Preparation method of lithium battery negative electrode slurry

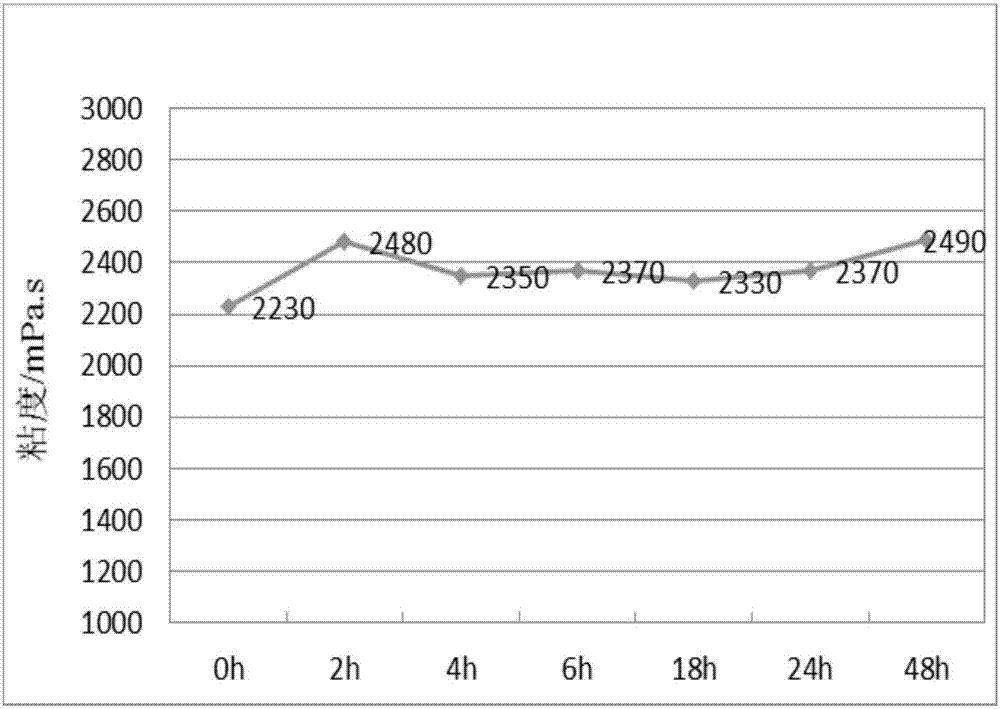

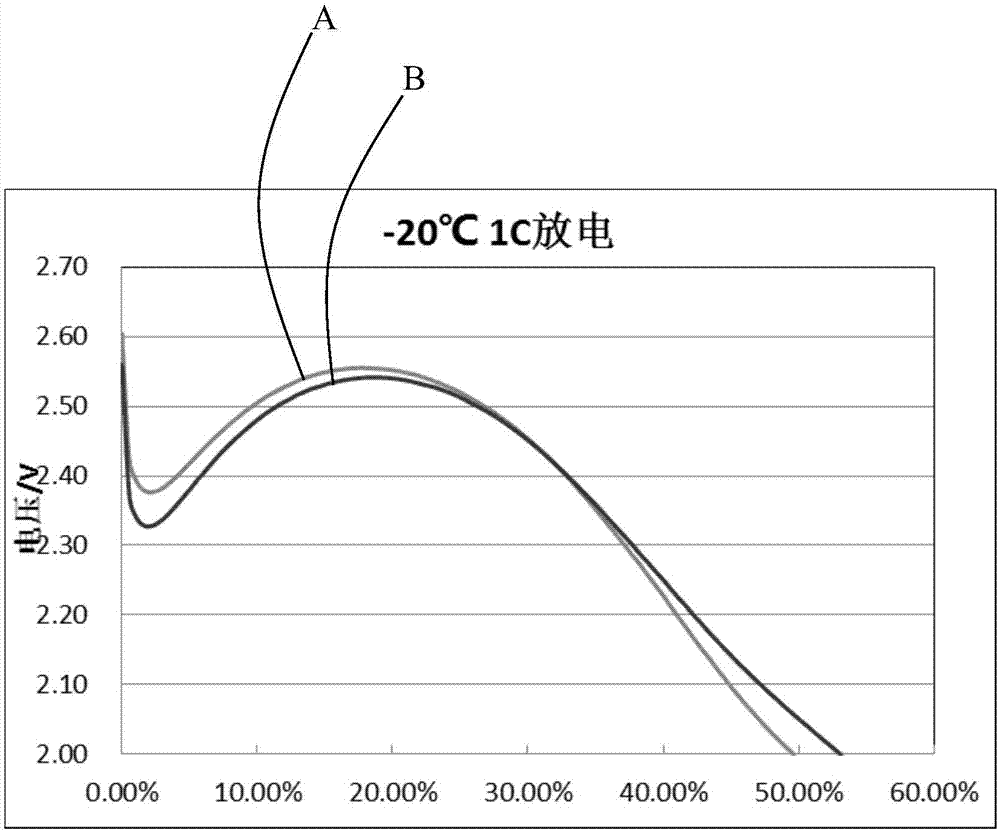

A negative electrode slurry, lithium battery technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as affecting lithium ion movement, affecting particle dispersion and uniformity, etc., to save production costs and achieve excellent discharge performance. , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

