Low-temperature type lithium ion secondary battery

A secondary battery and lithium-ion technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve problems such as increased viscosity of organic electrolytes, difficulty in lithium ion migration, and failure of lithium-ion batteries to achieve broadened Range of use, large migration rate, effect of lowering melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

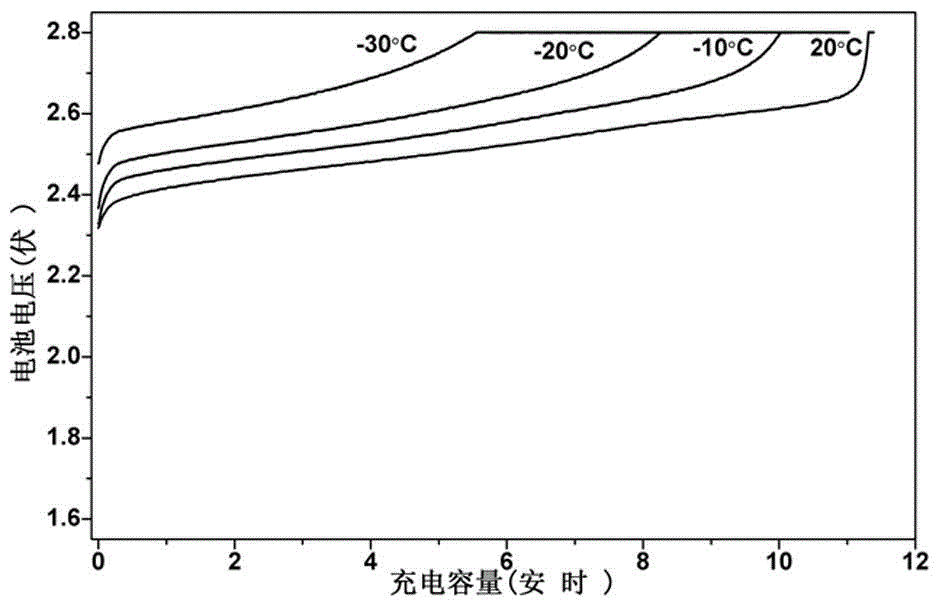

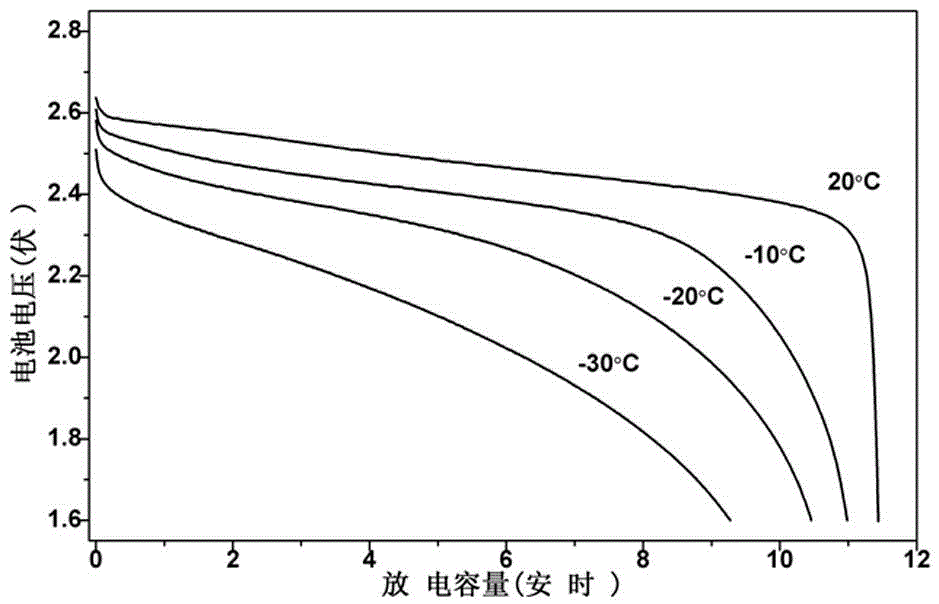

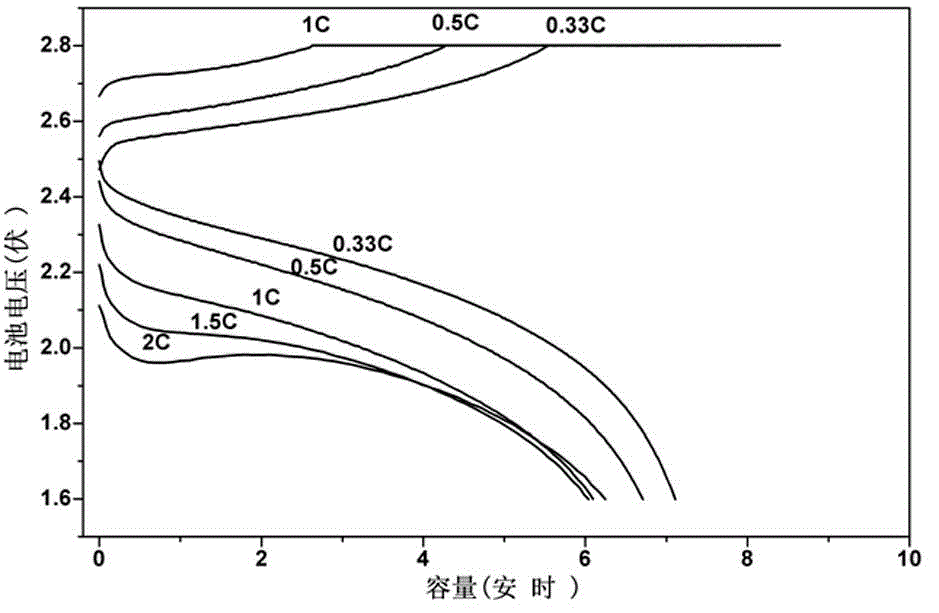

[0048] A low-temperature lithium-ion secondary battery, the positive electrode contains 2 parts of Super P, 1 part of carbon nanotubes, 2 parts of polyvinylidene fluoride, 95 parts of spinel lithium manganate, and its thickness is 60 microns, of which manganese acid The median diameter of lithium is 7.2 microns. The negative electrode contains 4 parts of Super P, 1 part of carbon nanotube, 2 parts of polyvinylidene fluoride, and 93 parts of spinel lithium titanate. The thickness is 50 microns, and the median diameter of lithium titanate is 120 nanometers. LiPF with a solute concentration of 1.0mol / L in the electrolyte 6 , the solvent is 10% PC, 20% DMC, 65% DEC and 5% EA.

Embodiment 2

