Lithium ion battery silicon-based negative electrode adhesive and preparation method of negative electrode piece with same

A lithium-ion battery, silicon-based negative electrode technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of disengagement, cycle performance degradation, damage to the integrity of the conductive system, etc., to improve energy density and Coulomb efficiency. Improved, mass-produced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

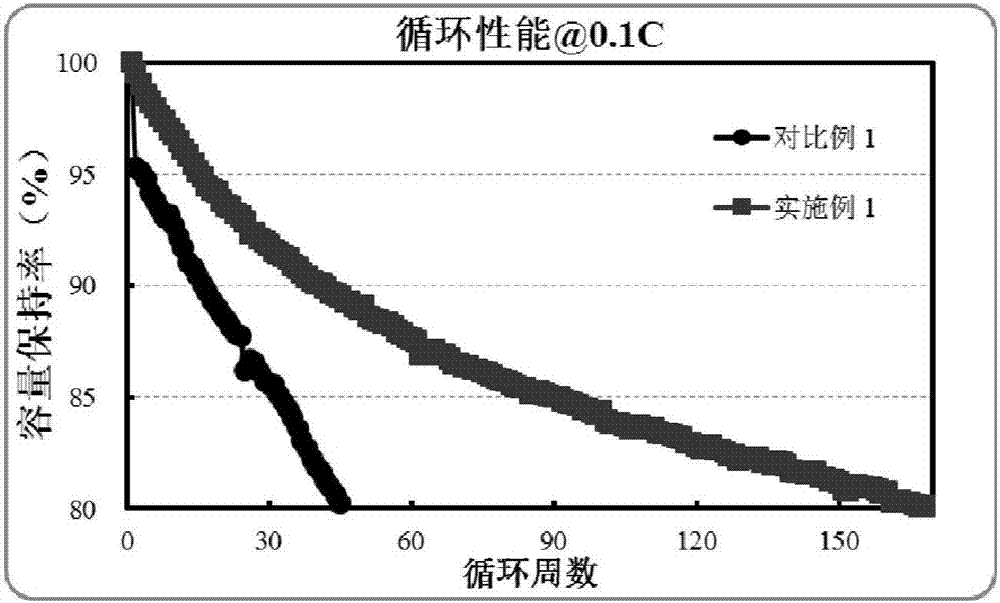

Embodiment 1

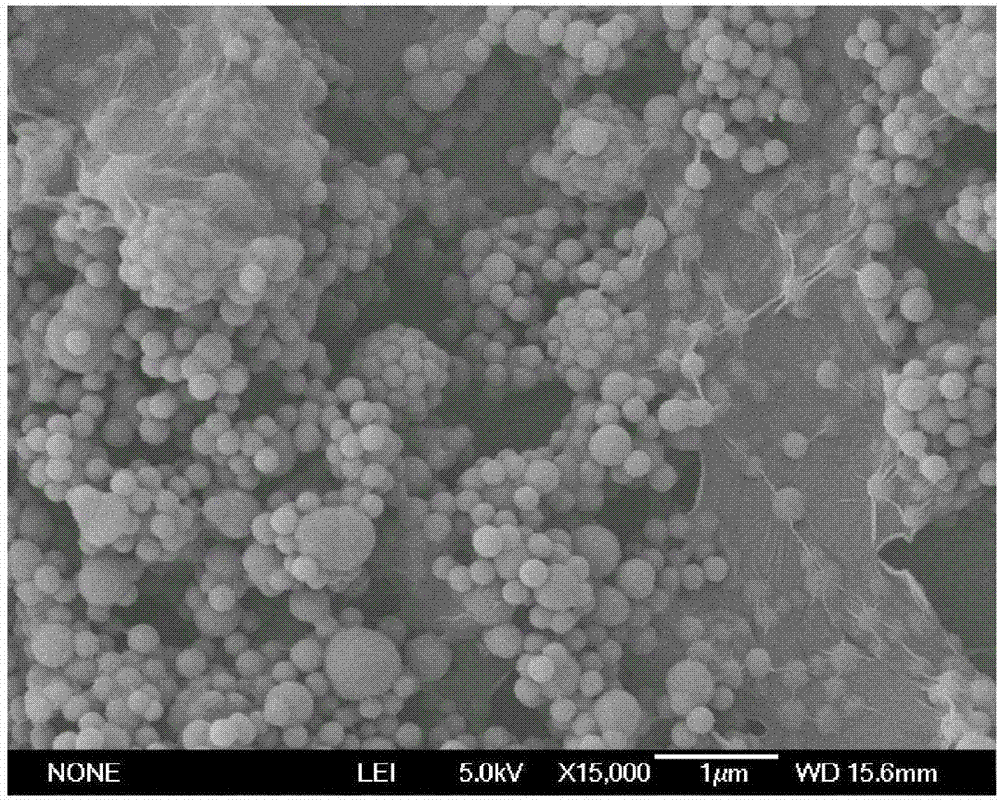

[0027] Ultrasonically disperse graphite oxide in water to obtain an aqueous dispersion of graphene oxide with a concentration of 1.5g / L, add a modified SBR binder, and the mass ratio of GO to modified SBR binder is 1:10. After stirring, you can get Lithium-ion battery silicon-based negative electrode binder (GO / modified SBR binder).

[0028] Weigh 95 parts of SiO / graphite and 1 part of Sp conductive agent, grind in a mortar for 20min to obtain a uniformly dispersed solid mixture, add 0.5 part of CMC powder to water, stir at a speed of 1000rpm to obtain 1.5wt% Disperse the CMC solution evenly, add the CMC solution to the ground solid mixture, stir at a speed of 2000rpm for 15min, add 3.5 parts of GO / modified SBR binder after defoaming, and continue stirring at a speed of 1000rpm for 8min, After defoaming, obtain the silicon-based negative electrode slurry that is evenly mixed; with 60g / cm 2 The areal density is coated on the copper foil, and dried in a vacuum oven at 85°C to o...

Embodiment 2

[0030] Ultrasonically disperse graphite oxide in water to obtain an aqueous dispersion of graphene oxide with a concentration of 0.5g / L, add modified SBR binder, the mass ratio of GO to modified SBR binder is 1:10, and obtain Lithium-ion battery silicon-based negative electrode binder (GO / modified SBR binder).