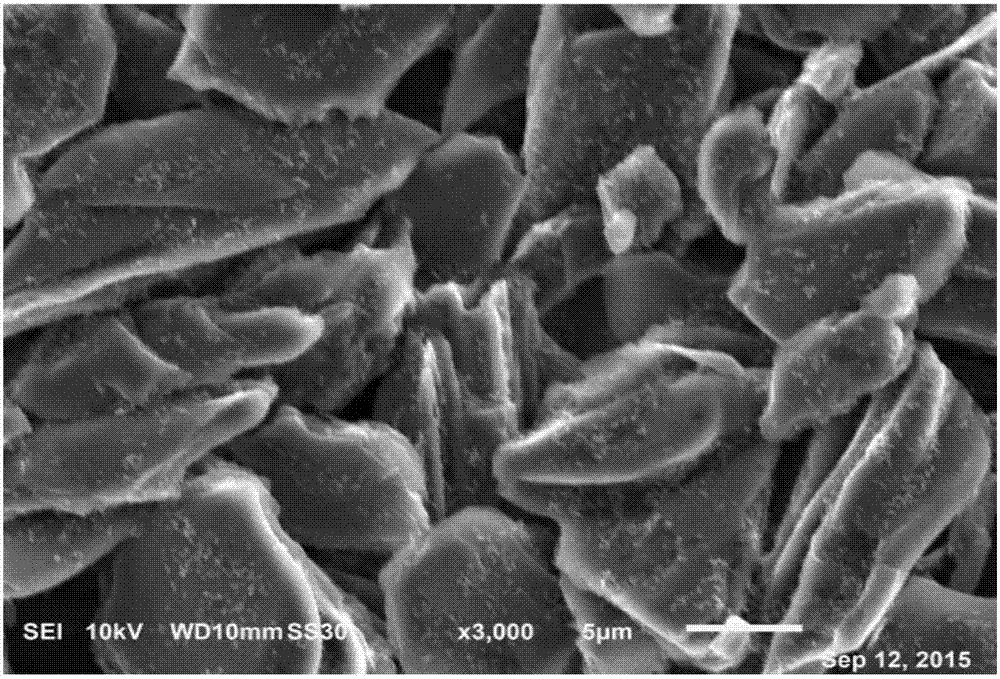

[0026] Please refer to figure 1 , The present invention provides a method for preparing a lithium battery negative electrode slurry, which includes the following steps:

[0027] Step 1: First weigh the graphite, conductive agent and sodium carboxymethyl cellulose dry powder with a mass ratio of 93-96:2-5:1.8-2.5, and then combine the graphite, conductive agent and 30%-70% of carboxymethyl The sodium base cellulose powder is added to the mixing tank, and the rotation and revolution of the mixing tank are turned on for the first mixing;

[0028] Step 2: Add part of 20%-60% deionized water in deionized water with a solid content of 45%-50% for a second stirring;

[0029] Step 3: Add the remaining 70%-30% of the dry powder of sodium carboxymethyl cellulose for the third time;

[0030] Step 4: Add the remaining 80%-40% deionized water and stir for the fourth time;

[0031] Step 5: Adjust the rotation of the mixing tank for the fifth time, and connect the circulating cooling water;

[0032] S...

Embodiment

[0043] Step 1: First weigh the graphite, conductive agent and sodium carboxymethylcellulose dry powder with a mass ratio of 96:2:2, and then add graphite, conductive agent and 30% part of the dry sodium carboxymethylcellulose powder into the mixing tank , Turn on the rotation and revolution of the mixing tank and perform the first stirring for 20 minutes, where the frequency of rotation is: 5Hz; the frequency of revolution is: 15Hz.

[0044] Step 2: Add 20% part of deionized water in deionized water with a solid content of 45%, and stir for a second time for 60 minutes.

[0045] Step 3: Add the remaining 70% part of the sodium carboxymethyl cellulose dry powder and stir for the third time for 5 minutes;

[0046] Step 4: Add the remaining 80% deionized water and stir for the fourth time for 5 minutes;

[0047] Step 5: Adjust the rotation of the stirring tank for the fifth time of stirring for 60 minutes, and turn on the circulating cooling water. The frequency of the rotation is: 25 Hz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com