion battery and the lithium ion battery, and belongs to the technical field of lithium ion batteries.The invention aims at solving the problems that the energy density, the power performance and the cycle performance of an existing lithium ion battery cannot meet the existing requirements. The methodcomprises the following steps of opening a stirring tank, adding a conductive agent, a ternary NCM, a positive electrode adhesive and NMP according to a mass ratio designed by a formula, stirring anduniformly dispersing at the revolution speed of 20-60 rpm and the rotating speed of a dispersing disc of 200-2000 rpm, adjusting the revolution speed to be 10-30 rpm, taking the material and measuring a solid content, opening a vacuum pump, keeping the vacuum degree to -0.08 to 0.09 MPa, stirring for 30 minutes, discharging the vacuum to obtain positive electrode slurry, and coating the positiveelectrode slurry on a positive electrode current collector in order to obtain the positive electrode. The prepared positive electrode is good in bonding force, high in ionic conductivity and capable of realizing high-rate rapid charging and discharging of the ternary lithium ion battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

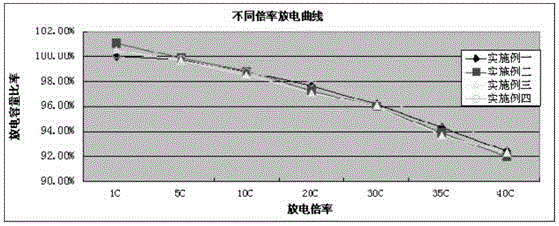

Nickel-cobalt-manganese NCM ternary material power lithium ion battery

InactiveCN107749477ASmall particlesImprove adhesionCell electrodesSecondary cellsInternal resistanceManganese

The invention relates to the field of lithium ion battery, and discloses a nickel-cobalt-manganese NCM ternary material power lithium ion battery including a positive electrode and a negative electrode; a positive electrode material includes, in parts by weight, 93-95 parts of a nickel-cobalt-manganese NCM ternary material, 3.5-4.5 parts of a positive electrode conductive agent, 2-3 parts of a positive electrode adhesive, and 15-25 parts of a dissolving agent; the negative electrode material includes, in parts by weight, 94-96 parts of a negative electrode particle material, 0.9-1.2 parts of anegative electrode conductive agent, 2-2.4 parts of a thickening agent, and 2-2.4 parts of a negative electrode adhesive; the negative electrode particle material has a core-shell structure, a core material is artificial graphite, and a shell material is amorphous carbon. The positive electrode material well cooperates with the negative electrode material; the negative electrode material has small particles and has good adhesion power and uniformity on a copper foil, and the contact internal resistance is low. After the lithium ion battery is prepared, not only is the internal resistance of the battery reduced, but also the low temperature performance, the high temperature performance and the cycle performance of the battery can be improved.

