Sticky ceramic diaphragm and preparation method thereof

A ceramic diaphragm and viscous technology, which is applied in the field of viscous ceramic diaphragm and its preparation, can solve problems such as wrinkling and curling, and achieve the effects of improving yield rate, improving thermal stability, and efficient automatic assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

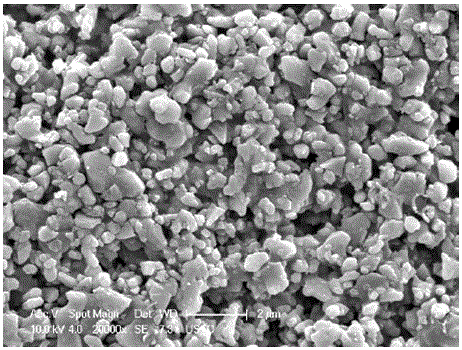

Image

Examples

Embodiment 1

[0034] 1) Select PP with a thickness of 25 microns and a porosity of 45% as the porous substrate;

[0035] Inorganic ceramic particles alumina (Al2O3) 13%, binder acrylonitrile polymer (LA133) 5%, dispersant polyvinylpyrrolidone 1.5%, leveling agent modified polysiloxane 0.5%, and the rest is solvent Ionized water, for high-speed dispersion to form a uniform inorganic ceramic slurry;

[0036] Select polymethyl methacrylate and acetone to fully stir and dissolve at a weight ratio of 3:97 to make glue.

[0037] 2) Immerse the porous substrate in the inorganic ceramic slurry, and at the same time, stir the inorganic ceramic slurry at a stirring speed of 30 rpm, so that it is evenly dispersed on the surface of the porous substrate;

[0038] 3) Dry it at 55°C to form a double-sided inorganic ceramic coating on the surface of the porous substrate to obtain a porous ceramic diaphragm; 4) Immerse the porous ceramic diaphragm in the glue solution, and simultaneously stir the glue solu...

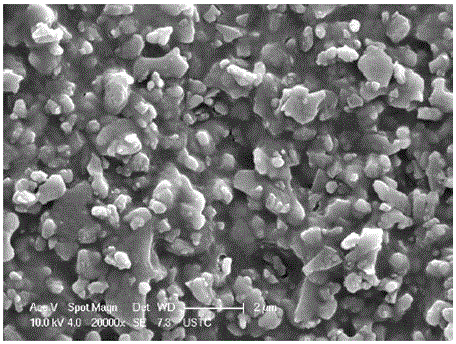

Embodiment 2

[0043] 1) Choose PE with a thickness of 20 microns and a porosity of 50% as the porous substrate;

[0044]Inorganic ceramic particle boehmite (AlO(OH)) 40%, binder polyacrylic acid 10%, dispersant sodium silicate 0.05%, leveling agent polyether modified polydimethylsiloxane 0.5%, The rest is the solvent N-methylpyrrolidone, which is dispersed at a high speed to form a uniform inorganic ceramic slurry;

[0045] Polyvinylidene fluoride-co-hexafluoropropylene and N-methylpyrrolidone were selected and stirred and dissolved at a weight ratio of 2.5:97.5 to make a glue solution.

[0046] 2) Immerse the porous substrate in the inorganic ceramic slurry, and at the same time, stir the inorganic ceramic slurry at a stirring speed of 100 rpm, so that it is evenly dispersed on the surface of the porous substrate;

[0047] 3) Dry it at 30°C to form a double-sided inorganic ceramic coating on the surface of the porous substrate to obtain a porous ceramic diaphragm;

[0048] 4) Immerse the...

Embodiment 3

[0051] 1) Select PP with a thickness of 25 microns and a porosity of 30% as the porous substrate;

[0052] Inorganic ceramic particle barium sulfate (BaSO4) 5%, binder polyvinylidene fluoride 2%, dispersant Hypermer KD-1 2%, leveling agent modified polysiloxane 3%, and the rest is solvent isopropanol, Fully mix and disperse at high speed to form a uniform inorganic ceramic slurry;

[0053] Select sodium carboxymethyl cellulose and acetone at a weight ratio of 10:90 and fully stir to make glue.

[0054] 2) Immerse the porous substrate in the inorganic ceramic slurry, and at the same time, stir the inorganic ceramic slurry at a stirring speed of less than 50 rpm, so that it is evenly dispersed on the surface of the porous substrate;

[0055] 3) Dry it at 70°C to form a double-sided inorganic ceramic coating on the surface of the porous substrate to obtain a porous ceramic diaphragm;

[0056] 4) Immerse the porous ceramic diaphragm in the glue solution, and at the same time sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com