Solid-state battery based on plastic crystal modified positive electrode and preparation method of solid-state battery

A solid-state battery and positive electrode technology, which is applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of insufficient battery performance, poor battery interface contact, low material conductivity, etc., and achieve positive electrode ion conductivity and Improved interface compatibility, ease of preparation and mass production, and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

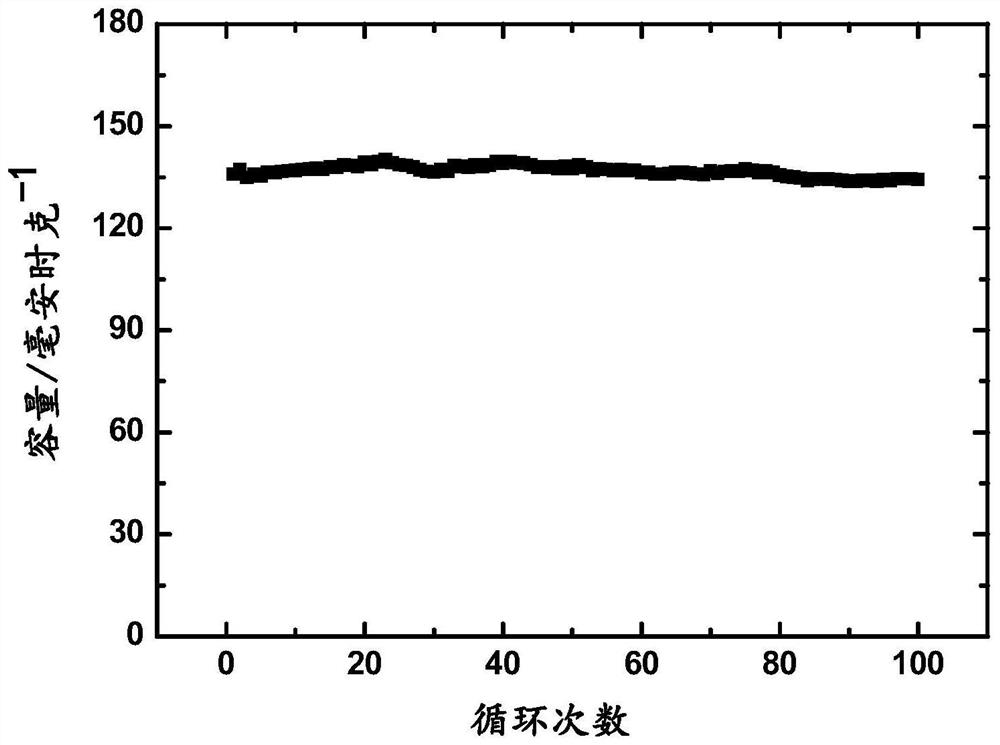

Embodiment 1

[0044] 1. Preparation of plastic crystal modified positive electrode

[0045] 3.2g succinonitrile (SN), 0.9g lithium salt LiTFSI, 0.2g inorganic filler SiO 2 and 1.1g of polyethylene oxide (PEO) with a molecular weight of 10w were mixed and heated to 60°C for 0.5h to form a uniform plastic crystal-based composite positive electrode glue, and then 9gLiFePO was added to the above mixed solution 4 Stir with the SP mixture and 20ml DMAc for 6h to make it evenly mixed;

[0046] Add 0.46g monomer TMPTMA (polymer monomer) and 0.005g thermal initiator ABVN to the solution obtained in step a), stir at room temperature for 1 hour to obtain positive electrode slurry, apply it on aluminum foil, and heat at 70°C for 1 hour in situ polymerization , and then vacuum-dried at 80°C for 12 hours to dry the solvent;

[0047] Cut the positive electrode in b) into Φ12 discs, according to the ratio in steps a) and b), add succinonitrile (SN), lithium salt LiTFSI, monomer TMPTMA, initiator ABVN, in...

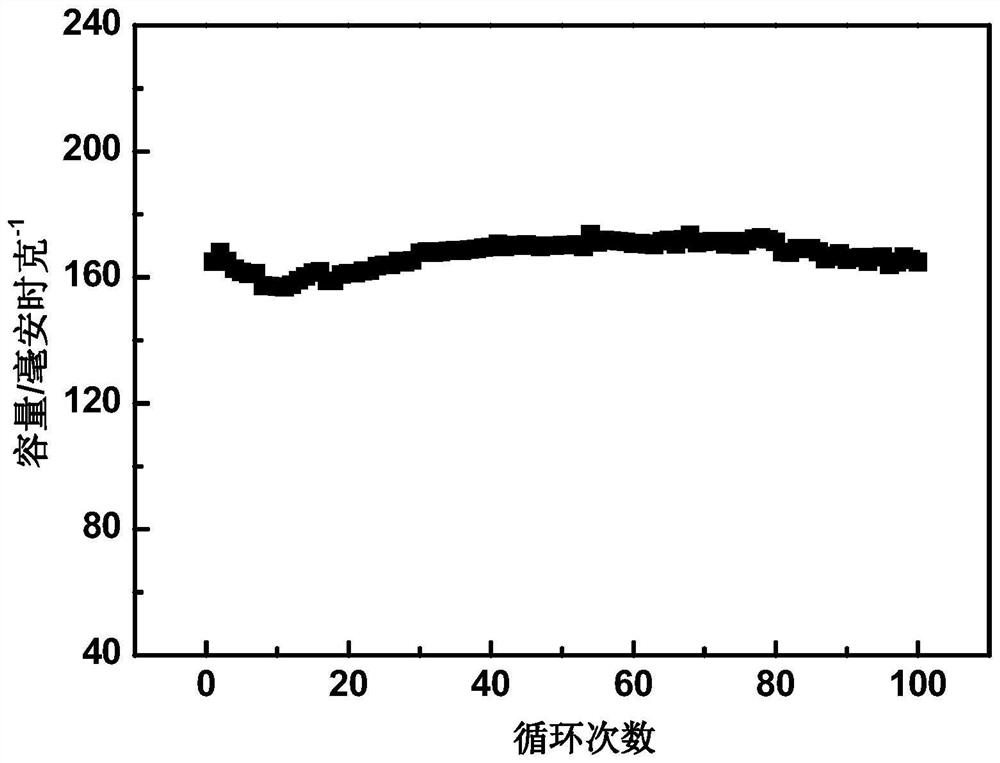

Embodiment 2

[0055] 1. Preparation of plastic crystal modified positive electrode

[0056] a) Mix 1.64g succinonitrile (SN) with 0.46g lithium salt LiTFSI, 0.1g inorganic filler Al 2 o 3 and 1.54g of PPC were mixed and heated to 60°C for 0.5h to form a uniform plastic crystal-based composite positive electrode glue, and then 9g of LiNi was added to the above mixed solution 0.85 co 0.1 Al 0.05 o 2 (NCA) was mixed with SP mixture and 25ml DMC for 6h to make it evenly mixed;

[0057] b) Add 0.24g of monomeric TPPTA and 0.003g of photoinitiator HMPP to the solution obtained in step a), stir at room temperature for 1h to obtain positive electrode slurry, apply it on aluminum foil, transfer it to a UV lamp for irradiation, and the intensity is 2000mW / cm 2 , the time is 20s, and then vacuum-dried at 70°C for 12h to remove the solvent;

[0058] c) Cut the positive electrode in b) into a disc of Φ12, according to the ratio in steps a) and b), succinonitrile (SN), lithium salt LiTFSI, monome...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com