Owner:WANXIANG 123 CO LTD +1

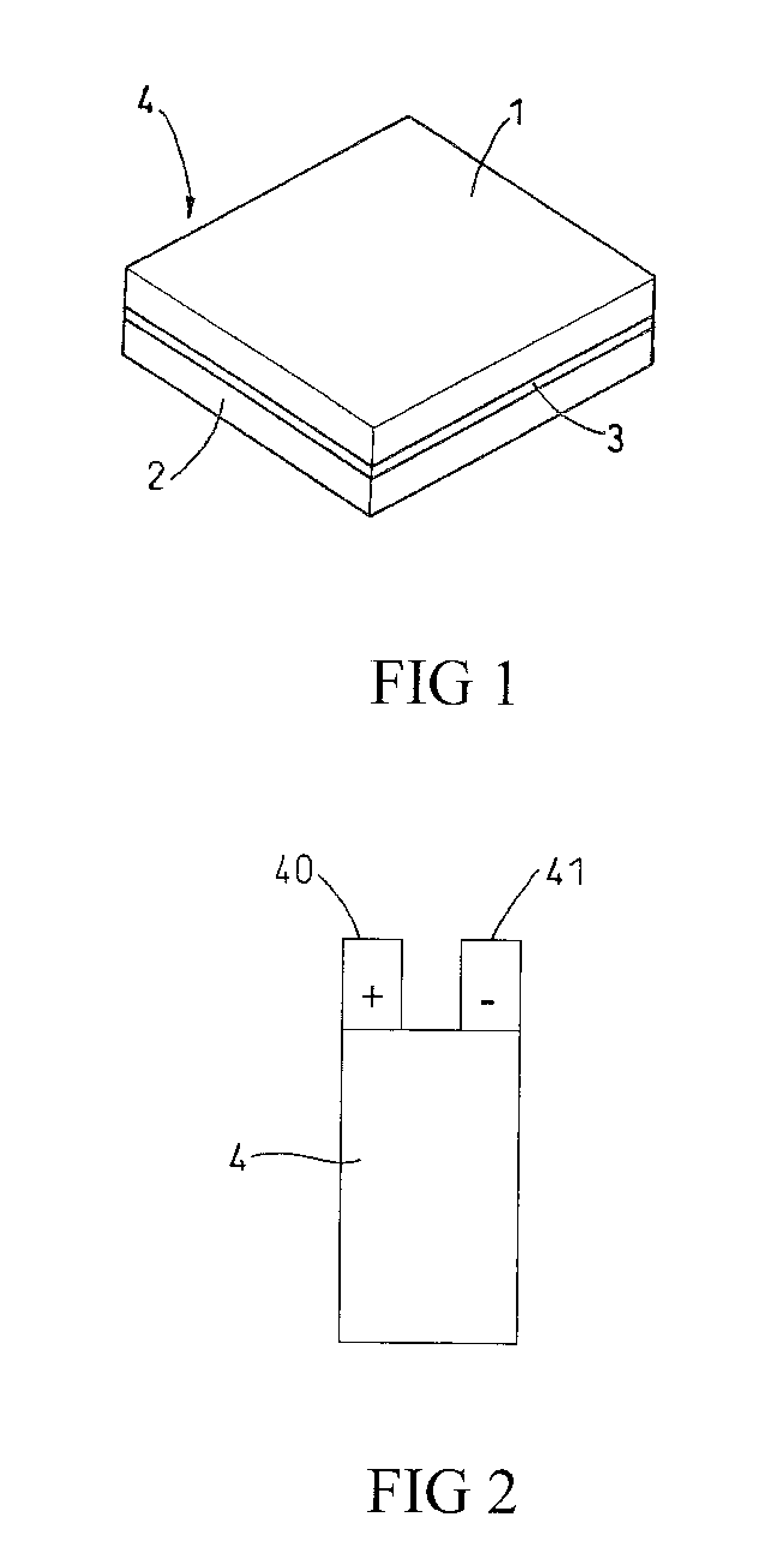

Binder for secondary battery electrode, secondary battery electrode composition including the same, and secondary battery using the same

InactiveUS20180294512A1Avoid separationEasy to makeElectrode carriers/collectorsSecondary cellsPolyvinyl alcoholElectrode adhesive

The present invention relates to a binder for a secondary battery electrode, a secondary battery electrode composition including the binder, and a secondary battery using the same. The binder includes a copolymer having a polyvinyl alcohol (PVA) and an ionically substituted acrylate. The binder may have an excellent electrode adhesive force, prevent an electrode deformation caused by the expansion and contraction of an electrode active material, and improve charge / discharge life characteristics, and further, simplify manufacturing processes.

