An electrode adhesive for a lithium ion battery, and preparing and using methods thereof

A lithium-ion battery and binder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery capacity attenuation, affecting the charging and discharging performance of lithium-ion batteries, low conductivity, etc., to reduce polarization, The effect of avoiding the deterioration of adhesion performance and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

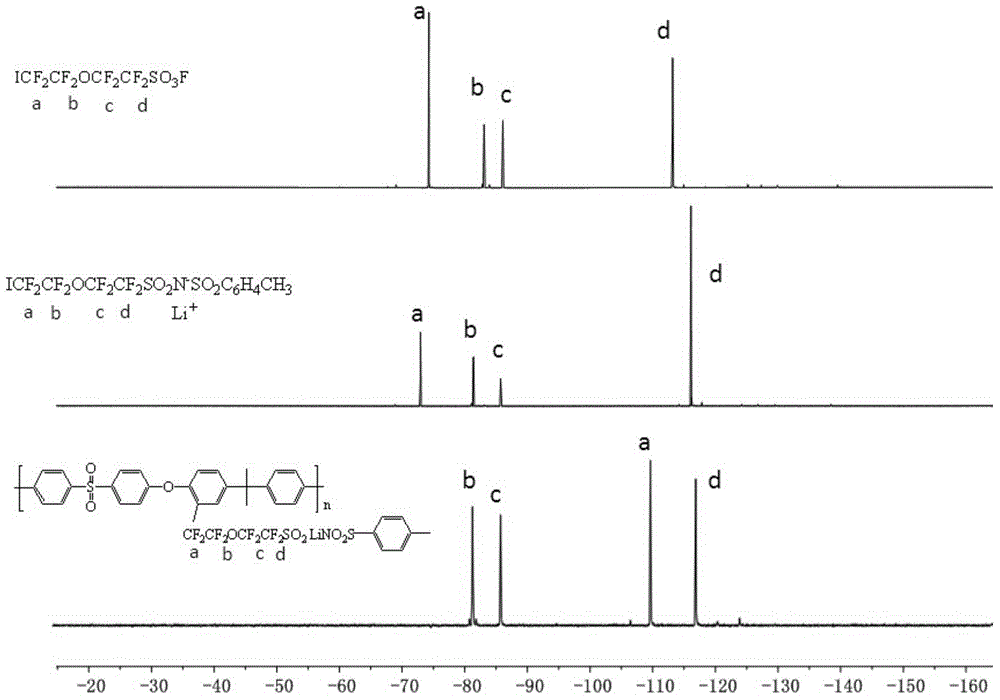

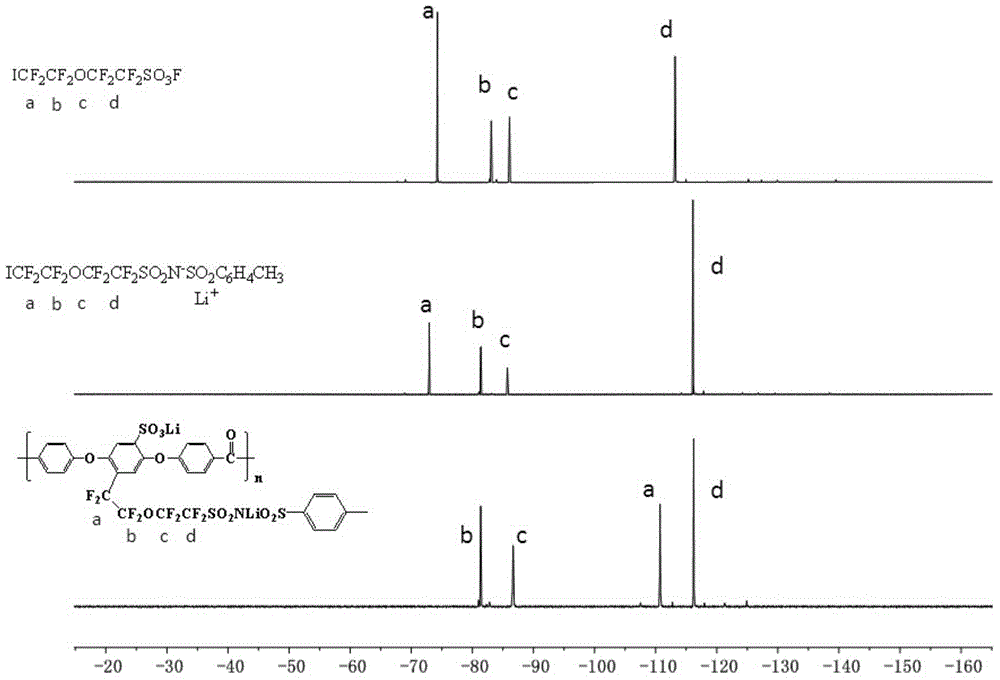

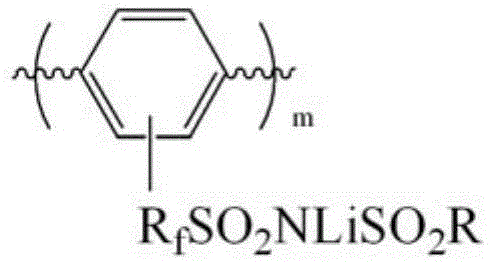

[0036] In this embodiment, the electrode binder of the lithium-ion battery is an ionic polymer, which is a polysulfone main chain as the main chain, and the side chain is grafted with fluorine-containing sulfonimide lithium salt, and its molecular formula is -[(Ar )-CF 2 CF 2 OCF 2 CF 2 SO 2N(Li)SO 2 C 7 h 7 ] n .

[0037] The method for preparing the electrode binder of above-mentioned lithium ion battery comprises the steps:

[0038] Step 1: Synthesis of ICF 2 CF 2 OCF 2 CF 2 SO 2 N(K)SO 2 C 7 h 7

[0039] Add 24.4mMol dry KF and 5.14mMolCH to the 50ml flask 3 C 6 h 4 SO 2 NHNa, evacuate to 2mHg at 100°C, then add 2.54 g of ICF 2 CF 2 OCF 2 CF 2 SO 3 F and 10ml of dry acetonitrile, under the