Preparation method of lithium ion battery negative electrode adhesive and method for preparing lithium ion battery negative electrode material

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low hydrogen bonding and low mobility of rigid polymer binders, and improve the stability of charge and discharge cycles. , the effect of high fluidity and high rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

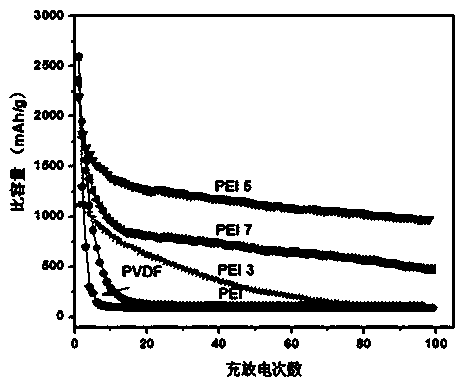

[0027] A method for preparing a lithium ion battery negative electrode binder, comprising the following steps: selecting hyperbranched PEI (polyethyleneimine), adding 0.5-10% by mass fraction of a cross-linking agent glutaraldehyde, and pre-cross-linking at room temperature to obtain The lithium ion battery negative electrode binder.

[0028] A preparation method of a lithium ion battery negative electrode binder, comprising the following steps: selecting hyperbranched PEI (polyethyleneimine) to prepare a PEI ethanol solution with a concentration of 0.125g / mL, adding 0.5- 10% mass fraction of the cross-linking agent glutaraldehyde, after pre-cross-linking at room temperature for 1-10 hours, to obtain the lithium ion battery negative electrode binder.

[0029] The weight-average molecular weight of the added hyperbranched PEI is 60,000.

[0030] The mass fraction of the added crosslinking agent glutaraldehyde is 3%.

[0031] A method for preparing a negative electrode materia...

Embodiment

[0044] First prepare 50 mL of ethanol solution of hyperbranched PEI (molecular weight: 60,000) with a concentration of 0.125 g / mL, add 3% mass fraction (relative to PEI) of cross-linking agent glutaraldehyde, and pre-cross-link at room temperature for 2 hours.

[0045] Then take out the ethanol solution containing 0.1g hyperbranched PEI, then mix and grind 30min with 0.3g of nano silicon powder (particle size is 50nm) and 0.1g of acetylene black in agate mortar, then coat on copper foil to form a film Finally, put it in an oven at 60°C for vacuum drying to complete the cross-linking reaction and dry the solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com