Owner:LG CHEM LTD

Electrode of metal powder substrate inductor and preparation method of electrode

InactiveCN105469954AReduce usageLow costTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureOptoelectronicsInductor

The invention provides an electrode of a metal powder substrate inductor. The electrode is arranged at an electrode of an inductor. The electrode comprises a base layer, a conductive layer and a tin layer which are sequentially laminated at the electrode, and the base layer is arranged at the electrode through an electroplating mode. The invention also provides a preparation method for the electrode of the metal powder substrate inductor. The preparation method comprises the following steps of fully or partially masking the inductor; removing a mask at the electrode of the inductor; preparing the base layer at the electrode; and sequentially preparing the conductive layer and the tin layer on the surface of the base layer. By reducing the usage of precious metal and the energy consumption in a process, the preparation cost of a conventional electrode process is substantially reduced, the electrode adhesive force is improved, the installation reliability of the electrode is enhanced, the preparation process is simplified, the yield of mass production is improved, the corrosion resistant capability of a metal powder substrate is improved, and the service life of a device is prolonged.

Owner:ZHONGSHAN YINSAISHITE ELECTRONICS TECH CO LTD

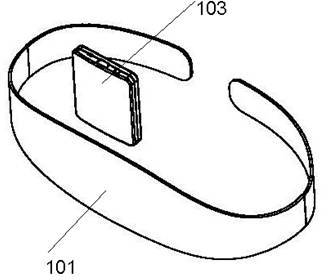

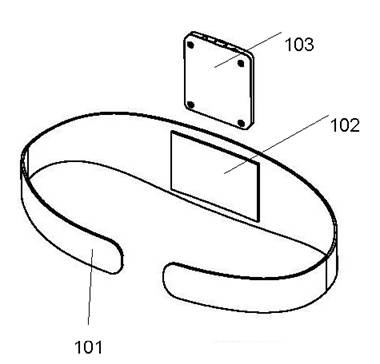

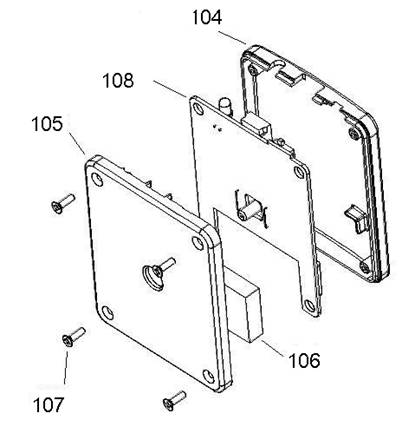

Sleep apnea detecting and treating instrument

ActiveCN102178528AReduce suffocationInstantly relieves congestionElectrotherapyRespiratory organ evaluationOxygenSurgery

The invention provides a sleep apnea detecting and treating instrument. The sleep apnea detecting and treating instrument comprises a belt and a belt box, an electric stimulation treating instrument and an optical treating instrument, wherein the detecting instrument comprises a detecting part; the electric stimulation treating instrument comprises an electric stimulation treating instrument body, an optical fiber, an electrode adhesive and a blood oxygen detecting head; the electric stimulation treating instrument body comprises a light needle head; the light needle head refracts a light needle to the electrode adhesive through the optical fiber; the optical treating instrument comprises a laser diode or a light-emitting diode; and the light needle generating the wavelength of 610 to 980 nm refracts and transmits an optical signal through the optical fiber. The breathing state of a user is obtained by an acceleration sensing technique, so that the simple and convenient detection effect is achieved. A Lieque acupuncture point is stimulated by electric shock pulse and optical acupuncture and moxibustion, so that a blockage phenomenon can be relieved timely. In addition, optical treatment contributes to reducing sleep apnea and improving sleeping quality. The sleep apnea detecting and treating instrument has the advantages of lightness, convenience and simpleness. By the sleep apnea detecting and treating instrument, a mild patient can be detected and treated at home.

Owner:ADVANCE TECH

Thin-film solar cell and its production method

InactiveCN101404297ALow costReduce production energy consumptionFinal product manufacturePhotovoltaic energy generationEpoxyGlass fiber

The invention discloses a thin film solar cell and a preparation method thereof. The thin film solar cell sequentially comprises a substrate, a front electrode, a semiconductor layer, a back electrode, an adhesive layer and a back sheet. The adhesive layer is made of epoxy resin; the back sheet is made of glass fiber reinforced plastic or organic glass. The solar cell and the preparation method can effectively reduce the cost of the adhesive layer and the back sheet, and can also add a multifunctional material layer so as to supplement the performances (such as water resistance, insulativity and the like) during a packaging period and to improve the packaging performance.