[0031] Weigh 81 parts of SiO / graphite and 10 parts of Sp conductive agent, and grind them in a mortar for 30 minutes to obtain a uniformly dispersed solid mixture. Add 3 parts of CMC powder into water, and stir at a speed of 1000 rpm to obtain a 1.5 wt % uniformly dispersed CMC solution. Add the CMC solution to the ground solid mixture, stir at a speed of 2000rpm for 15min, add 6 parts of GO / modified SBR binder after defoaming, continue to stir at a speed of 1000rpm for 8min, and obtain a mixed mixture after defoaming. and silicon-based negative electrode slurry; at 60g / cm 2 The areal density is coated on the copper foil, and dried in a vacuum oven at 85°C to obtain ...

Embodiment 3

[0033] Ultrasonically disperse graphite oxide in water to obtain an aqueous dispersion of graphene oxide with a concentration of 2.5g / L, add a modified SBR binder, the mass ratio of GO to modified SBR binder is 1:50, and obtain Lithium-ion battery silicon-based negative electrode binder.

[0034] Weigh 91.5 parts of SiO / graphite and 5 parts of conductive carbon nanotubes, and grind them in a mortar for 10 minutes to obtain a uniformly dispersed solid mixture. Add 2 parts of lithium carboxymethyl cellulose powder into water, and stir at a speed of 2000 rpm to obtain a 1 wt % lithium carboxymethyl cellulose solution uniformly dispersed. Add carboxymethylcellulose lithium solution to the ground solid mixture, stir at 1000rpm for 20min, add 1.5 parts of GO / modified SBR binder after defoaming, continue stirring at 1000rpm for 5min, eliminate Obtain the silicon-based negative electrode slurry that mixes evenly with after soaking; With 30g / cm 2 The areal density is coated on the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com