protection of nitrogen, keep the temperature at 60-80°C, stir the reaction for two days, then distill off the solvent under reduced pressure, and dry in vacuo to obtain 6.12 grams of solid product ICF 2 CF 2 OCF 2 CF 2 SO 2 N(K)SO 2 C 7 h 7 .

[0040] S...

Embodiment 2

[0050] In this embodiment, the electrode binder of the lithium ion battery is an ionic polymer, which is based on the main chain of polyether ether ketone, and the side chain is grafted with fluorine-containing sulfonimide lithium salt, and its molecular formula is -[( Ar)-CF 2 CF 2 OCF 2 CF 2 SO 2 N(Li)SO 2 C 7 h 7 ] n .

[0051] The method for preparing the electrode binder of above-mentioned lithium ion battery comprises the steps:

[0052] Step 1: Synthesis of ICF 2 CF 2 OCF 2 CF 2 SO 2 N(K)SO 2 C 7 h 7

[0053] Add 24.4mMol dry KF and 5.14mMolCH to the 50ml flask 3 C 6 h 4 SO 2 NHNa, evacuate to 2mHg at 100°C, then add 2.54 g of ICF 2 CF 2 OCF 2 CF 2 SO 3 F and 10ml of dry acetonitrile, under the protection of nitrogen, keep the temperature at 60-80°C, stir the reaction for two days, then distill off the solvent under reduced pressure, and dry in vacuo to obtain 6.12 grams of solid product ICF 2 CF 2 OCF 2 CF 2 SO 2 N(K)SO 2 C 7 h 7 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com