Owner:上海拓引数码技术有限公司

Recovery method of retired lithium ion battery positive electrode binder

InactiveCN111710932ARealize rational utilizationLess investmentWaste accumulators reclaimingBattery recyclingPolyvinylidene difluoridePolyvinylidene fluoride

The invention provides a method for recycling a retired lithium ion battery positive electrode adhesive, and aims to recycle a positive electrode adhesive polyvinylidene fluoride (PVDF), so that the damage of fluorine to the positive electrode material and the pollution of fluorine to the ecological environment are reduced, and the solid waste reutilization is realized. The method comprises the following steps: soaking retired lithium ion battery positive electrode powder in an organic mixed solvent, then placing in a reaction kettle, mechanically stirring to fully dissolve an adhesive, separating by using a centrifugal machine to obtain the positive electrode powder and a PVDF-containing organic solution, and separating and recovering the organic mixed solvent and PVDF by using a vacuum rotary evaporation evaporator. According to the invention, the method is simple in process, short in flow and reasonable and feasible in technical route, the adhesive in the positive electrode powder of the retired lithium ion battery is recycled by utilizing the technology, the purity is high, the recycling rate reaches 98% or above, the adhesive can be used as a raw material for manufacturing pipes and membrane materials, and the separated organic mixed solvent can be recycled.

Owner:HUNAN ZHENGYUAN ENERGY STORAGE MATERIALS & DEVICE INST

Composition for preparing electrode adhesive layer of automobile oxygen sensor and method for preparing electrode adhesive layer

The invention discloses a composition for preparing an electrode adhesive layer of an automobile oxygen sensor. The composition comprises the following components in parts by weight: 1 part of ceramic powder, and 1-1.5 parts of a diluter, wherein the ceramic powder is prepared from yttrium oxide (Y2O3) and zirconium oxide (ZrO2) according to a molar ratio of (5-8):(92-95); and the diluter is prepared from a mixture which is heated in water bath, wherein the mixture contains 2-10wt% of ethyl cellulose and 90-98wt% of terpilenol, and the temperature of the heating in the water bath is 70-90 DEG C. The invention also discloses a method for preparing the electrode adhesive layer by using the composition. According to the composition and the method, the electrode adhesive layer can be tightly combined with a zirconium tube blank body and can enhance the roughness of the zirconium tube blank; and when an electrode protective layer is prepared by using a plasma spraying method, the electrode protective layer is easily adhered to an electrode and the zirconium tube blank body.