[0050] A low-temperature lithium-ion secondary battery, the positive electrode contains 2 parts of Super P, 2 parts of KS6, 3 parts of polyvinylidene fluoride, 93 parts of spinel lithium manganese oxide, and its thickness is 80 microns, wherein the lithium manganate The bit diameter is 8.3 microns. The negative electrode contains 4 parts of Super P, 2 parts of Vapor-grown carbon fiber (VGCF for short), 2 parts of polyvinylidene fluoride, and 92 parts of spinel lithium titanate, with a thickness of 65 microns, of which titanate The median diameter of lithium is 150 nm. LiPF with a solute concentration of 1.1mol / L in the electrolyte 6 , The solvent is 15% PC, 50% EMC, 15% DMC and 20% EA.

Embodiment 3

[0052] A low-temperature lithium-ion secondary battery, the positive electrode contains 3 parts of Super P, 2 parts of KS6, 4 parts of polyvinylidene fluoride, 91 parts of spinel lithium manganese oxide, and its thickness is 95 microns, wherein the lithium manganate The bit diameter is 9.1 microns. The negative electrode contains 6 parts of Super P, 1 part of VGCF, 3 parts of polyvinylidene fluoride, and 90 parts of spinel lithium titanate. The thickness is 75 microns, and the median diameter of lithium titanate is 200 nanometers. LiPF with a solute concentration of 1.0mol / L in the electrolyte 6 , the solvent is 60% DEC, 10% DMC, 25% EA and 5% PC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com