Owner:TIANJIN RUIYITAIKE AUTO ELECTRONICS

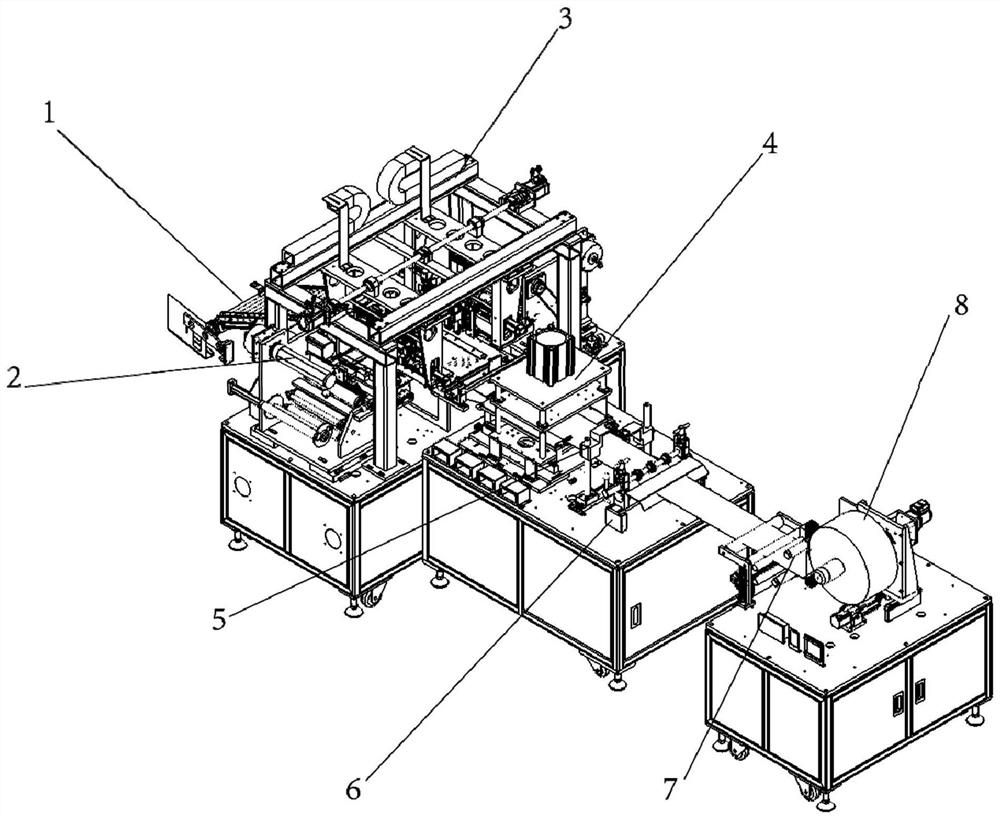

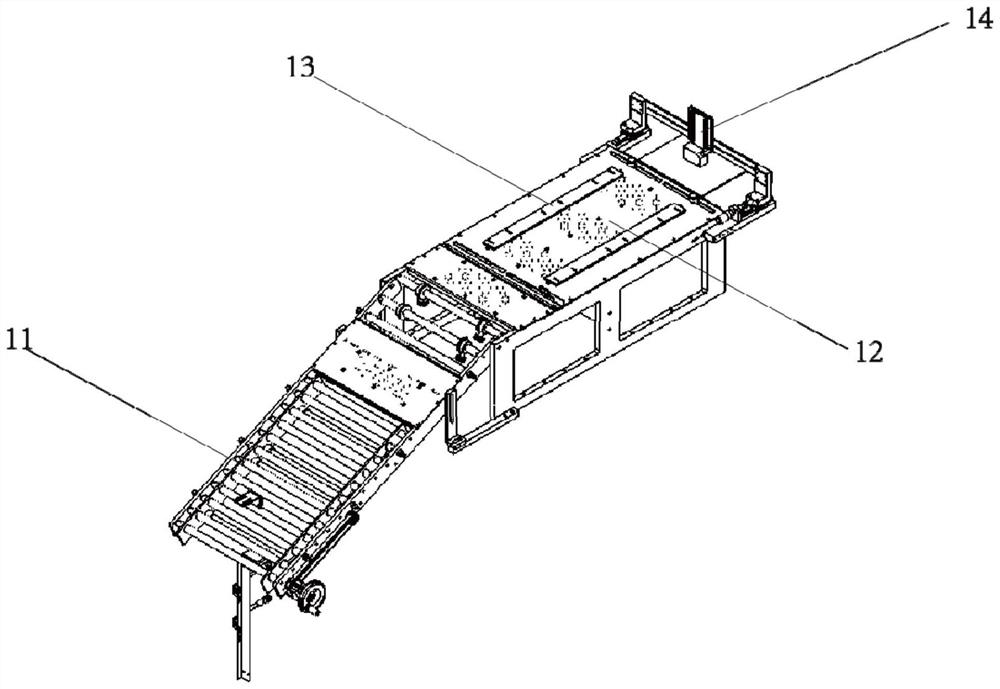

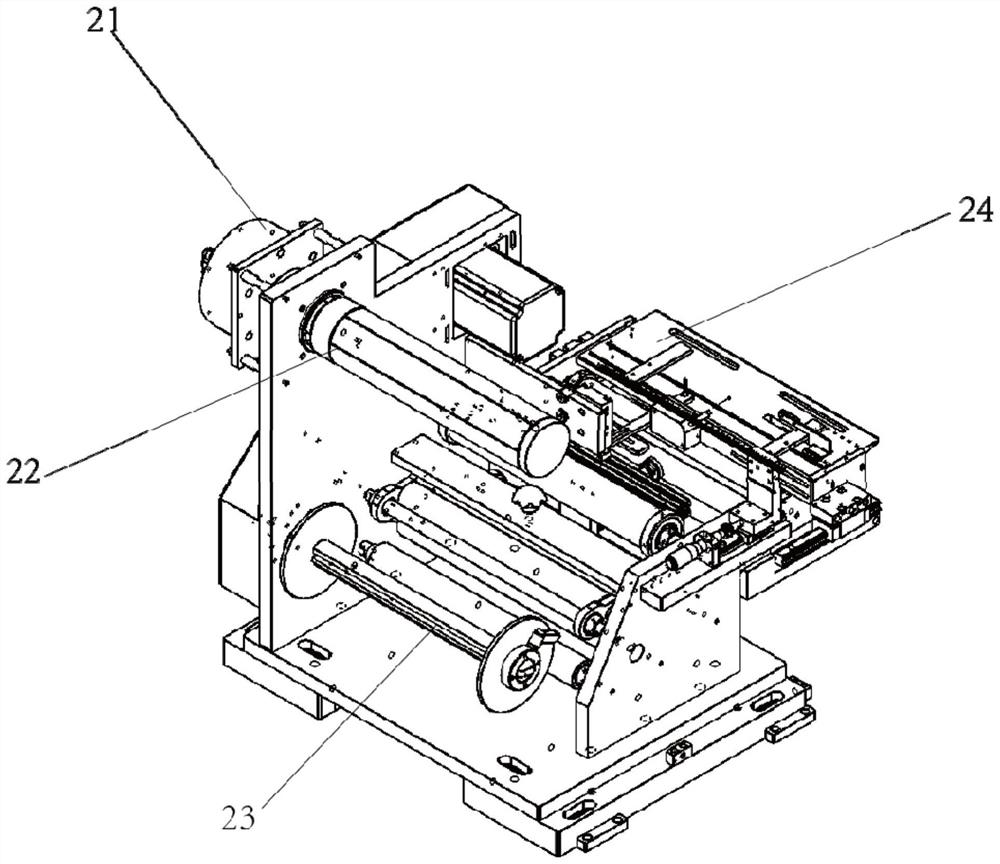

Automatic laminating device and method for positive and negative electrode plates of paper battery

ActiveCN112707214ASolve deviationFacilitate strippingElectrode manufacturing processesArticle deliveryPaper batteryElectrical battery

The embodiment of the invention provides an automatic laminating device for positive and negative electrode plates of a paper battery. The automatic laminating device comprises a positive electrode unwinding portion, a negative electrode unwinding portion, a positive and negative electrode pressing portion and a finished product winding portion; the positive electrode unwinding portion is arranged on the input side of the negative electrode unwinding portion; the positive and negative electrode pressing portion is arranged on the output side of the negative electrode unwinding portion; and the finished product winding portion is arranged on the output side of the positive and negative electrode pressing portion. According to the device and method, full-automatic integrated operation from positive and negative electrode feeding to positive and negative electrode patch pressing and recycling is achieved; meanwhile, a positive electrode feeding portion and a negative electrode feeding portion are provided with positive electrode incoming material edge guide plates so that positive electrode incoming materials can be adjusted leftwards and rightwards, and the problem of deviation of the positive electrode incoming materials is solved; and the negative electrode feeding portion adopts the mode of combining a negative electrode adhesive unwinding assembly and a negative electrode adhesive taking assembly, so that not only stripping of negative electrode roll materials is facilitated, but also laminating treatment of the positive electrode incoming materials and stripped negative electrode incoming materials is facilitated.

Owner:深圳市泽诚自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com